Updates:

- 2024/11/30: Mono X 6Ks reversed engineered (UV LCD, GUI LCD)

- 2023/11/18: published

- 2023/11/11: printer ordered

- 2023/10/24: starting writeup

Table of Contents

Introduction

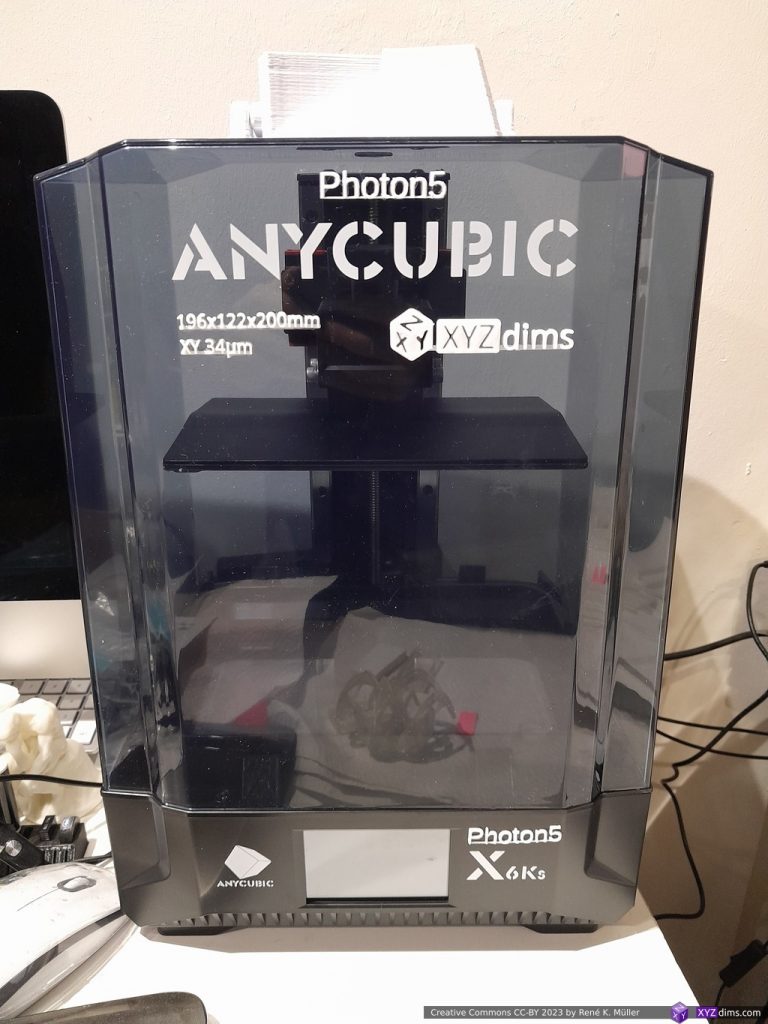

After using Anycubic Photon Mono X2, and not that happy with it, I saw Anycubic released another resin printer:

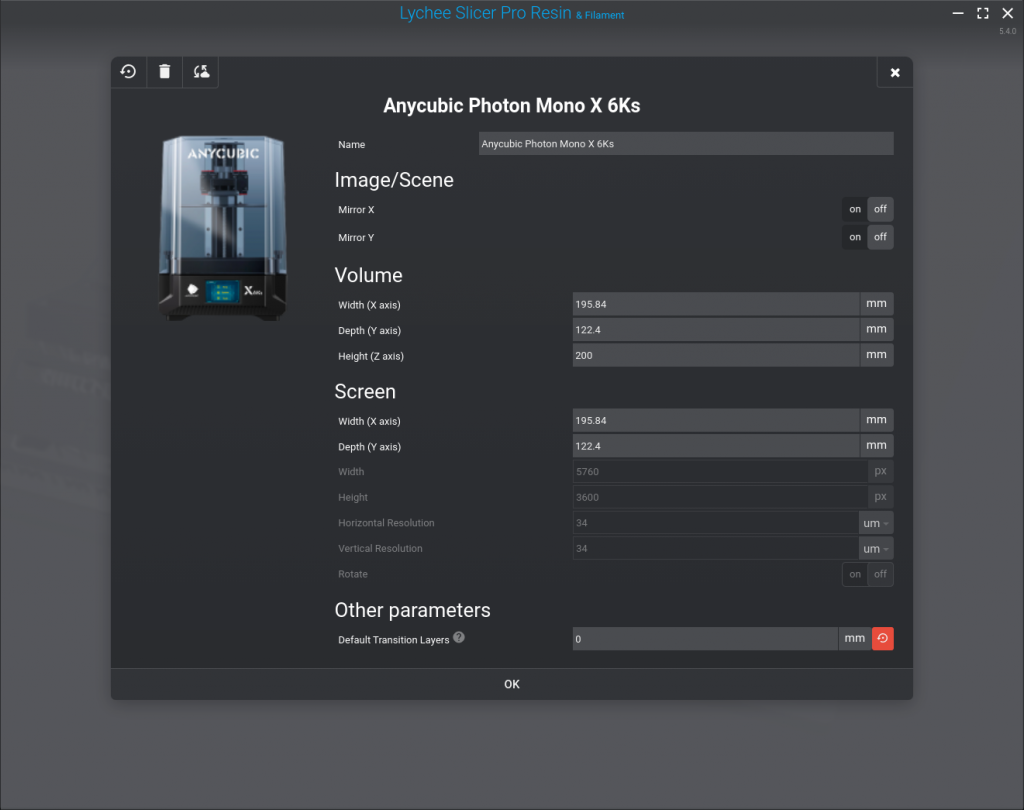

- build volume: 195.8 x 122.4 x 200 mm (WxDxH), same size as Mono X2:

