Status: built, but not much tested yet

Updates:

- 2024/12/22: referenced in Multi Gantry Printer with MG-MIEX upgrade

- 2022/12/09: finally built it, and photos of first print done

- 2021/01/14: very experimental IDEX upgrade option added

- 2021/01/08: starting with details of Y belt/pulley (non-)printable parts

- 2020/12/28: beautifying X & Y motor and pulley mounts with

rcube(),rcylinder()andchainhull() - 2020/12/25: starting with some basic parametric enclosure, refining some details

- 2020/12/24: X & Y motor mounts as well X & Y pulley mounts done

- 2020/12/23: starting with Ashtar C frame and transforming it to classic X/Y head, X/Y motor mounts and pulleys mounts missing

Table of Contents

Introduction

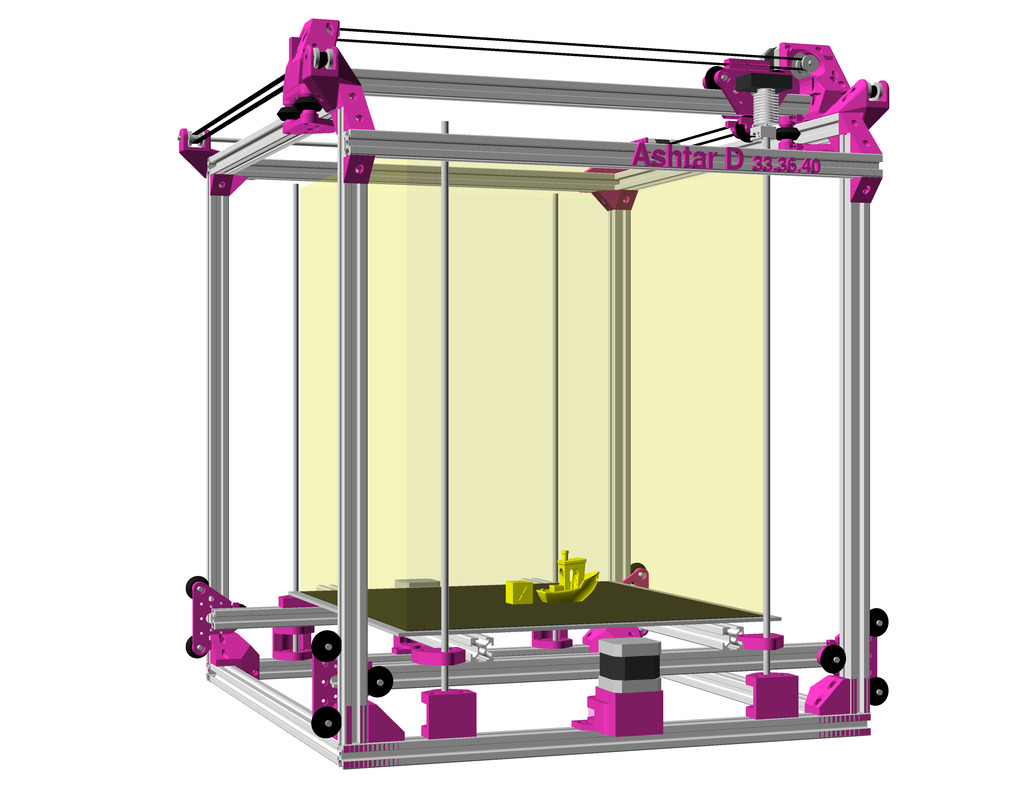

