My first Formnext in 2019 I realized there was no way to explore the expo in 1 day only, so I reserved for Formnext 2021 (Frankfurt, Germany) 4 days fully (November 16-19). Although the expo was smaller than in 2019, it was still massive to explore. I’m not even sure I saw all of the 600+ exhibitors despite roaming the two halls (12.0 ground floor, 12.1 first floor and 11.0 ground floor only) multiple times.

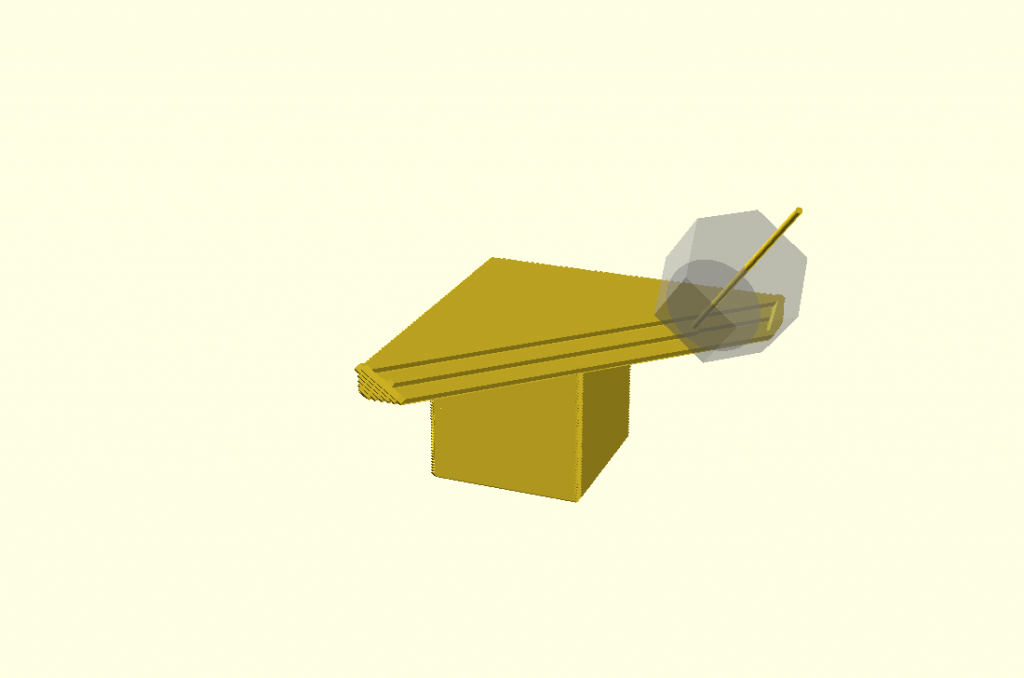

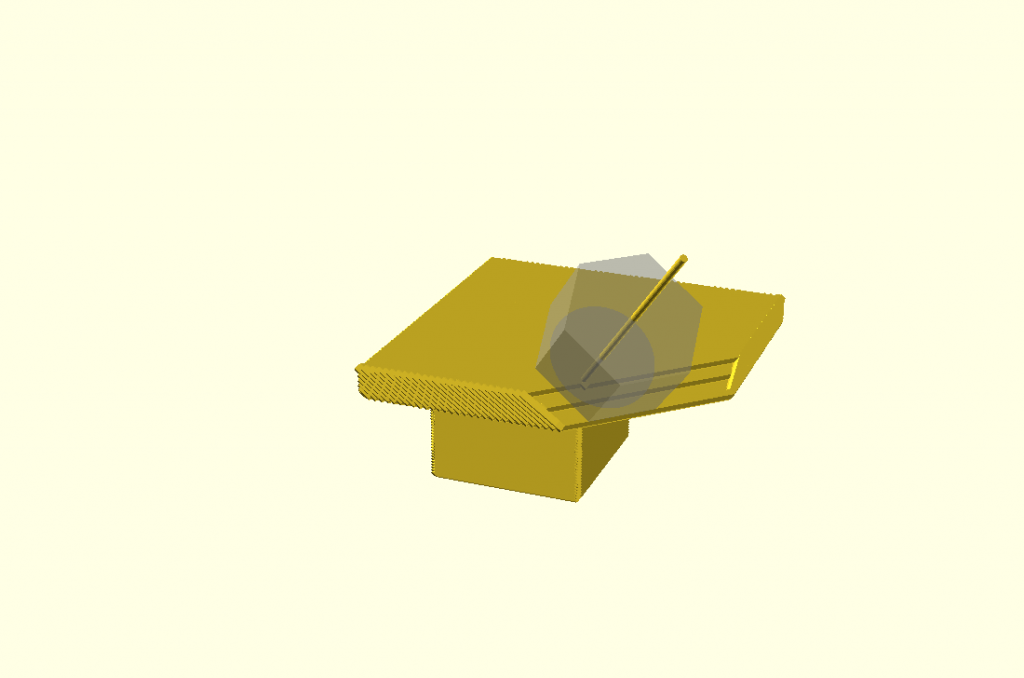

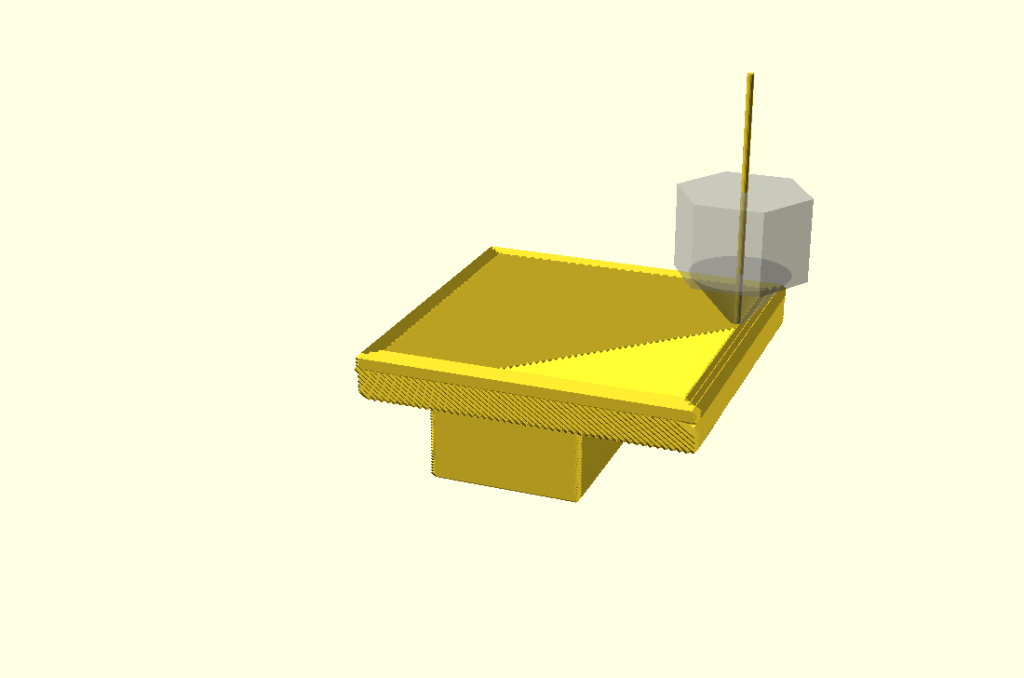

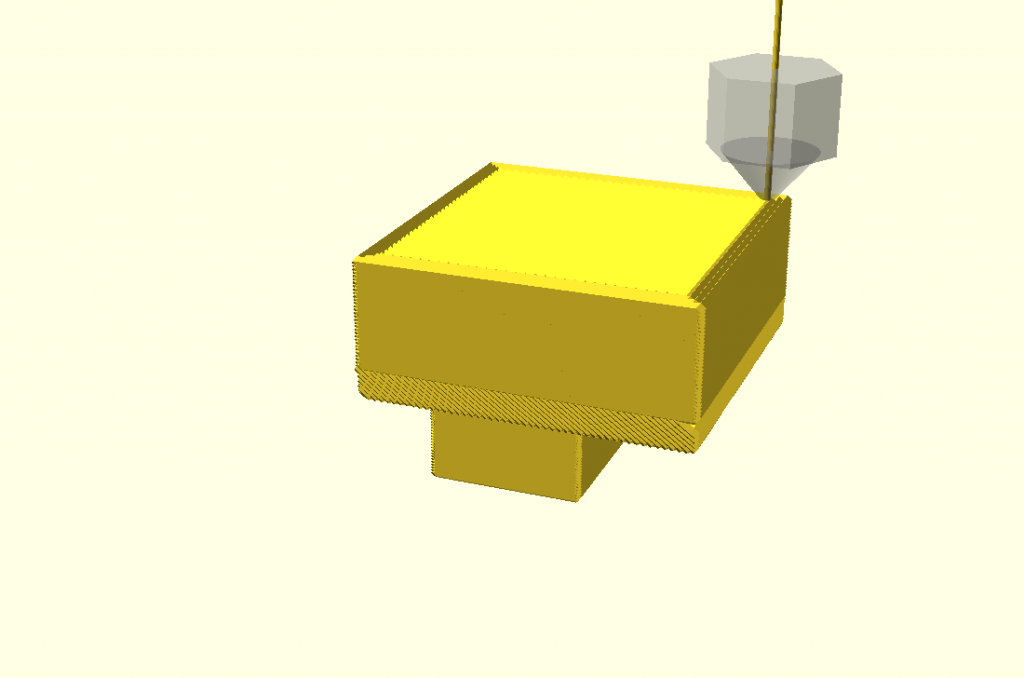

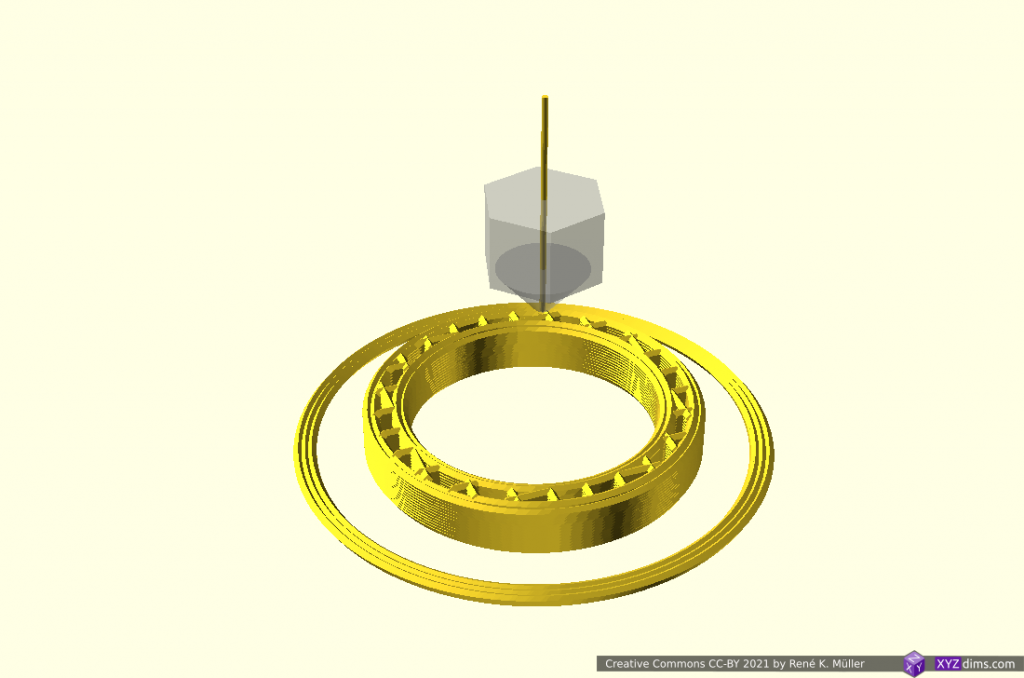

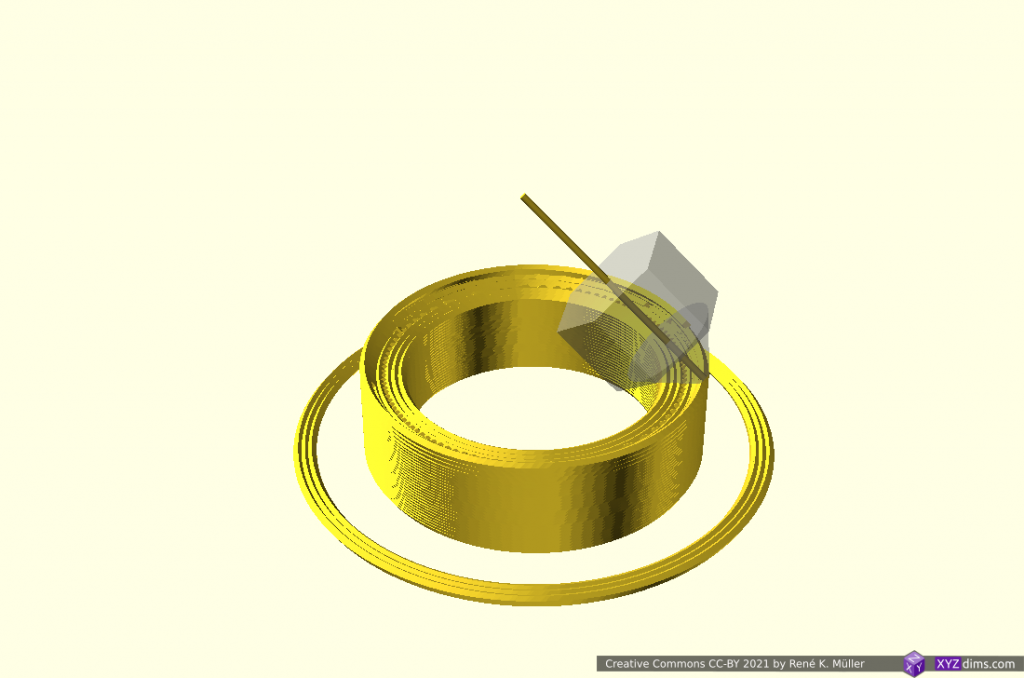

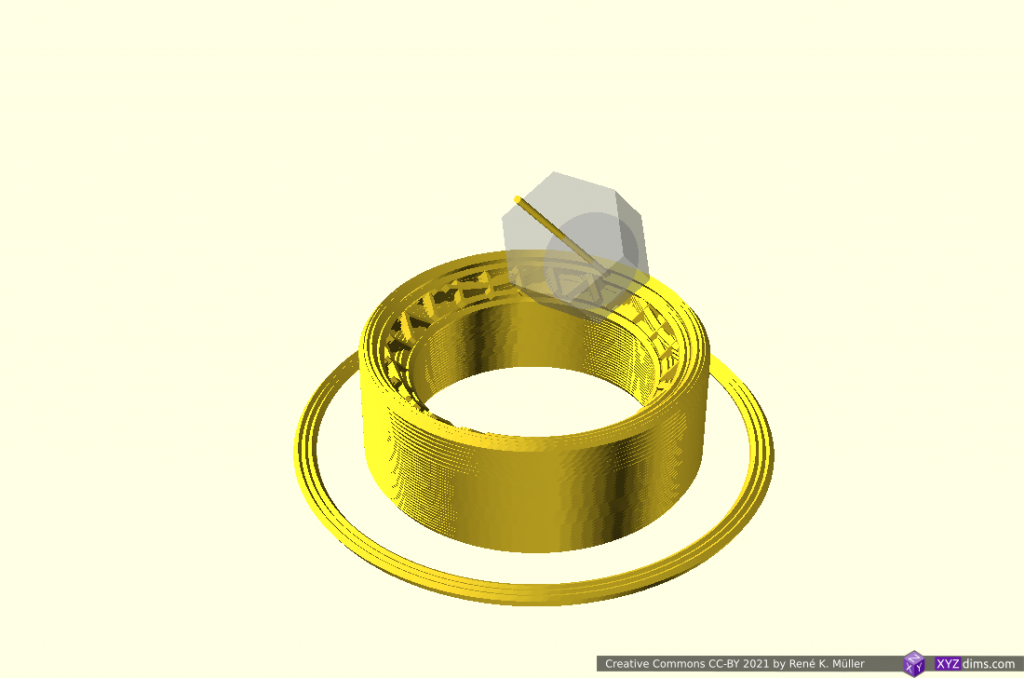

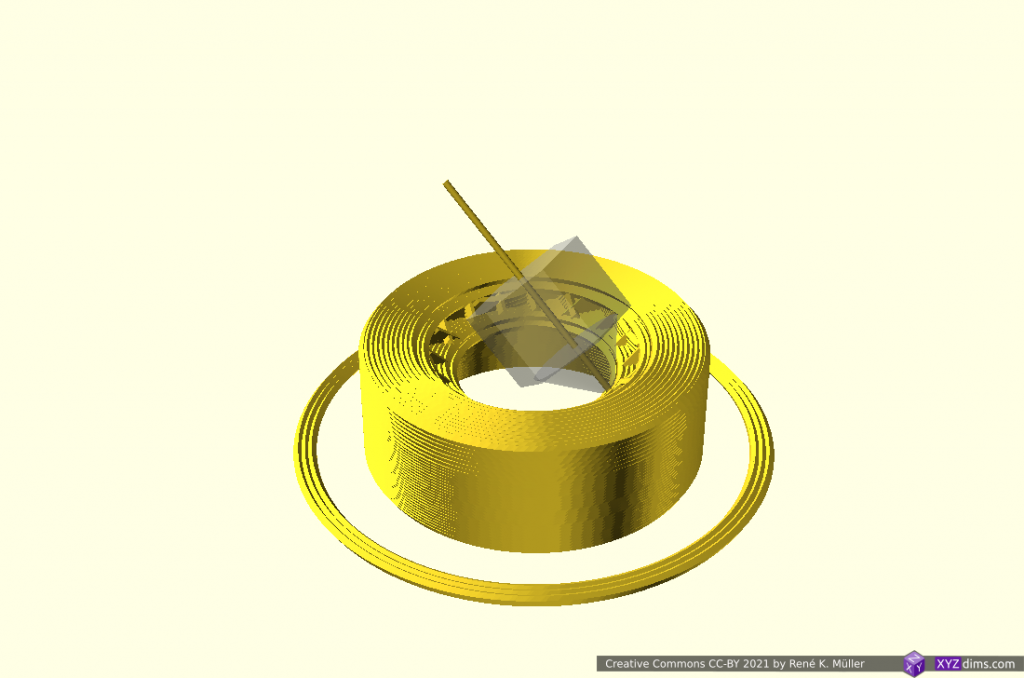

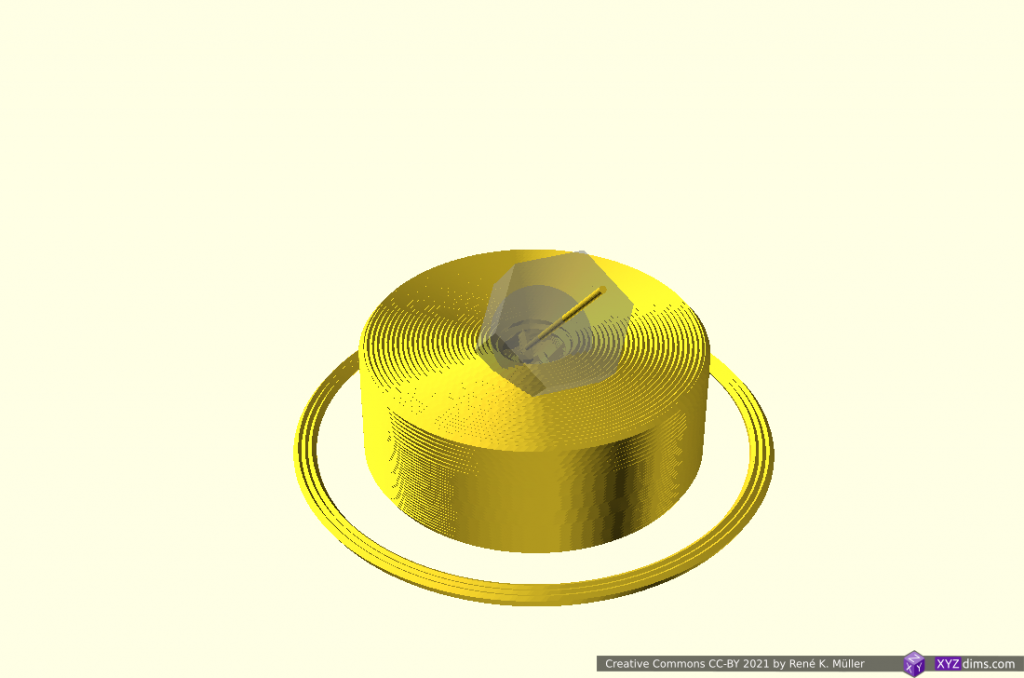

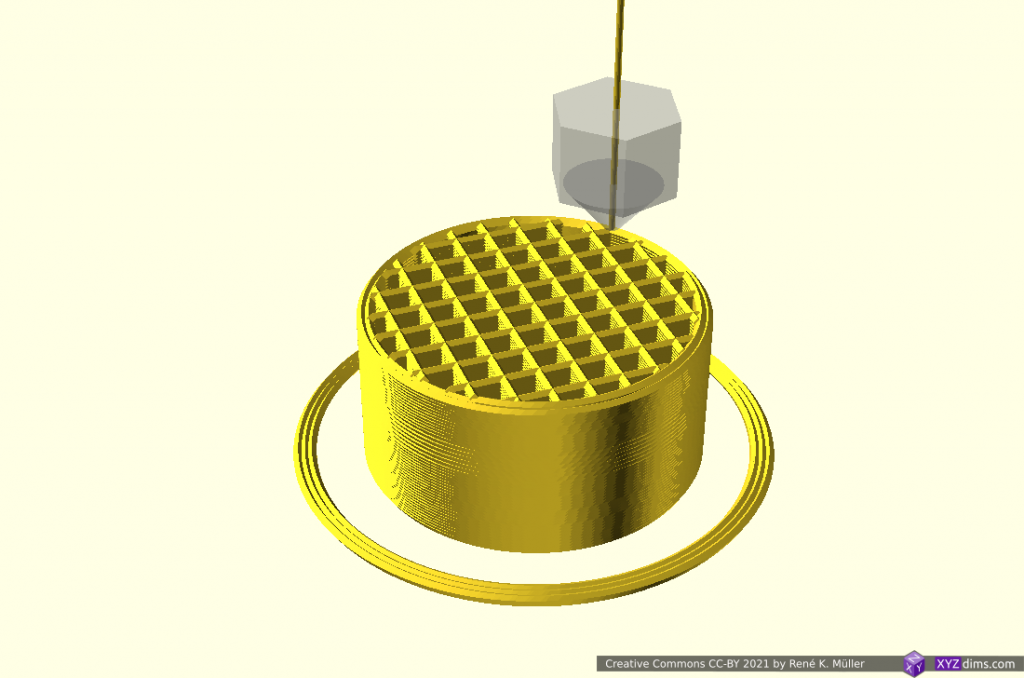

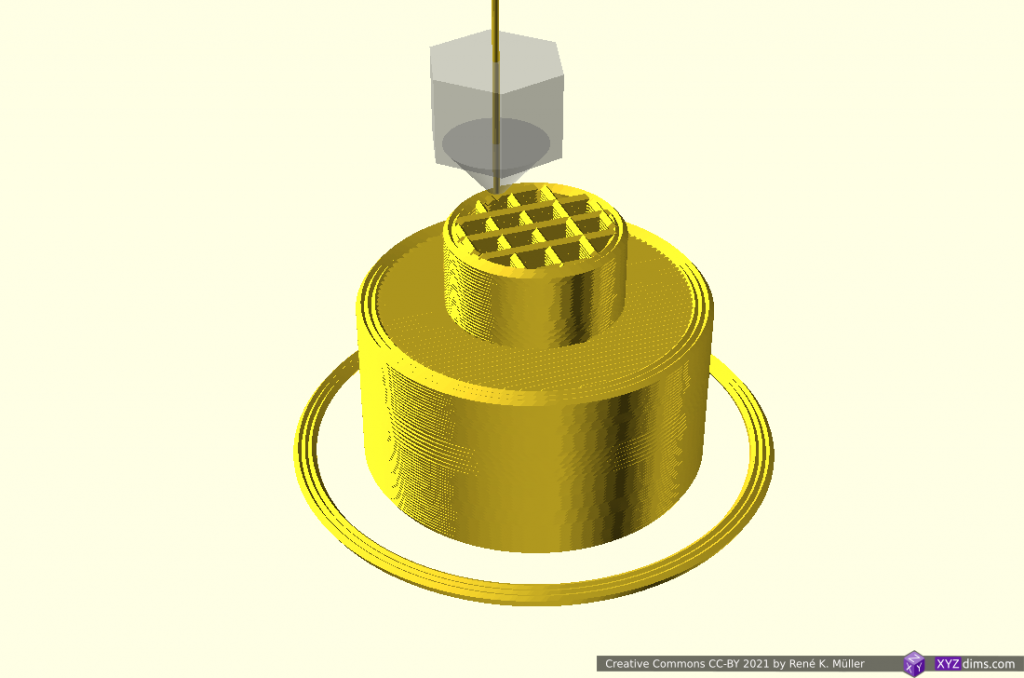

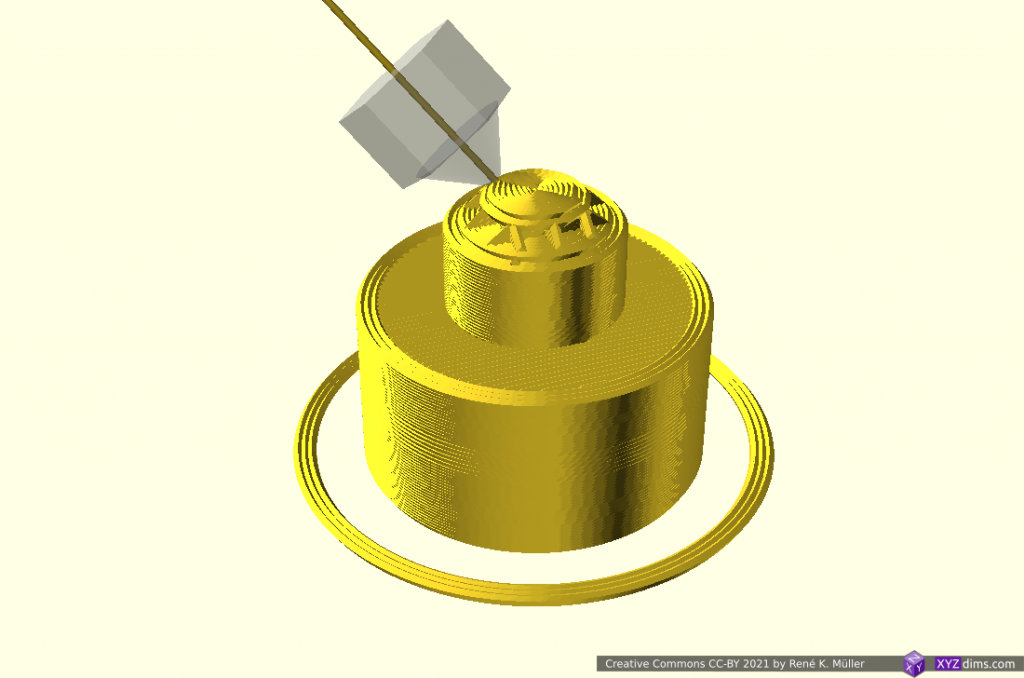