- reuse all its third party parts also compatible with X2: vat, FEP films etc

- resolution: XY 34μm, Z 10-50μm

- 9.1″ display with 6K resolution (5760×3600) display

- monochromatic LCD (hence “Mono”), faster printer due shorter exposure

- affordable with EUR 250-280 (2023/11)

- no network, only USB drive printing

The Photon Mono X2 with XY 48μm has not so well performed for me in regards of precise parts, as 100μm precision was not really delivered, either it was underexposing and fail on 1mm walls, or solid walls but thicker – somehow I could not find a good balance. The Photon Mono 4K performed more reliable for me and was able to print geometrically more reliable and correct with XY 35μm; so my hope is that the X 6Ks delivers with 34μm pixel size.

I ordered the Photon Mono X 6Ks in 2023/11 for EUR ~230 incl. shipment, and it arrived a few days later from a warehouse in Germany to Switzerland.

Anycubic’s Naming Convention & Communication

The X 6Ks is kind of successor of the X2 with the same body shape and build volume, but who cares of good naming? It could have been X2 6K simply. Aside, Anycubic seems the care little to provide customers the XY resolution anymore on info material or their web-site (2023/11) but only state XY build area and XY resolution, and announces 4K, 6K or whatever – you need to calculate the XY pixel size yourself . . .

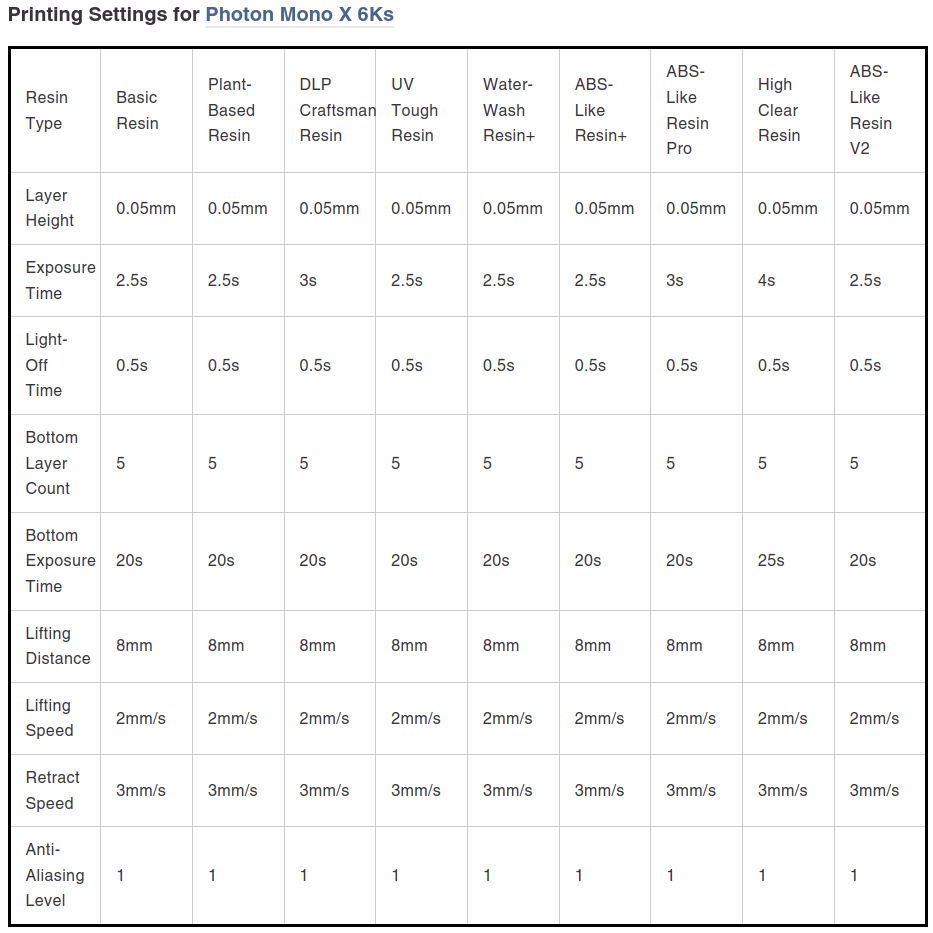

Print Settings

retrieved from Anycubic 2023/11/11 as screenshot:

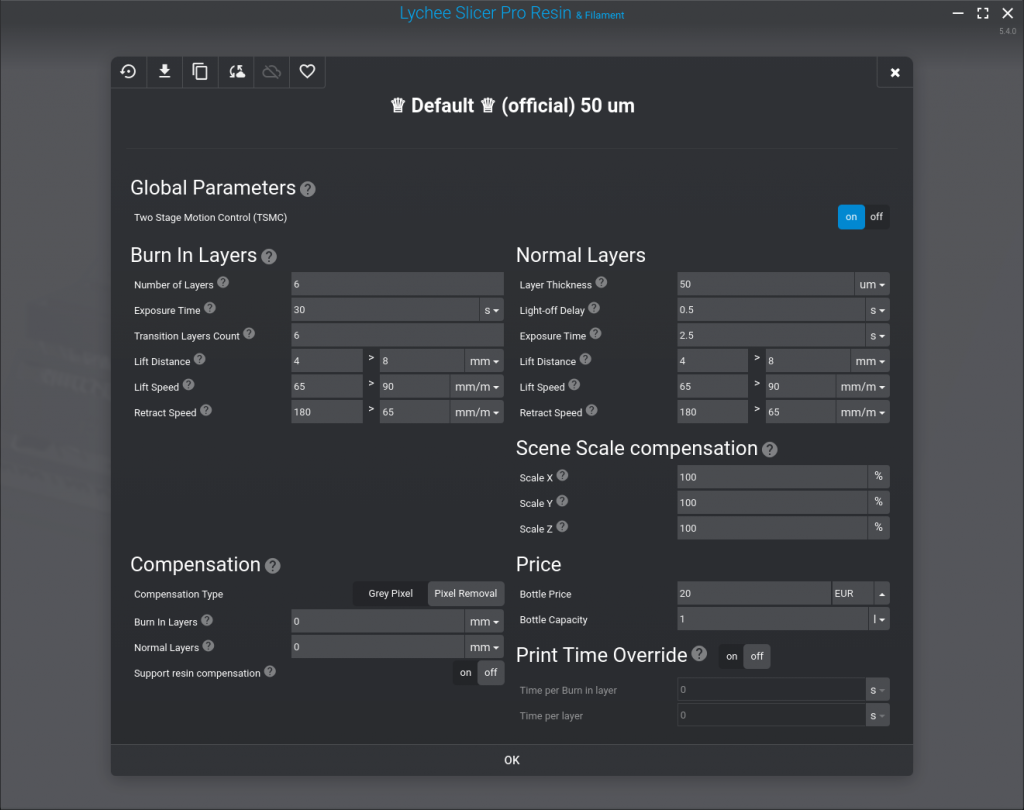

For Lychee Slicer (2023/11) I recommend following settings:

- enable Two Stage Motion Control (TSMC)

- Bottom Layer: 1-6 (1 for small pieces, 6 for larger pieces)

- Transition Layers: 10 (for flat pieces reduce to 1)

- Lift Distances: [1] 4mm, [2] 8mm

- Lift Speeds: [1] 1mm/s, [2] 3mm/s or 60mm/min, 180mm/min

Here my settings:

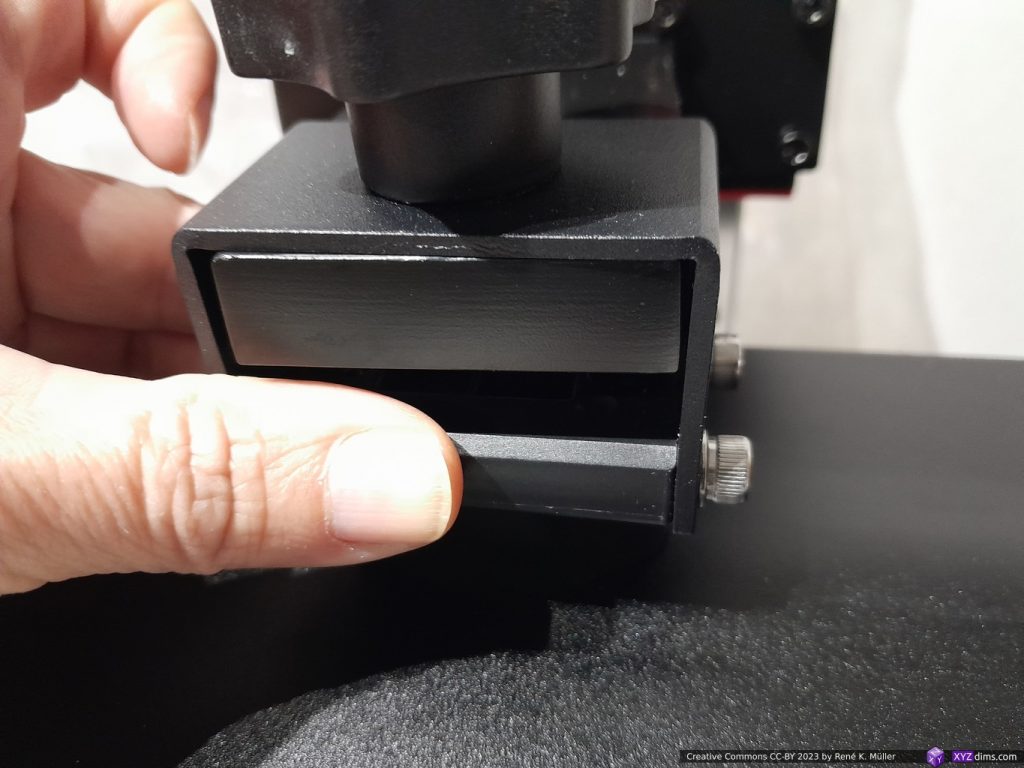

Flex Build Plate

I’ve got a spring steel plate 202×128 mm from Aliexpress, and as I ordered two of them for X2 but I can reuse one for the X 6Ks as well:

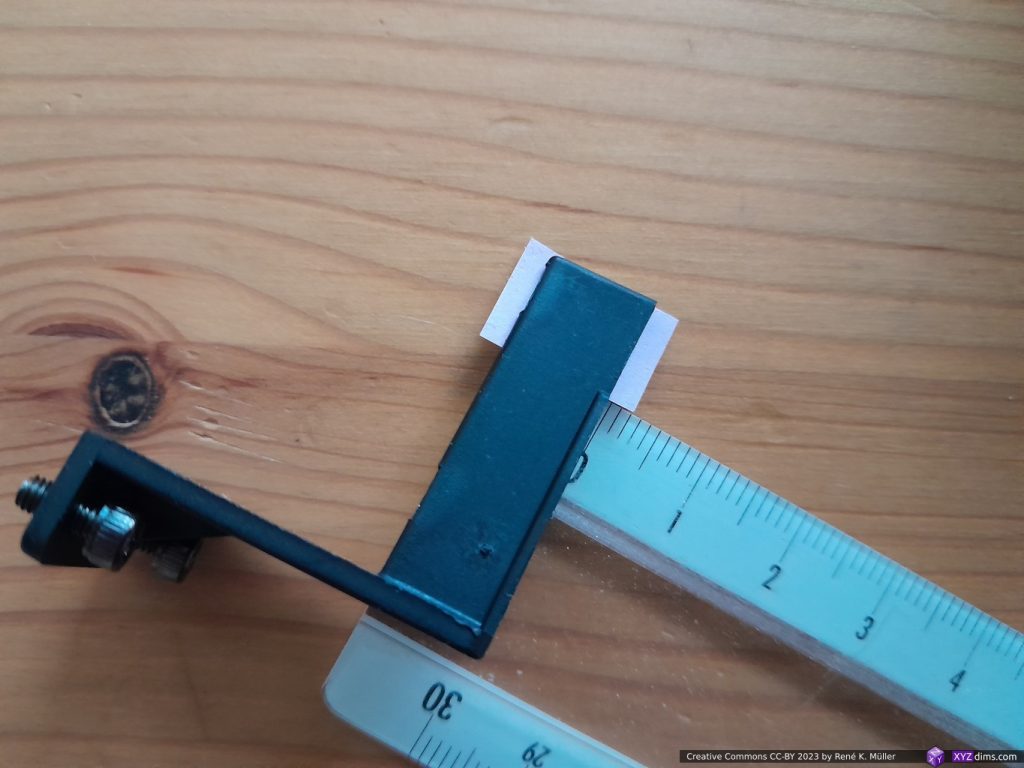

- magnetic base: 2.2mm thick, slightly extends, 203x129mm

- steel plate: 0.5mm thick, exact 202x128mm, I roughed up the exposed surface with sandpaper to increase adhesion

so one has to compensate 2.5 – 3mm in Z height and adjust, speak extend, the Z-level probe. I just glued a black strip of paper, and then of course re-level the bed again afterwards.

Update 2024/11: I had mixed long-term experience with flex steel plate with X2 (same build plate size as X 6Ks).

Preliminary Review Mono X 6Ks

Pros:

- cost-effective for 196x122mm build area and 34μm pixel size

- good third party market (X K6s parts are mostly compatible with X2, except UV LCD & mainboard)

Cons:

- Mechanical Quality Control (QC):