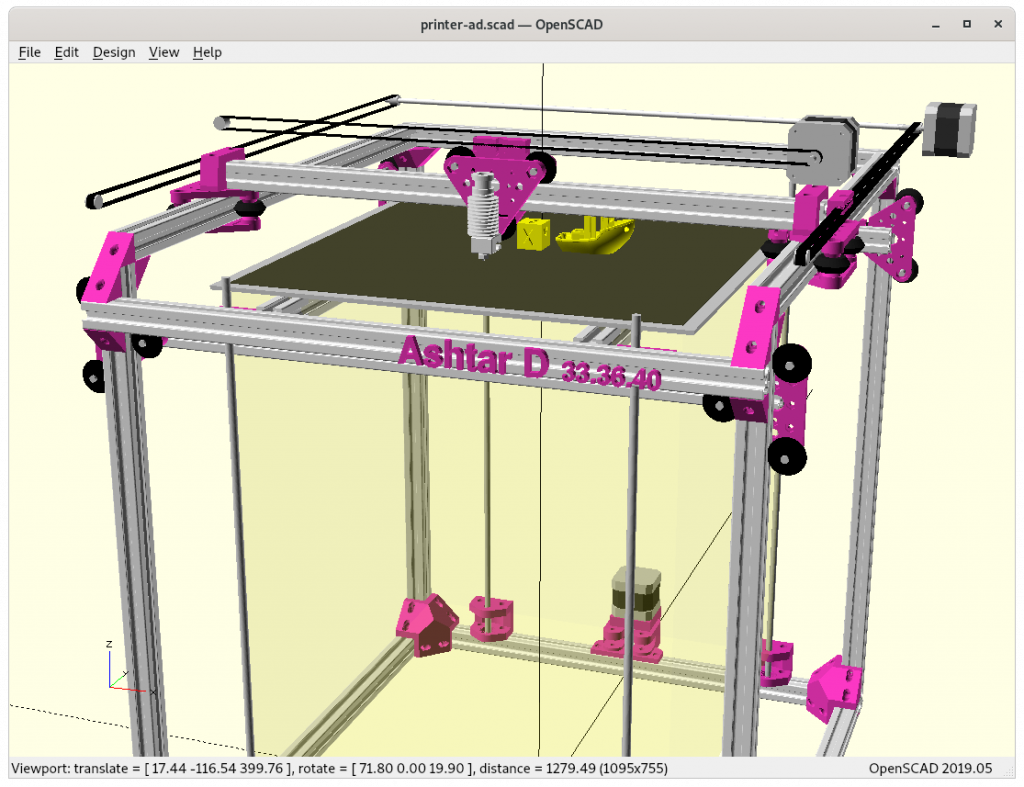

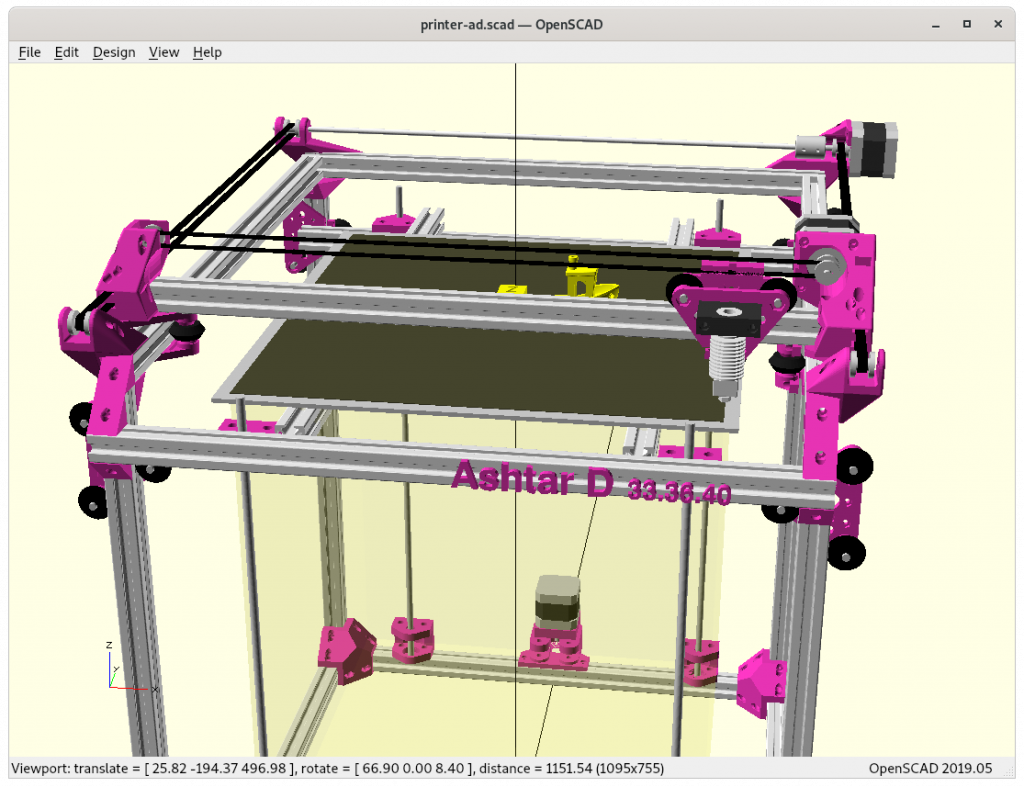

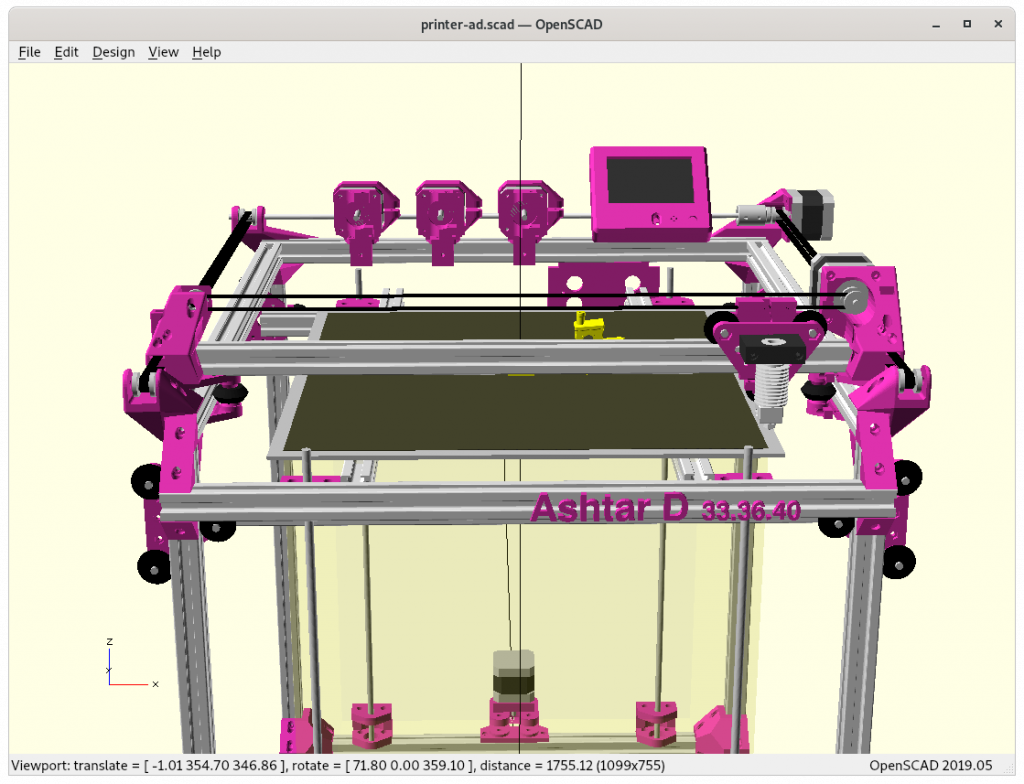

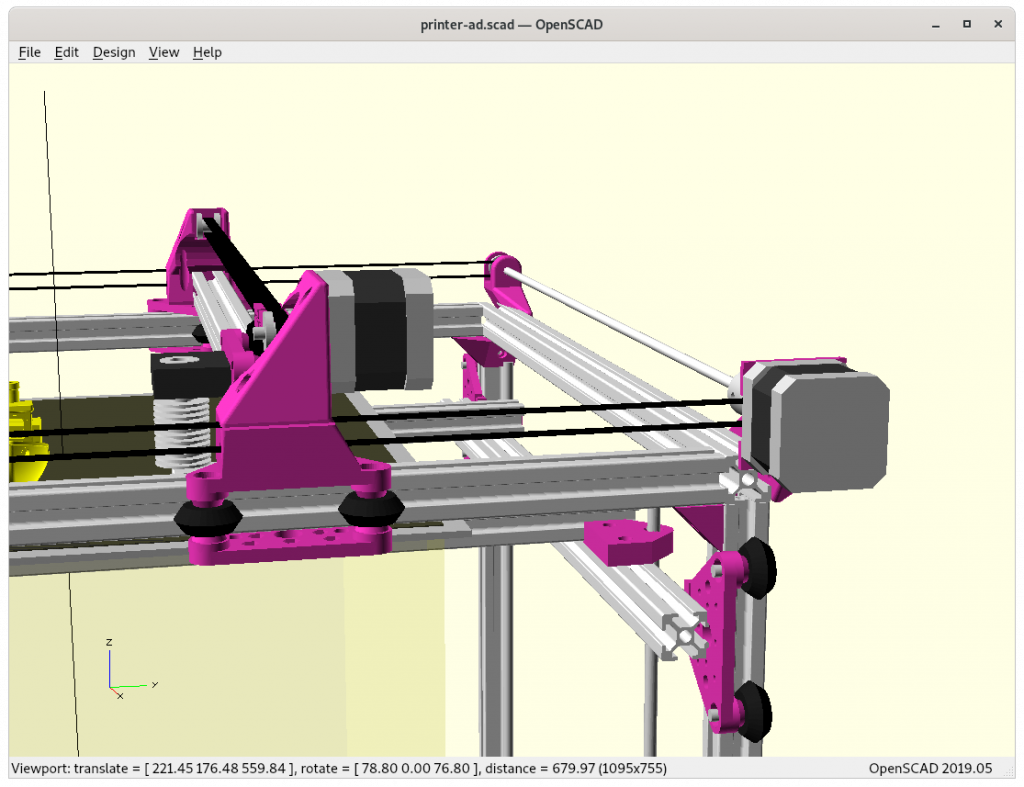

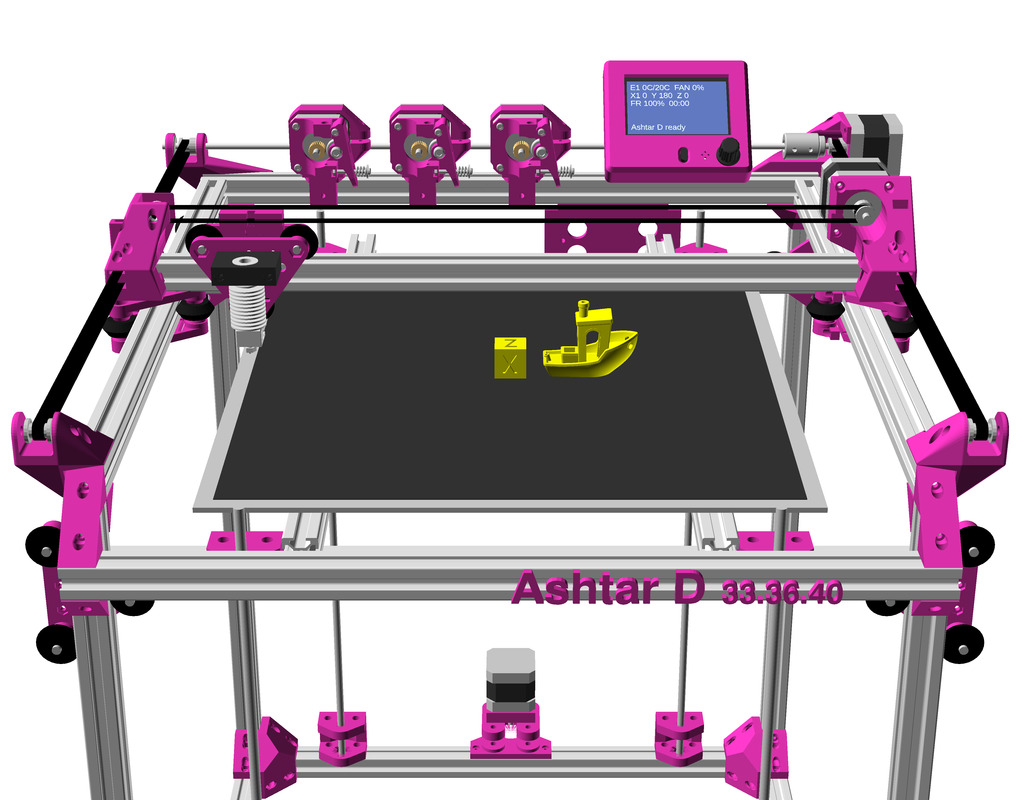

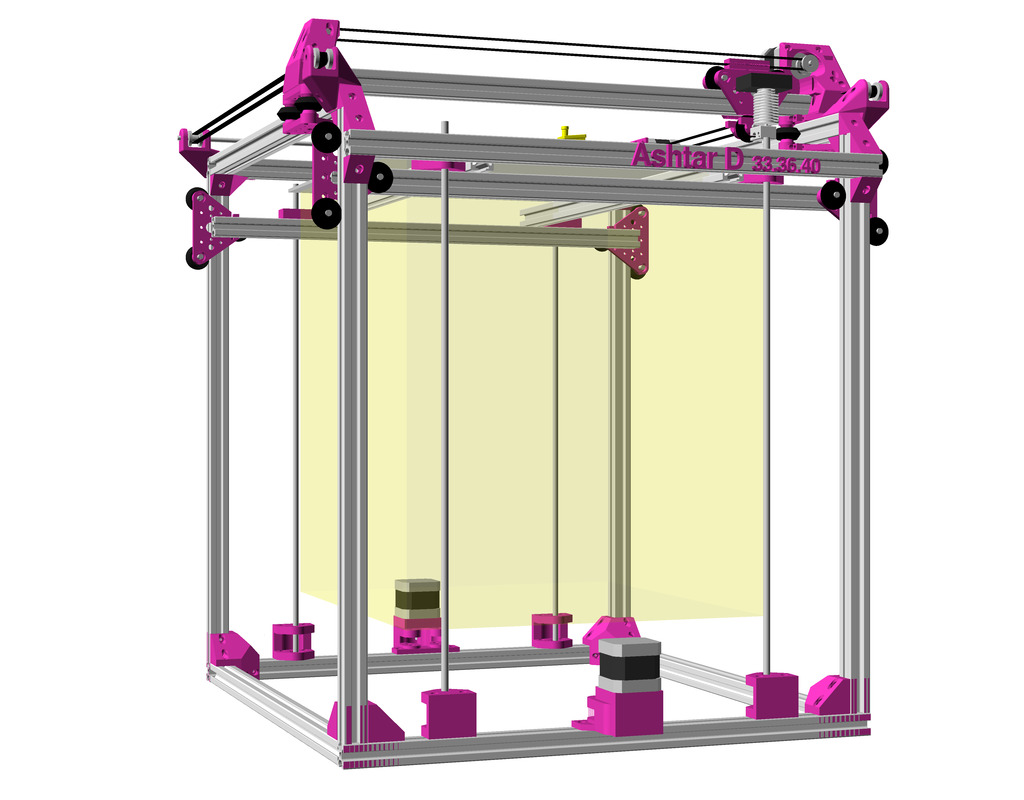

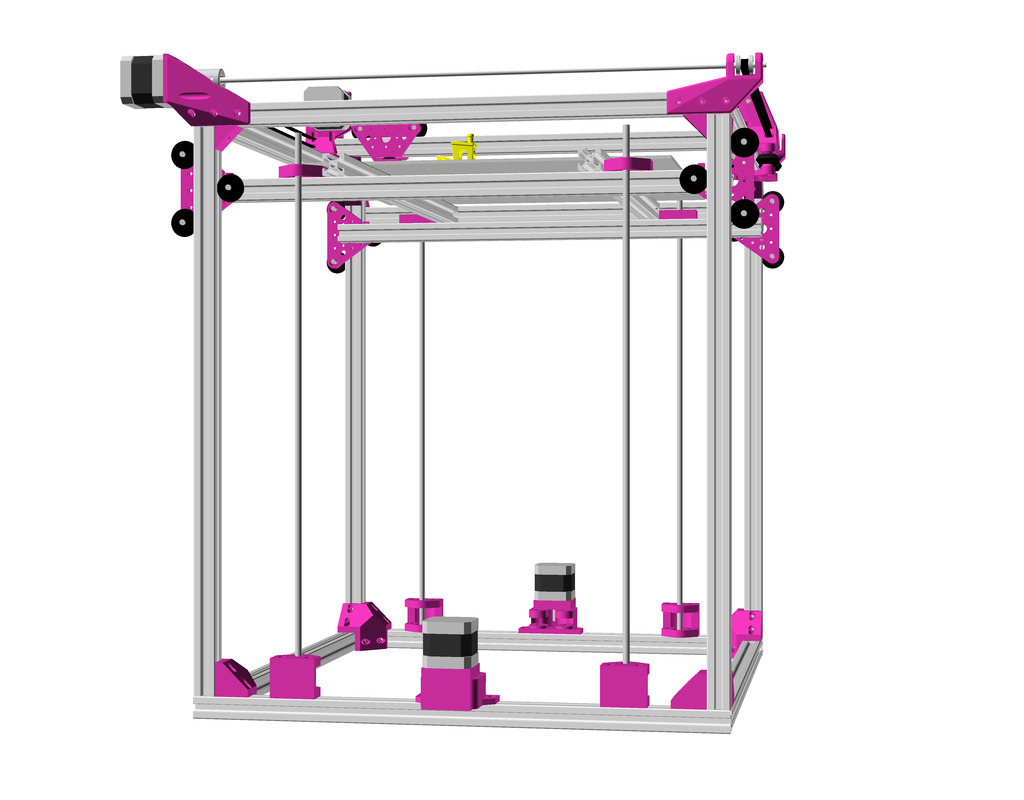

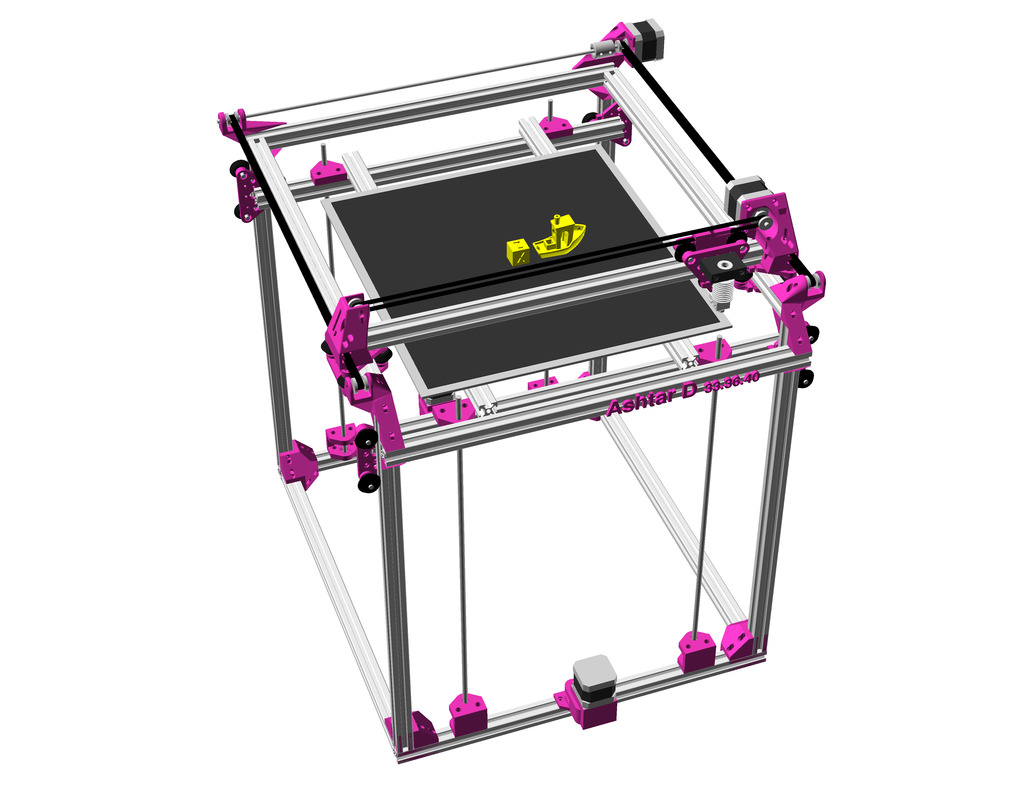

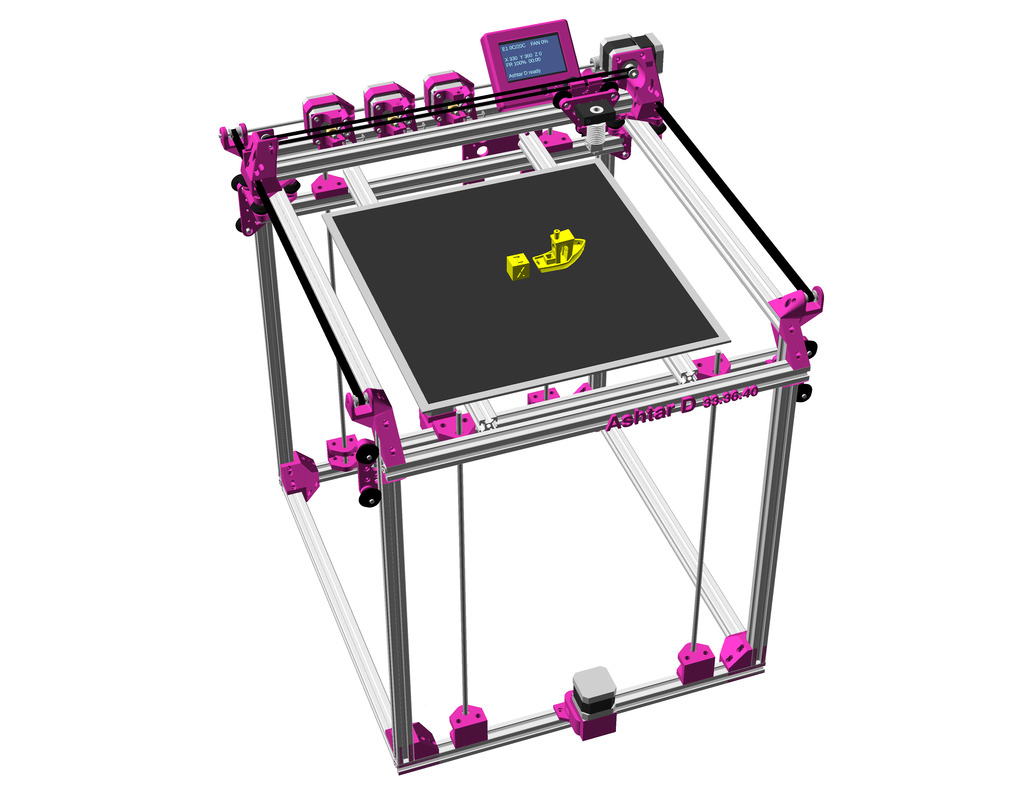

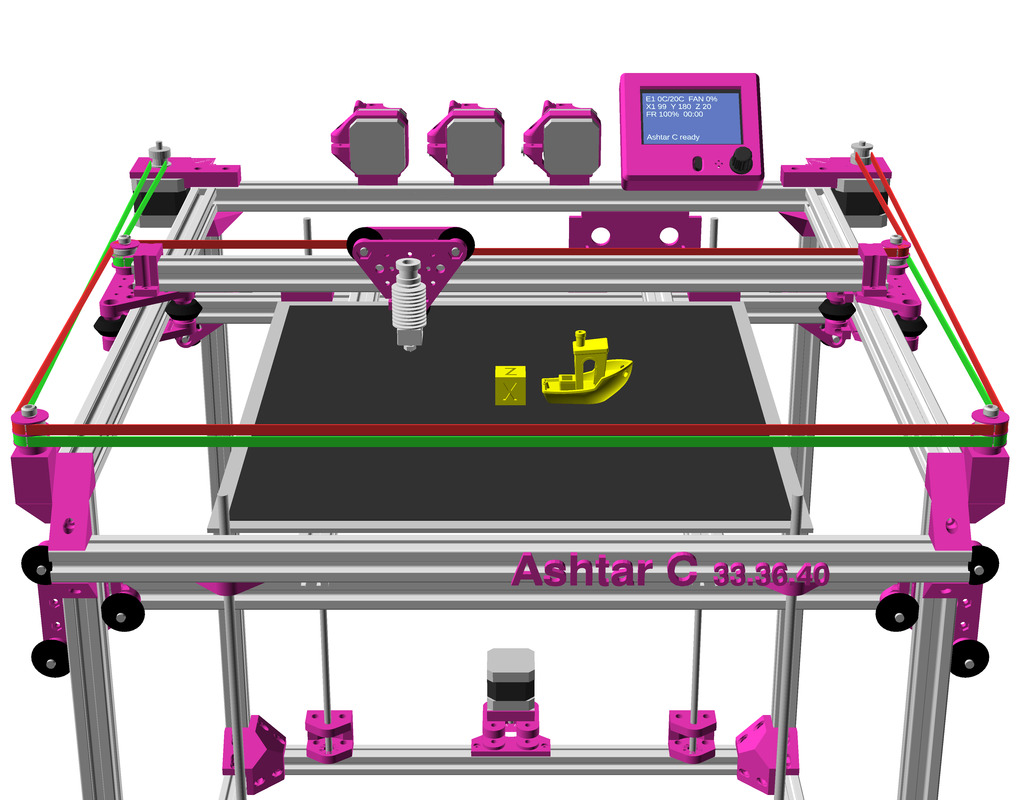

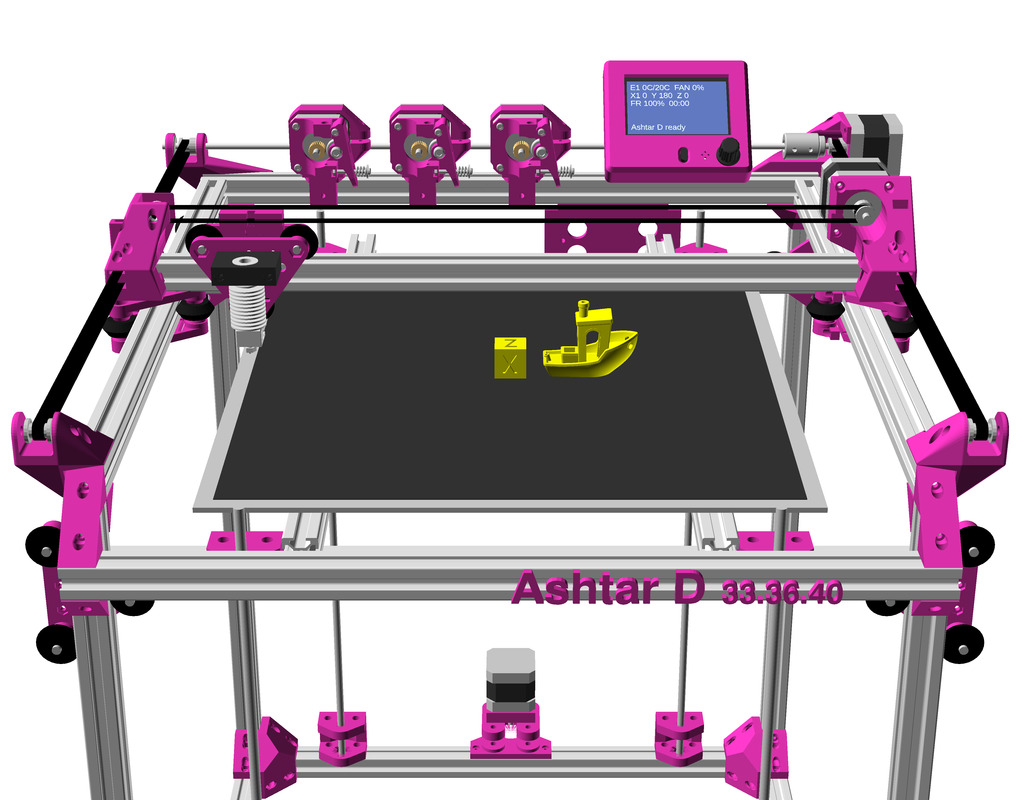

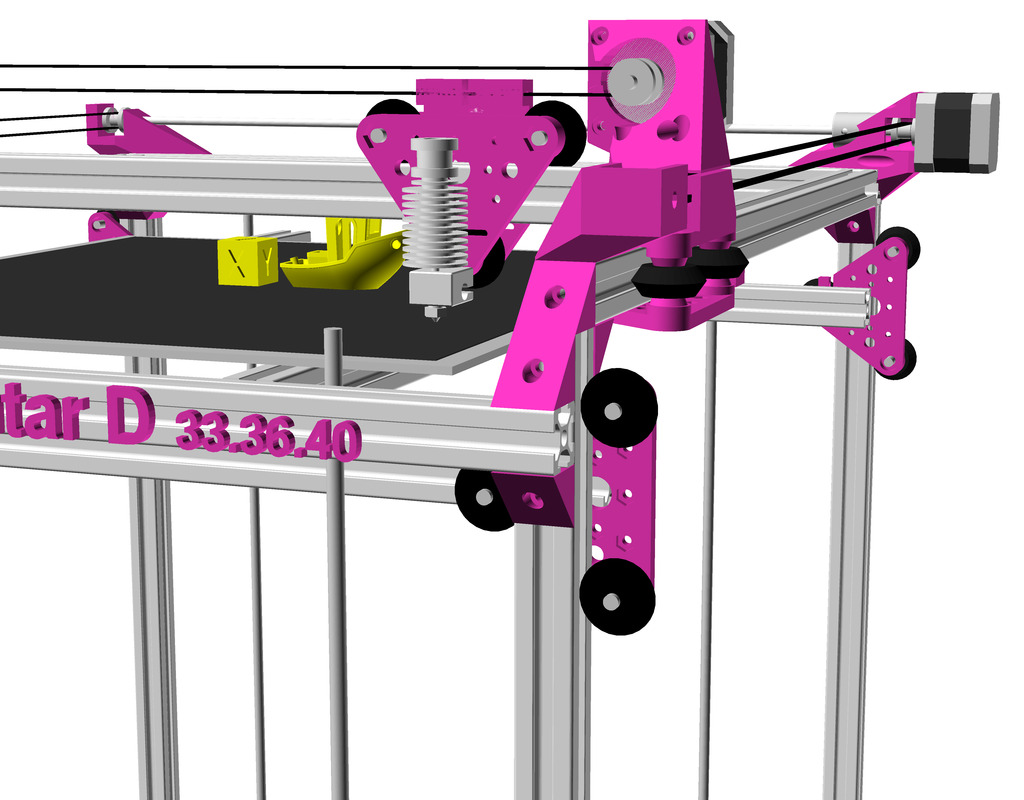

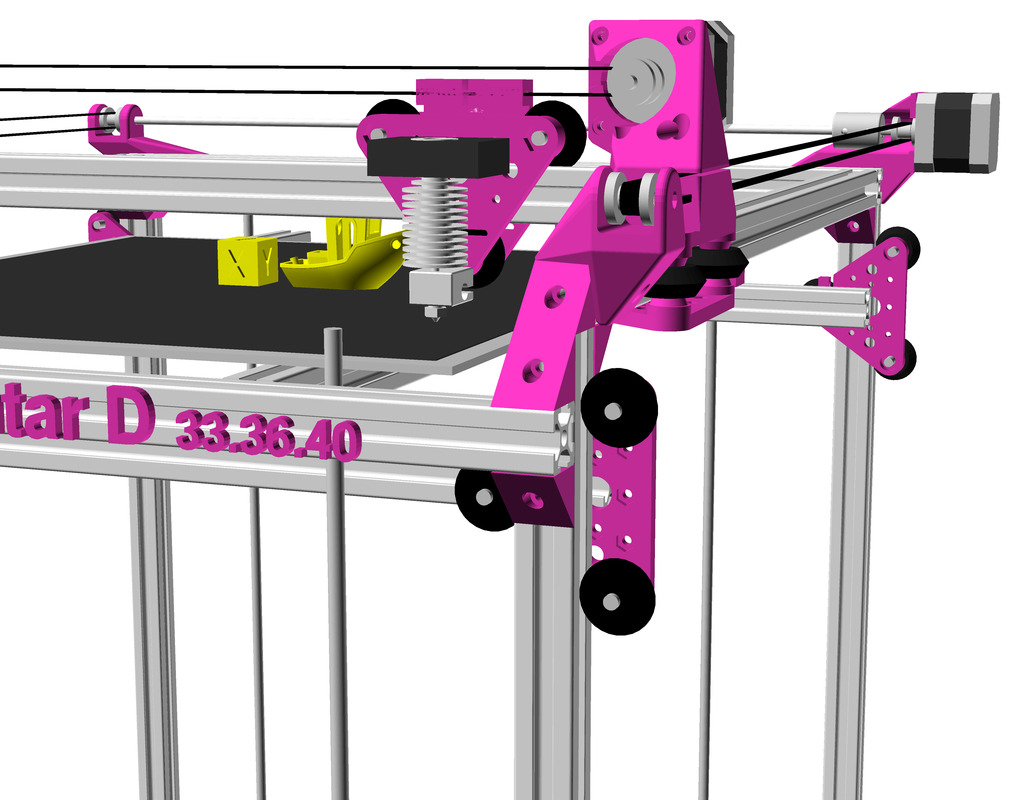

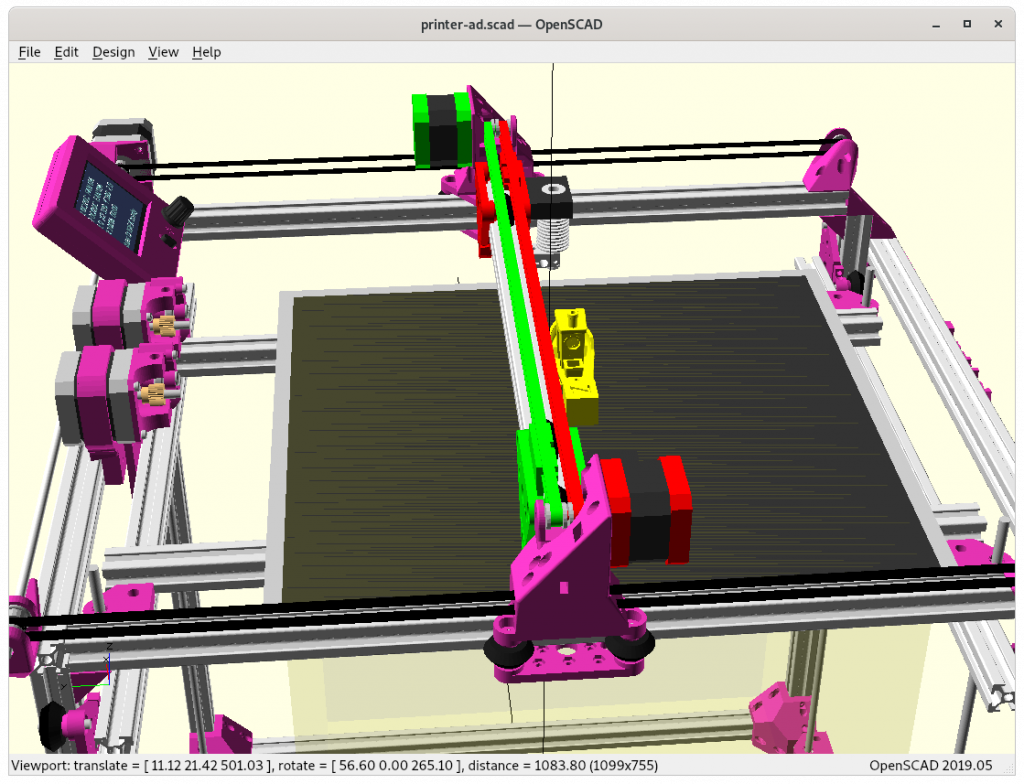

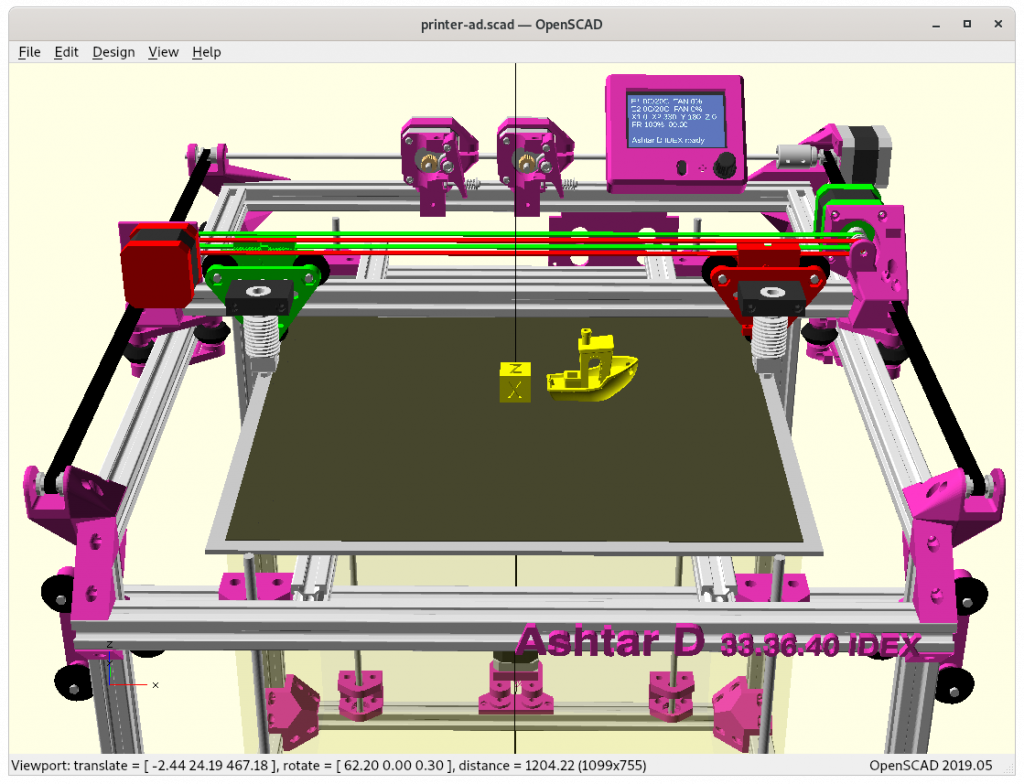

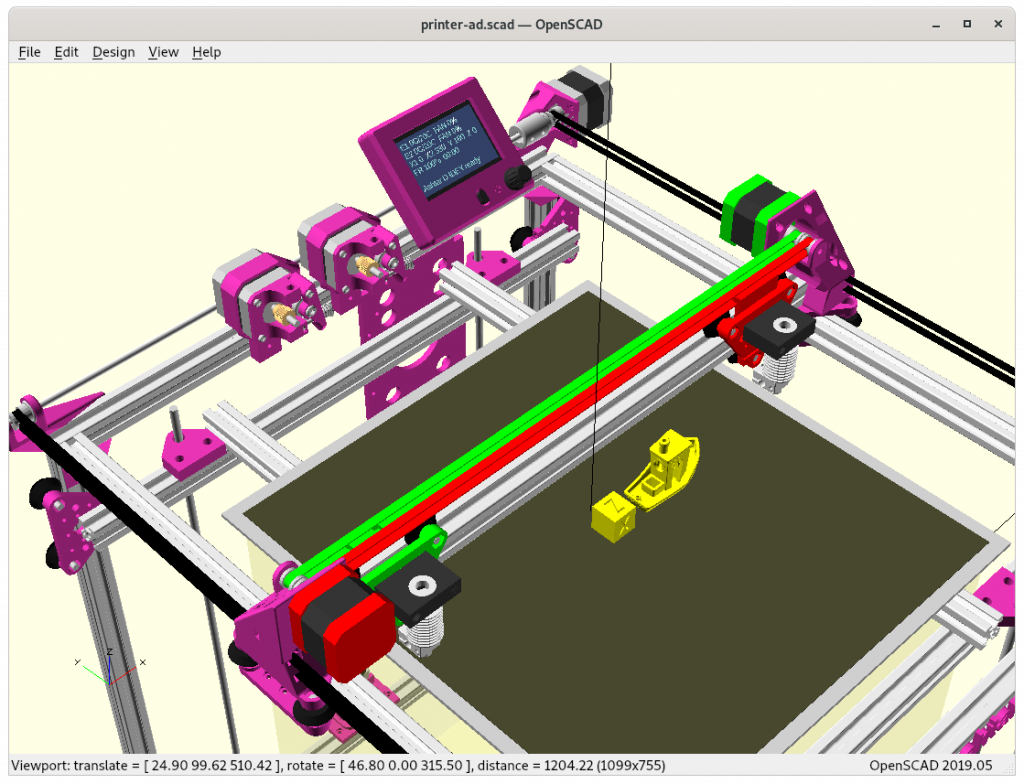

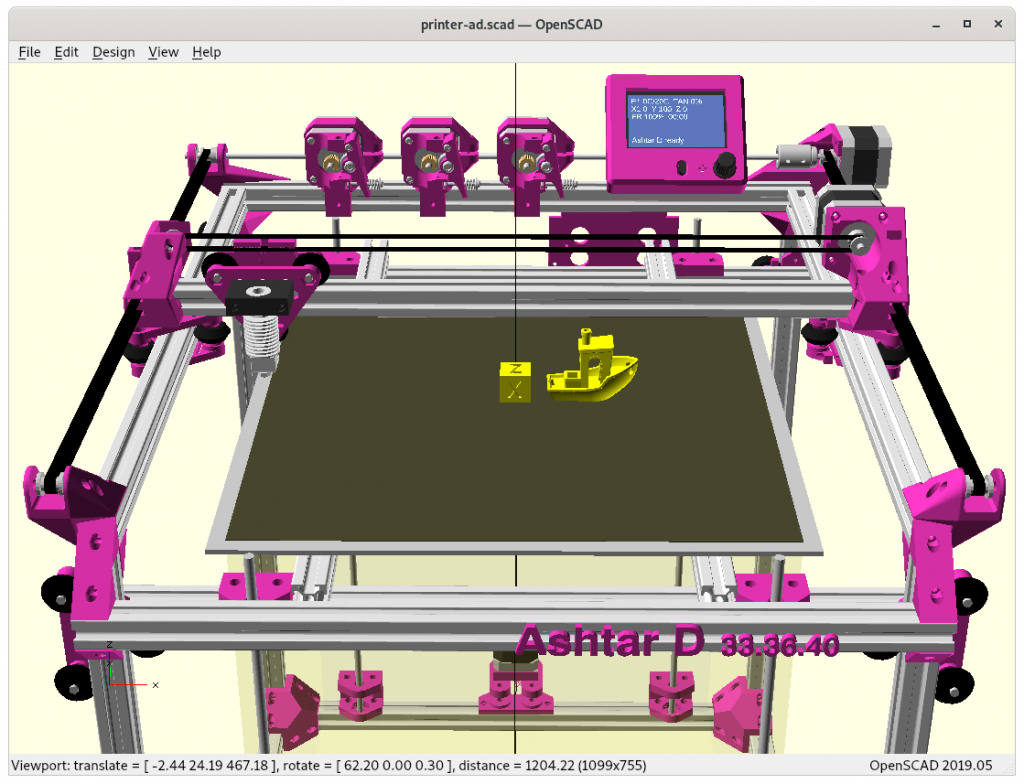

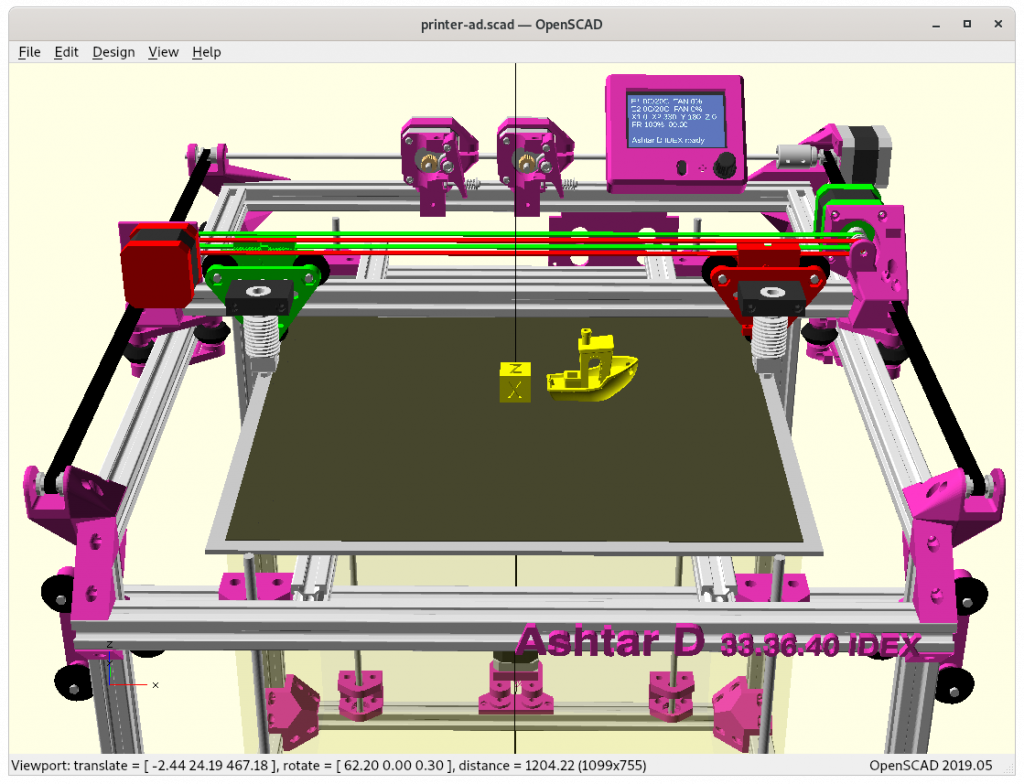

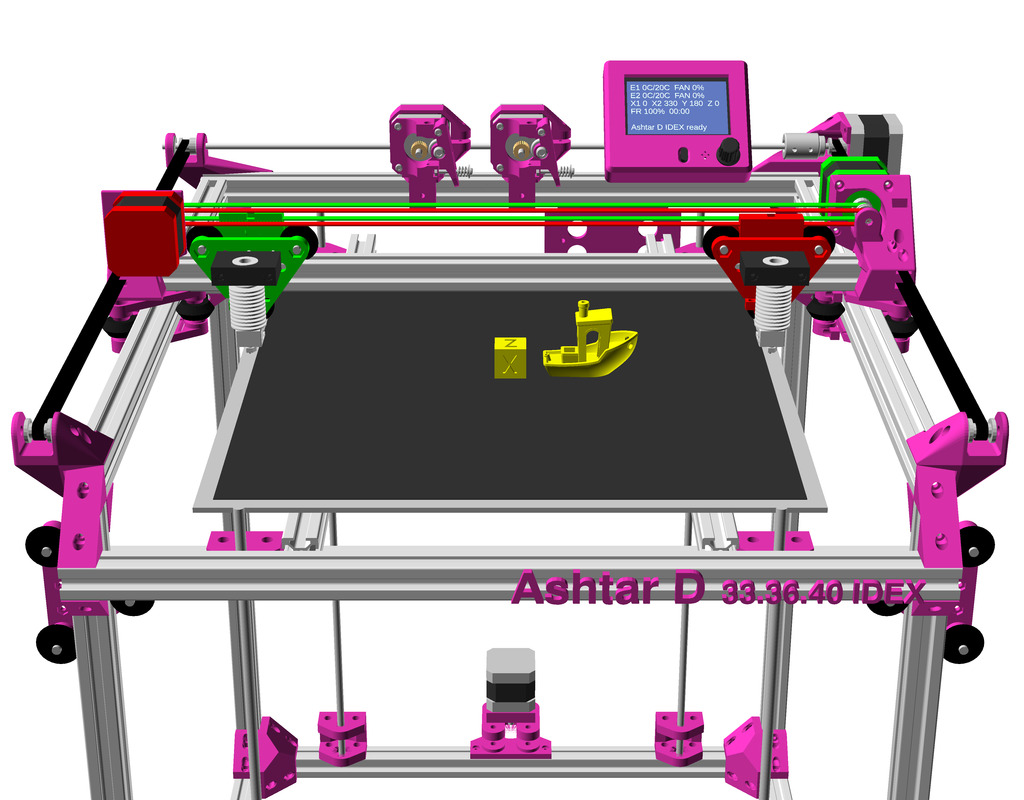