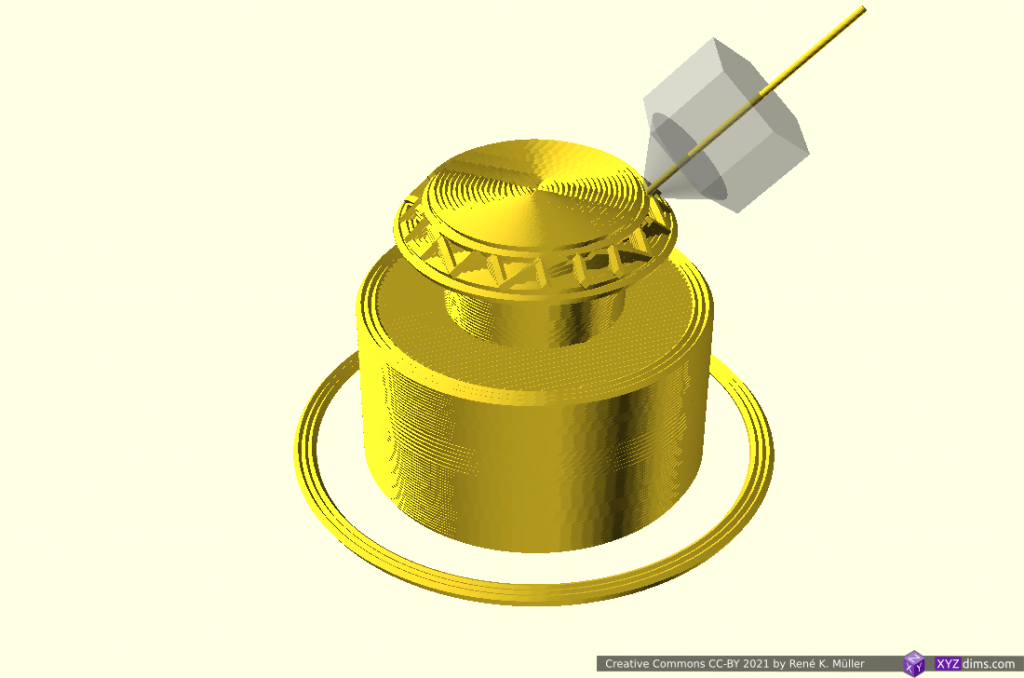

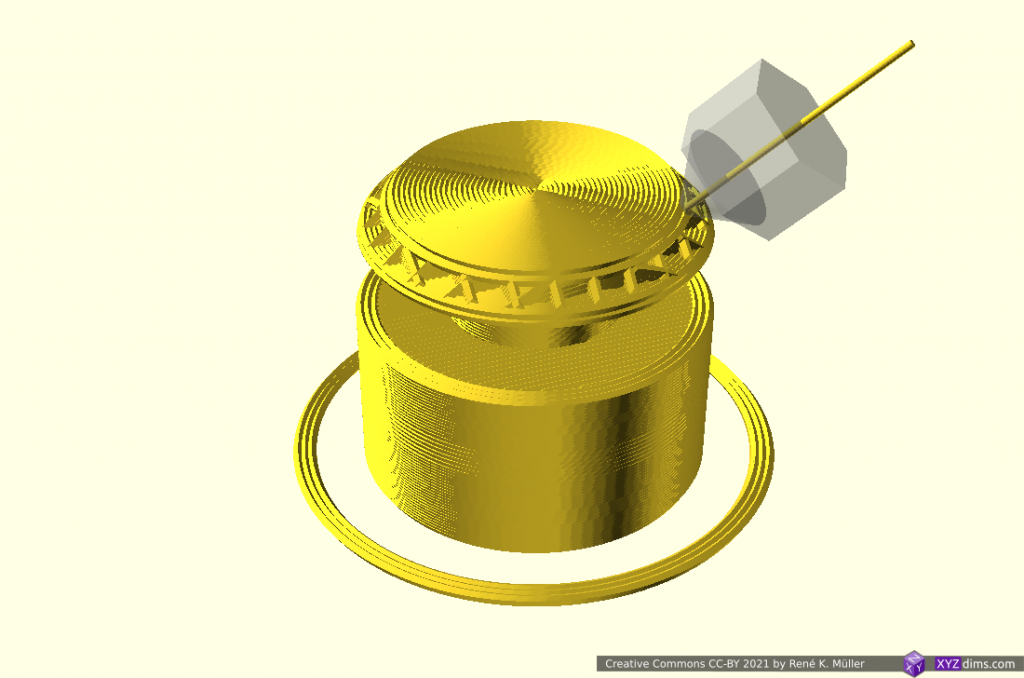

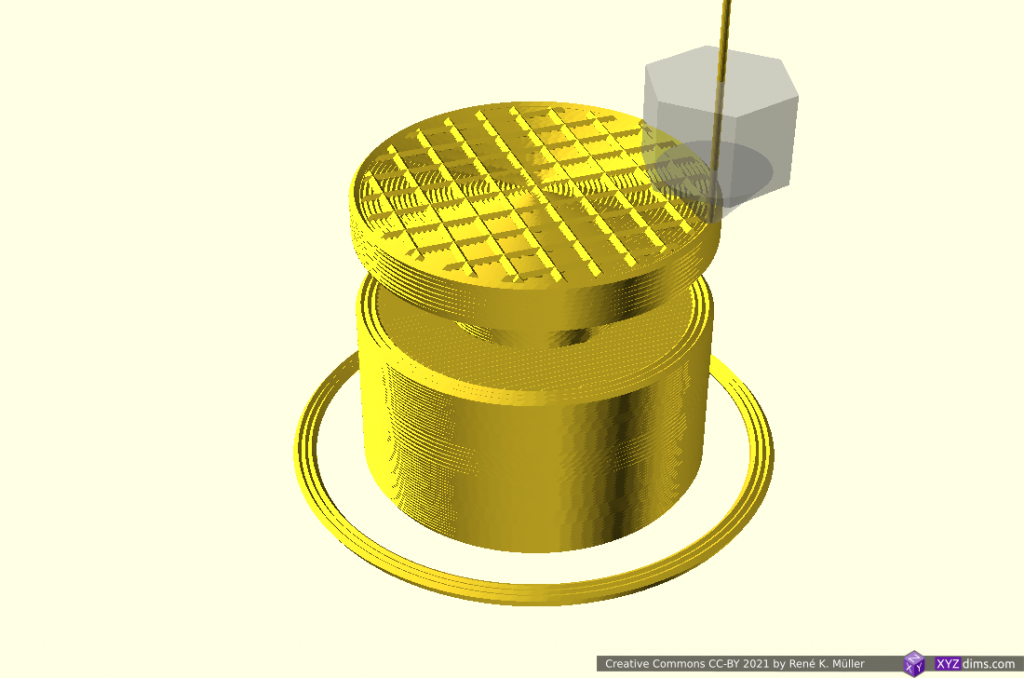

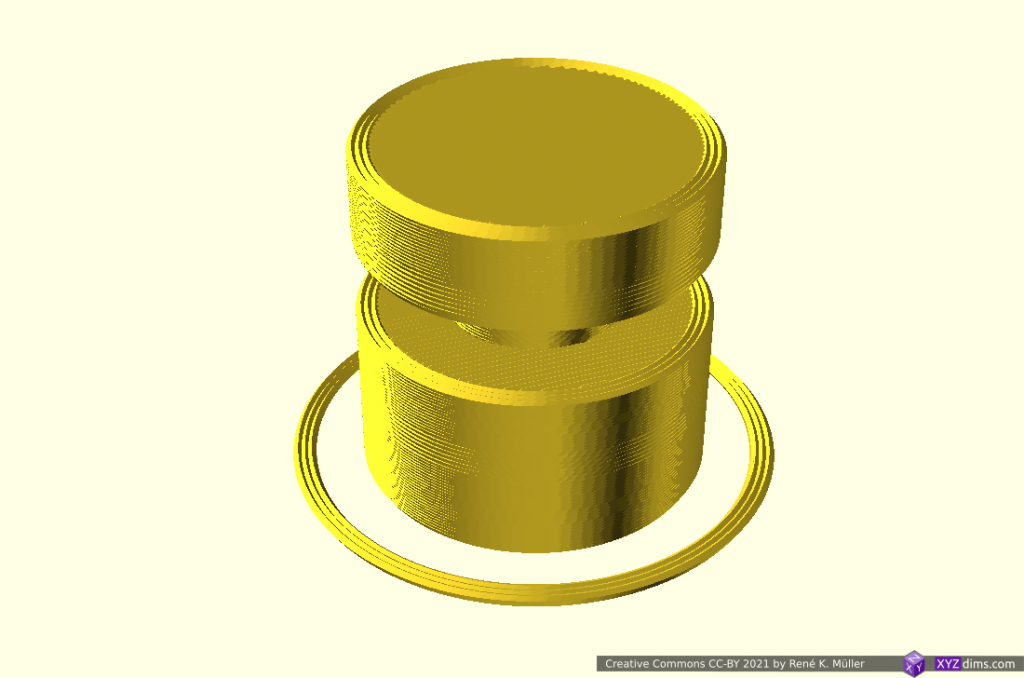

Inhouse Developments: ZPlusSlicer & 5DMaker

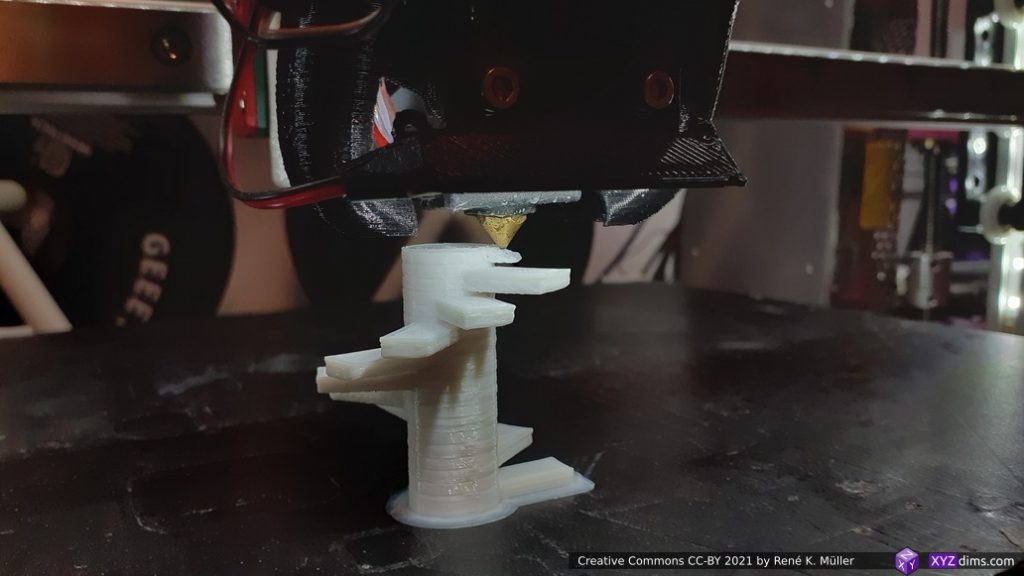

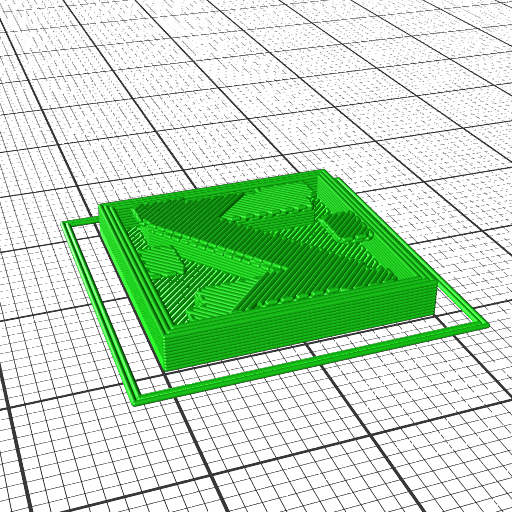

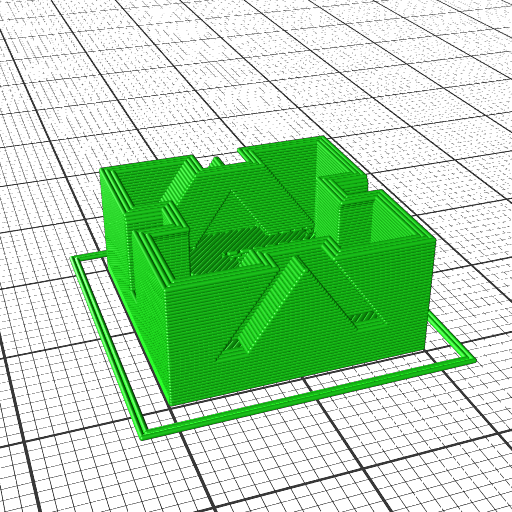

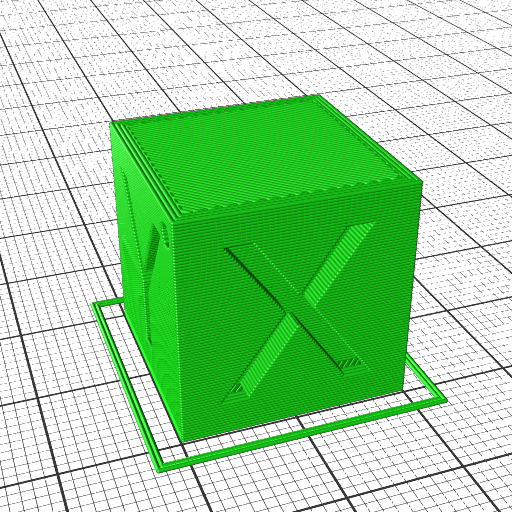

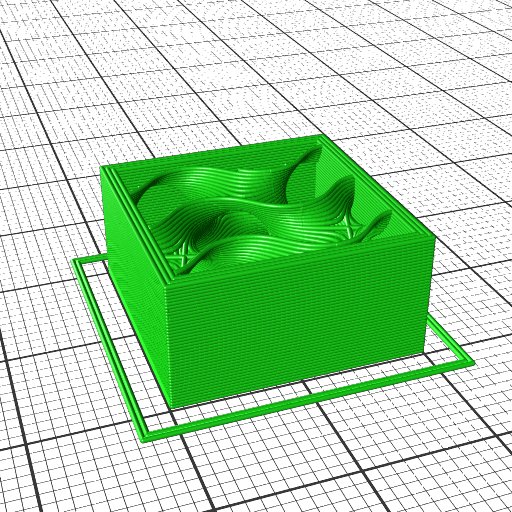

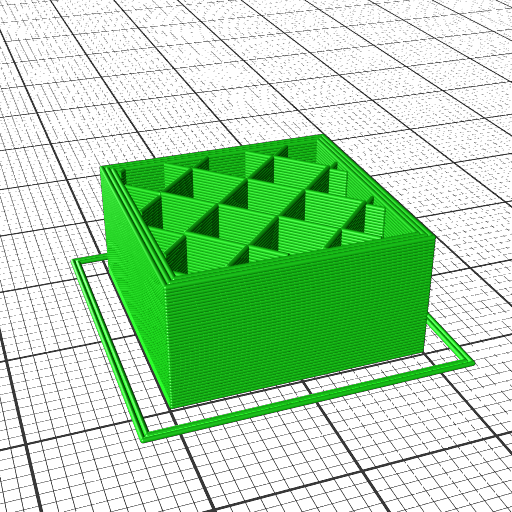

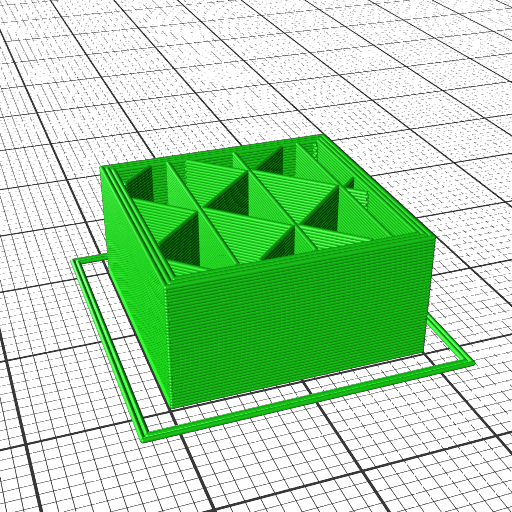

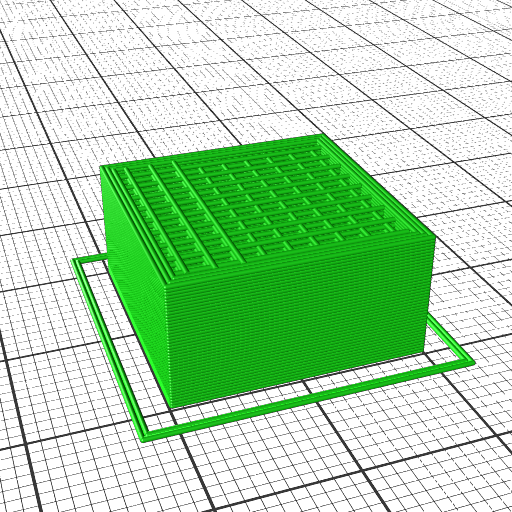

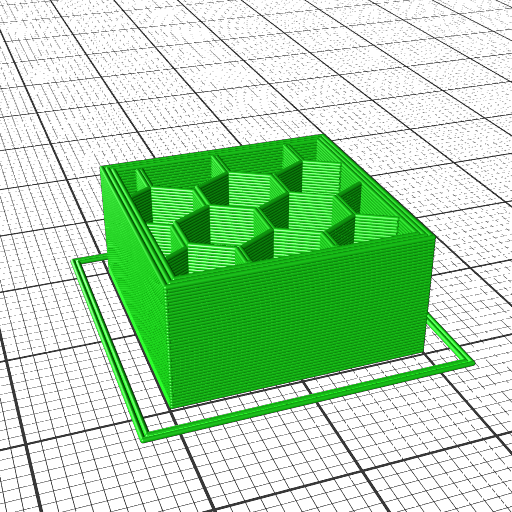

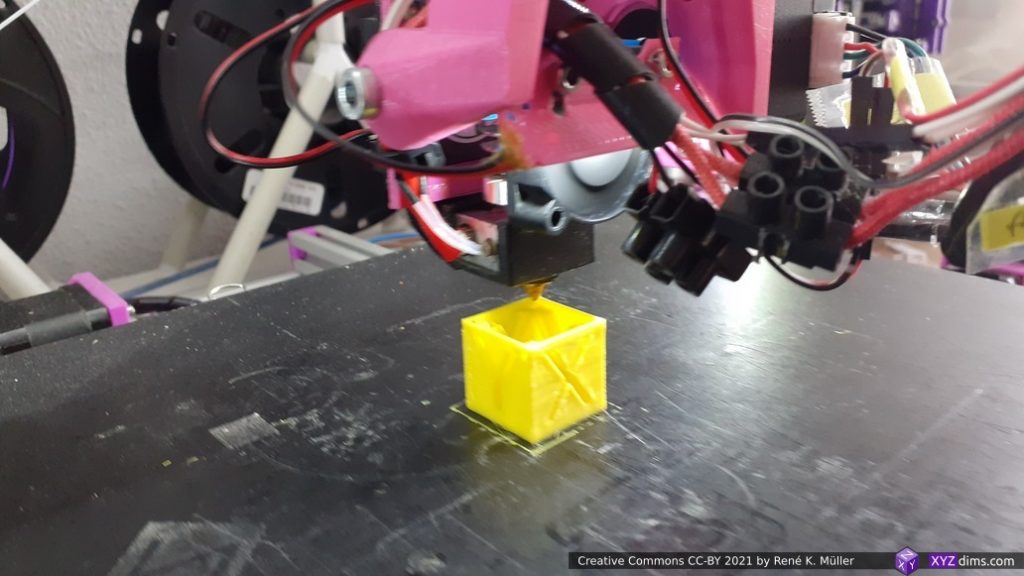

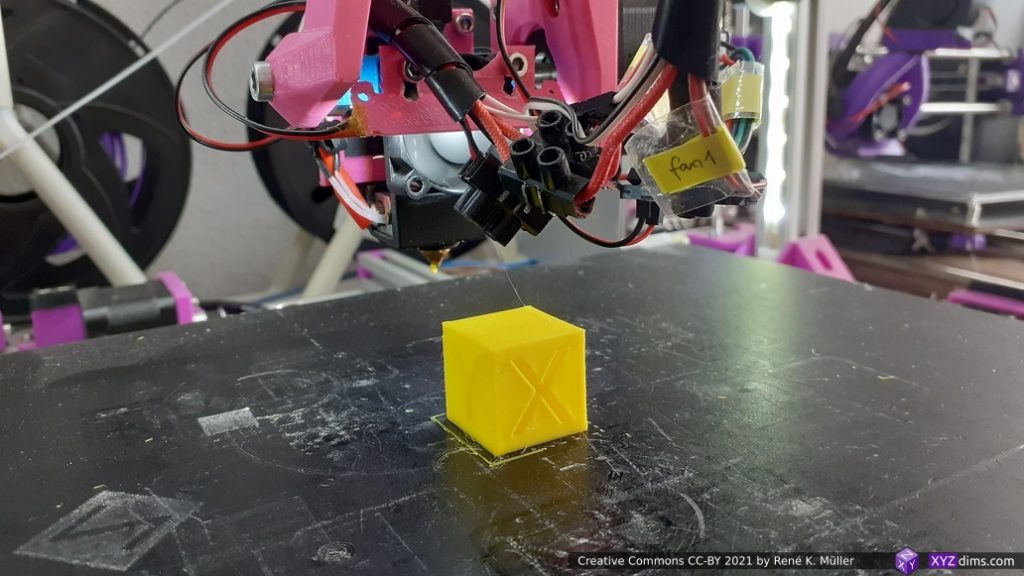

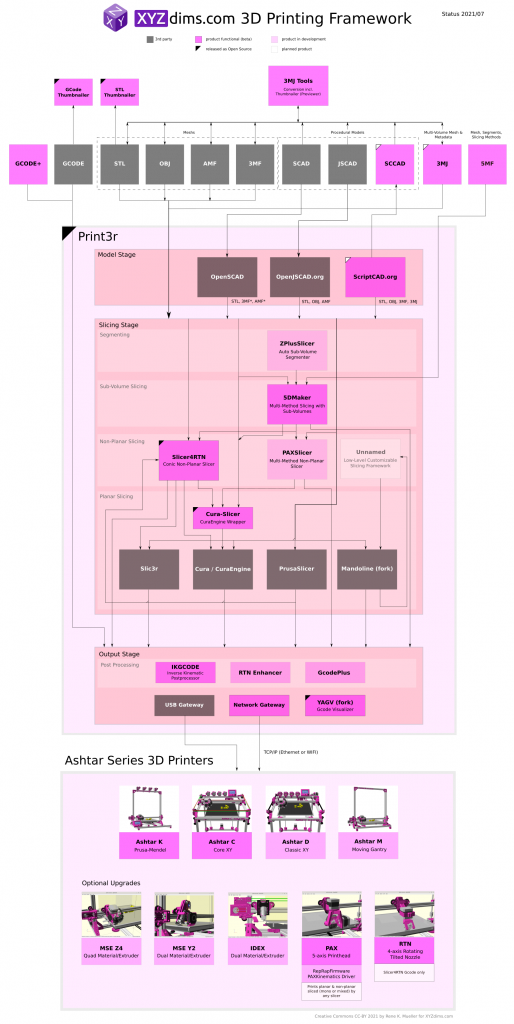

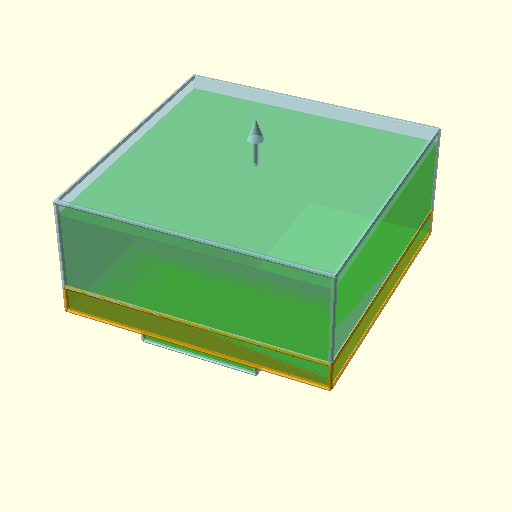

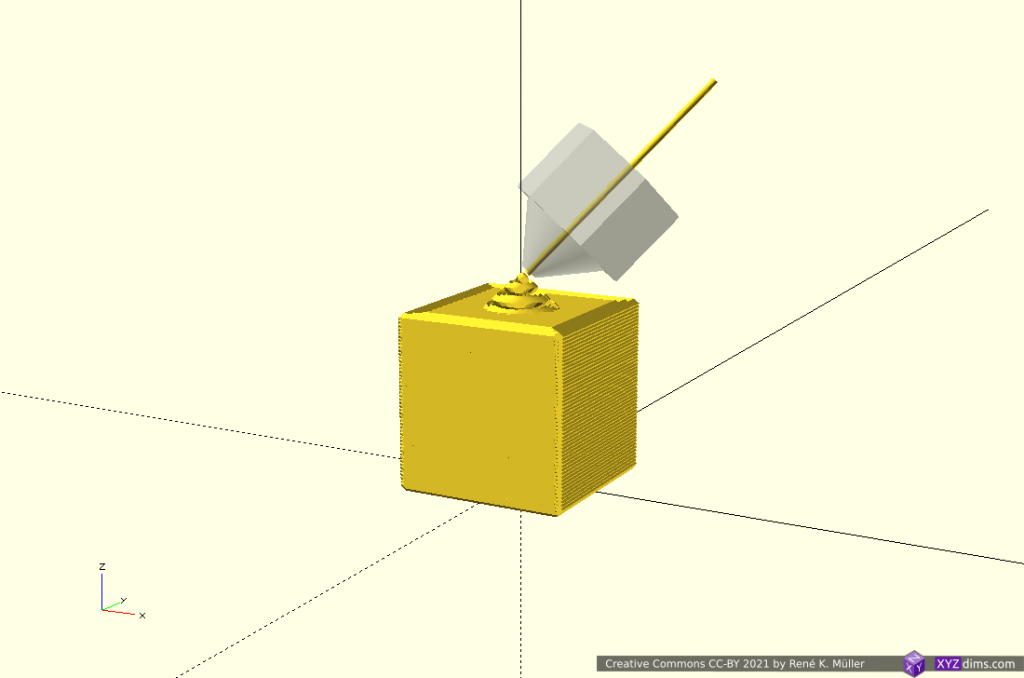

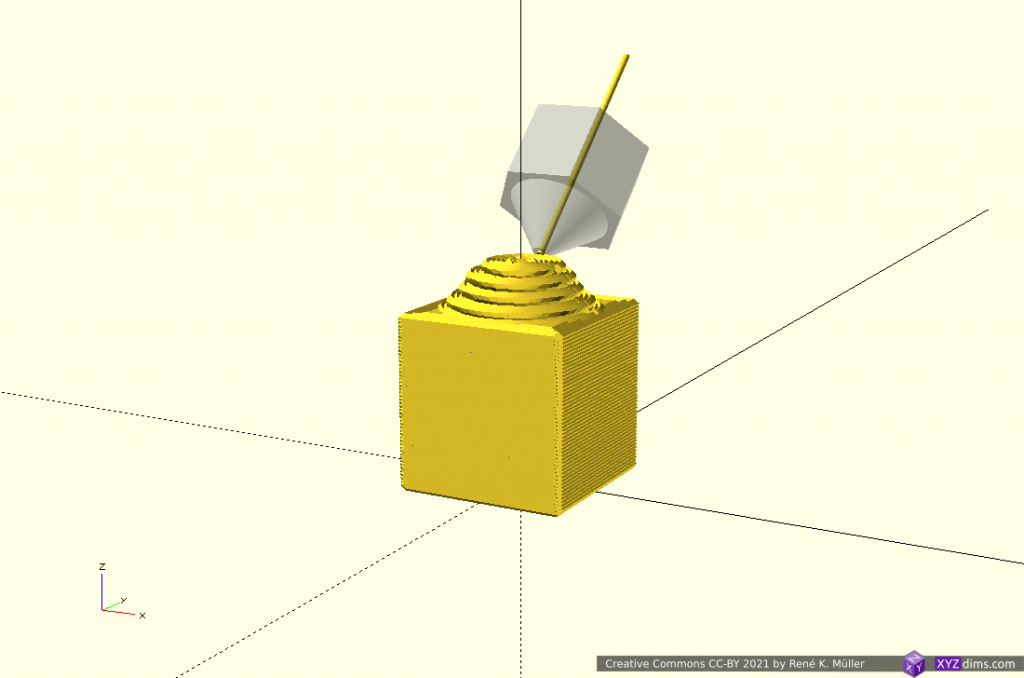

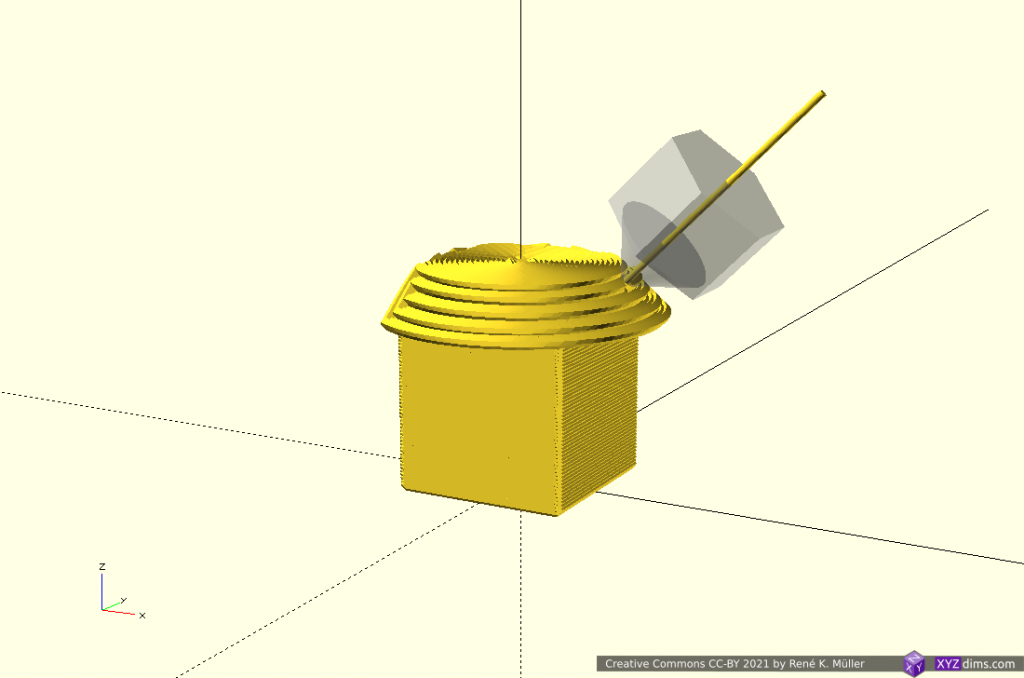