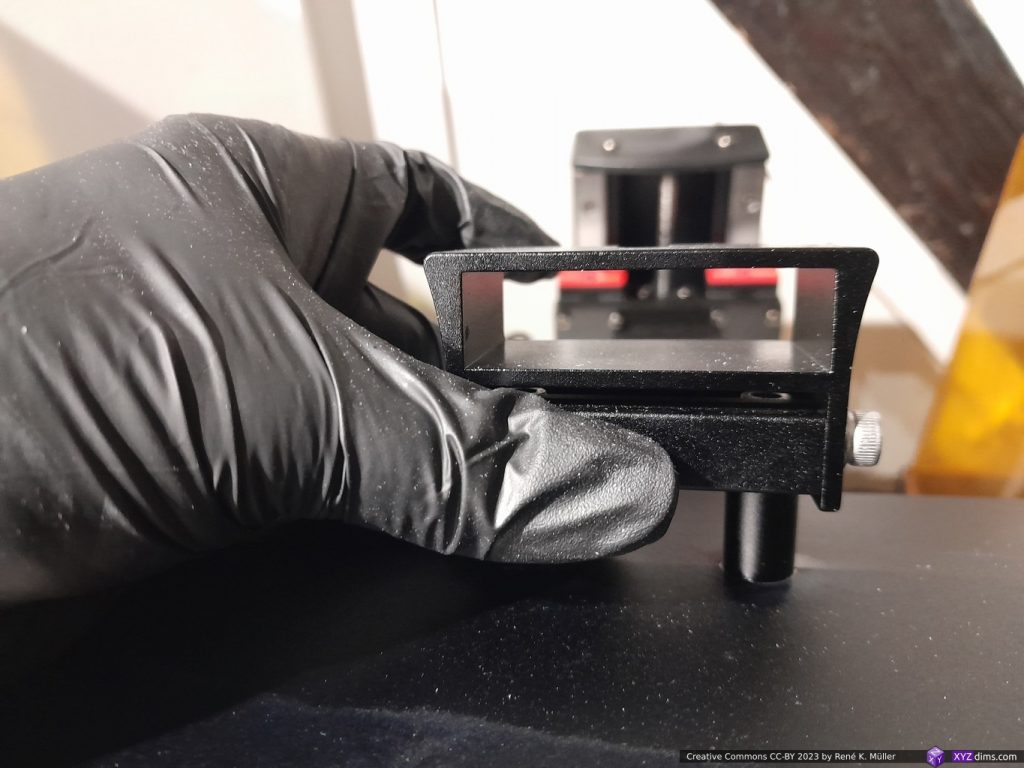

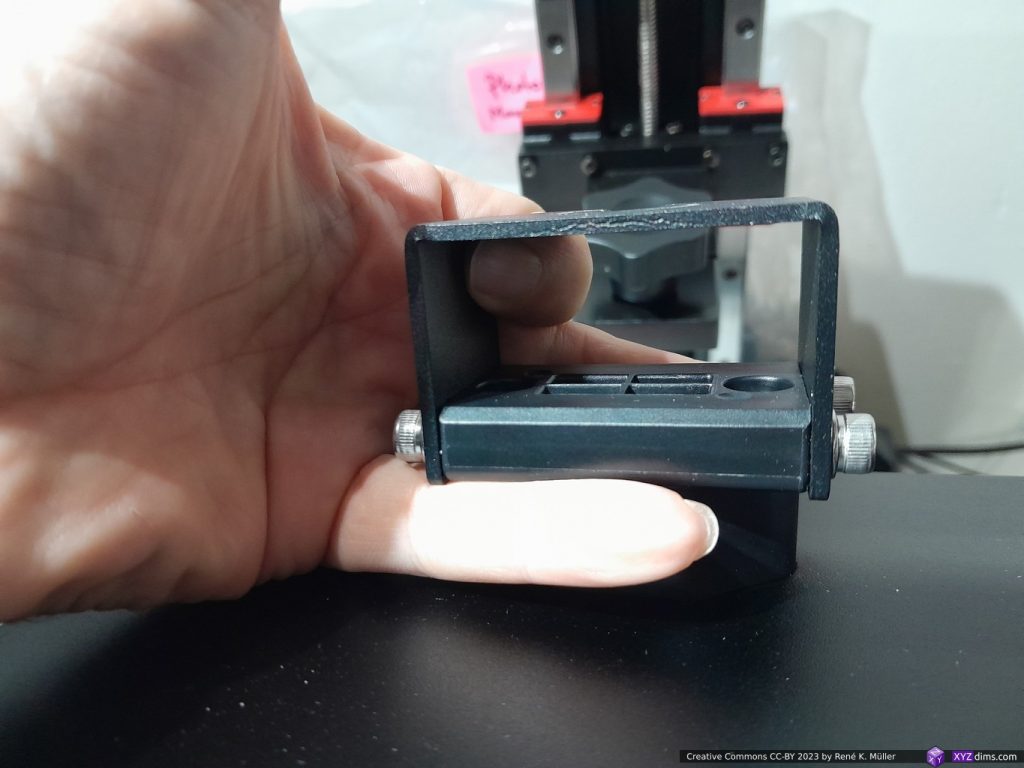

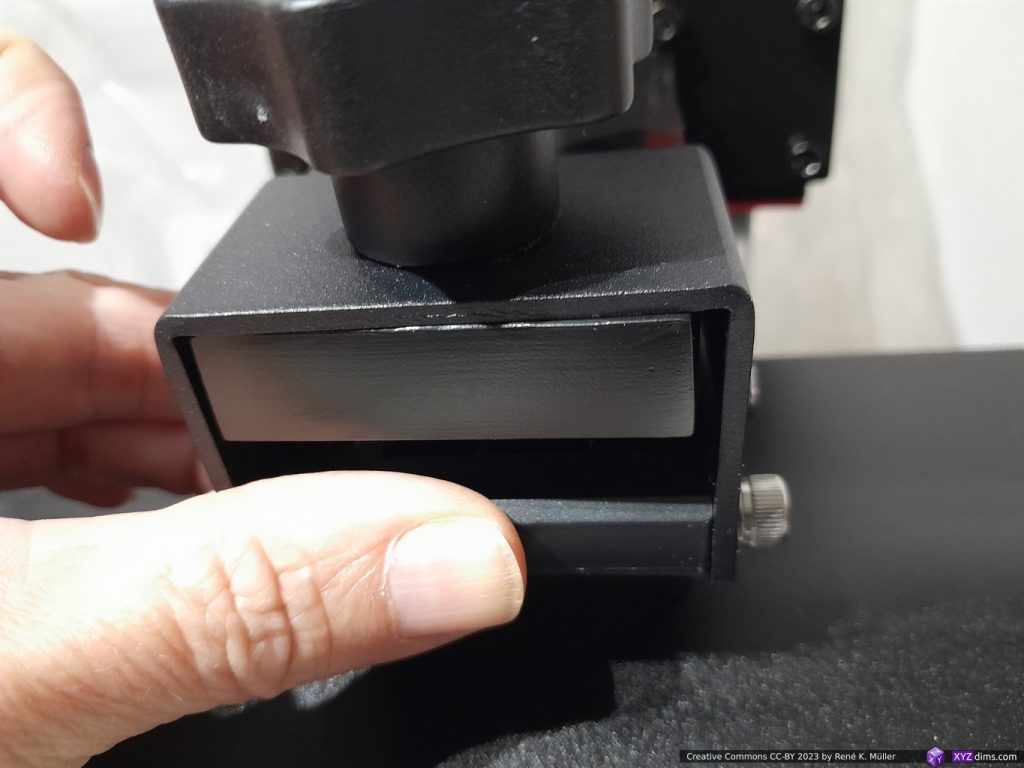

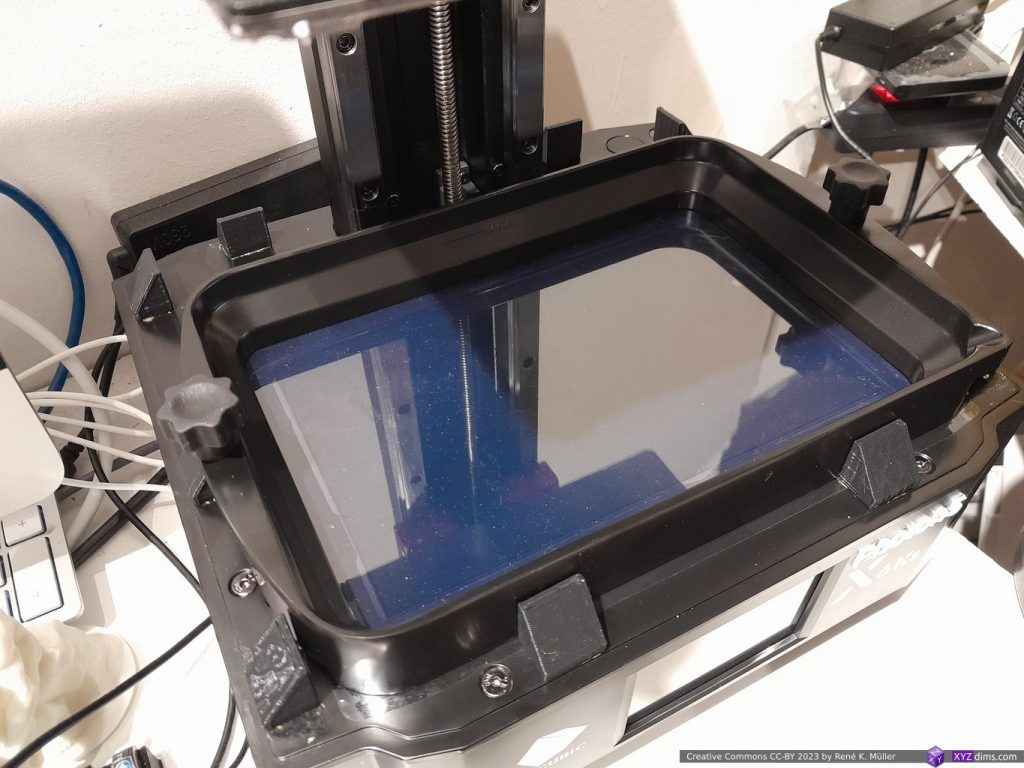

- build-plate has too much horizontal play (2+mm), the Mono X2 build-plate which has the same size fits tighter (see below for detailed photos)

- grey/clear upper case is/was warped, doesn’t fit seamless off by 3-4mm bent inside on left & right; likely package long stored in wrong position or bad clear plastic deforming over time (remedy below “Cover Wedges”)

- no WiFi

- very basic firmware

- poor quality SD stick, it usually won’t last a couple of weeks before it becomes unwritable or unreadable, but this time I couldn’t even backup the data, the stick failed right away; visit anycubic.com and download the slicer, handbook and test files to calibrate UV exposure times

Anycubic is known to invest very little into the firmware which is provided by Chitubox, given they are one of the biggest resin printer sellers, it affects 100,000s of customers.