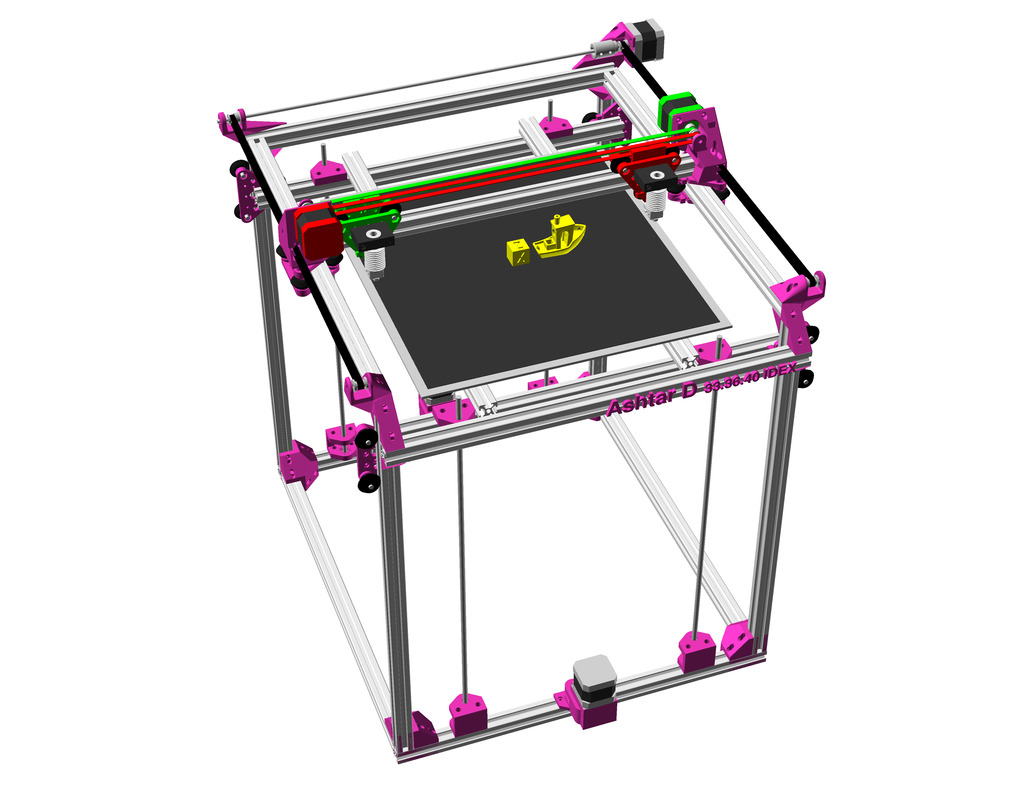

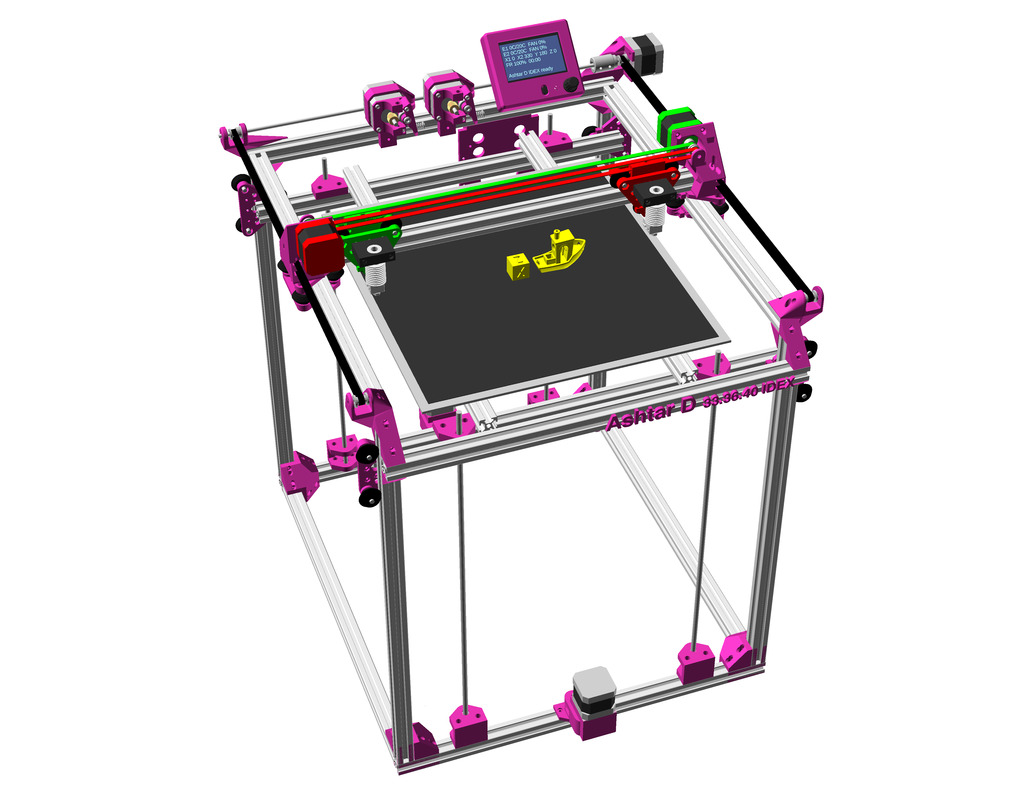

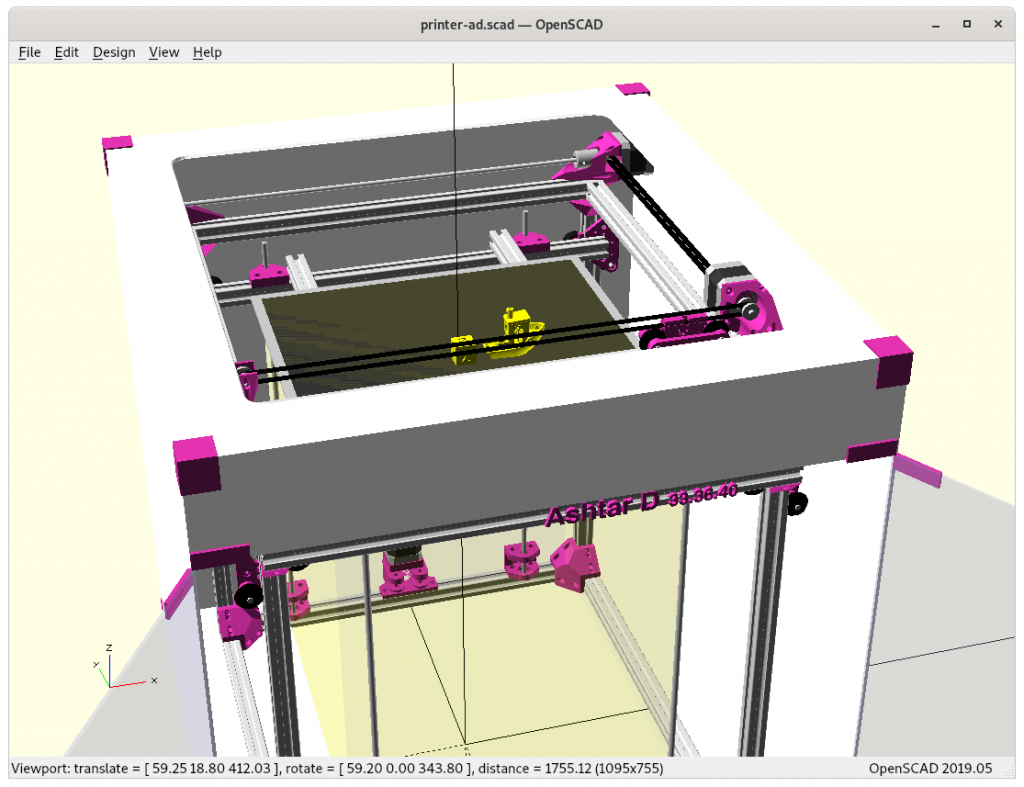

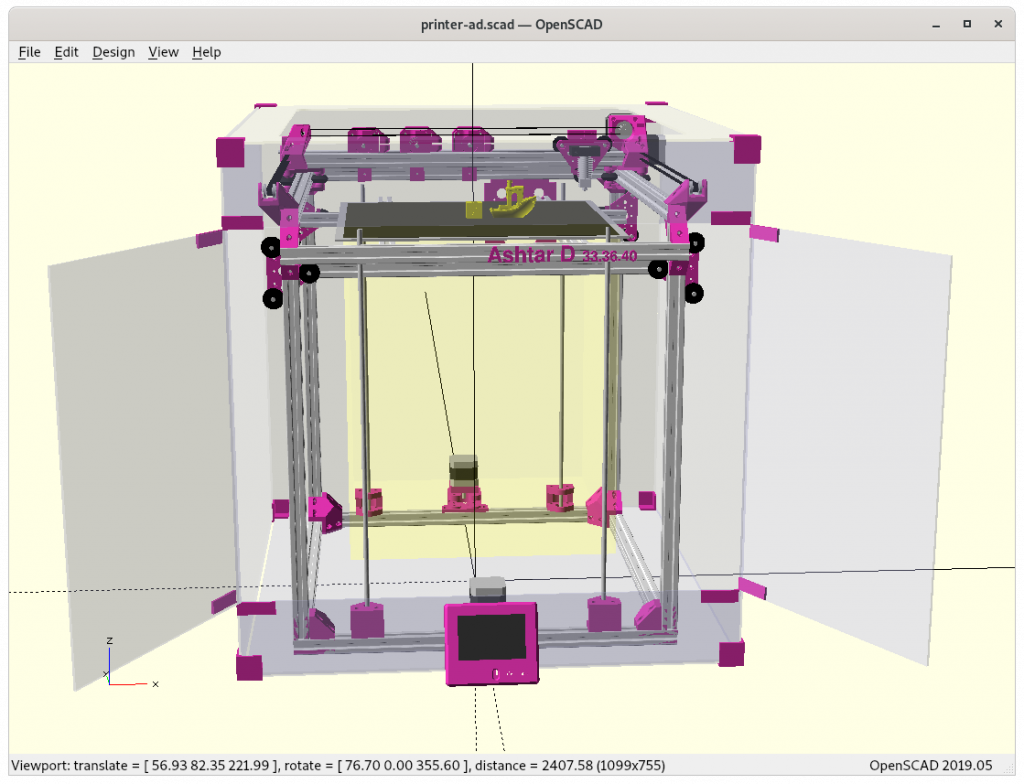

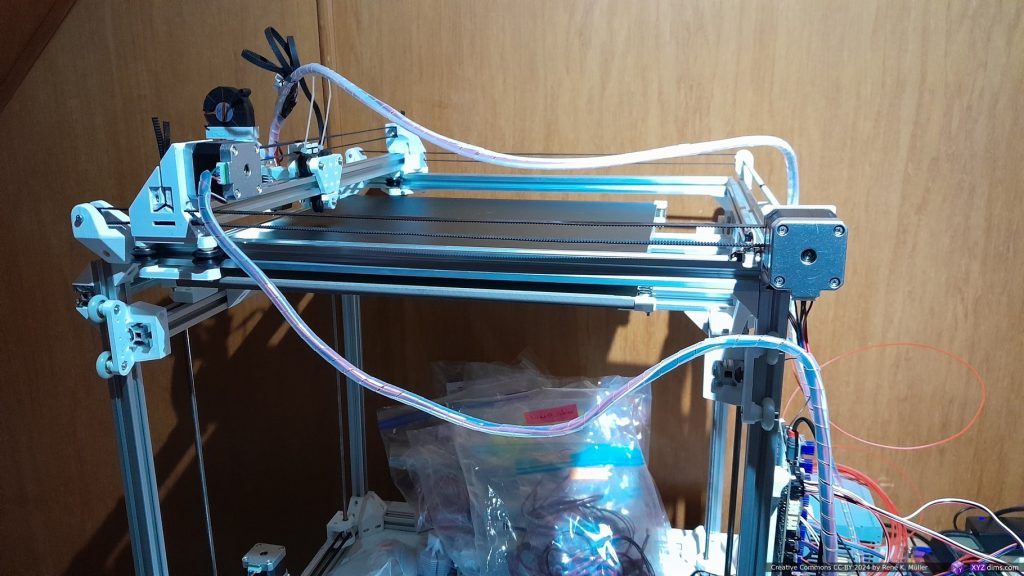

After the Core XY of Ashtar C I thought to convert it to a more classic kinematic X/Y head with two dedicated NEMA17 motors for each axis – independent XY. Mostly using the same frame setup with 500mm alu extrusions, same V-carriages/modules as before, but reposition both motors to dedicate for X and Y axis now. The main goal is to achieve 400x400mm print area with 500mm alu extrusions.

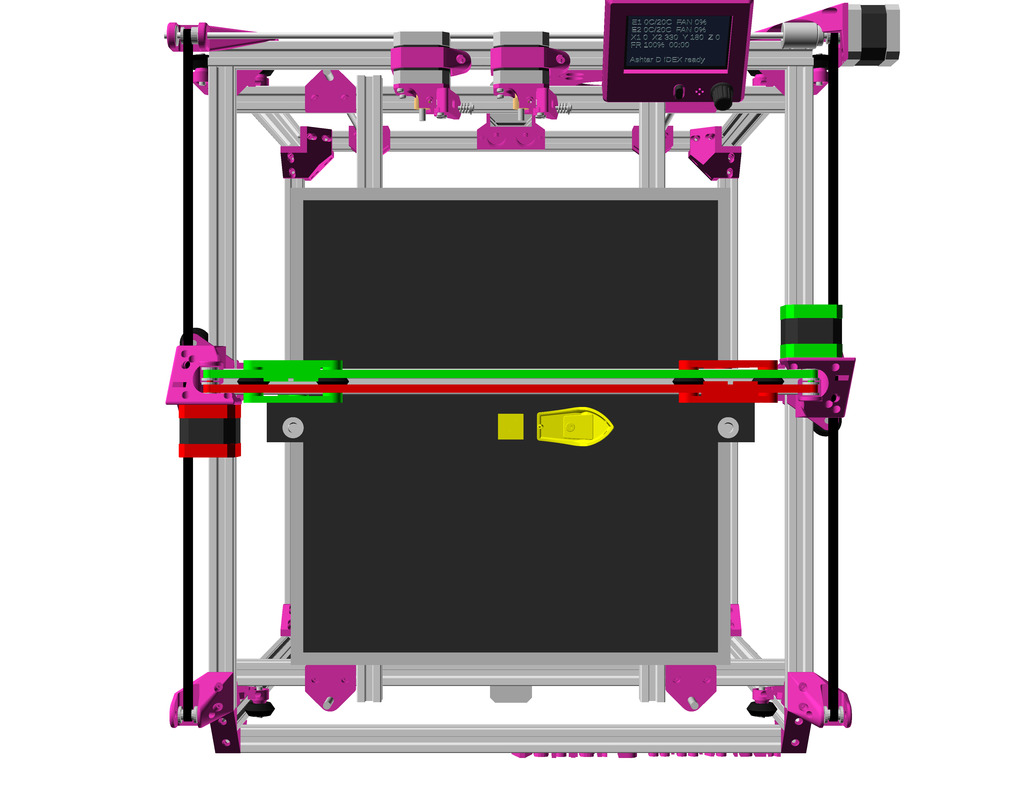

Ashtar D (Classic XY)

- X motor & Y motor

- no XY frame tension

- shorter belts

- one moving motor (Y-wise)

Ashtar C (Core XY)