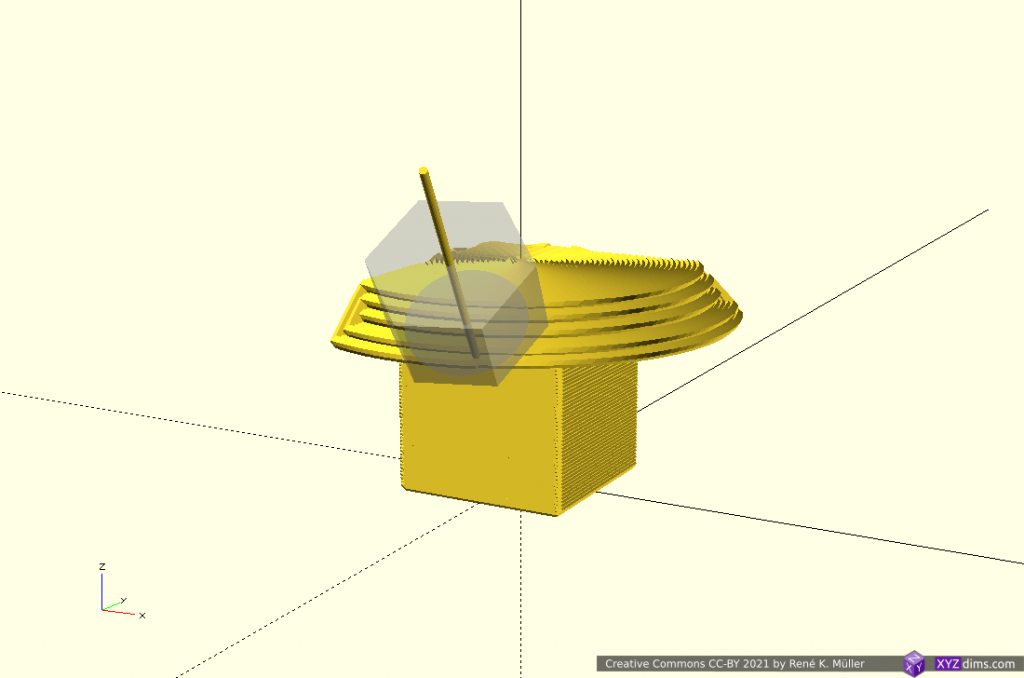

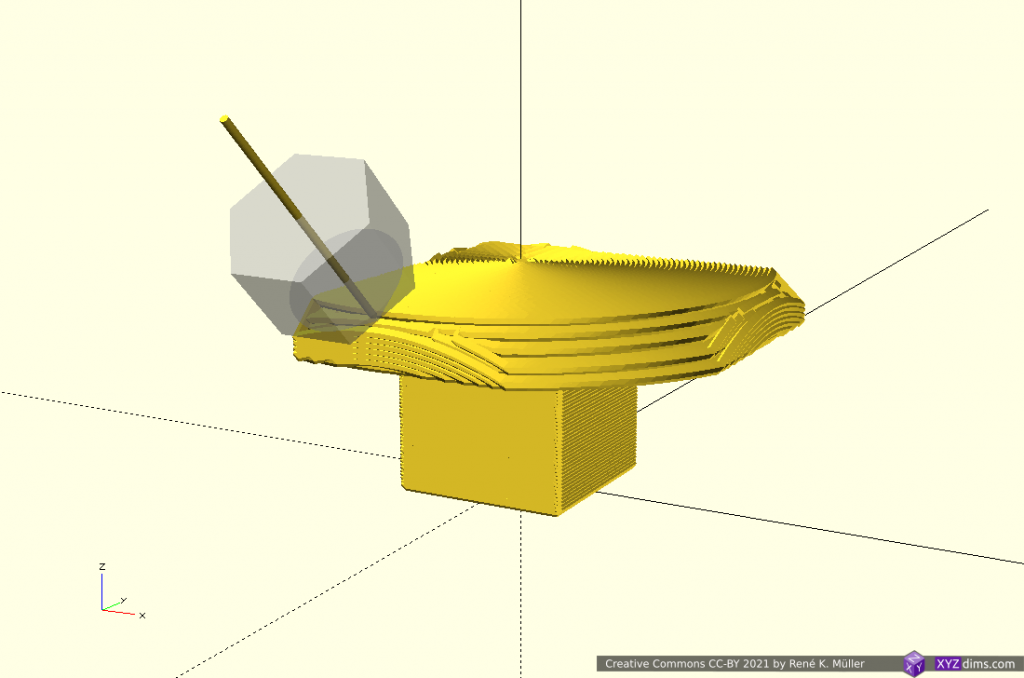

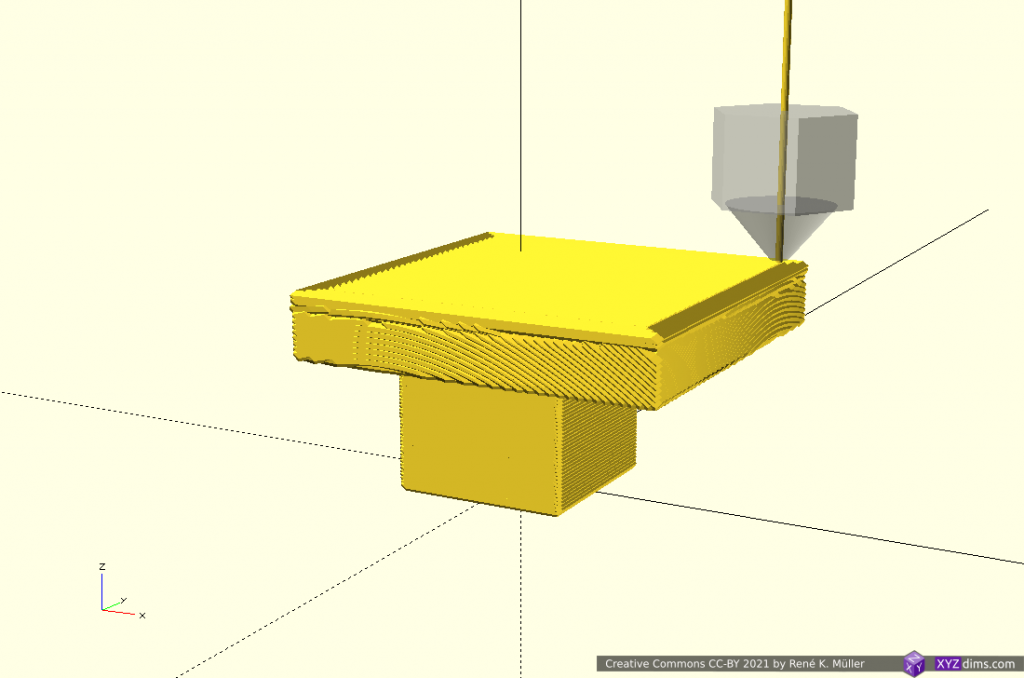

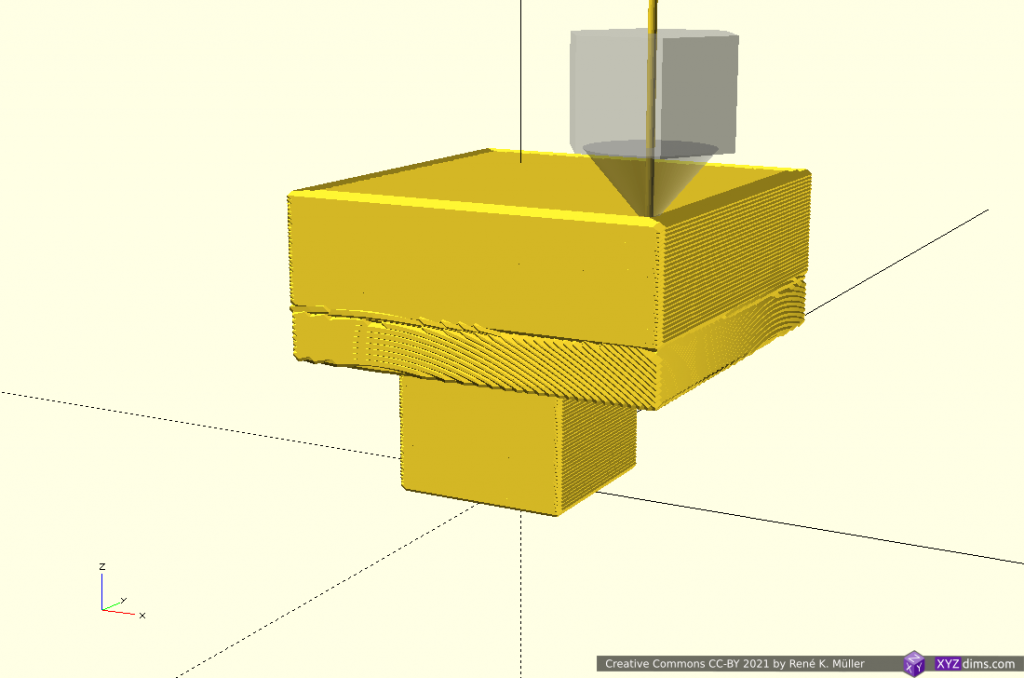

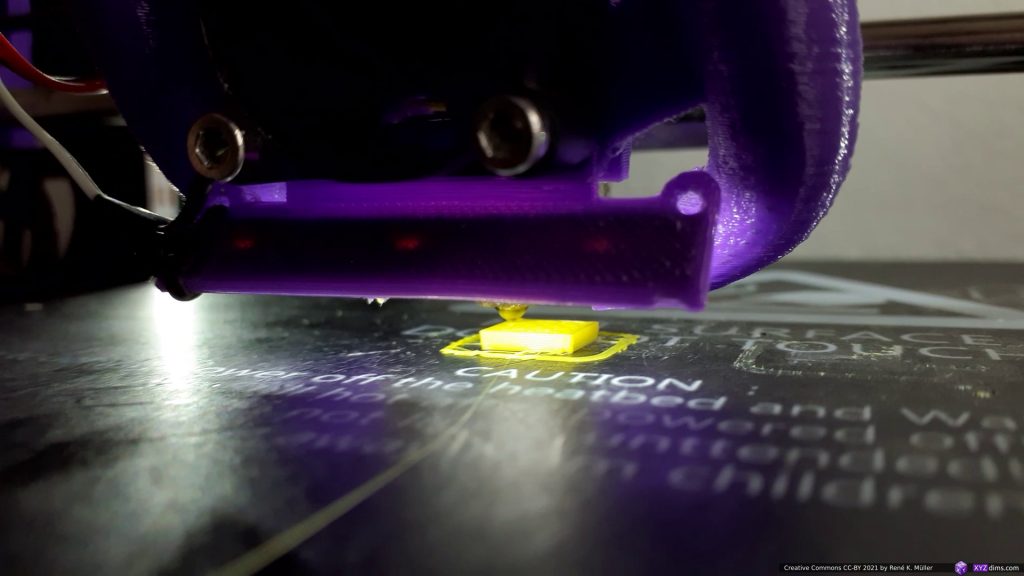

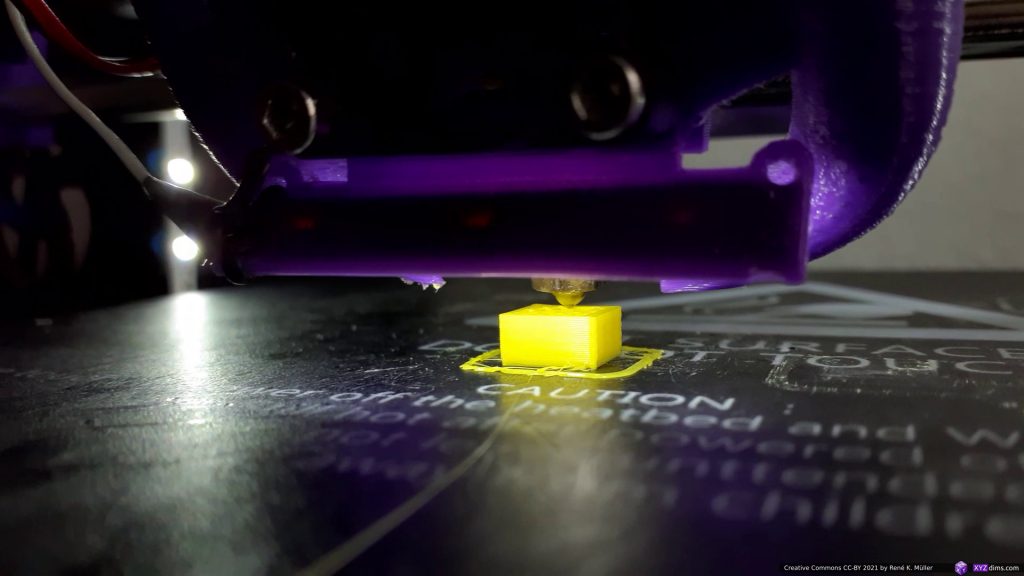

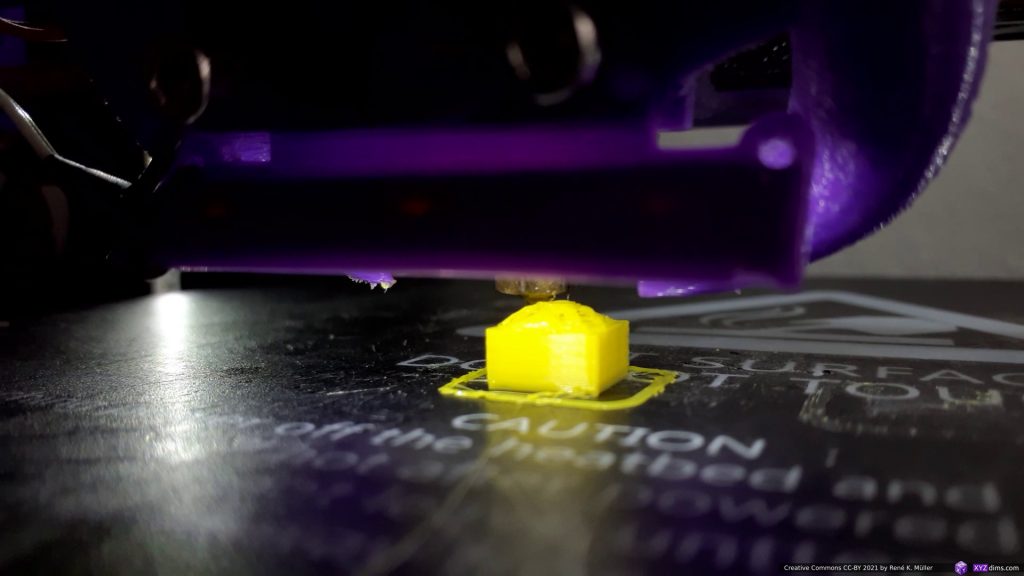

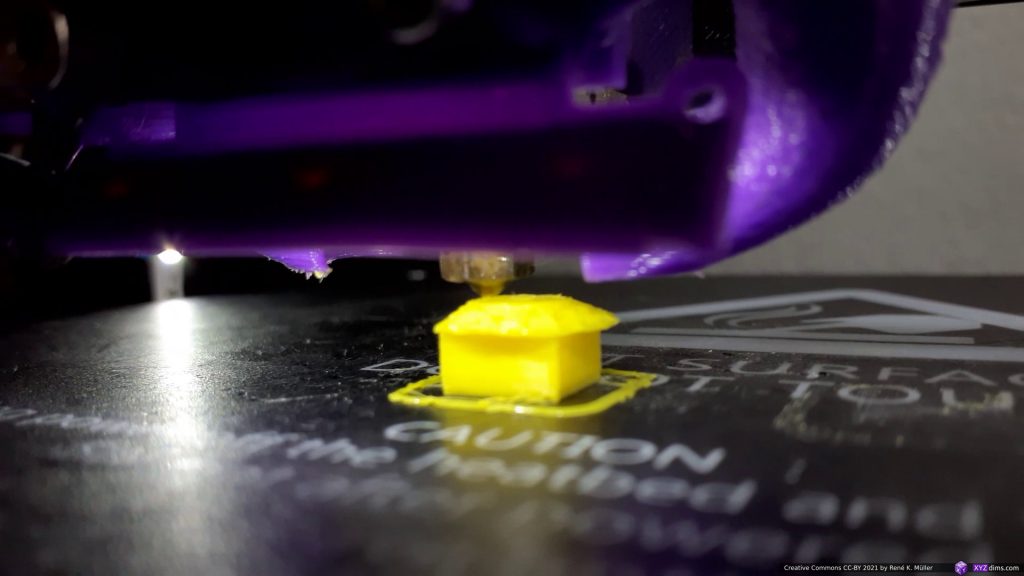

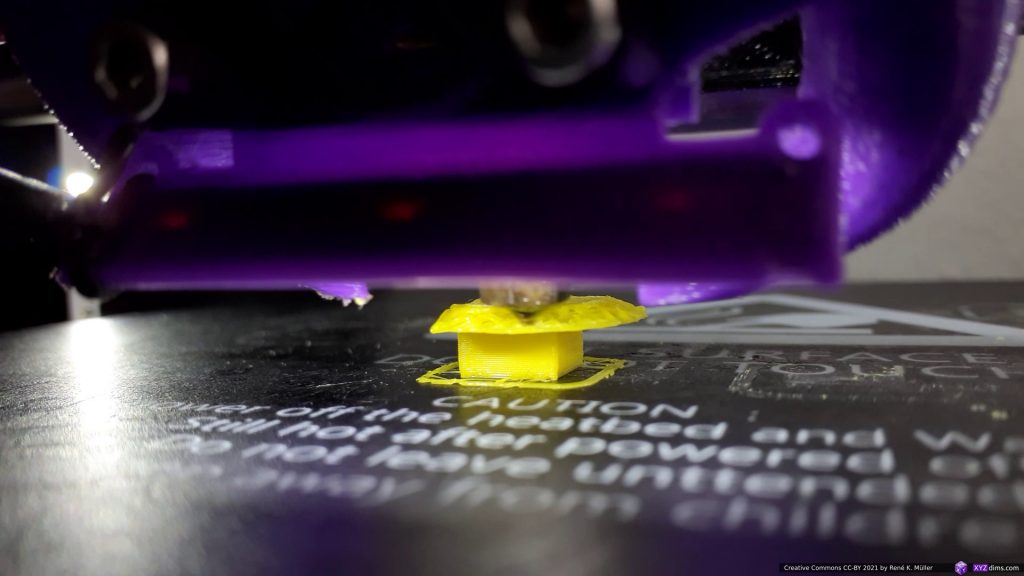

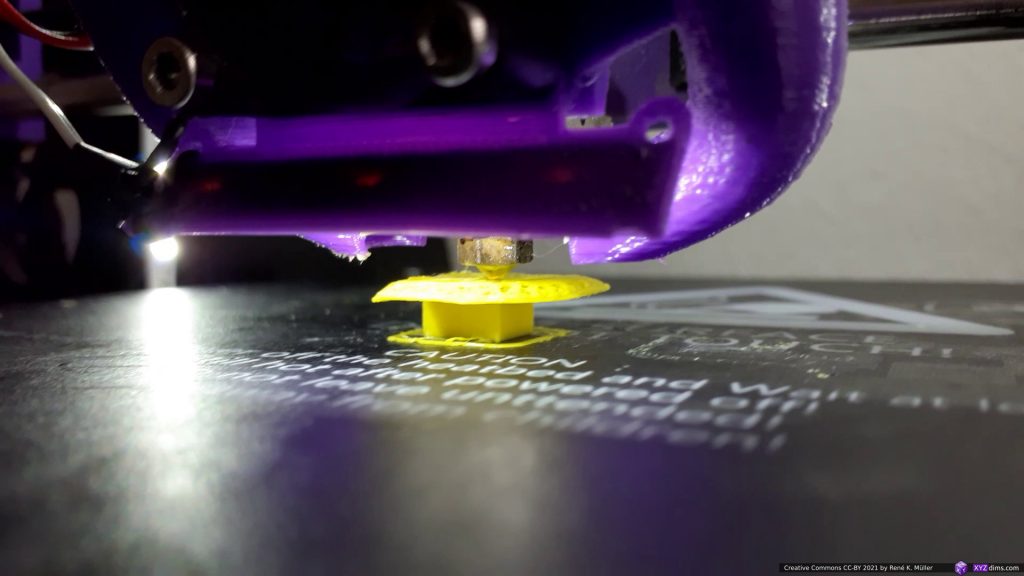

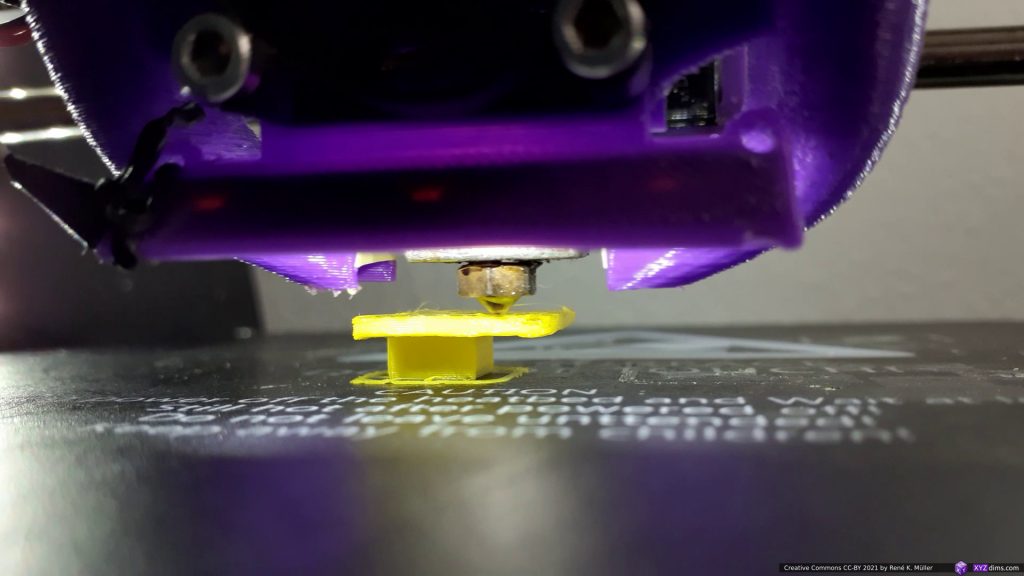

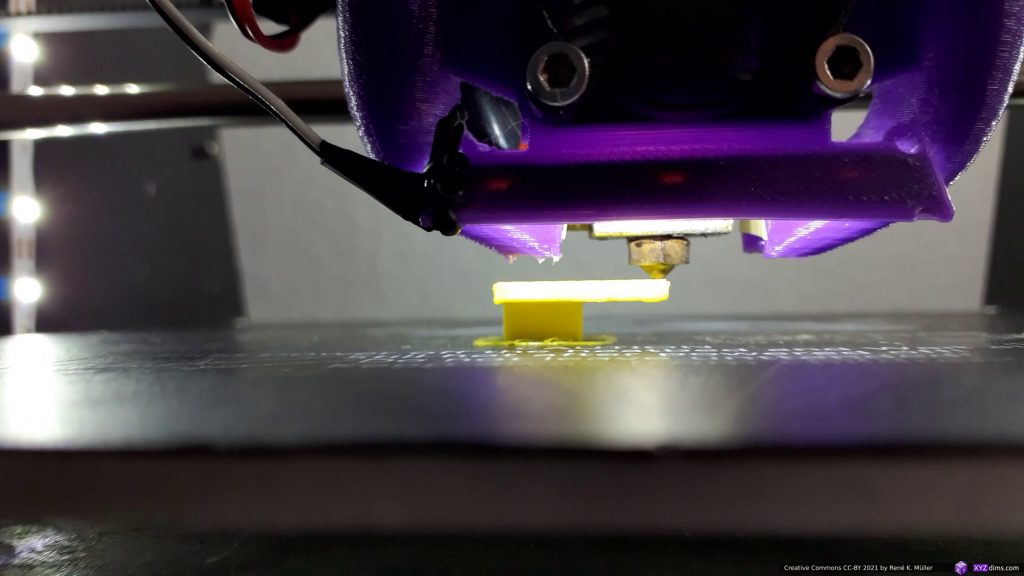

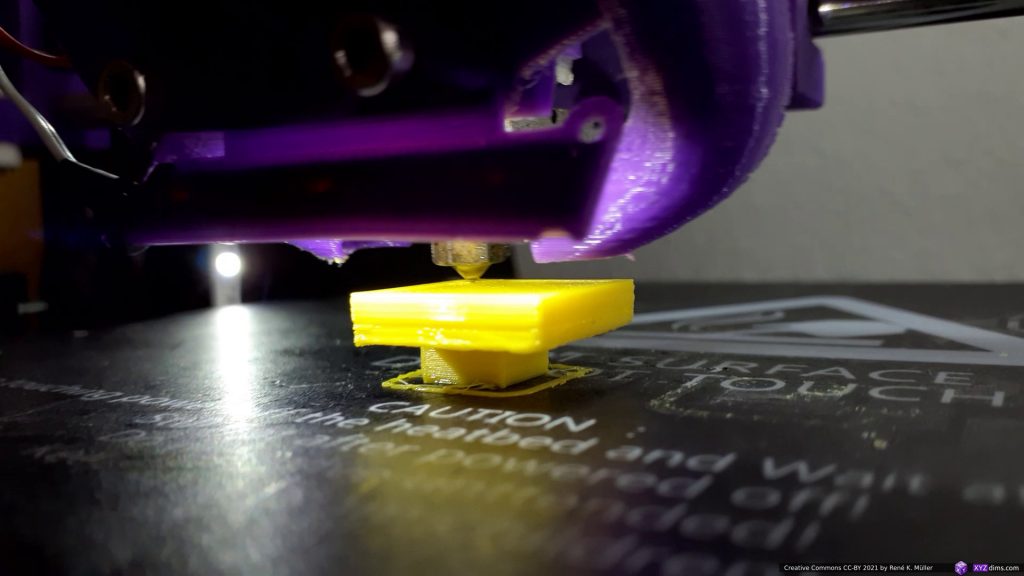

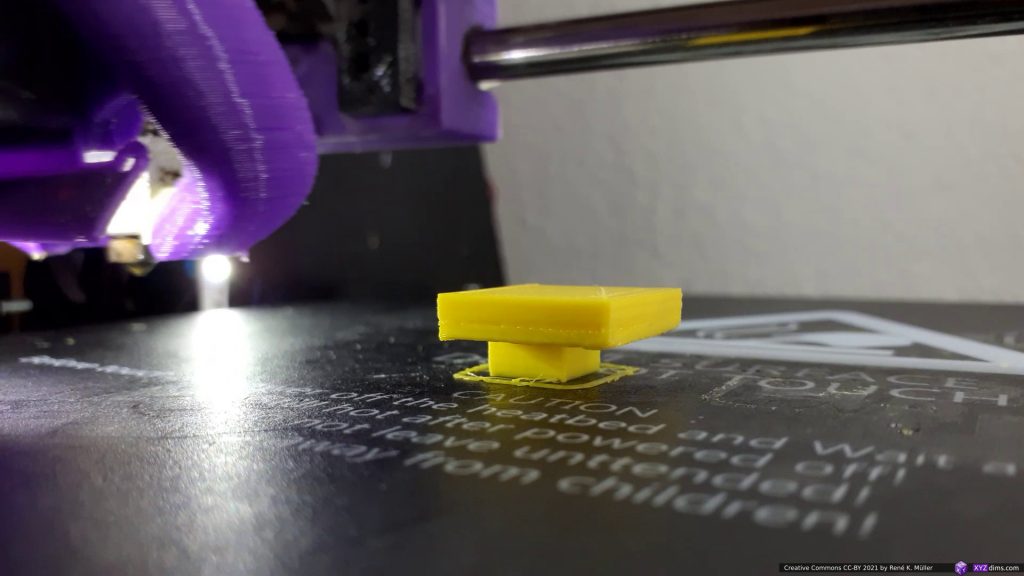

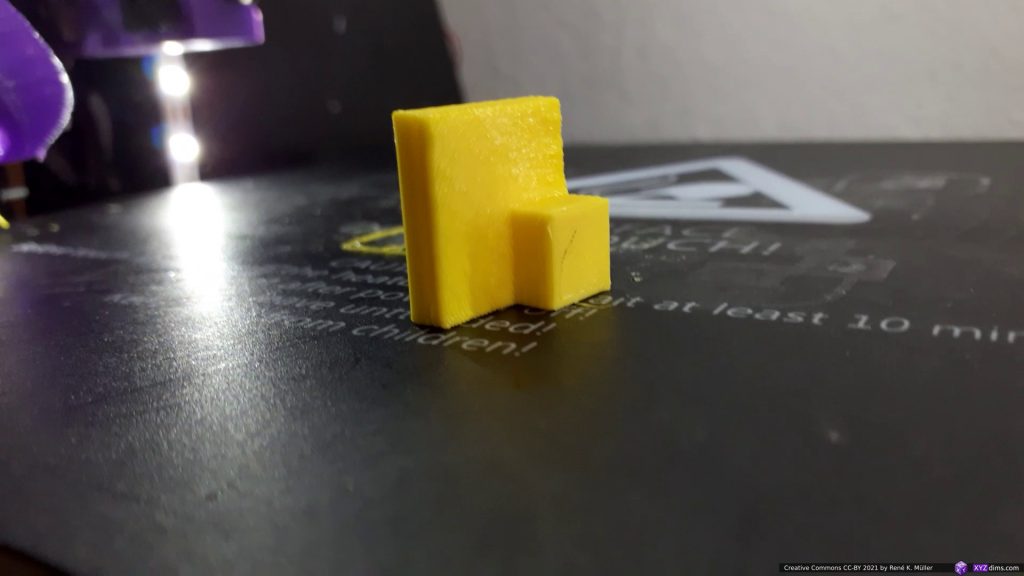

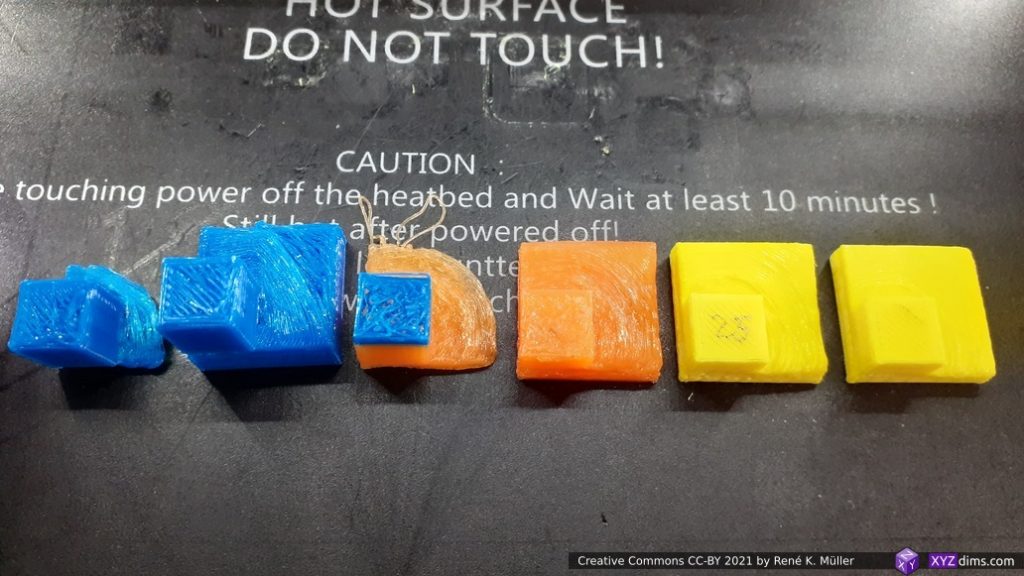

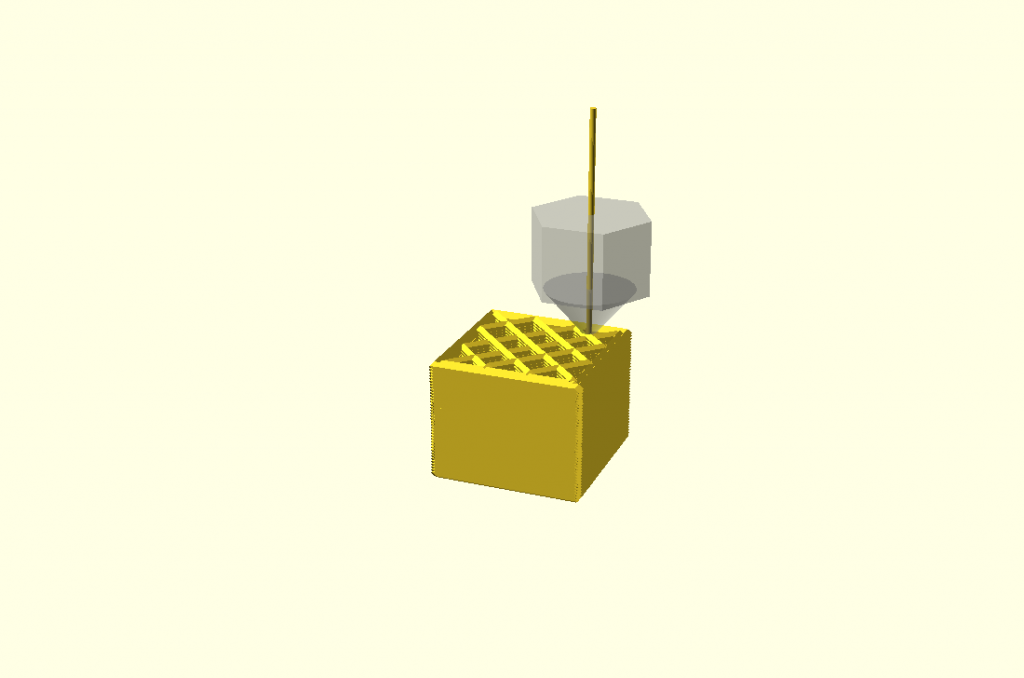

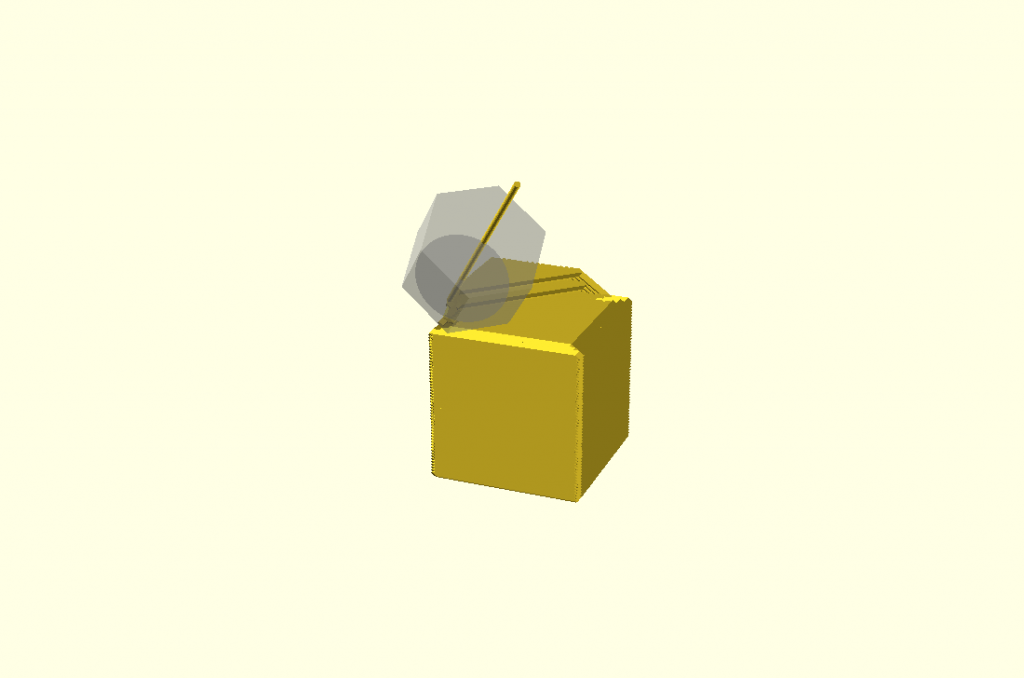

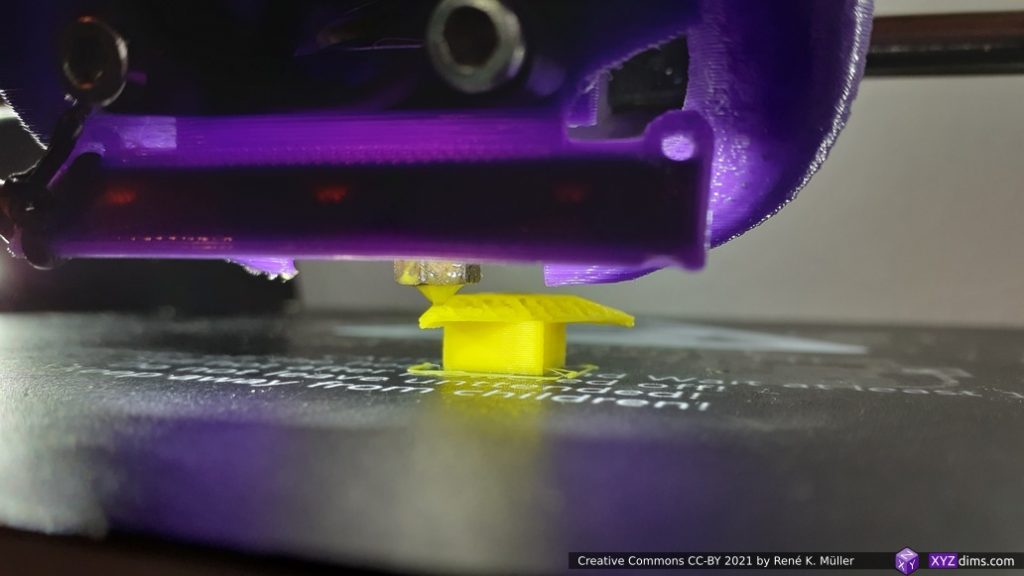

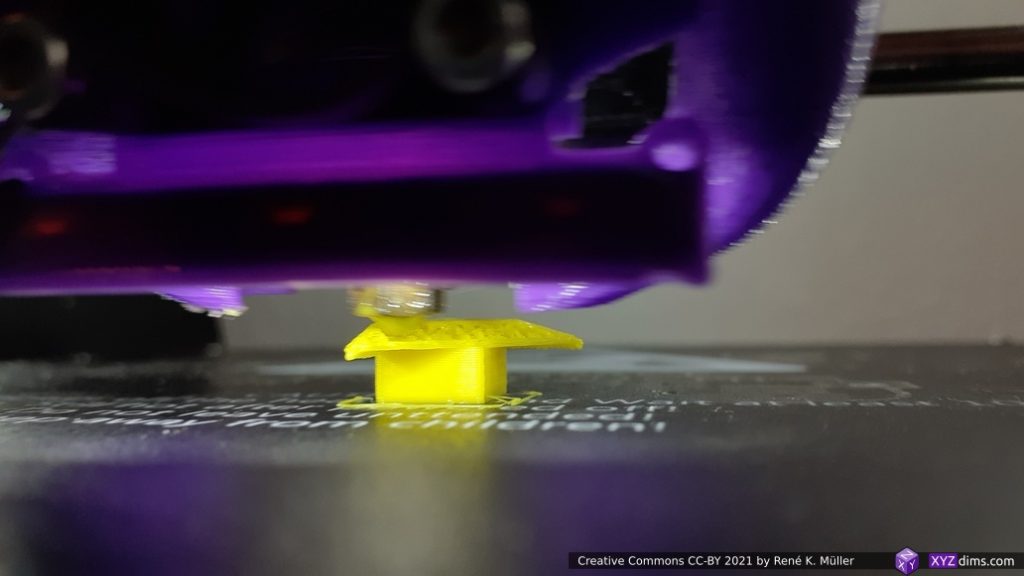

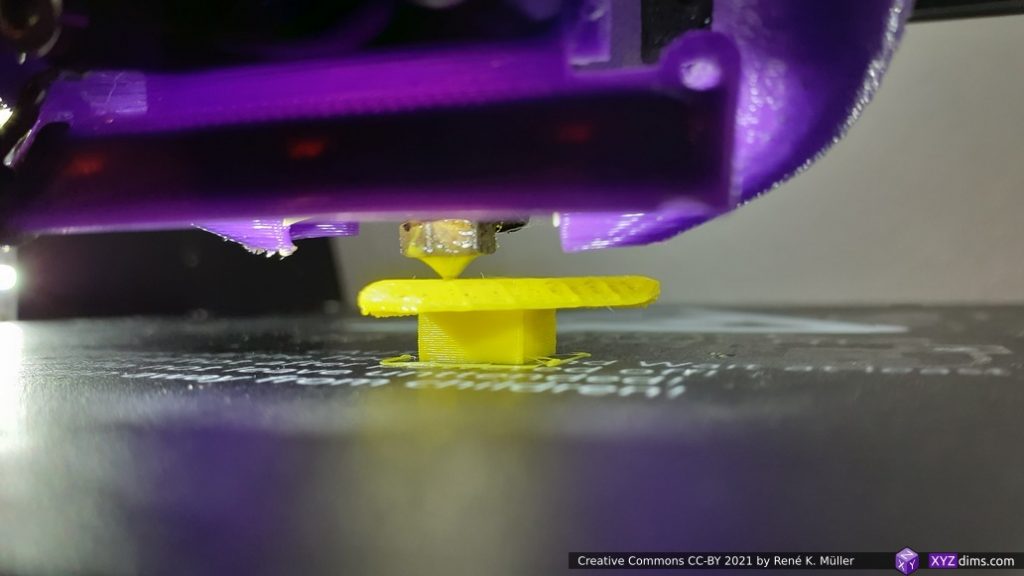