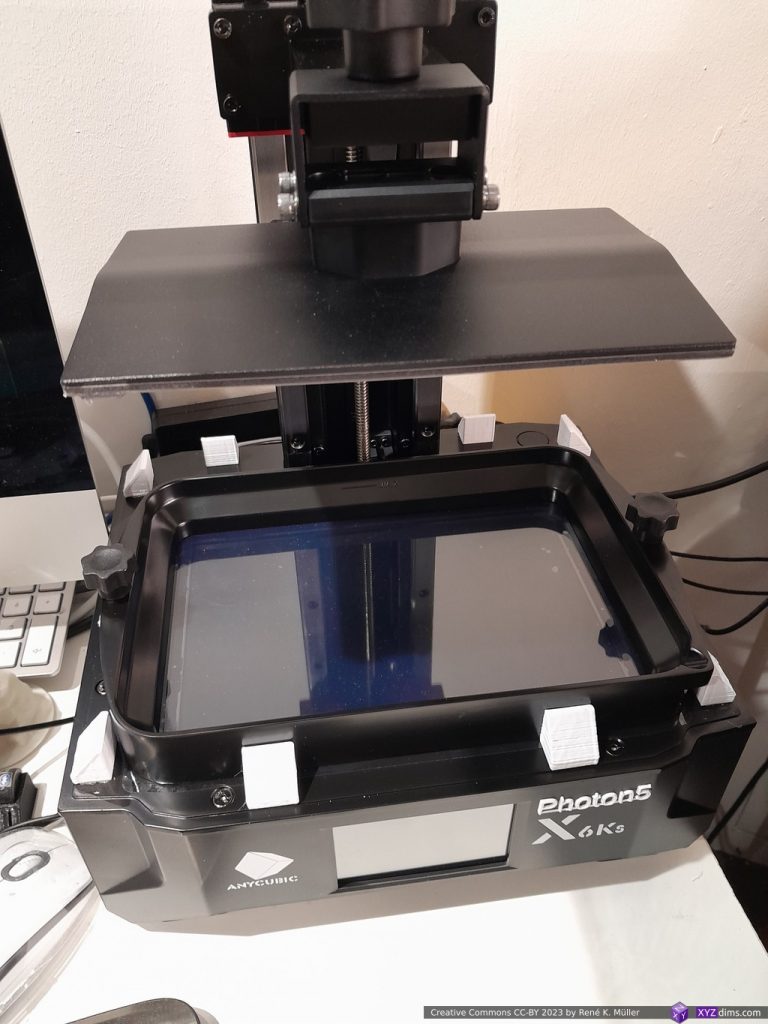

The build plate also has new a black plastic connector to the mount, an attempt to reduce cost perhaps. The Mono X2 build plate mount is much better in my opinion, more solid; the Mono X 6Ks build plate has more wiggle/play horizontally, therefore pieces printed you want definitely in the center of the UV LCD/vat, not on the side to avoid any wiggle or play while printing introducing imprecisions.

Cover Wedges

As the X K6s came with a warped cover, and with the X2 with the same case geometry it was wiggly everytime I put the cover over, I printed a few “wedges” which align the cover easily:

and I did the same with my Mono X2.

Reverse Engineering

Goran Mahovlic started to reverse engineer the Mono X 6Ks:

See also the Github repo reverse Mono X 6Ks; the UV LCD and the user GUI LCD are working.