- Core XY with motor A & B

- XY frame tension

- long belts

- no moving motors

Draft

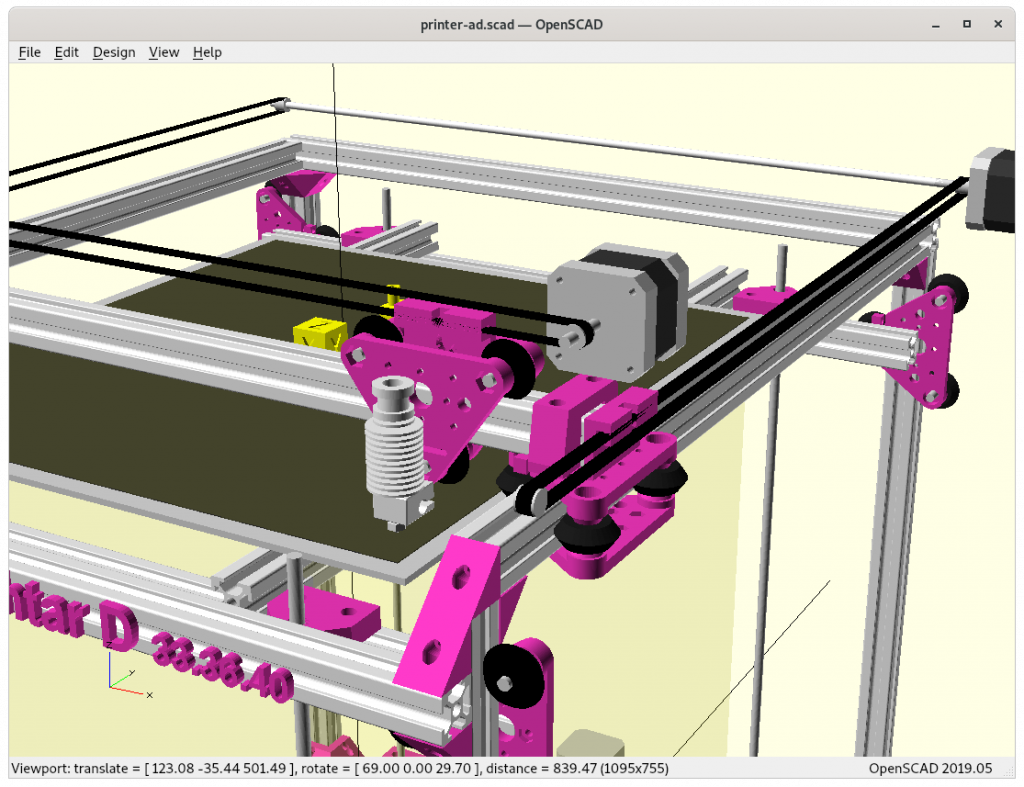

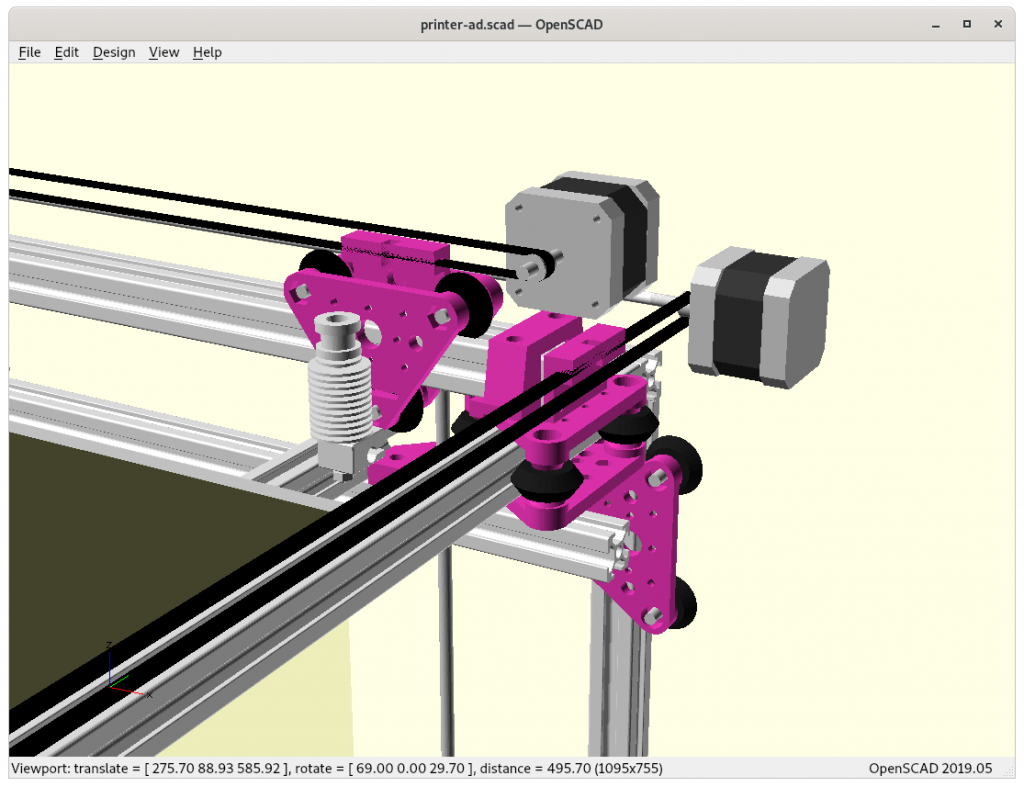

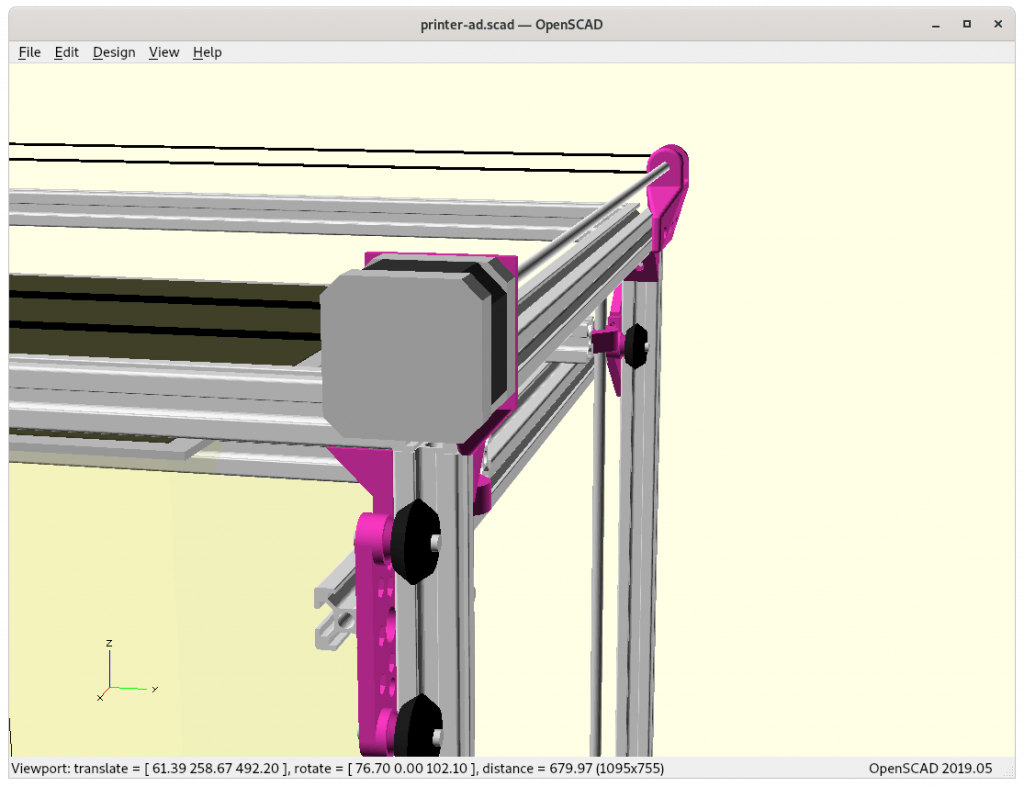

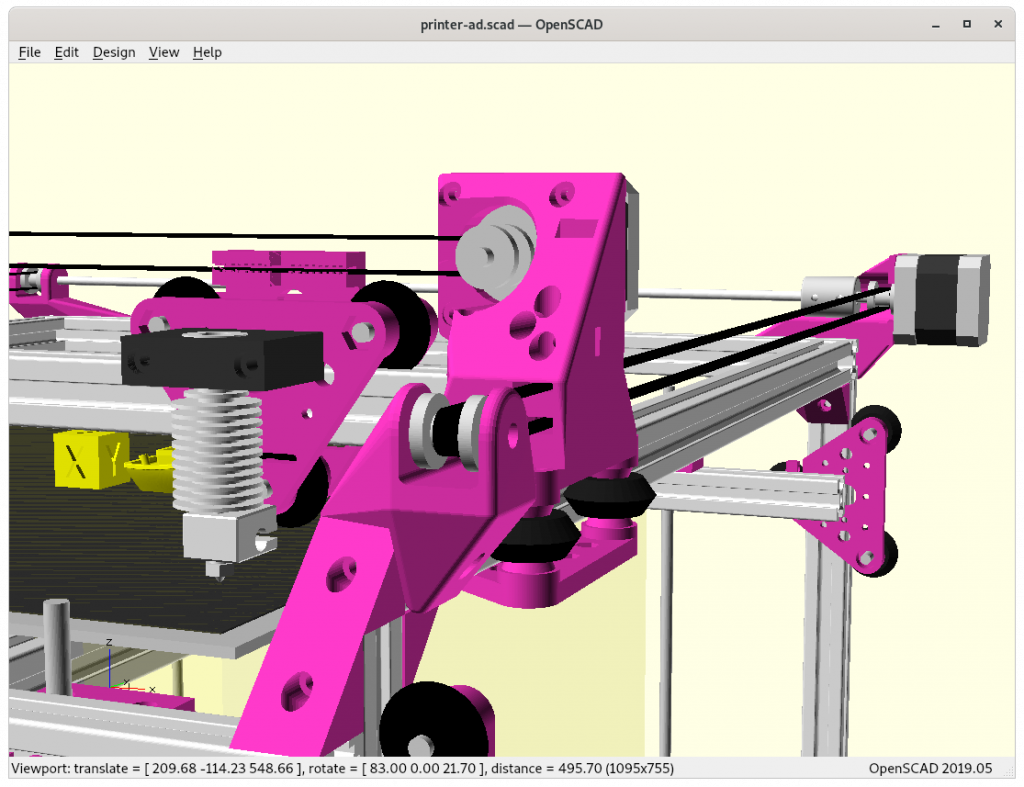

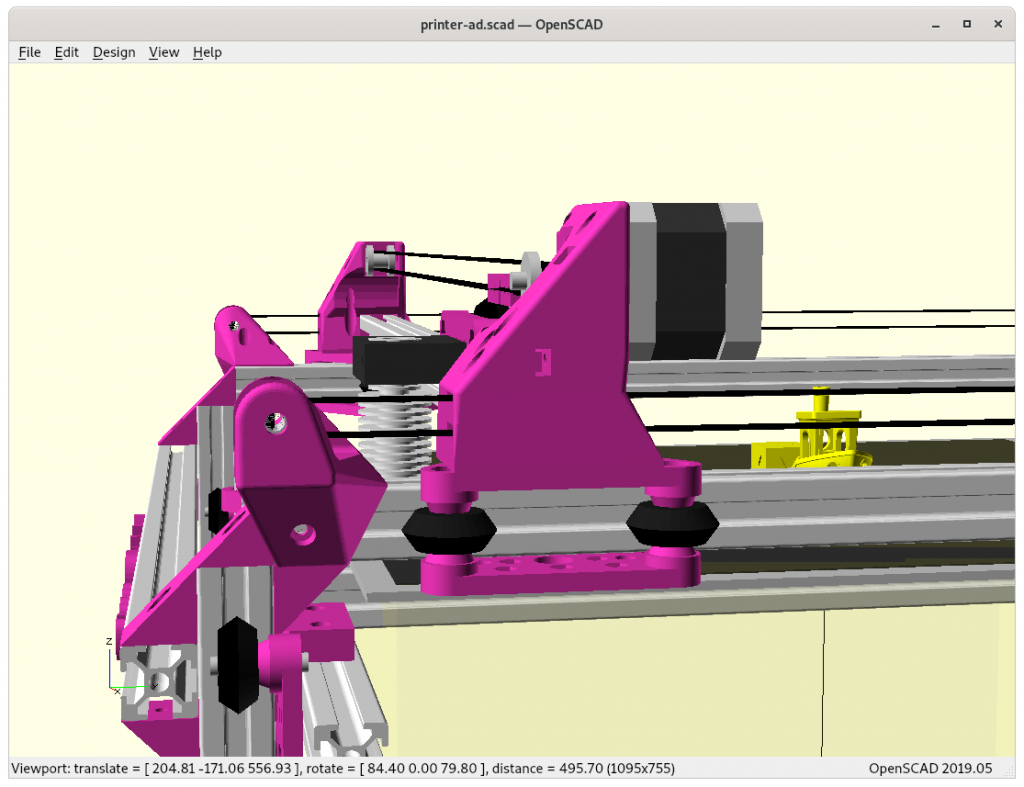

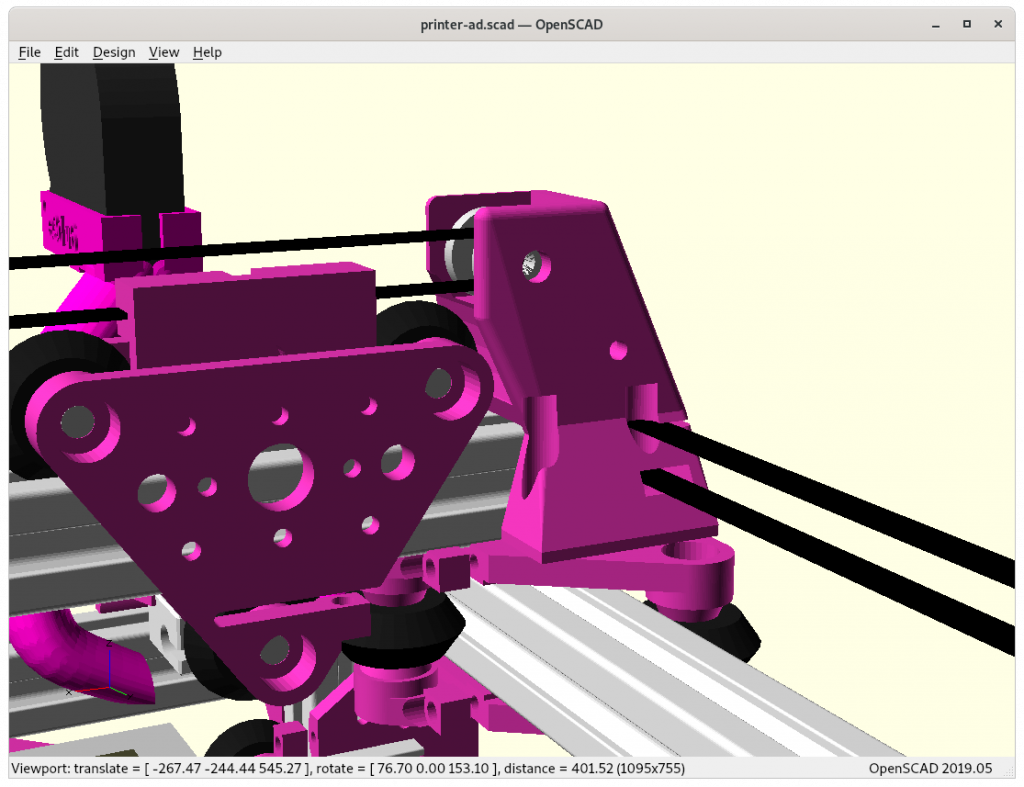

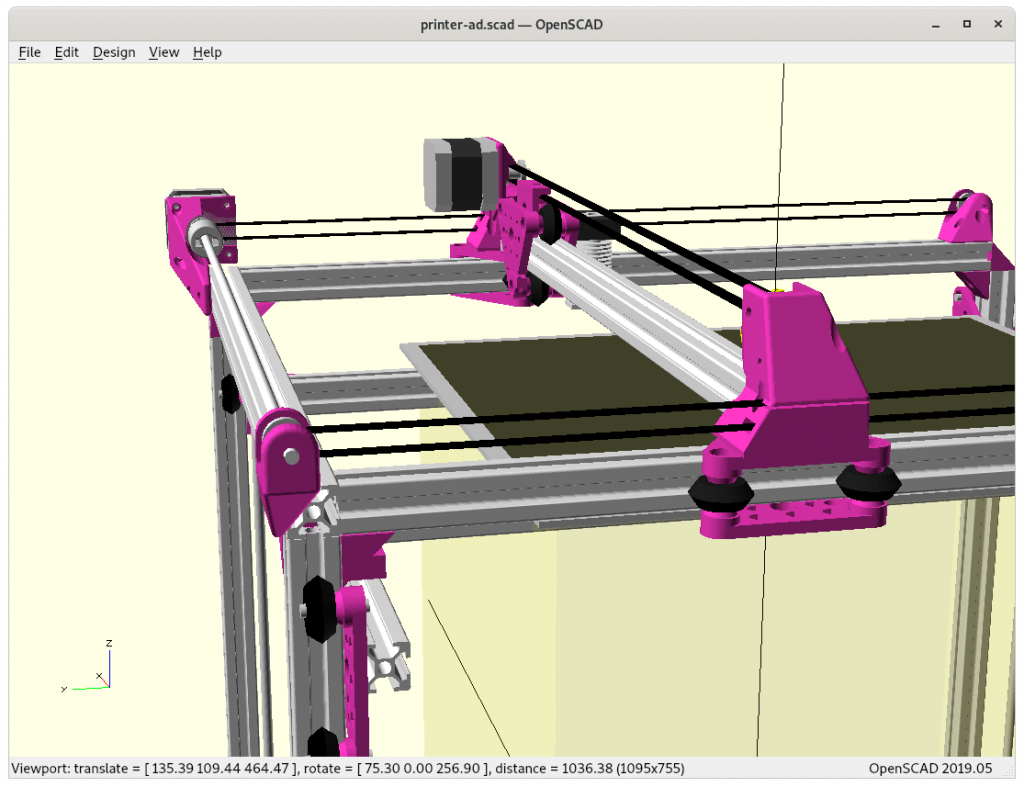

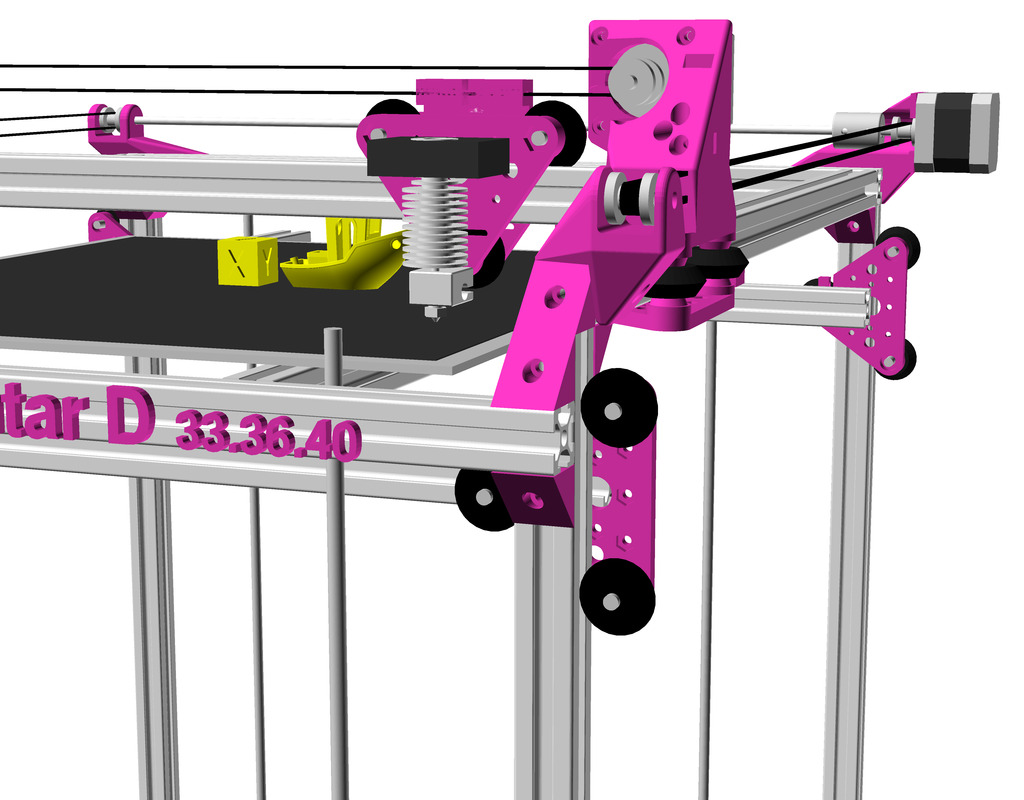

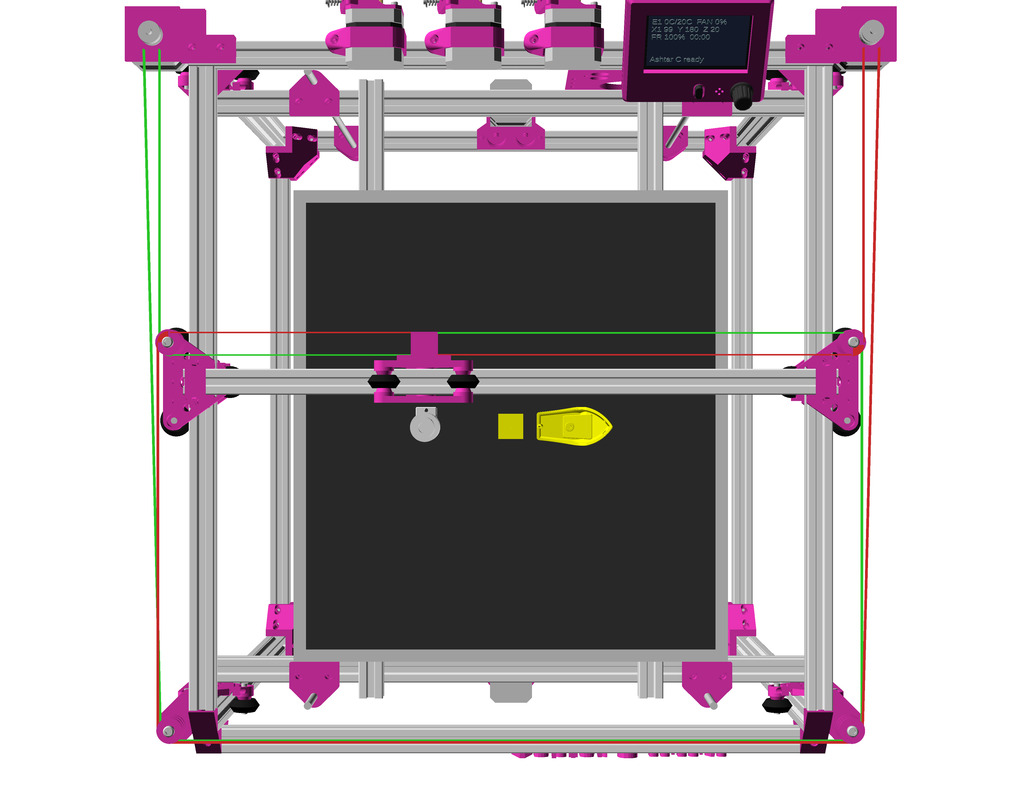

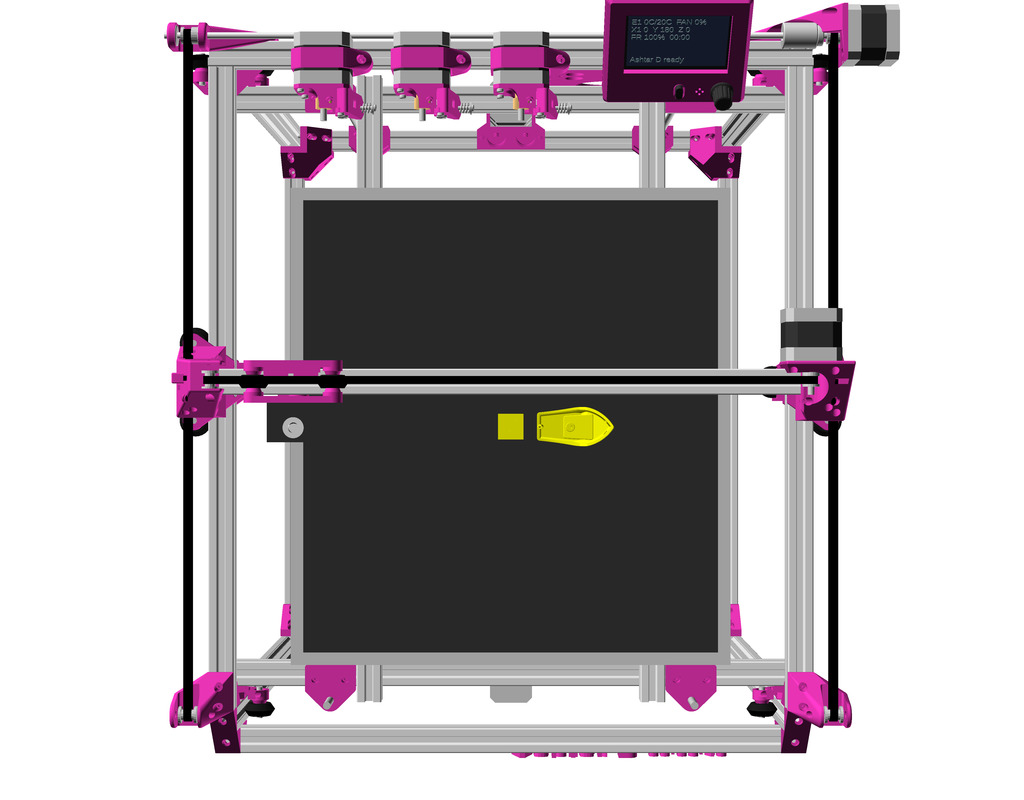

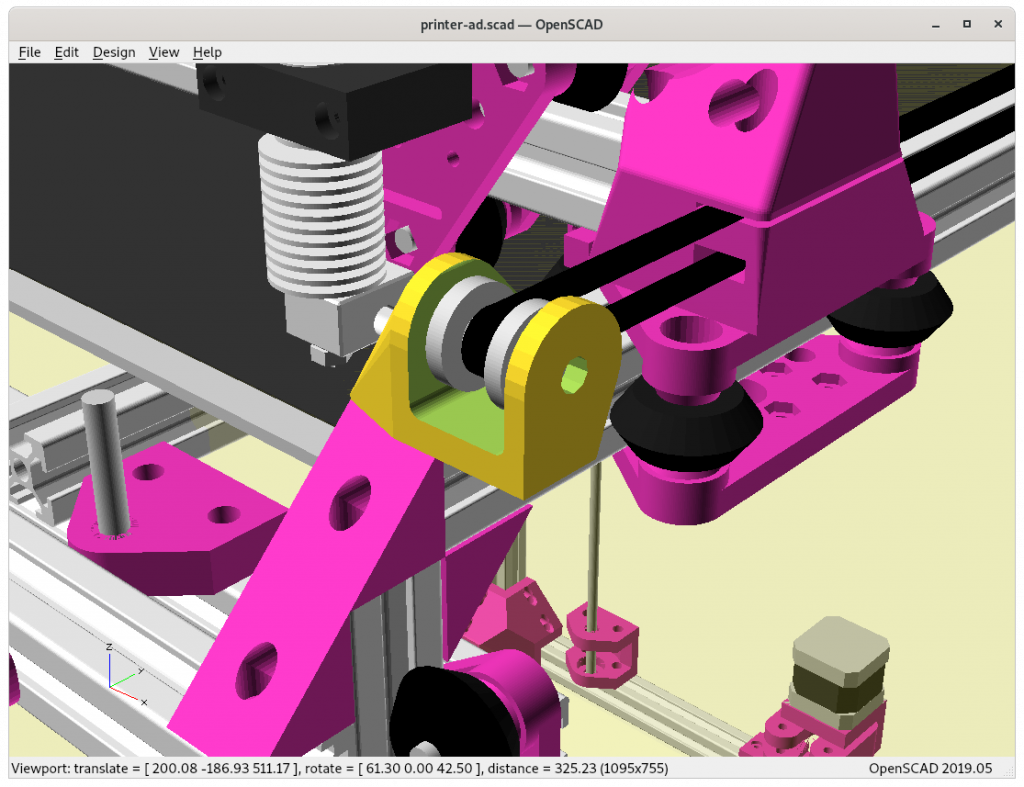

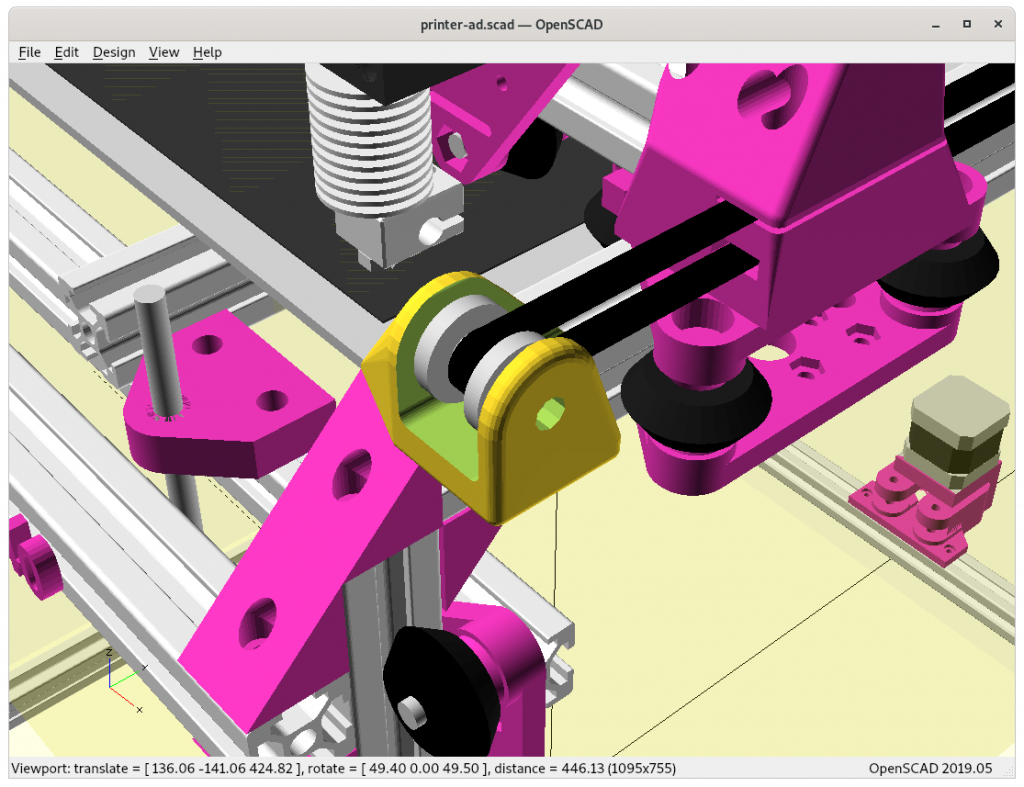

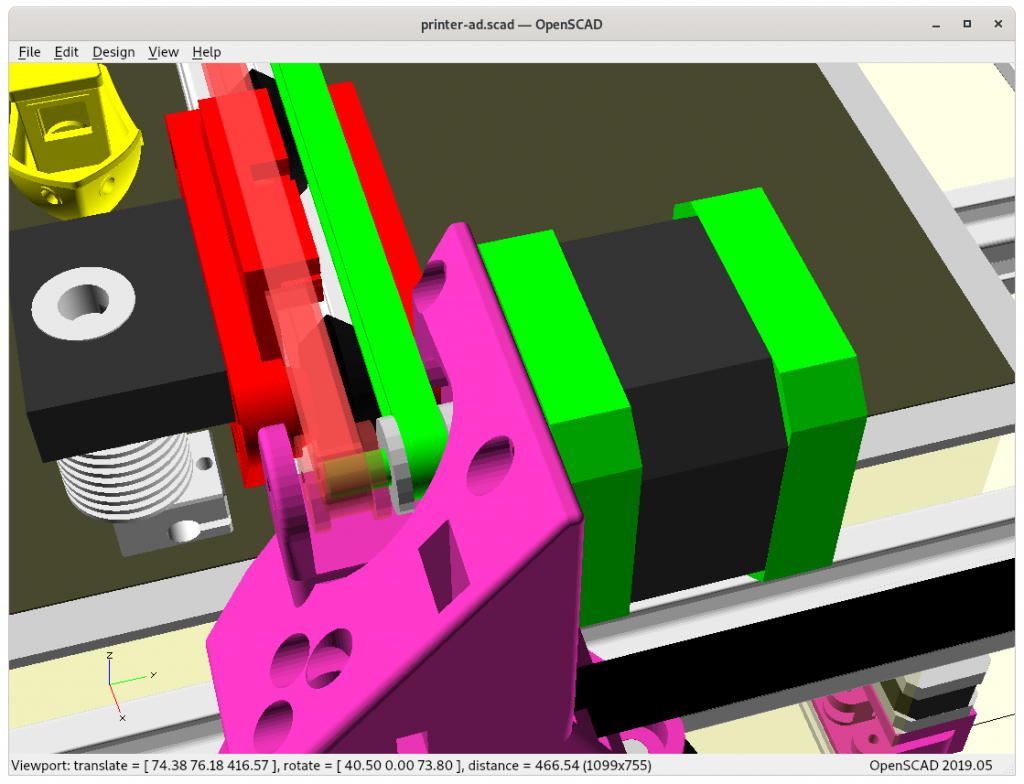

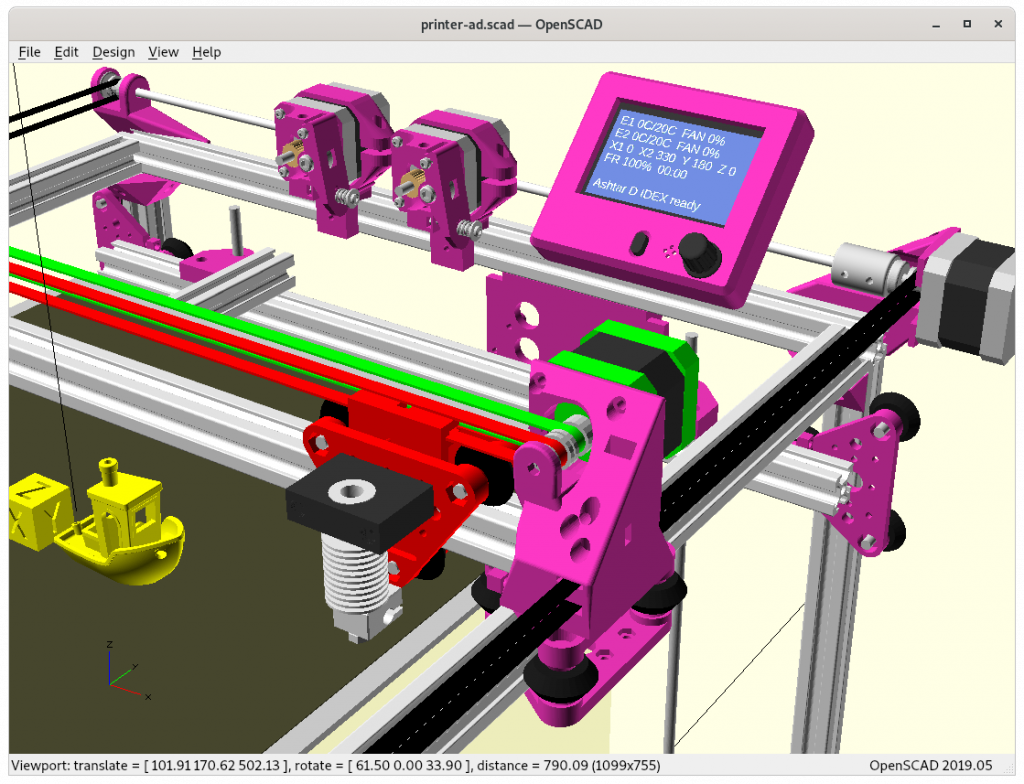

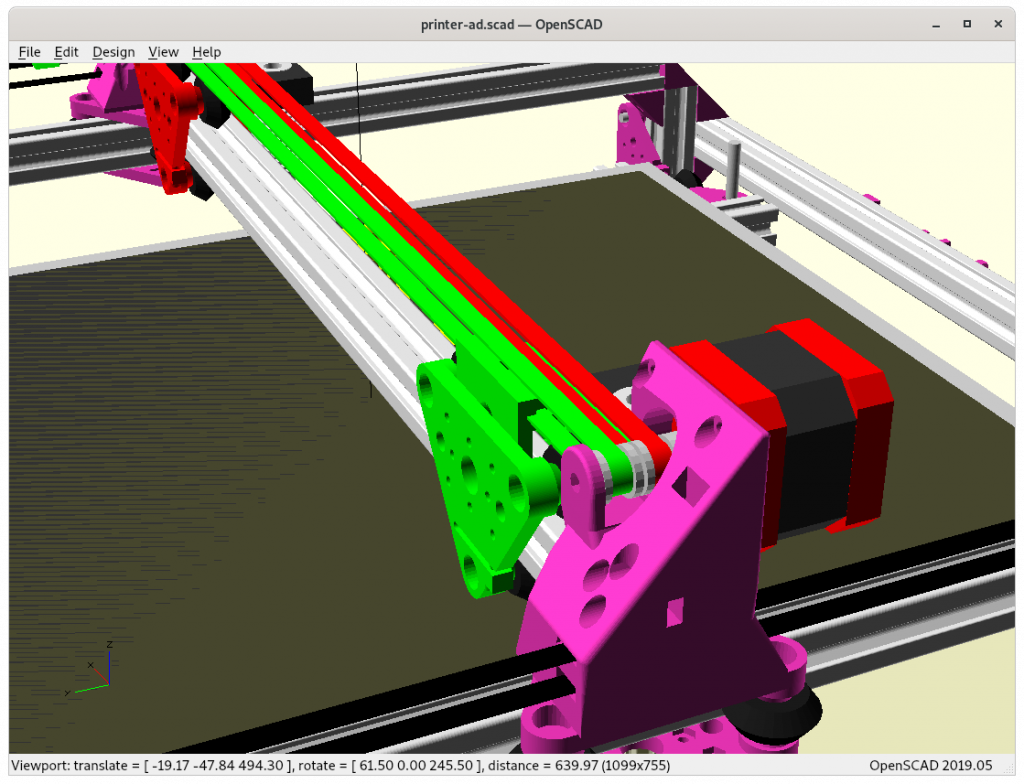