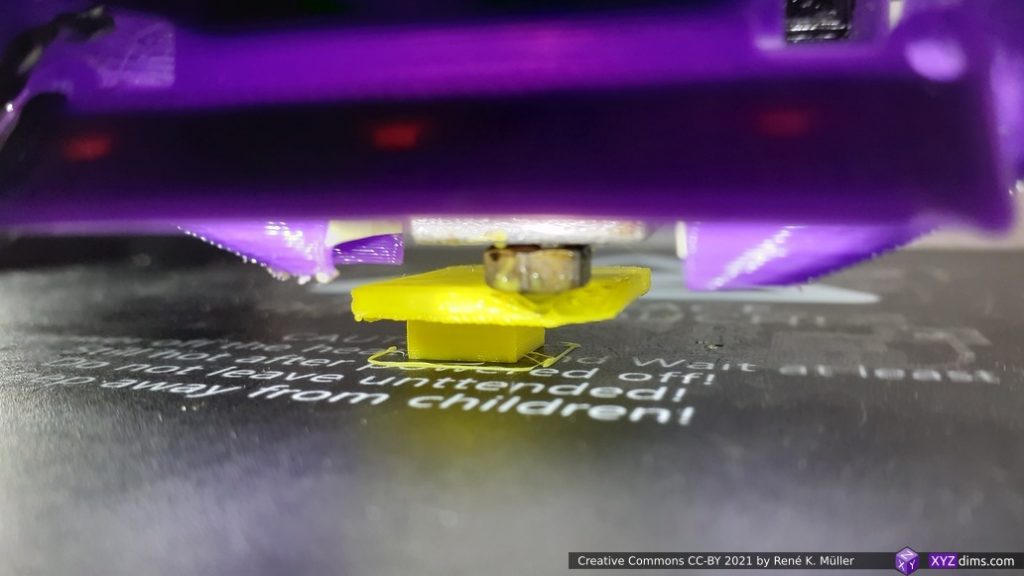

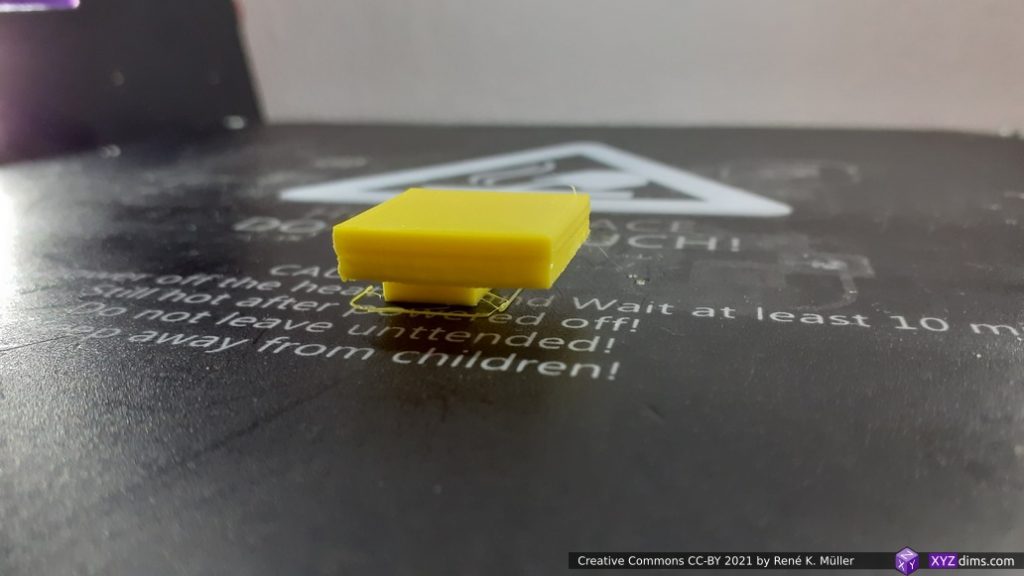

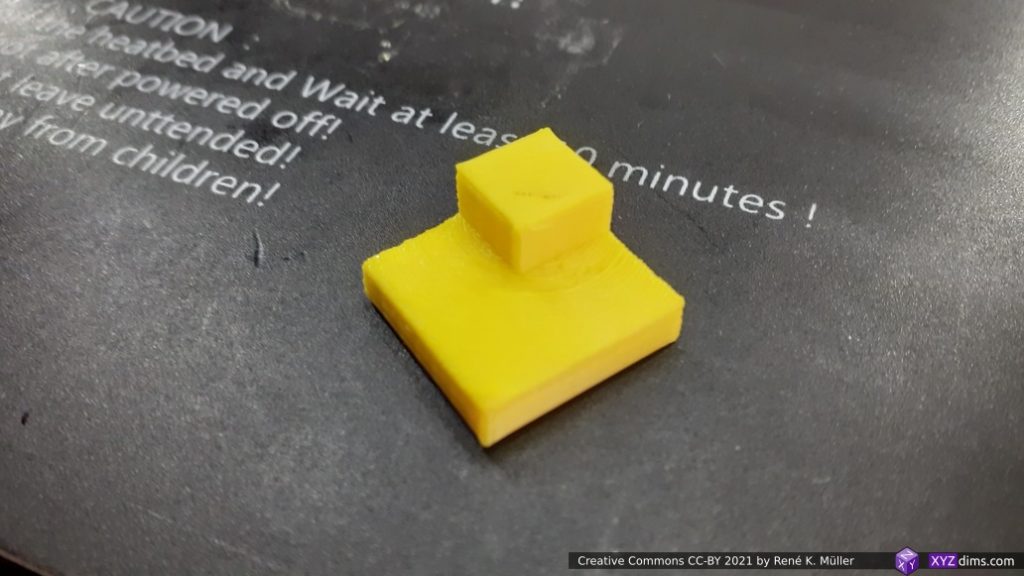

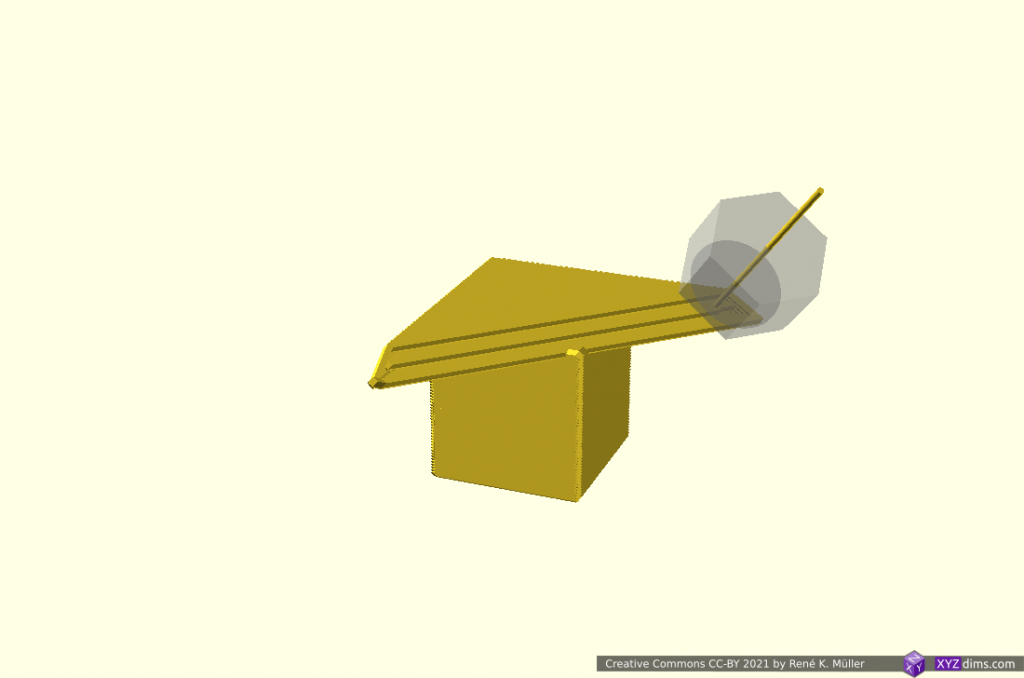

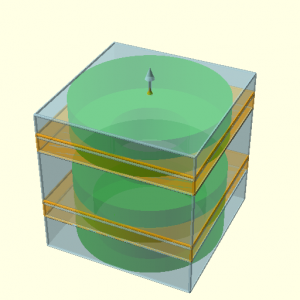

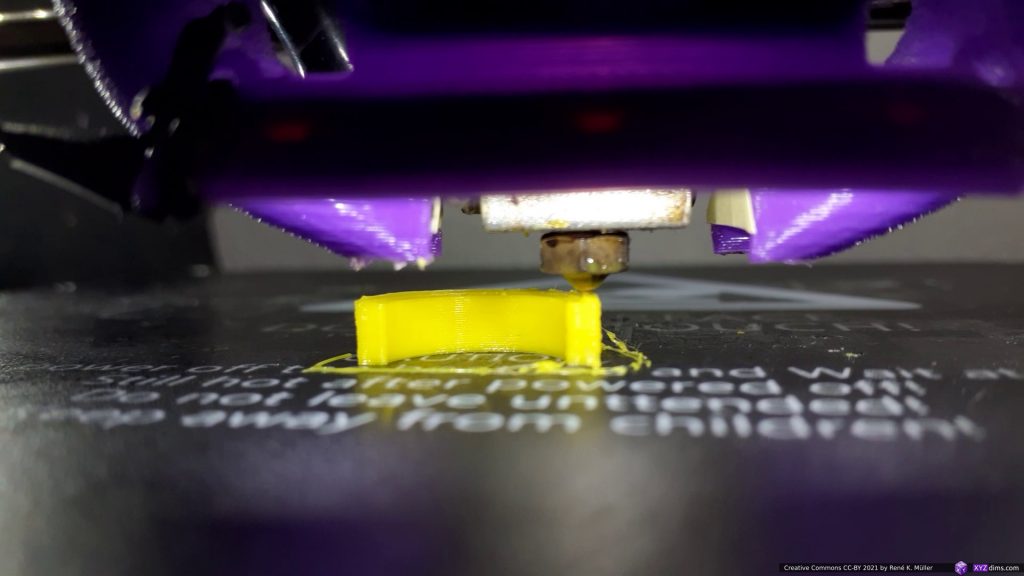

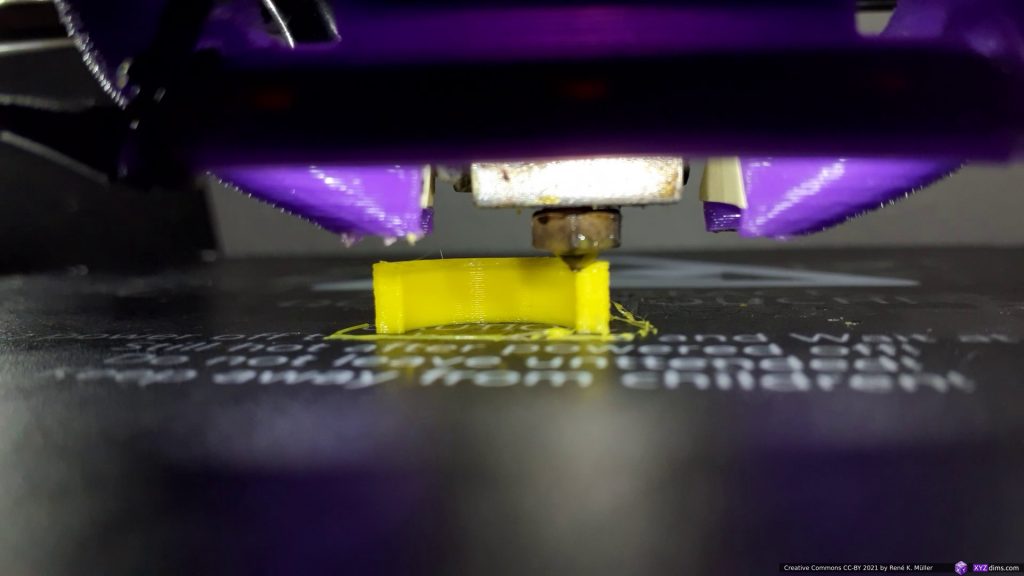

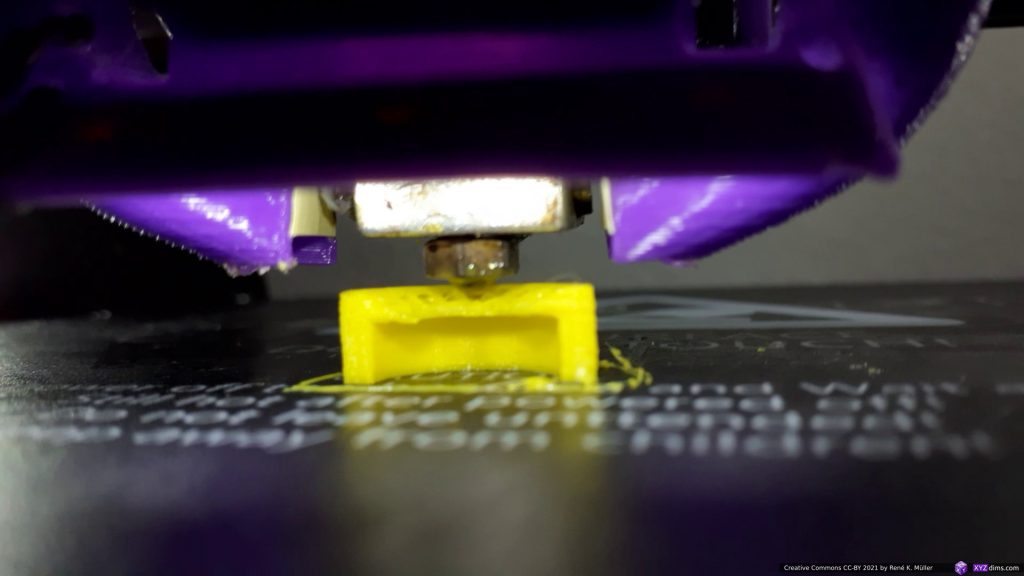

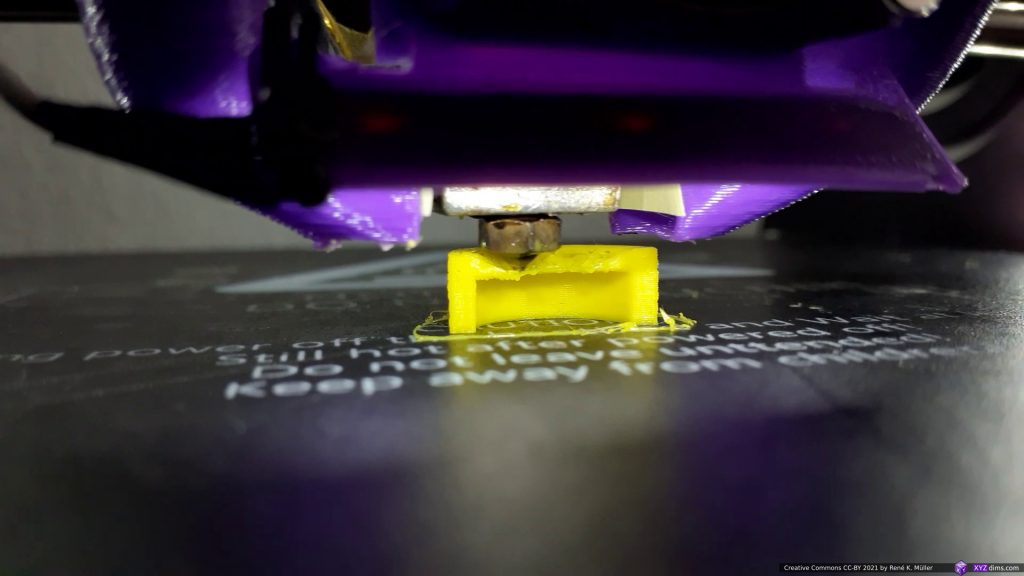

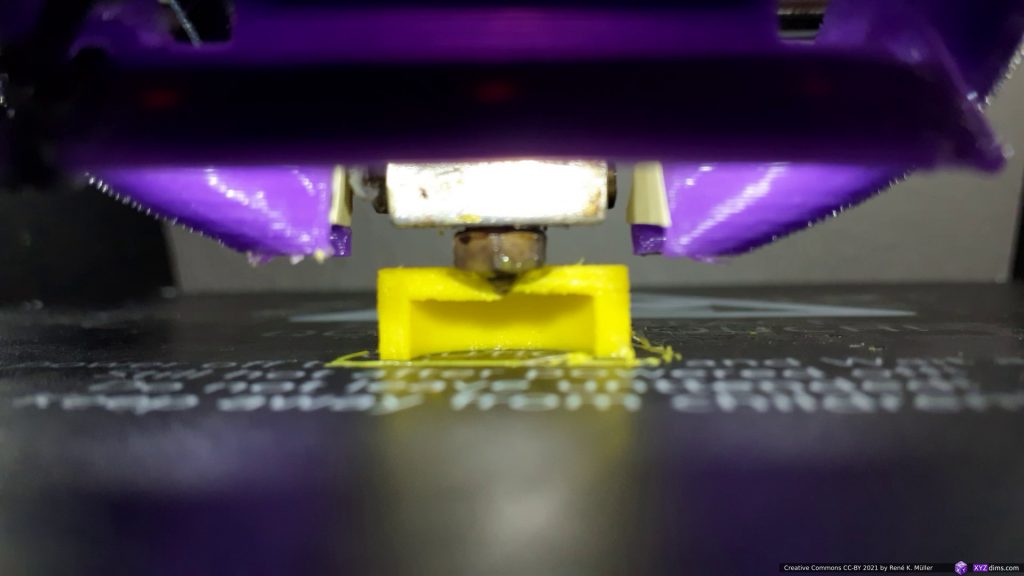

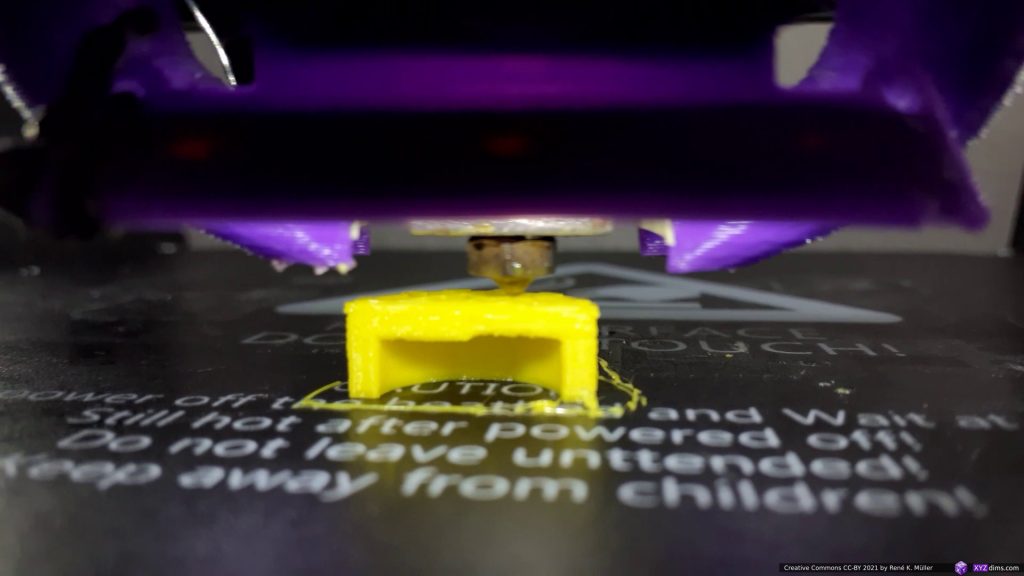

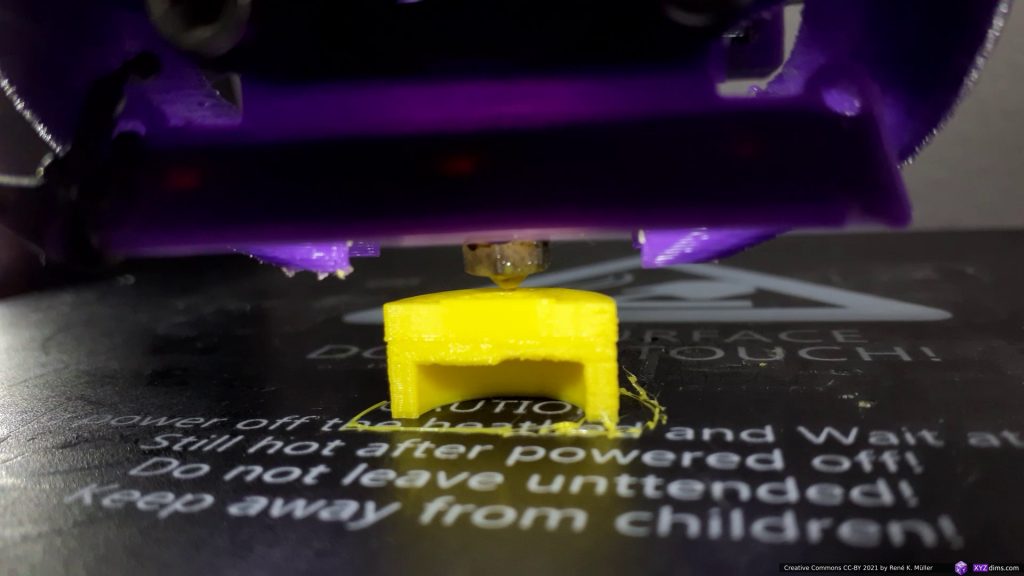

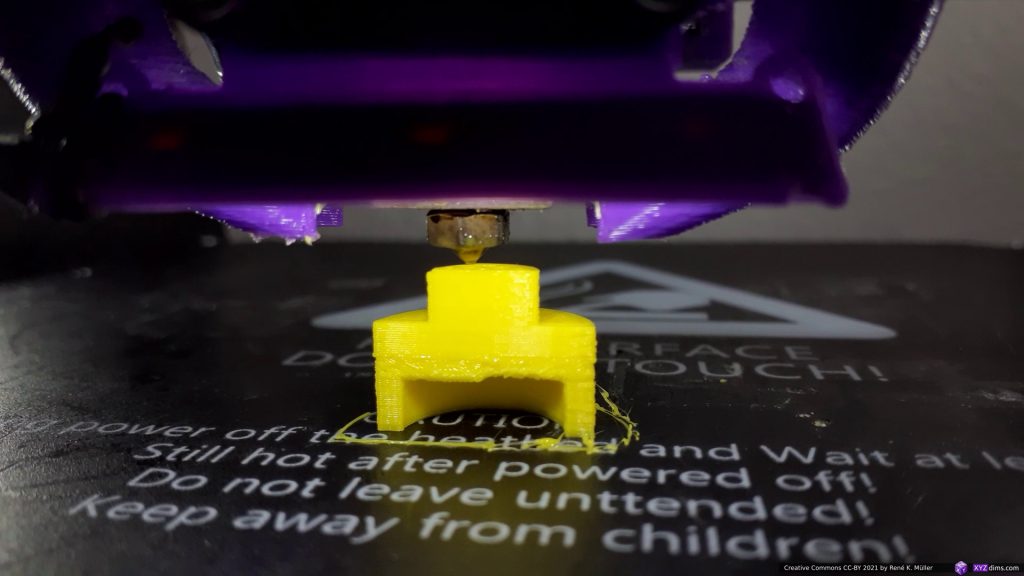

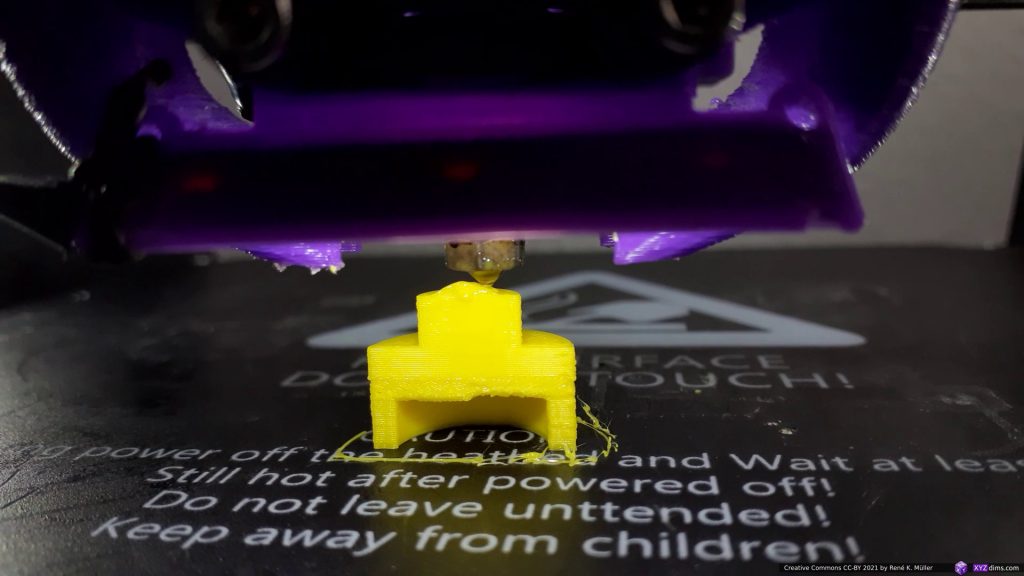

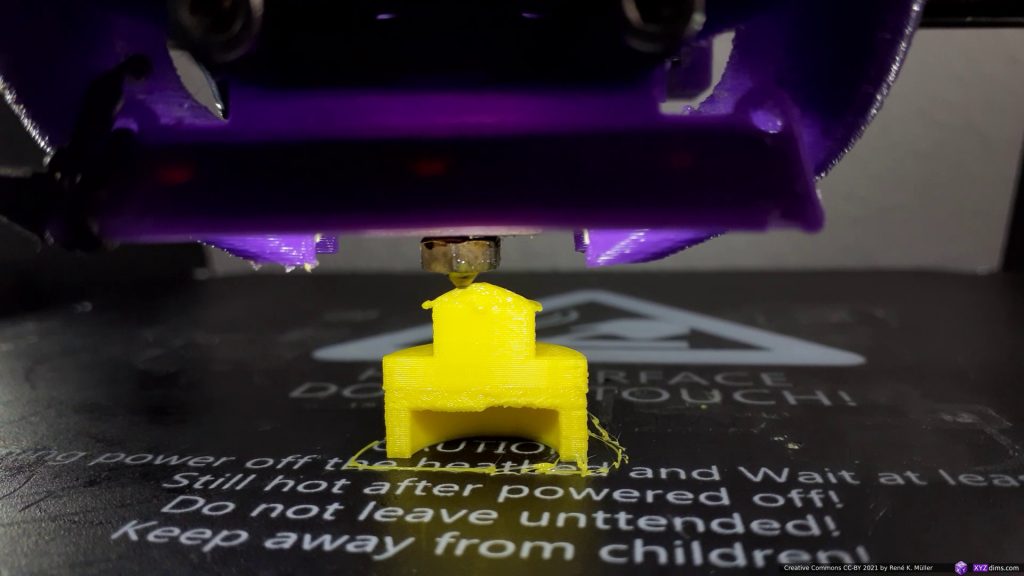

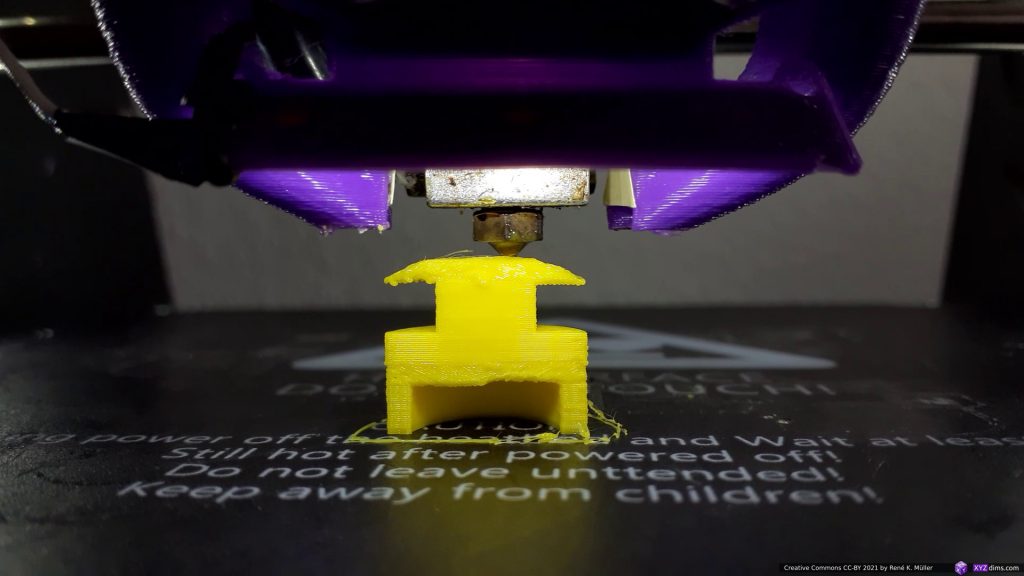

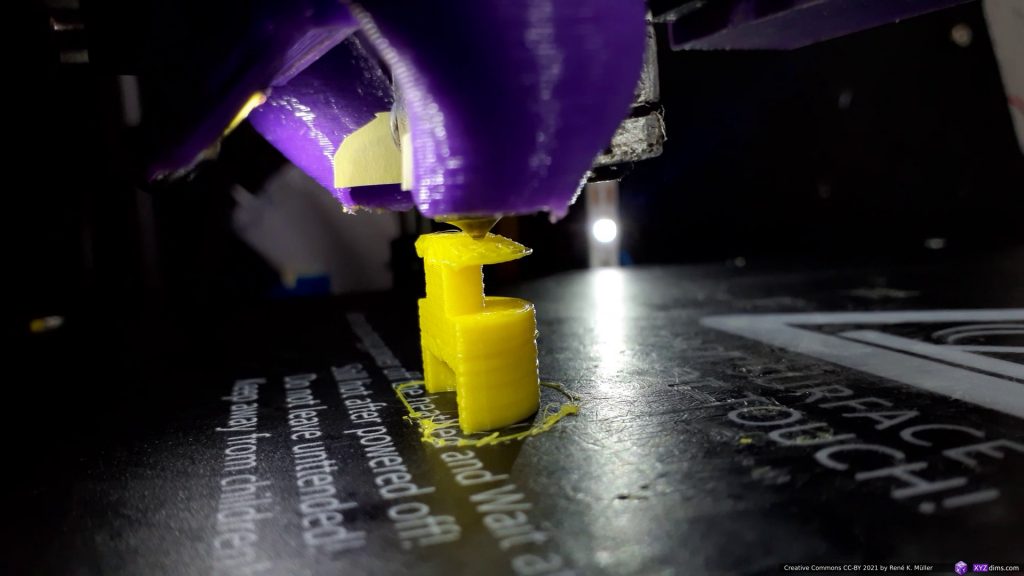

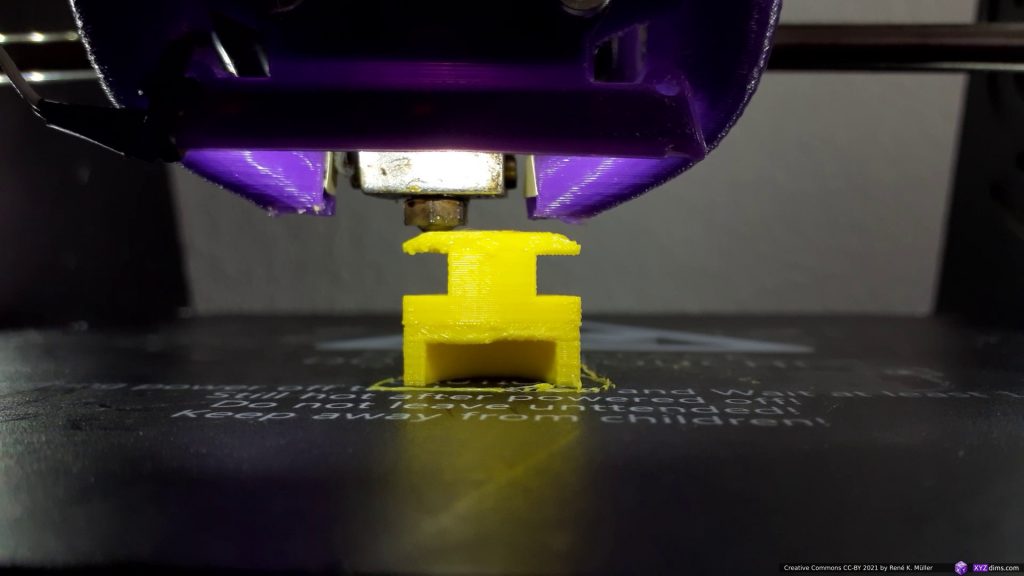

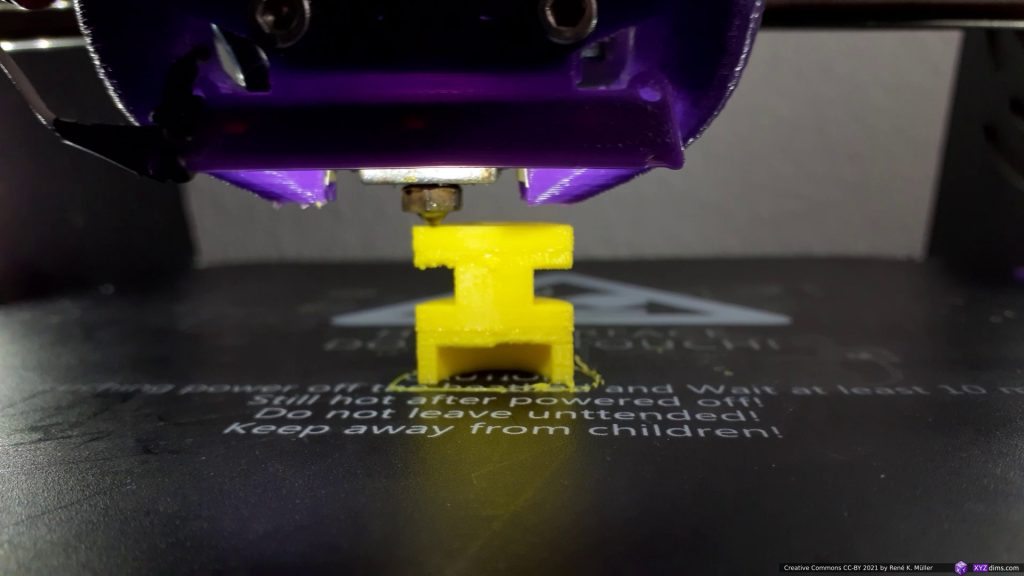

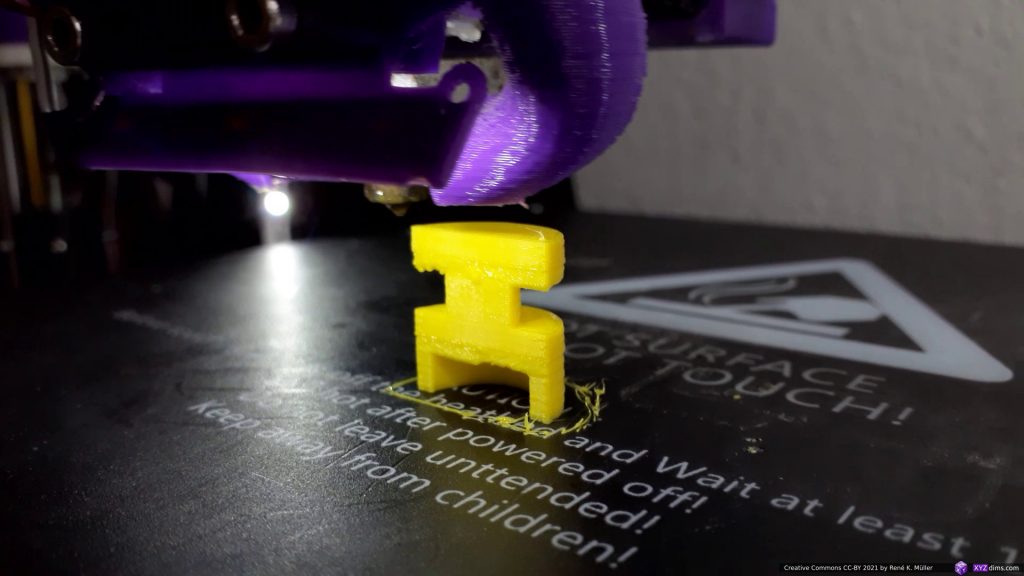

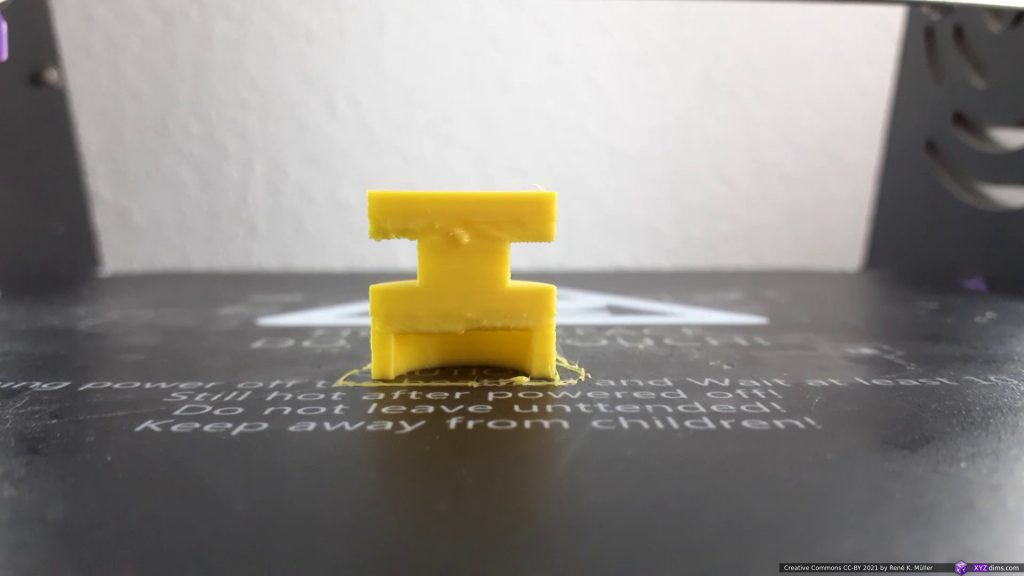

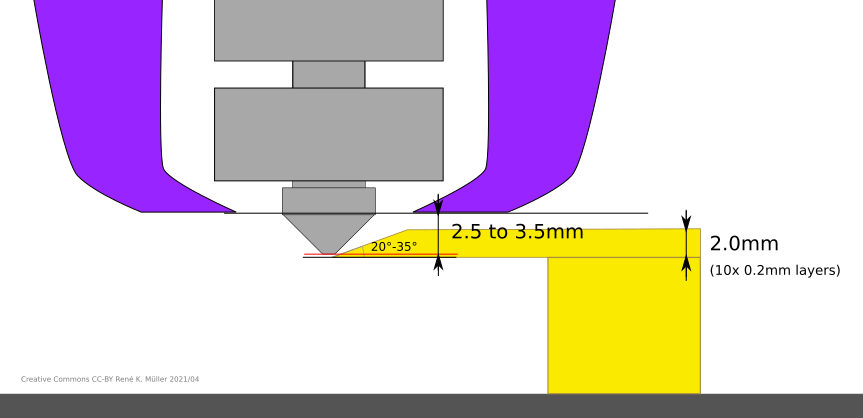