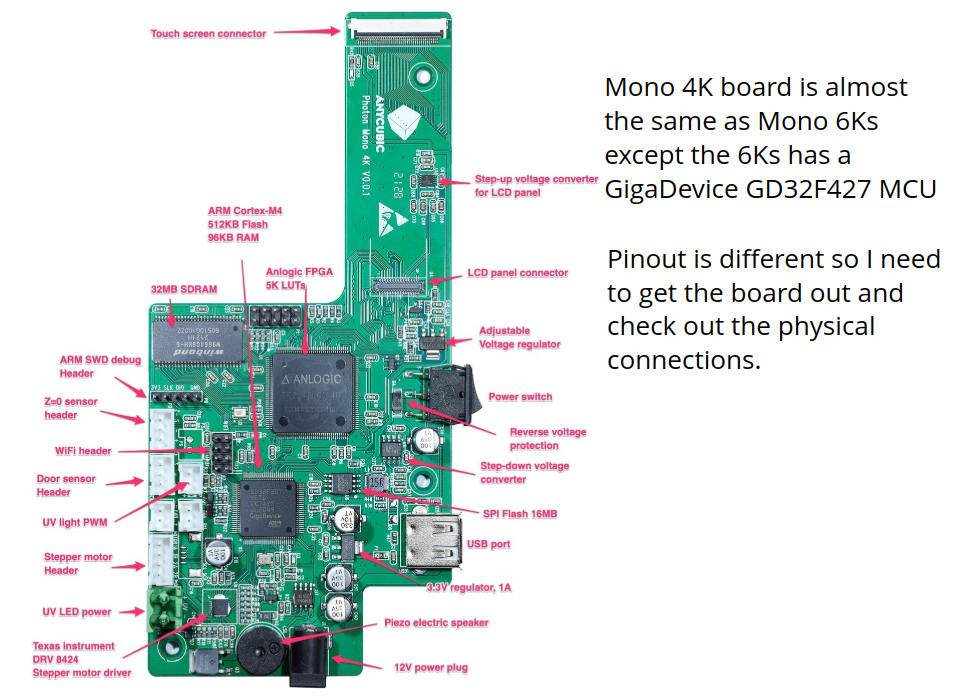

- GD34F427 MCU (Cortex M4, 512KB Flash, 96KB RAM)

- 32MB SDRAM

- SPI 16MB Flash

- FPGA 5K LUTs

- DRV 8424 stepper motor driver

(M)SLA Value Comparison

A numeric value summarization for features I care about, the rough & simple formula:

XY Area [mm2] / Price [EUR] / XY Resolution [μm]

The bigger the XY area, the smaller the price and the smaller the resolution, the higher the value:

State 2024/11

| PRINTER | year | XY RESOLUTION | Type | BUILD VOLUME XYZ | PRICE | Value |

|---|---|---|---|---|---|---|

| Elegoo Saturn 4 | 2024- | 19μm x 24μm2) | MSLA | 218x122x220 | 300 EUR | 3.74 |

| Elegoo Saturn 4 Ultra | 2024- | 19μm x 24μm2) | MSLA | 218x122x220 | 400 EUR | 2.81 |

| Anycubic Photon Mono M5 | 2023- | 19μm x 24μm2) | MSLA | 218x123x200 | 410 EUR | 2.72 |

| Elegoo Mars 5 Ultra | 2024- | 18μm | MSLA | 153x78x165 | 270 EUR | 2.54 |

| Anycubic Photon Mono X 6Ks | 2023- | 34μm | MSLA | 196x122x200 | 280 EUR | 2.51 |

| Anycubic Photon Mono M7 | 2024- | 17μm x 25μm2) | MSLA | 223x126x230 | 450 EUR | 2.49 |

| Elegoo Saturn 3 Ultra | 2023- | 19μm x 24μm2) | MSLA | 218x123x260 | 480 EUR | 2.32 |

| Anycubic Photon Mono 4K | 2021-2022 | 35μm | MSLA | 132x80x165 | 150 EUR | 2.01 |

| Anycubic Photon Mono X2 | 2023- | 48μm | MSLA | 196x122x200 | 260 EUR | 1.91 |

| Anycubic Photon Mono 2 | 2023- | 35μm | MSLA | 143x89x165 | 210 EUR | 1.73 |

| Elegoo Jupiter SE | 2023- | 51μm | MSLA | 277x156x300 | 700 EUR | 1.21 |

| Anycubic Photon M7 Max | 2025- | 46μm | MSLA | 298x164x300 | 900 EUR | 1.18 |

| EMake Galaxy 1 | 2023 | 25μm / 100μm1) | SLA | 400x200x400 | 2,700 EUR | 1.18 |

| Anycubic Photon M3 Max | 2022-2024 | 45μm | MSLA | 298x164x300 | 980 EUR | 1.10 |

| UltraCraft Reflex RS | 2024- | 30μm | MSLA | 222x122x200 | 1,200 EUR | 0.75 |

| EMake LCD 16″ 8K | 2024- | 46μm | MSLA | 353x198x400 | 2,700 EUR | 0.56 |

| Formlabs 3L | 2020-2024 | 25μm / 100μm1) | SLA | 335x200x300 | 9,000 EUR | 0.29 |

| Formlabs 3+ | 2020-2024 | 25μm / 100μm1) | SLA | 146x145x185 | 3,500 EUR | 0.24 |

| Formlabs 4L | 2024- | 46μm | MSLA | 353x196x350 | 11,000 EUR | 0.14 |

| Prusa SL1S | 2021- | 49μm | MSLA | 127x80x180 | 1,700 EUR | 0.12 |

| Formlabs 4 | 2024- | 50μm | MSLA | 200x125x210 | 5,175 EUR | 0.09 |

- Formlabs 3’s & EMake SLA printers use a laser beam which has 100μm in diameter, but it can be positioned 25μm exact, the latter was used to calculate the value

- The UV pixels are non-square, the longer side was used to calculate the value

The XY area in SLA scales not as good as with MSLA, as the laser beam takes longer the more XY area (e.g. more pieces) need to be rendered per layer – so, MSLA is recommended for aiming fast parallel printing. Interestingly Formlabs 4 is now a MSLA as well (2024/04), they seem to have abandoned the SLA laser-based approach.

One of the main reason I choose Anycubic MSLA is the third party market for add-on’s, like flex build plate, vats, LCD replacement etc, and I also like the build plate mount with 4 screws for alignment; and I hoped to replace the firmware of the Mono 4K which did not happen as the Open Source variant is still incomplete (2023/11).