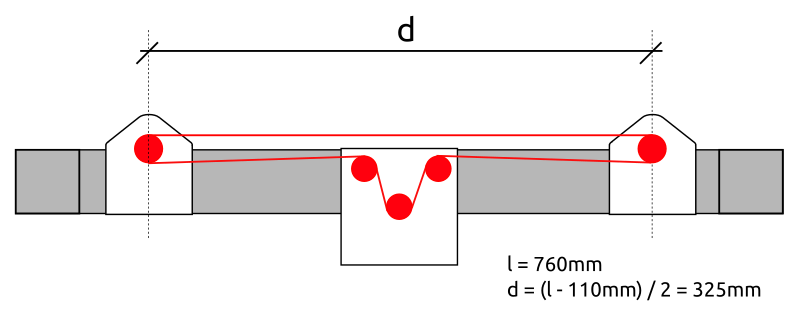

After the rough design was OK, with X = 0 .. max and Y = 0 .. max and maintaining max of printable area, I went ahead and did basic Y motor mount and X motor mount, and I was designing the pieces in OpenSCAD, the ad_[xy]mount(type="motor" or "pulley") and I changed the 42×42 interface for NEMA17 to pulley holder which made it quite a fast design – so motor-side and pulley-side are very similar made with the same OpenSCAD module:

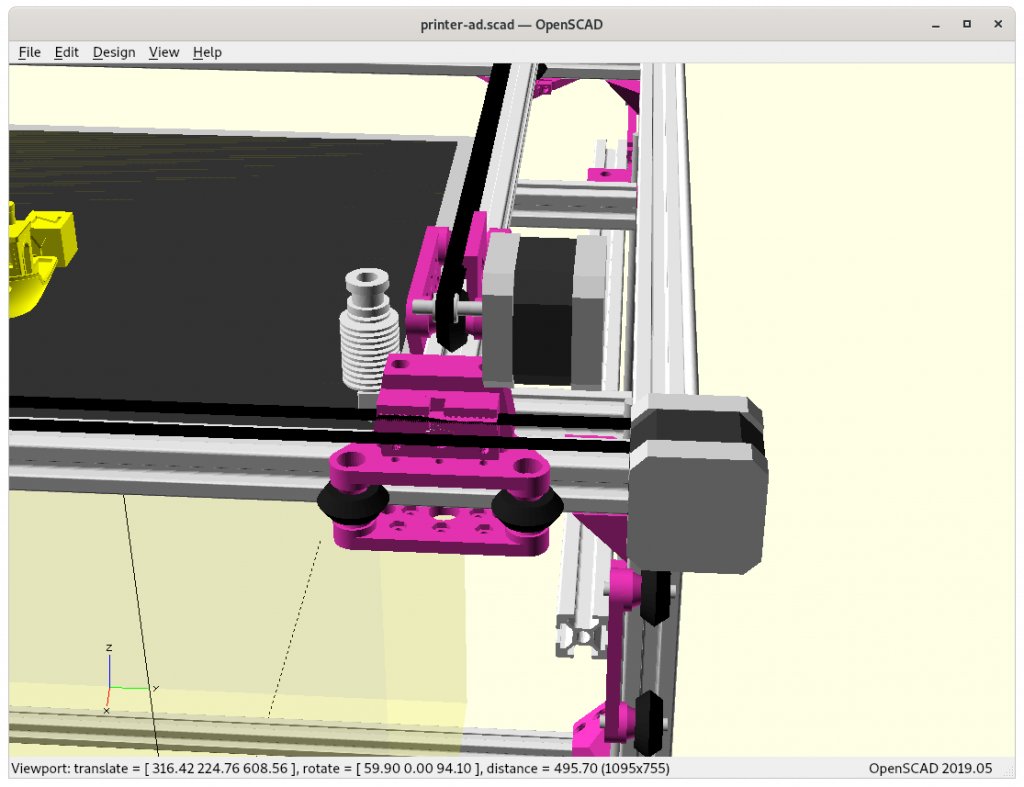

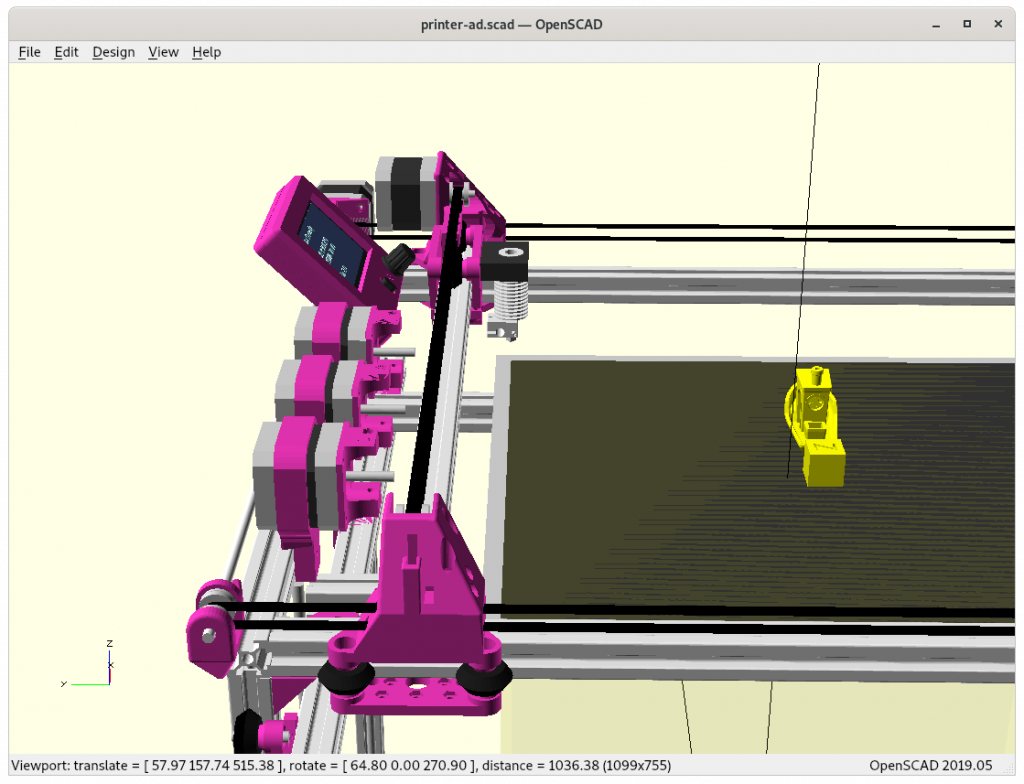

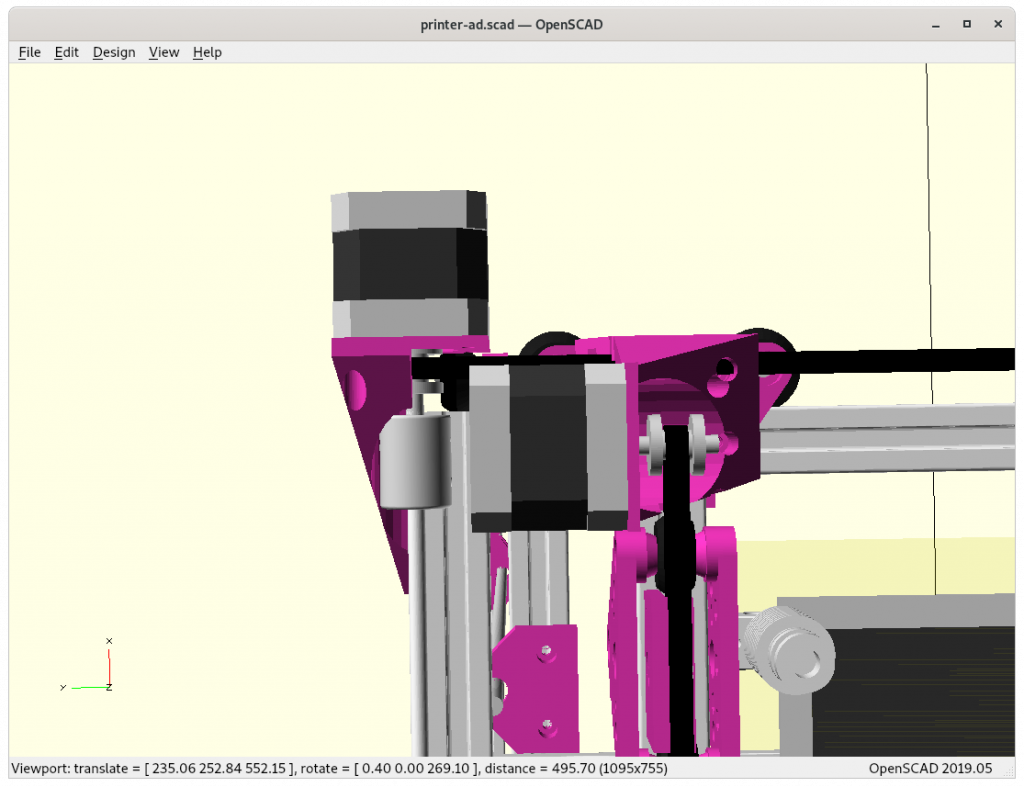

Y Motor Mount

At Y = max + Y margin (beyond print bed, but not yet touching anything else):