I presented my inhouse developments of ZPlusSlicer and 5DMaker for the first time in public (otherwise just illustrated in About: Big Picture), as of November 2021, it’s not yet published or otherwise documented.

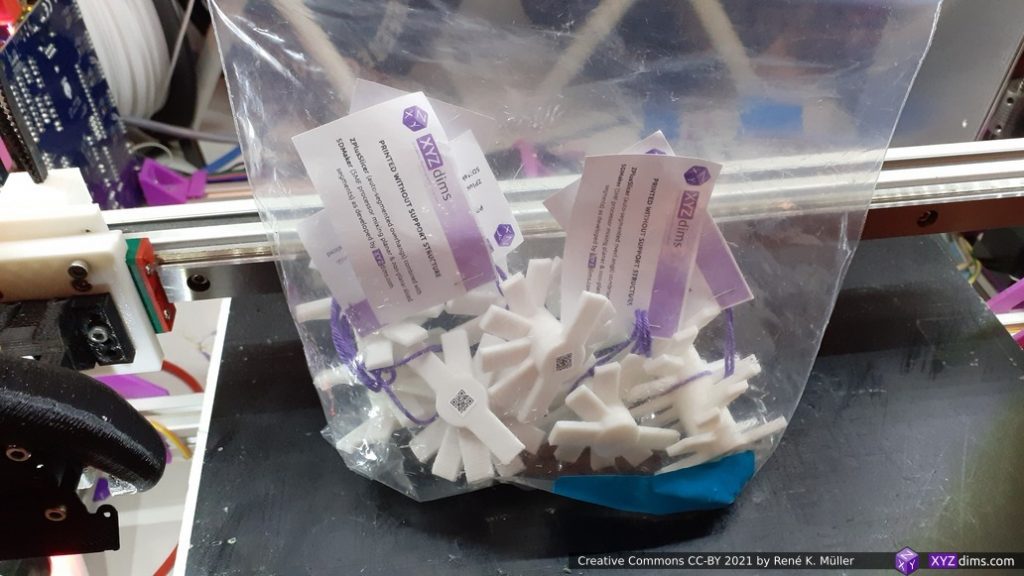

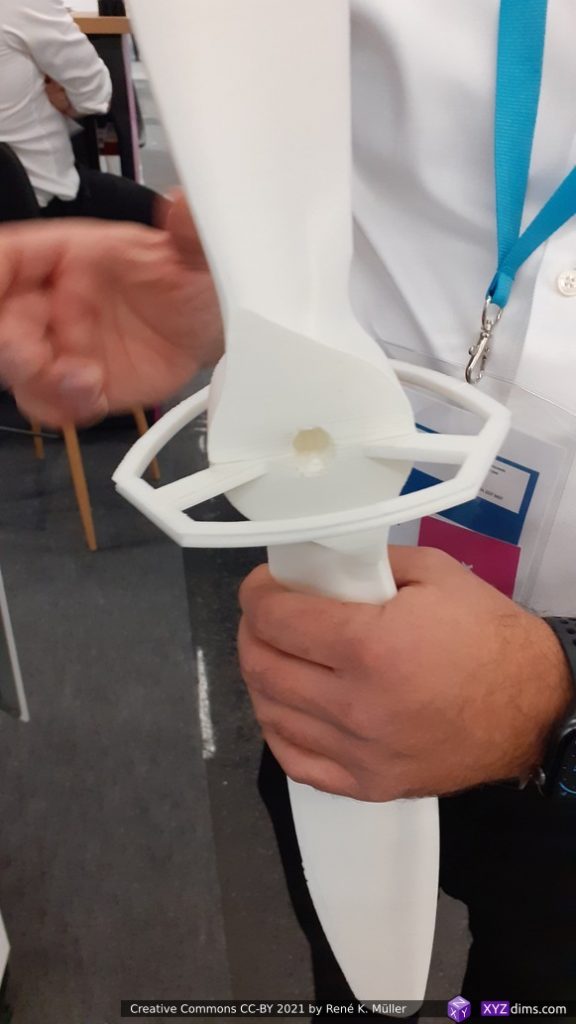

About 40+ samples I handed out and alike amount some brief documentation (on paper) on ZPlusSlicer and 5DMaker (5MF processor) – both in early stage of development, and the “overhang stairs” a proof-of-concept of the benefit of both new conceptual layers on top of traditional slicing. By spring 2022 I will publish more publicly on both products once they matured to Beta stage.

Notables

- Ultimaker: they didn’t have any booth, yet their machines were placed at many booths, resellers kind of represented them – combination of dominance and absence

- Makerbot wasn’t there