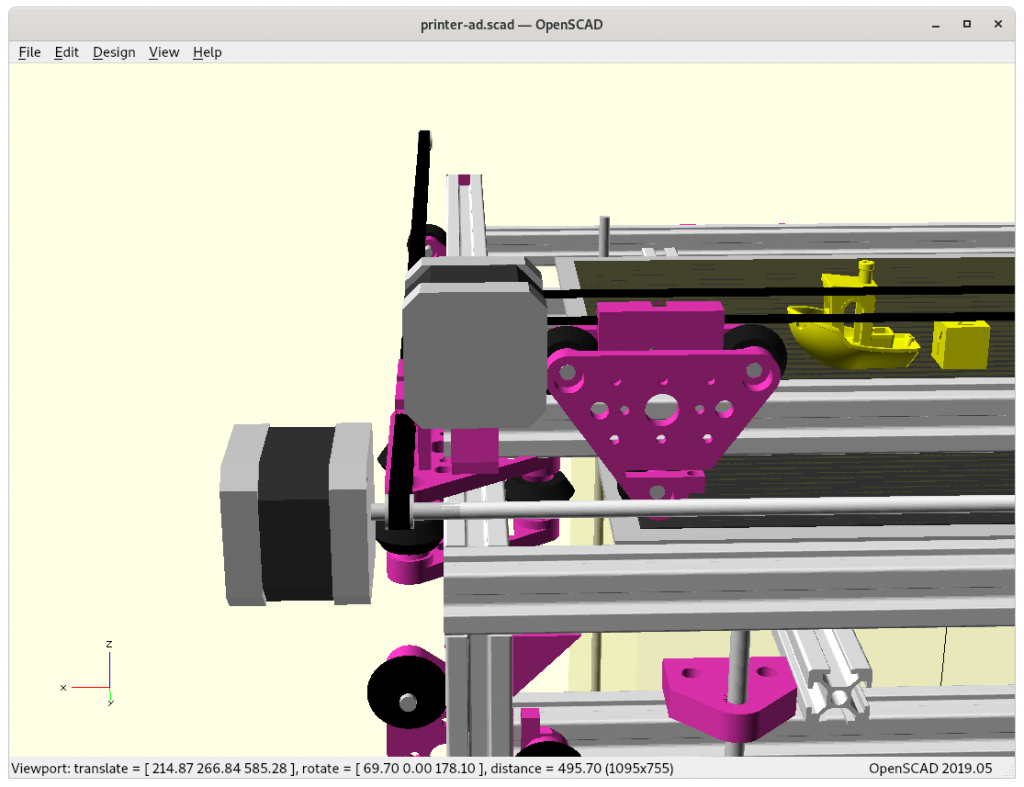

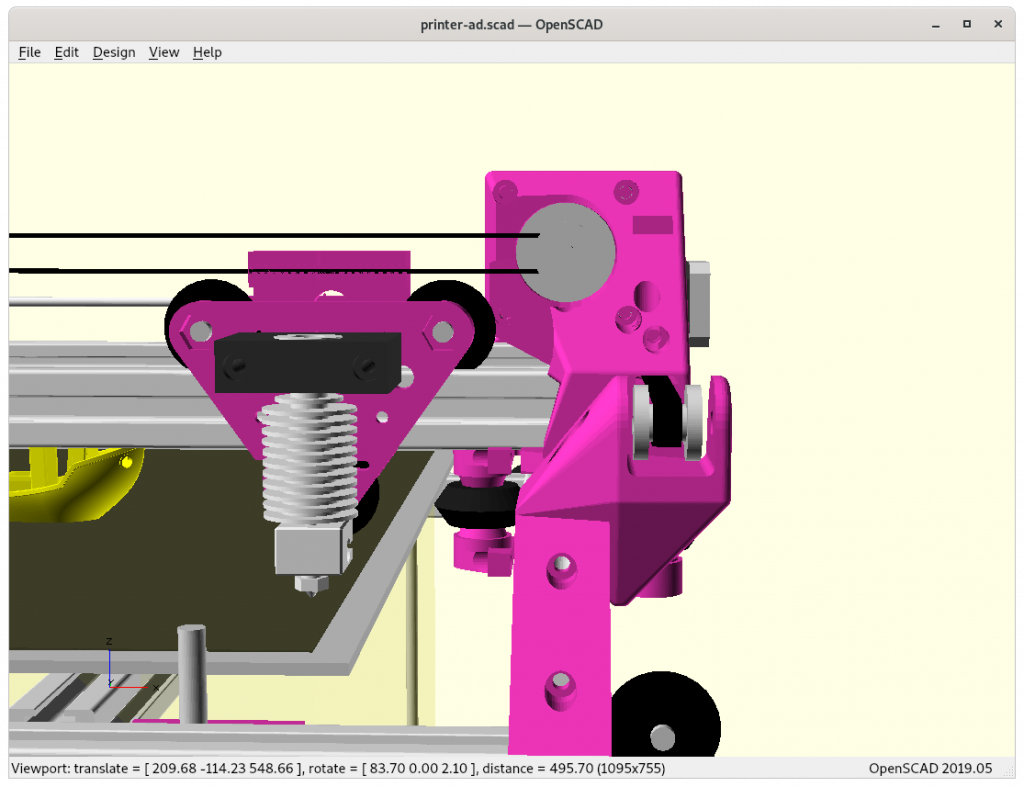

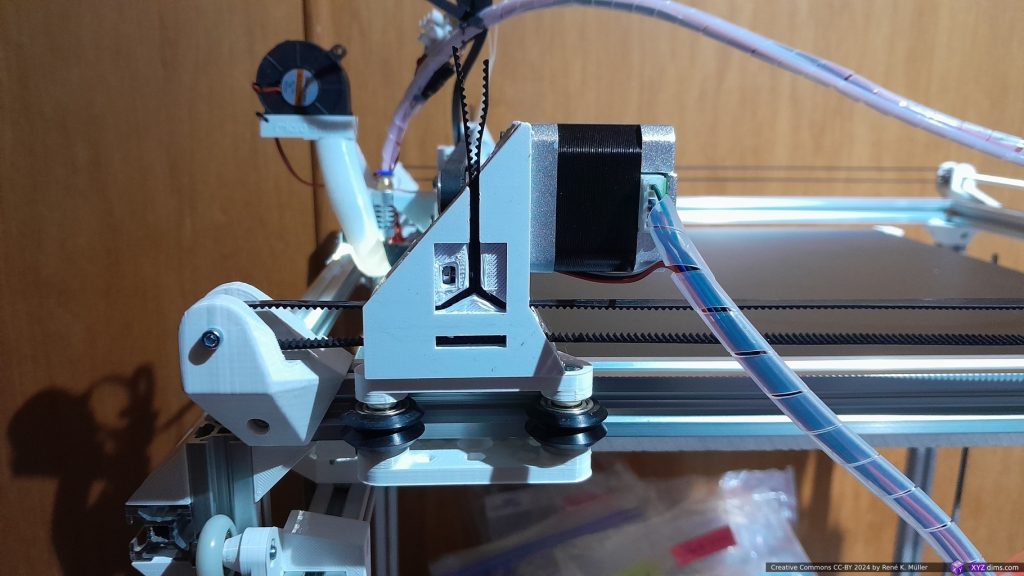

X Motor Mount

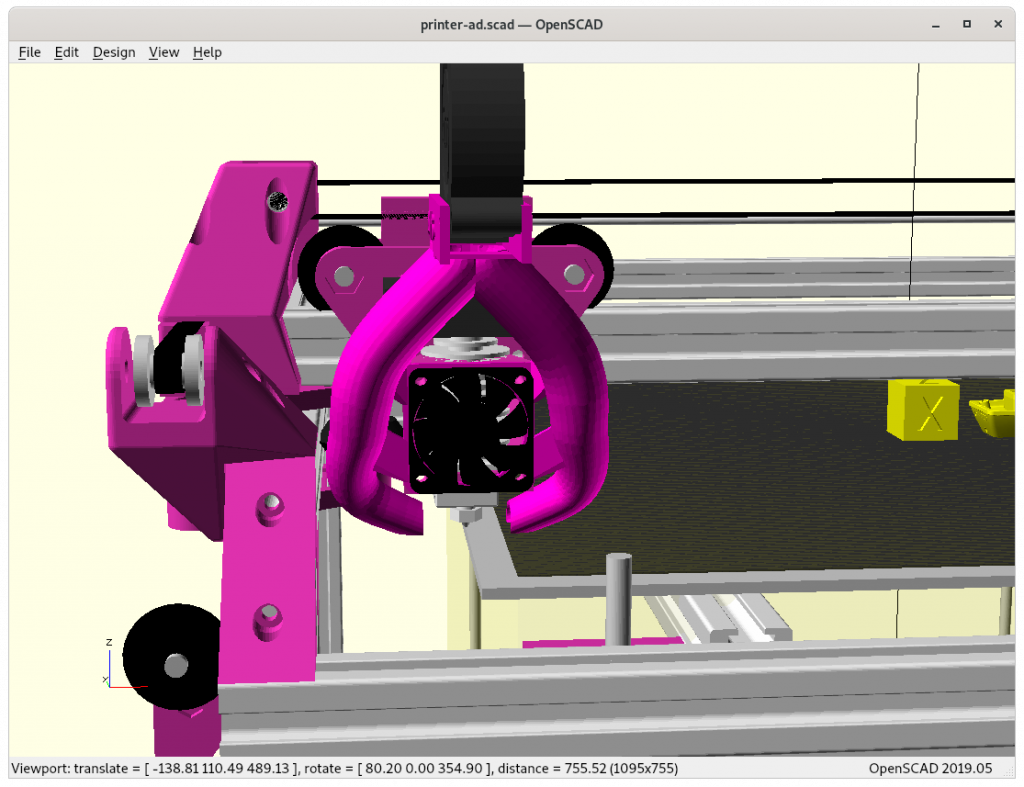

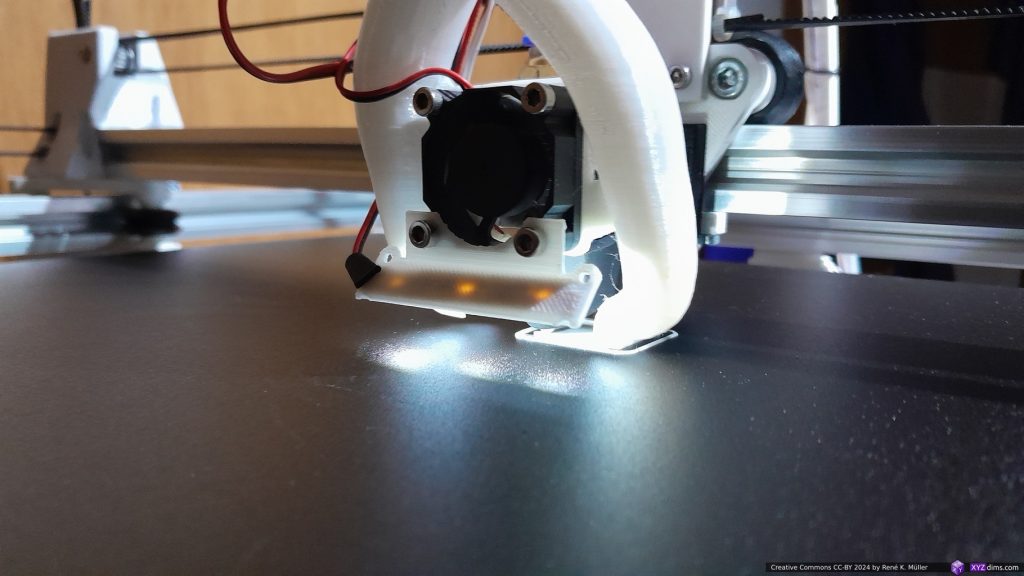

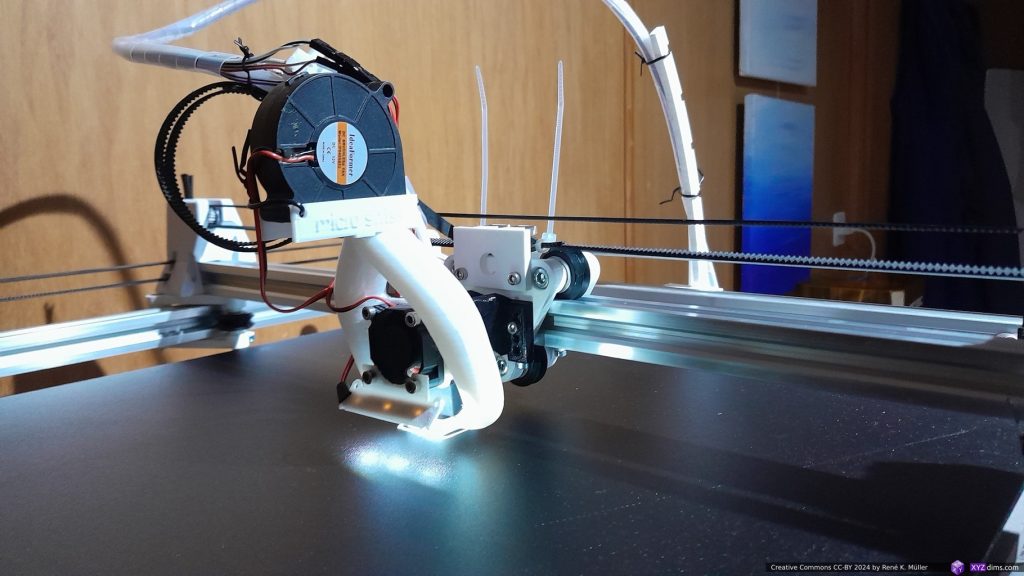

Exploring the X & Y minimum, how X carriage can as close as possible with the part cooler attached:

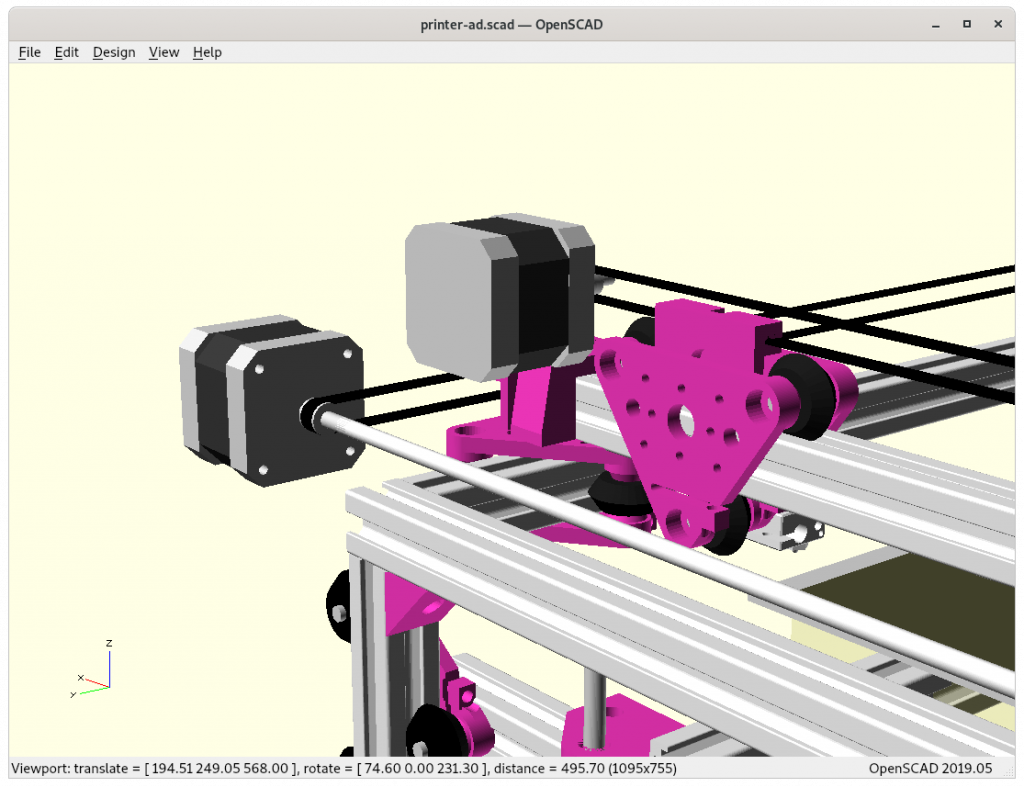

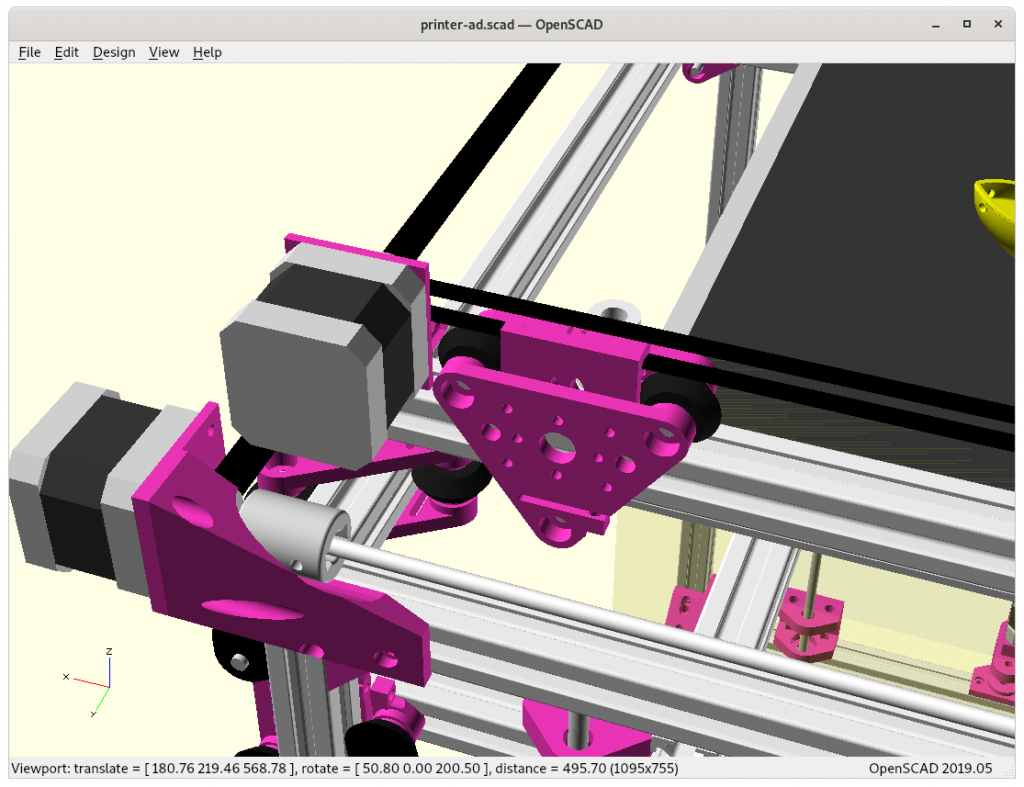

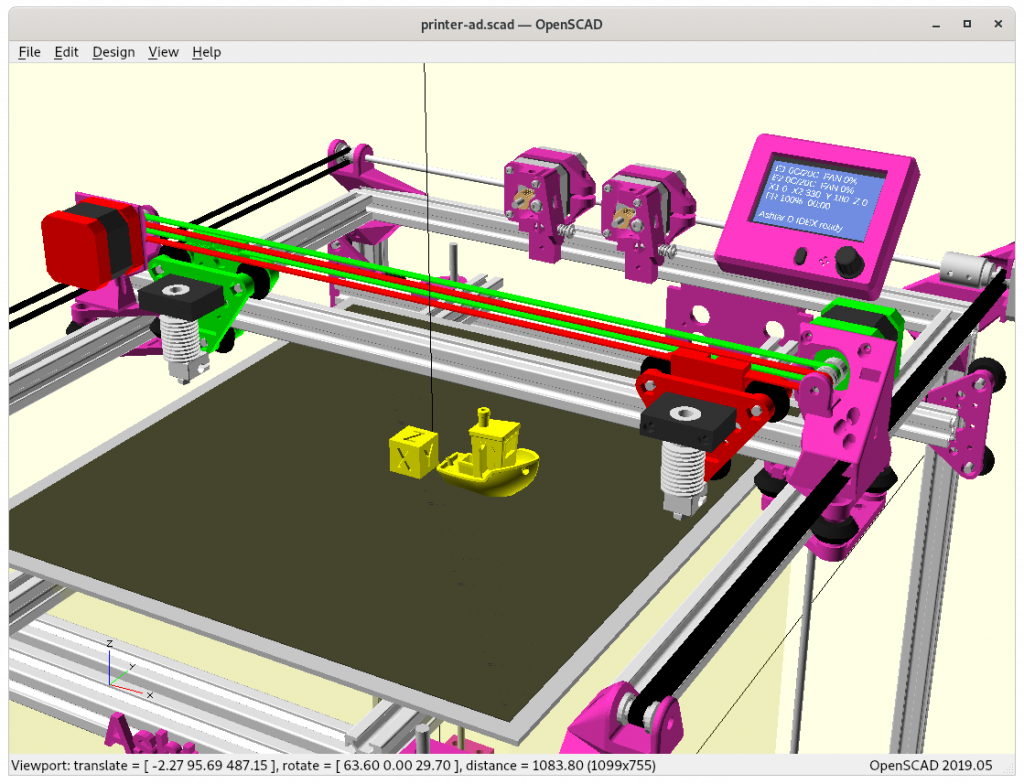

X & Y Motors / Axis

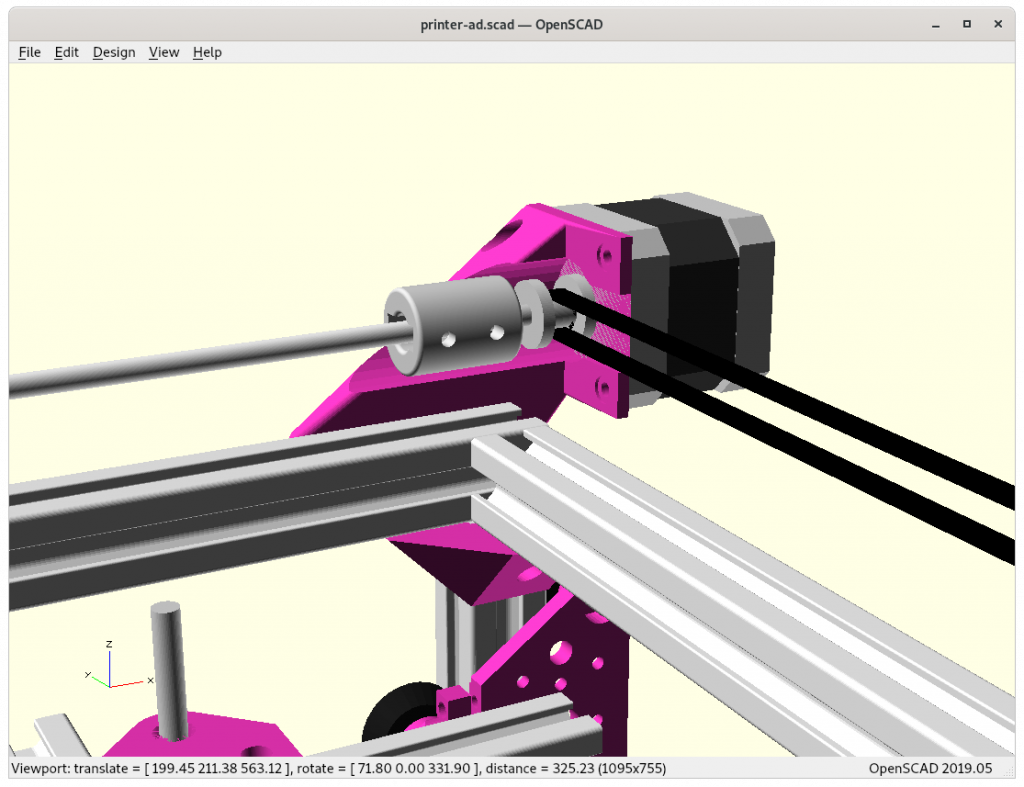

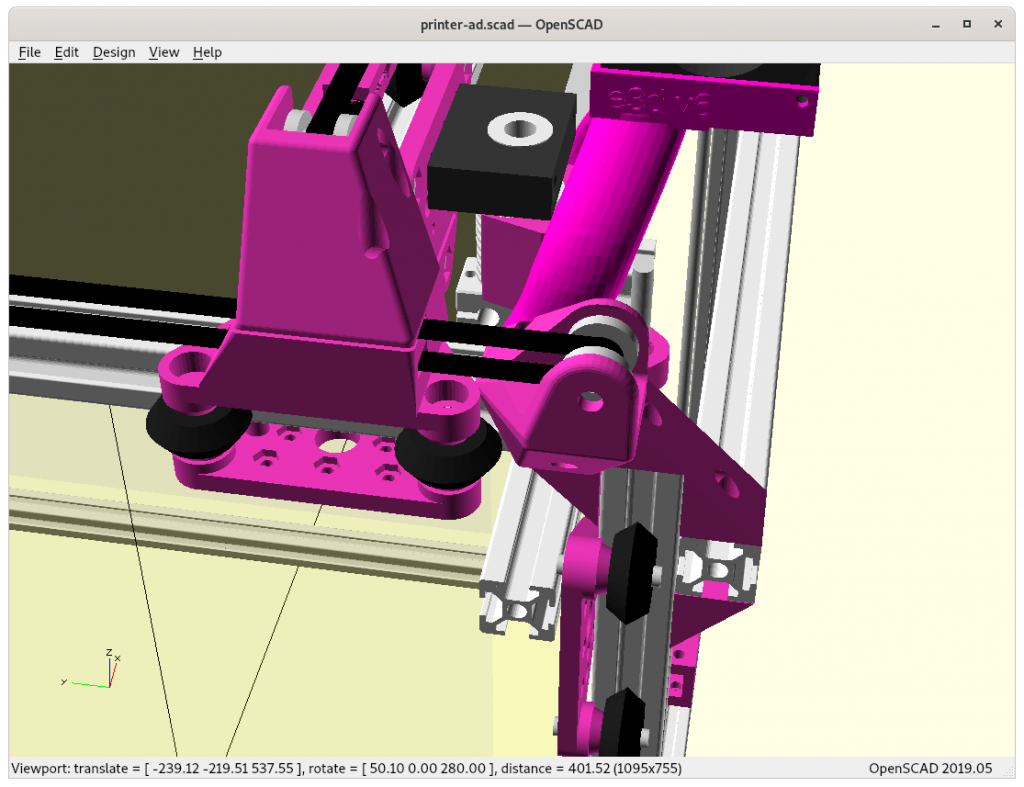

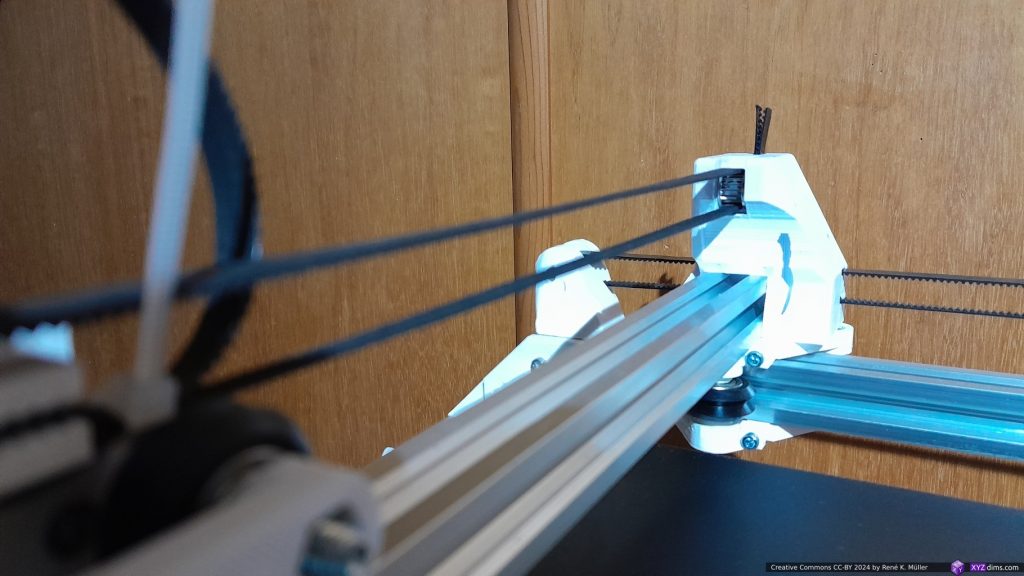

Y motor mount and shaft extender and Y pulley

Specifications

- Build Volume: ~380 x 400 x 380mm (not yet finalized)

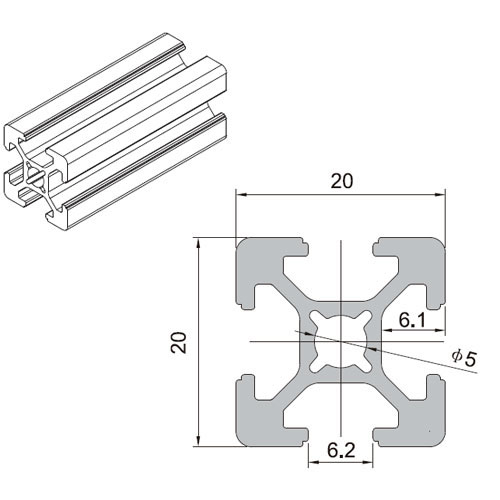

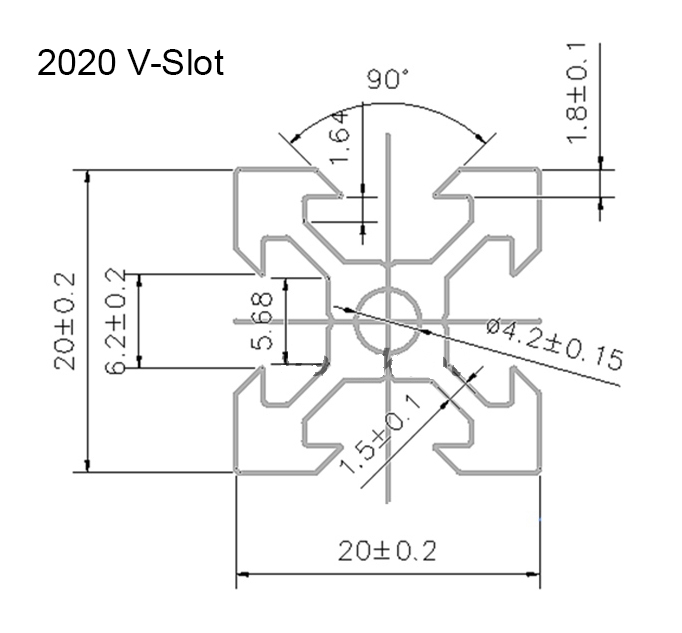

- Frame: 17x 500mm 2020 alu profiles

- 14x 500mm 2020 T-slot alu profiles

- 3x 500mm 2020 V-slot alu profiles

T-Slot 2020

V-Slot 2020

V wheel

Issues to Resolve

mounting X motor, resolvedmounting X pulleys, done

mounting Y motor, resolvedmounting Y pulleys, done- using