- Markforged considers itself as startup but outsiders consider them as big player already – impressive integration of machine, material and slicer, yet, all closed down; hard(er) to integrate with 3rd party software

- nScrypt micro-dispensing on cylindrical or spherical surfaces, PCB 3d printing and pick-place SMD components:

- Krause DiMaTec showed its EDDY 3D printer, slow Z axis, but quite affordable at ~8K EUR for the machine with 600 x 600 x 600mm build-volume, and the 3D metal printed hotend was quite an eye-catcher:

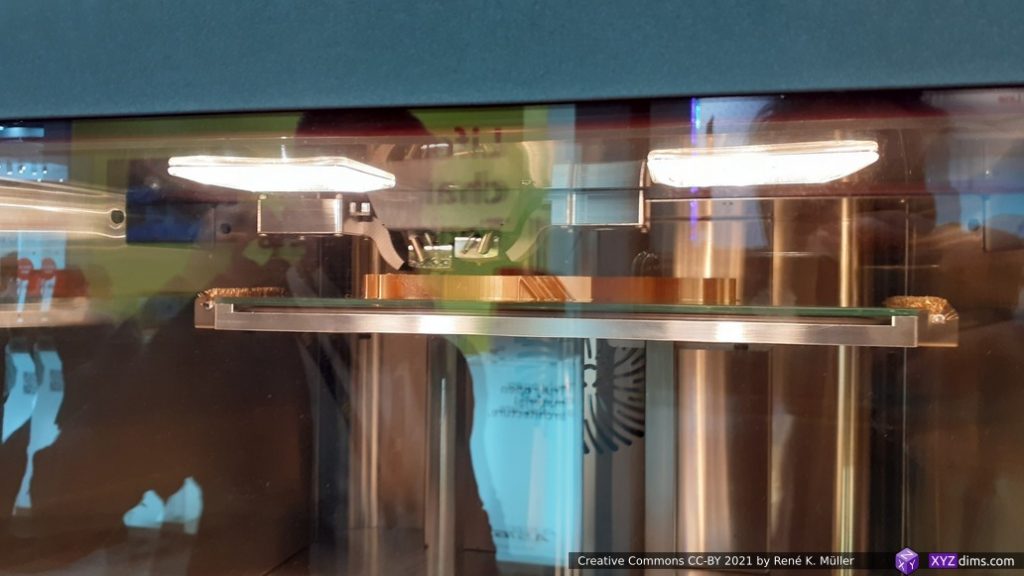

- Duplex3D printer: two nozzles starting to print on upper & lower side of the build plate, once reached some distance, the plate is removed (!!) and 3D prints continues in both Z directions (the front glass is very glaring so not many details, also the representatives didn’t want to me to take too close photos):

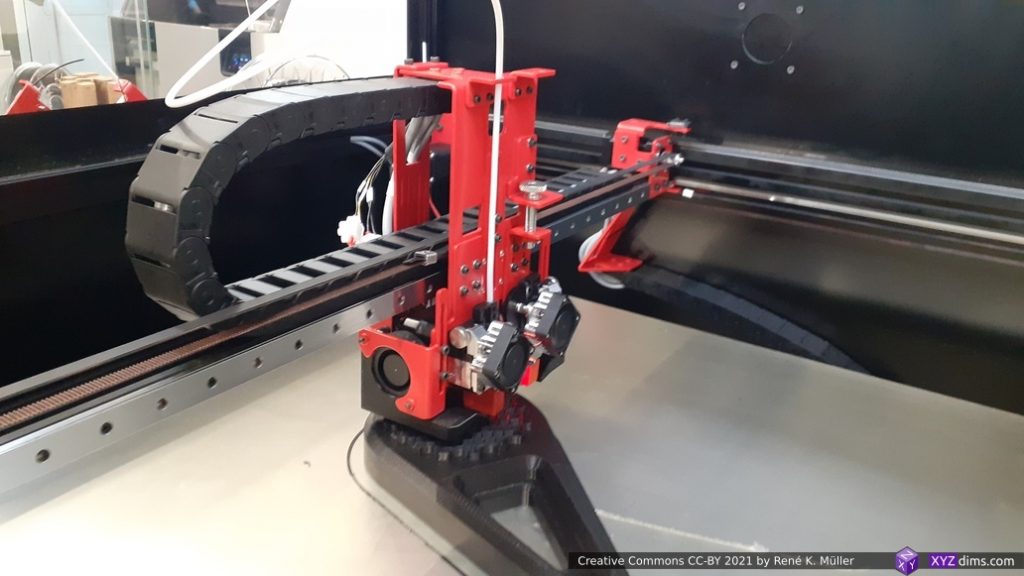

- Prusa Research released its Prusa XL – a Core XY based printer, I took a few photos with a lot of small innovations:

- 360 x 360 x 360 mm build volume

- mechanical pressure-based Z calibration built into the printhead (nozzle probes mechanical on the build plate)

- segmented heating of build plate, heat there where the part is located

- new printhead with geared filament drive motor

- optional tool changer

- optional foldable air-draft prevention

- pricing from 2.5K EUR to 3.5K EUR

- pre-order, delivery Q2/Q3 2022 (!!)

- Modix as sold by 3Dmensional:

- 600 x 600 x 600mm build-volume

- fully enclosed

- DIY kit or fully assembled

- pricing 3.5K EUR (kit) to 6K EUR (assembled)

- TreeDFilaments: 55 different materials

- Kimya: materials too, great (paper) catalogue with detailed information on how to print their filaments and use-cases

Formnext 2021 Impressions

Sintratec

BCN3D

Desktartes

Craftbot Machines & Slicer

Print&Go

Print&Go GUI

Intamsys & Evonik

AIM3D

Metrotom 3D Printer

3DGence Element

Prusa Research

Prusa Research

3D printed Groot

Prusa Research

AMT

Massivit 3D: curing 3d printed gel

Massivit 3D: multiple cams

Polymaker

Polymaker colors

More Polymaker colors

6 Axis FDM

Massive print

Formnext 2021

Raise3D

Raise3D IdeaMaker

Zotrax

Harz Labs

miniFactory

miniFactory

TreeDFilaments: 55 Materials

Total Z

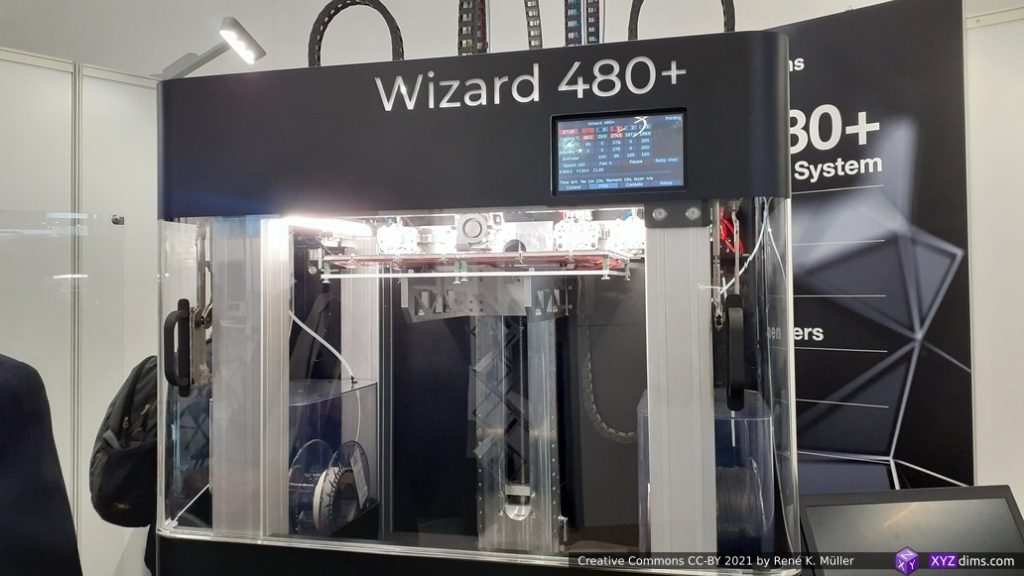

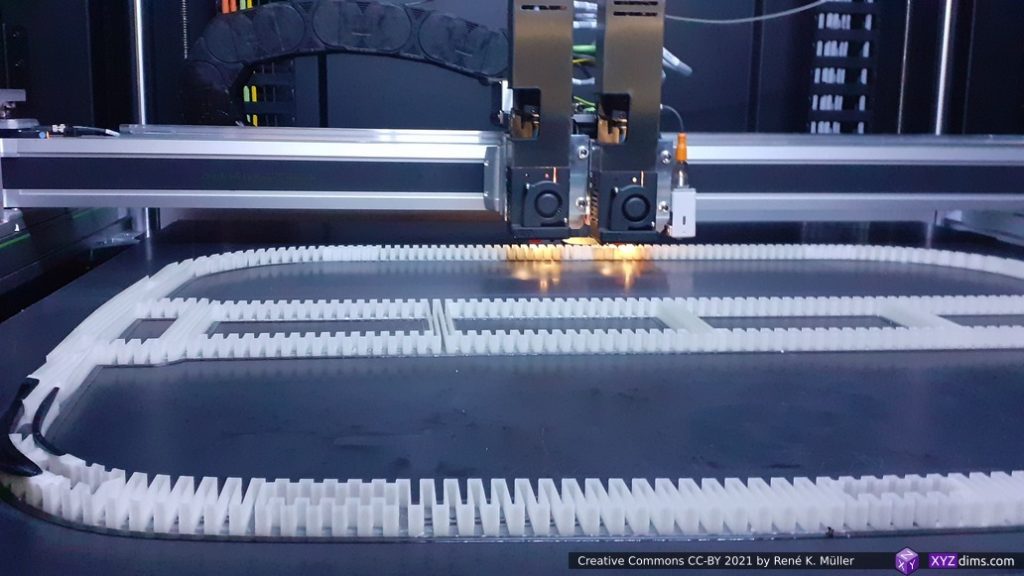

APS tech solutions & Wizard 480+

Wizard 480+ samples

Wizard 480+

Dyze Design

Dyze Design: Typhoon Hotend

Bigrep

Bigrep Pro

Bigrep Pro

Stratasys

Formlabs

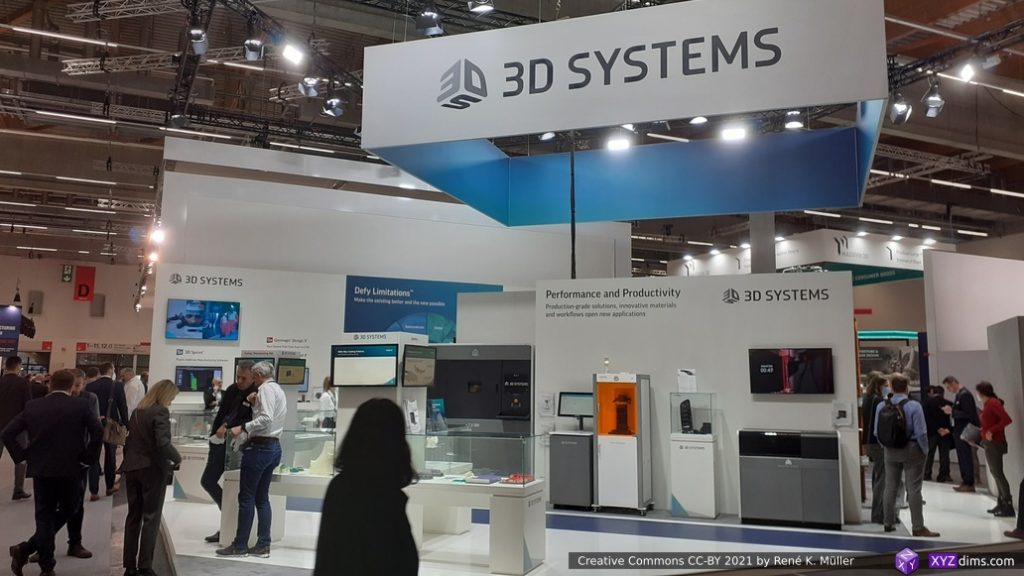

3D Systems

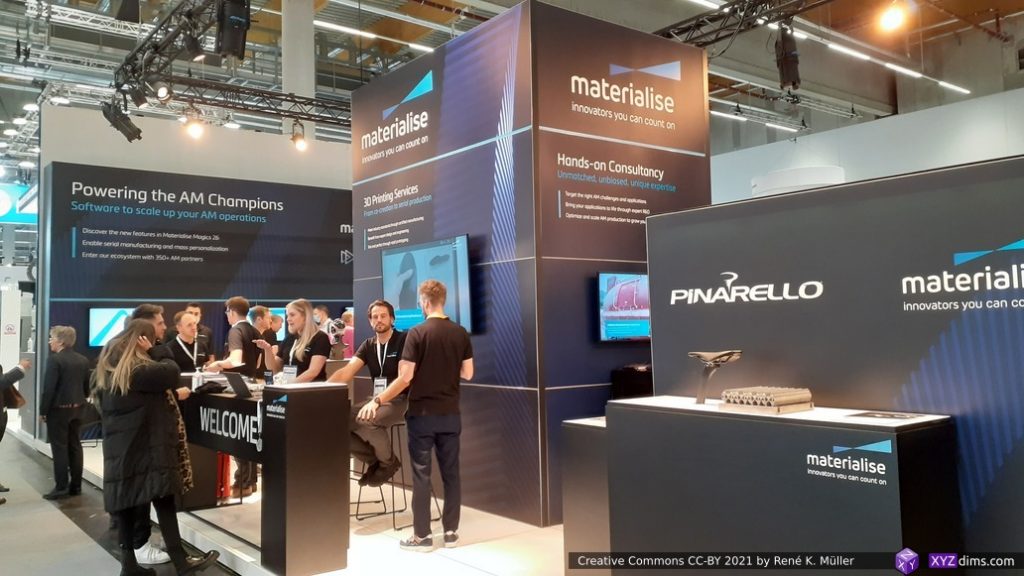

Materialise

IGO3D

AIM3D: Post processing

AIM3D: post processing

WASP

Polymaker materials

3Dmensionals

Modix DIY kit

Modix DIY kit

Additive Laser Technology / alt-print.com

Novum & VTT

Lunovu

Fraunhofer

Nexa3D

Markforged

Markforged: Continuous Carbon and Glass Fiber

Markforged: Continuous Carbon Fiber

Autodesk

AM Solutions

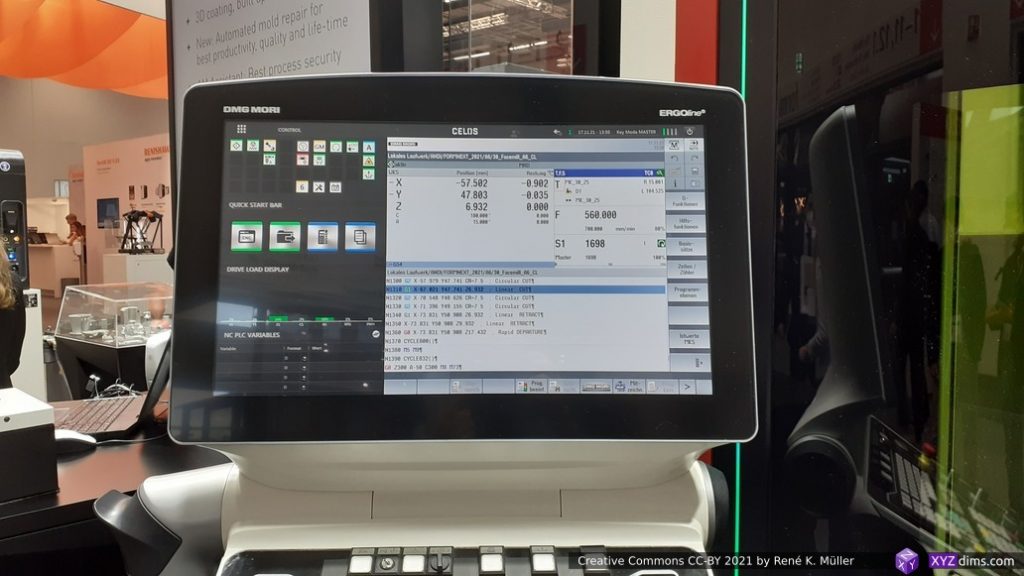

DMG Mori

AMG Mori: Lasertec 65 3D Hybrid

DMG Mori: Lasertec 65 GUI

DMG Mori Lasertec 65 swappable tools

Renishaw

DNAam

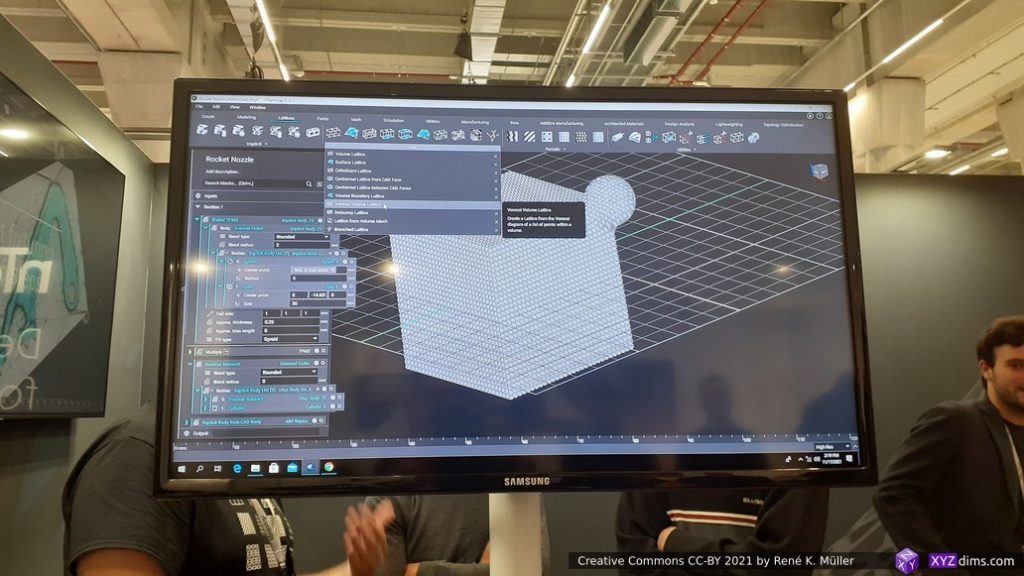

nTopology

nToplogy GUI

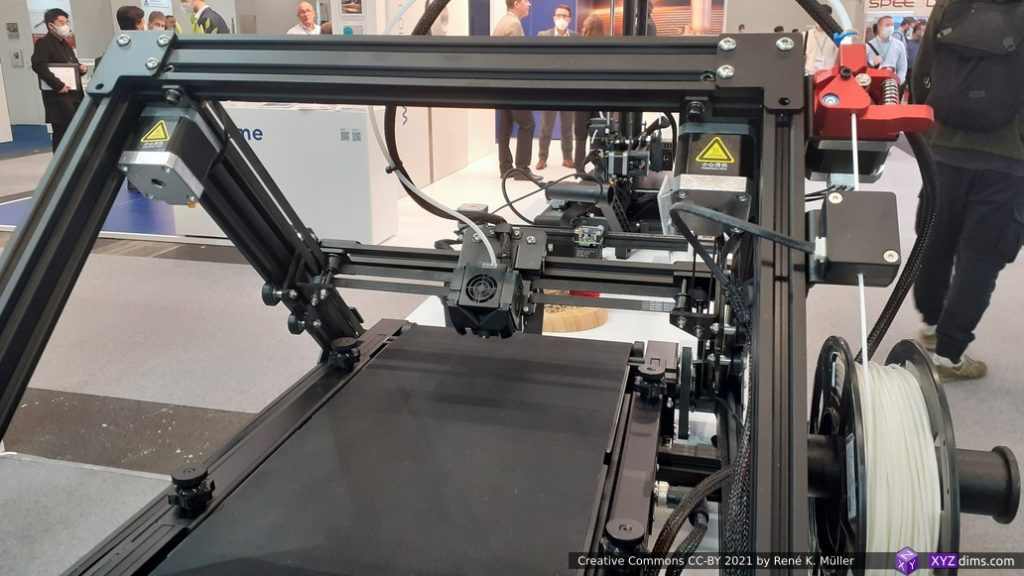

Creality

Creality CR30

Creality CR30

Creality

Creality

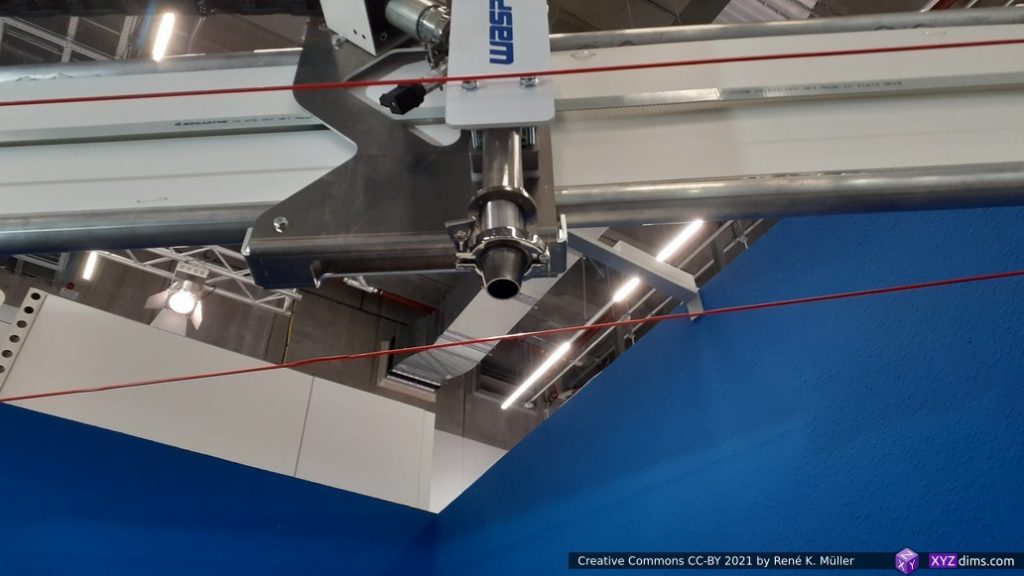

WASP

WASP: huge nozzle

WASP: huge nozzle

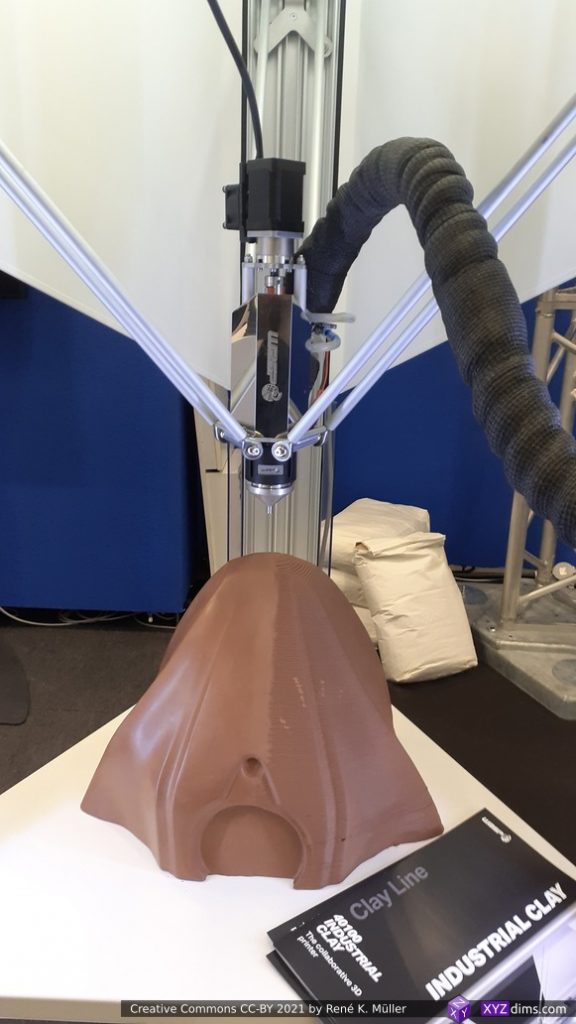

WASP: printing clay

WASP: printing clay

AZUL

Renishaw: delta-based multi-head calibrator

Renishaw: delta-based multi-head calibrator

Aon3D

Aon3D printhead

Aon3D

Aon3D

Aon3D print with support

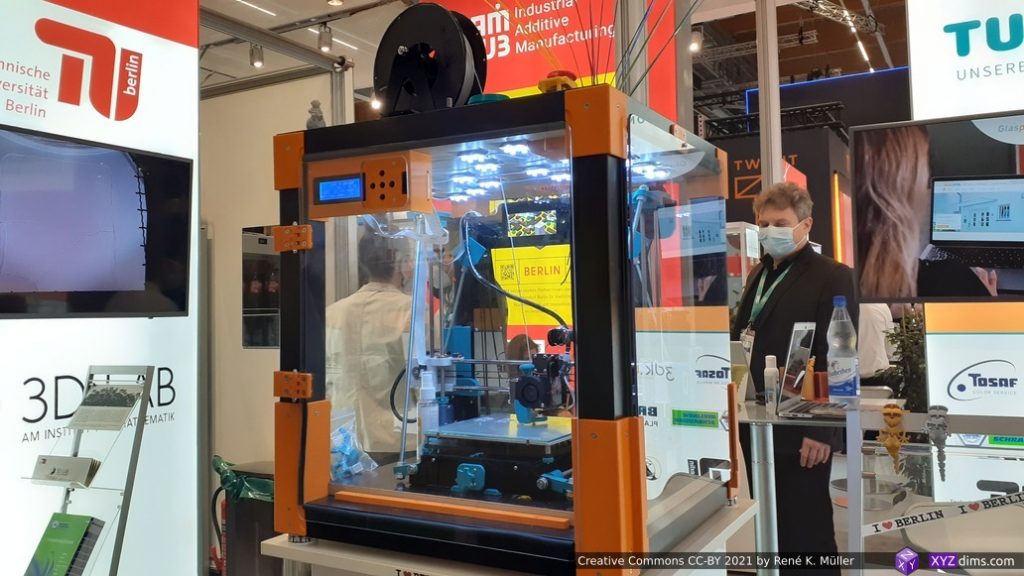

TU Berlin: Prusa Mendel enclosed, certified for schools

TU Berlin: Prusa Mendel enclosed, certified for schools, ventilation

Prusa Resarch: robot dog (remote controlled)

Arburg Freeformer 300-3X

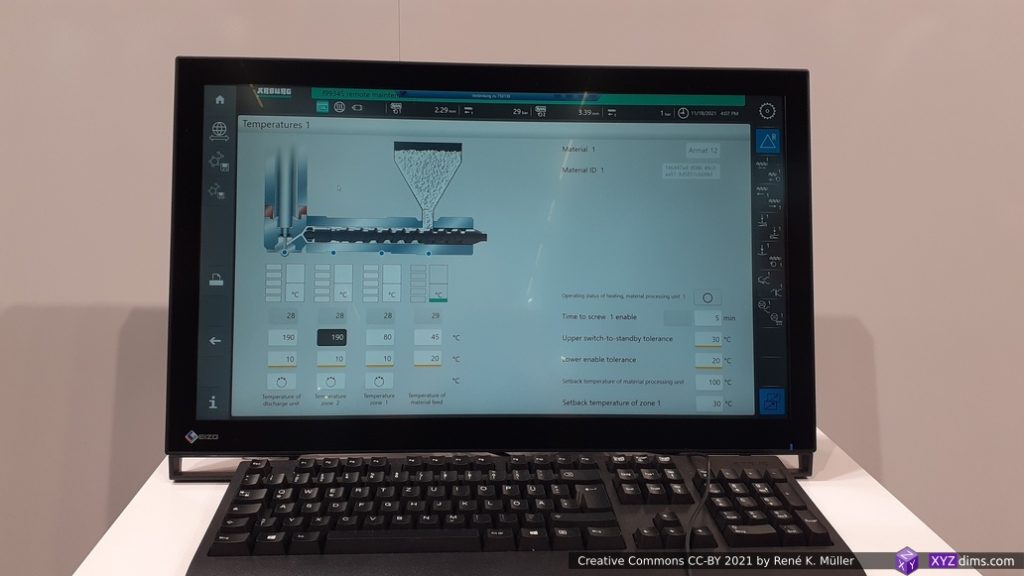

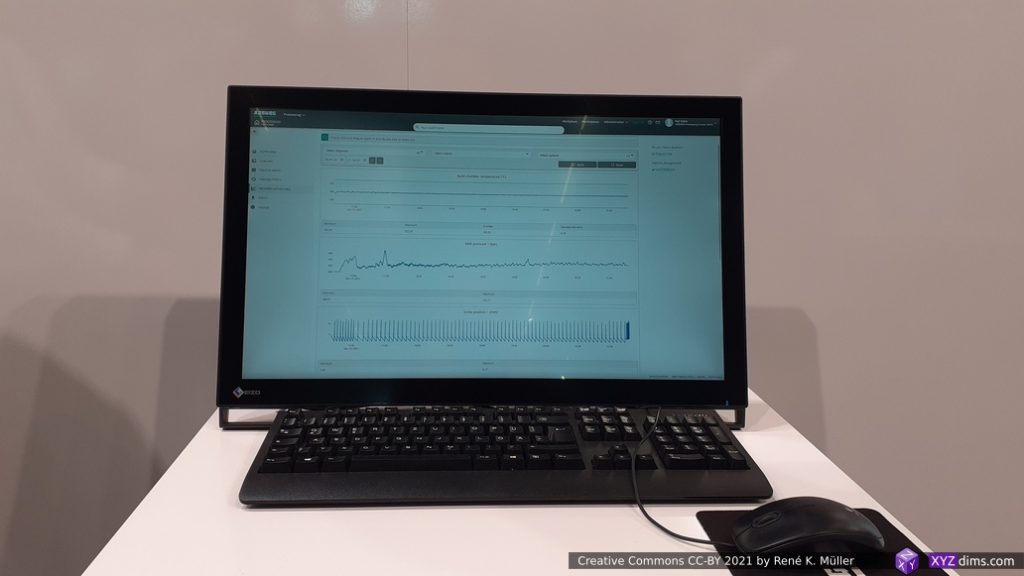

Arburg Freeformer GUI

Arburg Freeformer GUI

No STL

Craftbot

BCN3D

Yizumi / SpaceA

Yizumi

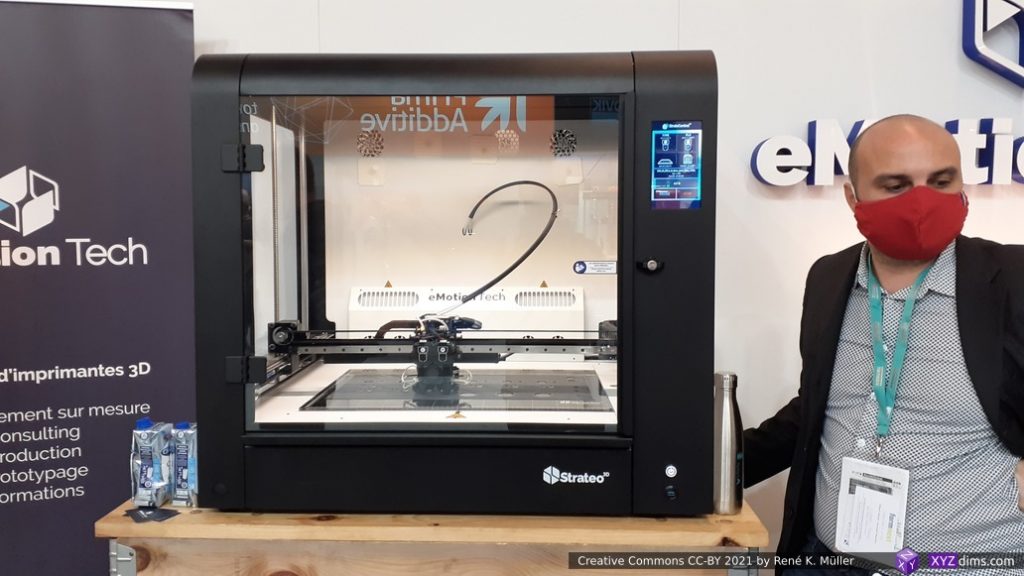

eMotion Tech: Strateo

Chromatic: liquid deposition

Zaxe

Pollen: delta printers

Pollen: delta printer, moving bed, steady nozzle

3D printed concrete

3D printed concrete

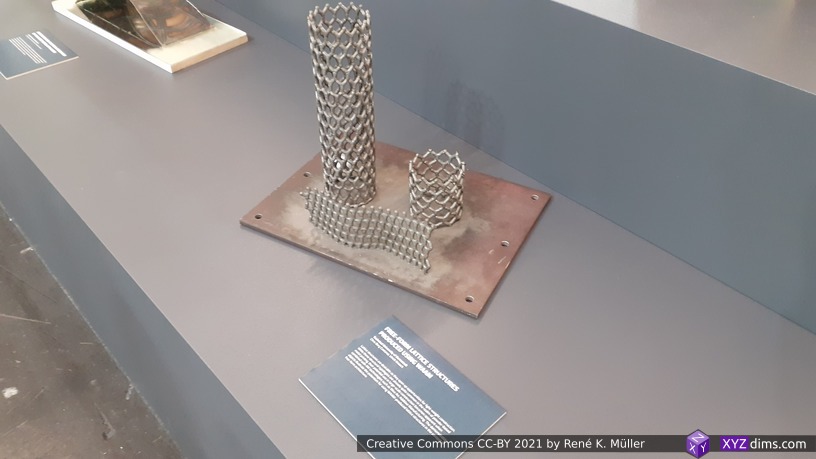

3D printed metal

3D printed concrete

BASF materials

BASF materials

iFactory3D: belt printers made in Germany (photo by iFactory3D)

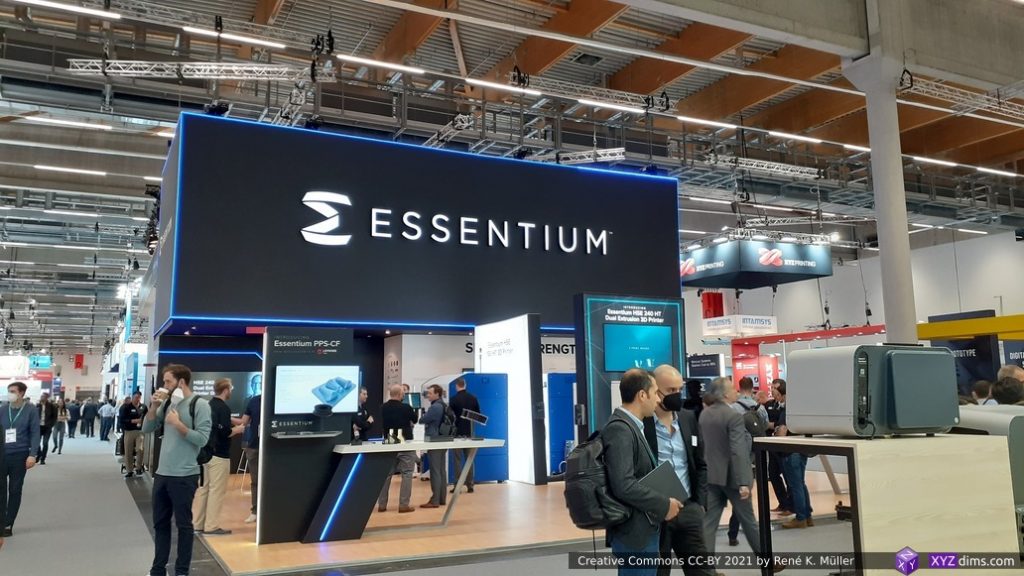

Essentium

Essentium HSE 240 HT

Essentium HSE 240 HT GUI

People vs Companies

Although all the companies appear quite anonymous, if you spend more than just a few minutes, and are able to talk to some technical skilled people – aside of the sales representative – you will notice “normal” people with the same passion like you and me: 3D printing enthusiasts, who turned their hobby into a professional passion, either as a startup or joining a bigger company to explore 3D printing further.

The most worthwhile and interesting interactions were the ones I had with little business aim but technical exchange on new slicing methods and algorithms, new G-code extensions or pre-/post-processing, and new hardware designs in particular 4-axis approaches by different individuals and companies based on my slicing software and hardware designs they found via my YouTube videos – which was quite a revelation for me.

Covid & Expo

As of November 2021, Covid-19 isn’t over but I was glad to explore Formnext 2021 in person, a “2G event”, means, either one had to be vaccinated or recovered from Covid. The first days most people worn masks, by each day less and less – me included, as it was hard to talk with the mask on and hear each other properly even standing close to each other due the overall noise level in the halls.

Mood

Certainly the overall mood was great among the exhibitors and visitors as well – professional interest, respectful cordial interactions – less noisy than in 2019 which was more hectic due more visitors overall. Tuesday (1st day) and Friday (last day) had less visitors, whereas Wednesday and Thursday was quite overwhelming and significant more visitors.

At last, some impressions of Frankfurt (Germany) itself . . .

“Hammering Man” (animated) with small sign for Formnext 2021

Alte Oper Frankfurt (Old Opera)

Skyscrapers of Frankfurt

Deutsche Bank, impressive building & architecture

Tower 185 in Frankfurt

Frankfurt

Lightsculpture by Christian Herdeg – “Synergie / Synergy”, Platz der Einheit, Frankfurt

Frankfurt am Main (river)

That’s it.