M6 orM5 smooth or threaded rod to extend Y motor shaft

Y belt mount to carriage, done- positioning: extruders, controller, power-supply (like Ashtar C)

- positioning: X, Y and Z end-switches

- tuning toward 400x400x400mm build volume with 500mm 2020 alu profiles

- build printer

- print tests

- release parts

- release code

Gallery

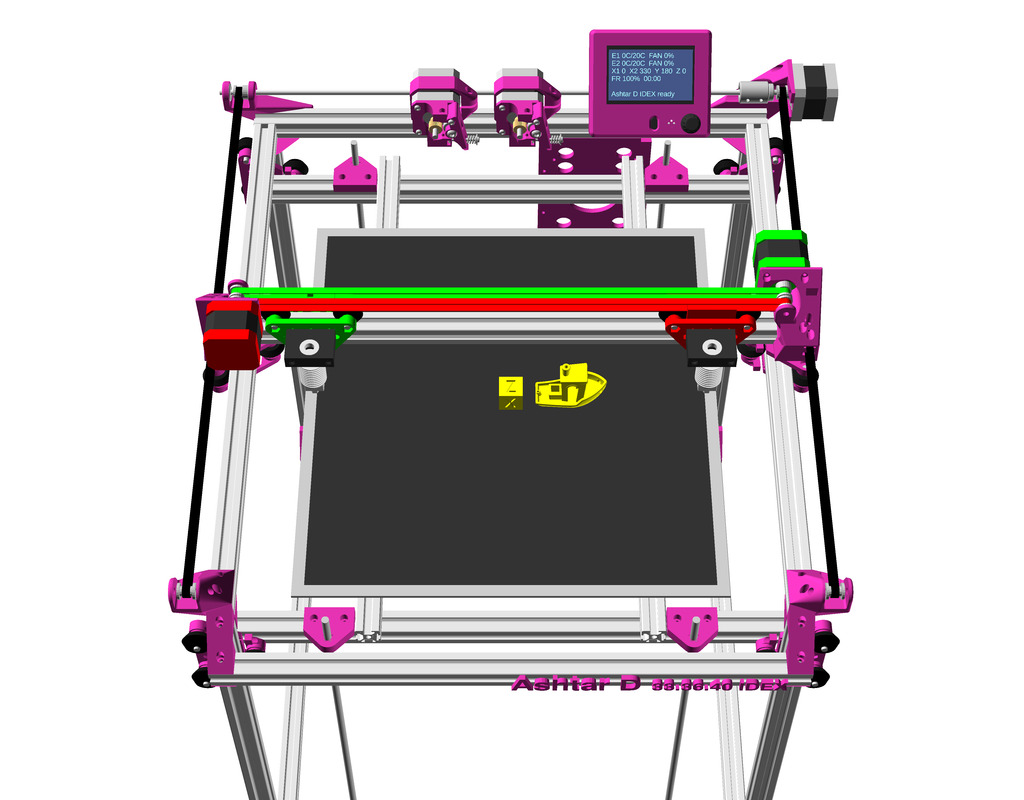

Classic XY vs Core XY

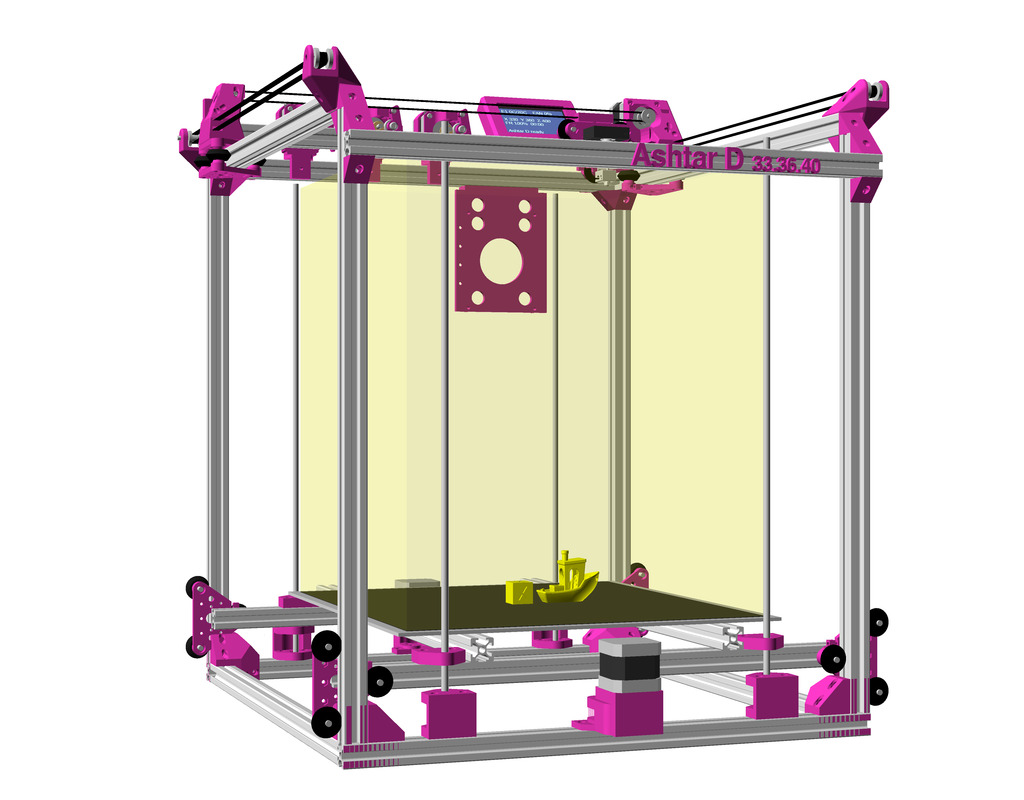

Compared to Ashtar C Core XY the Ashtar D is less elegant, more complex parts but better setup using the rather thin 2020 alu profiles for such a big build volume.

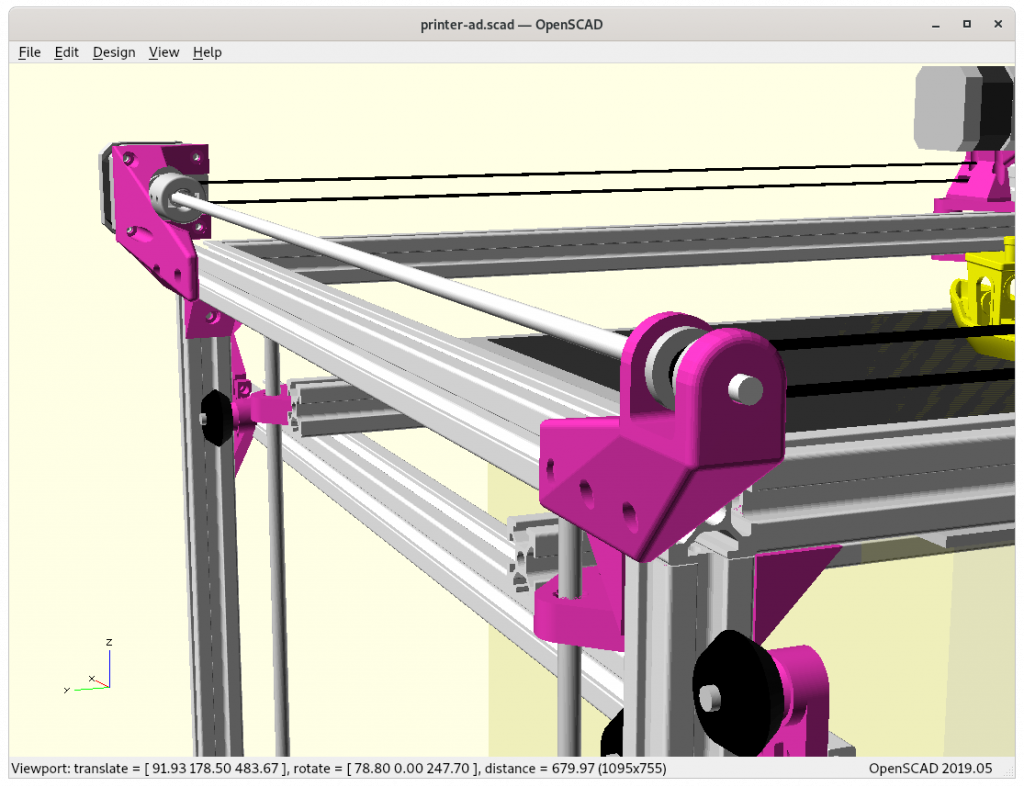

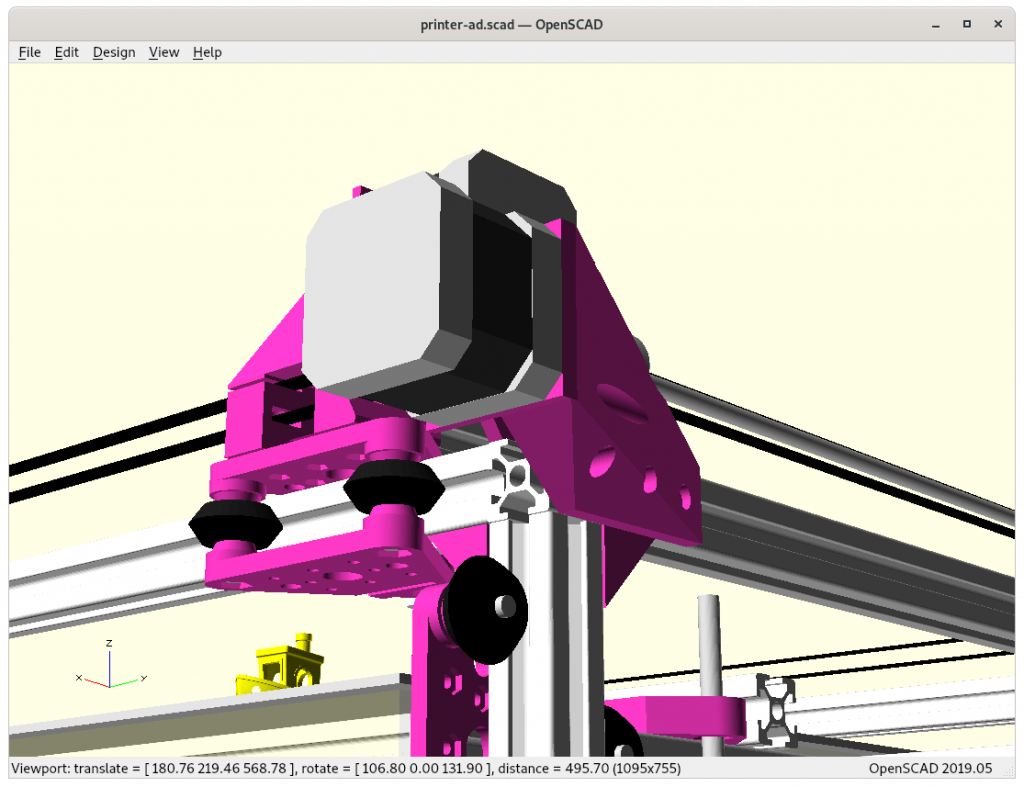

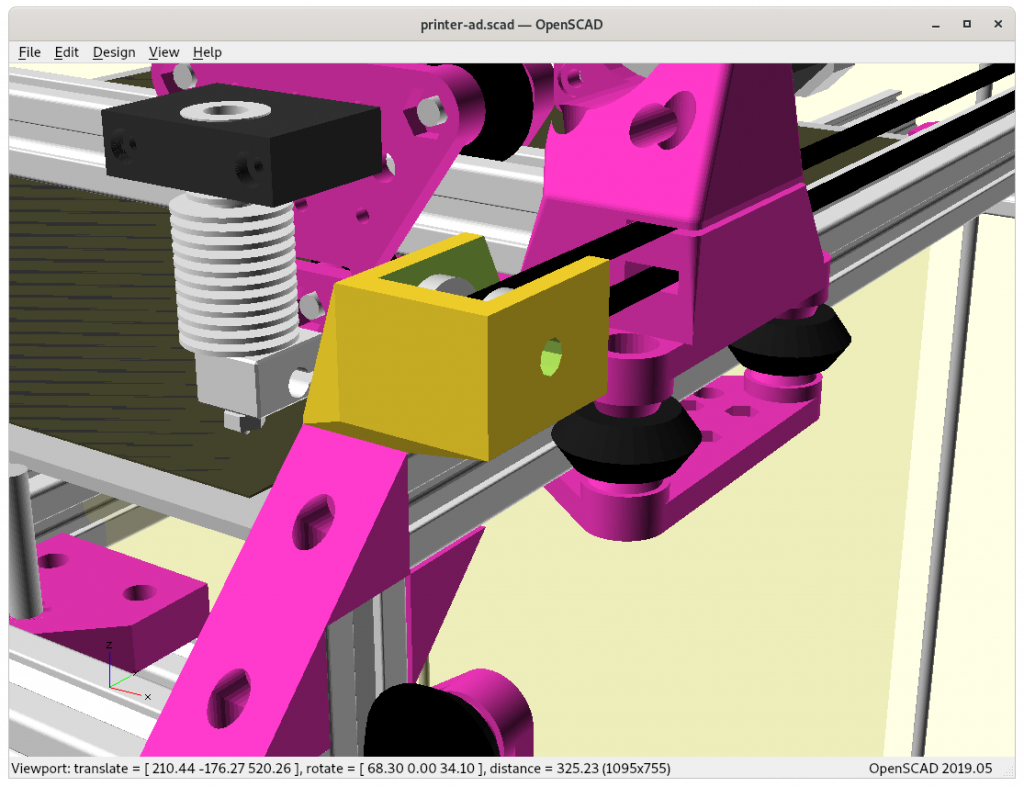

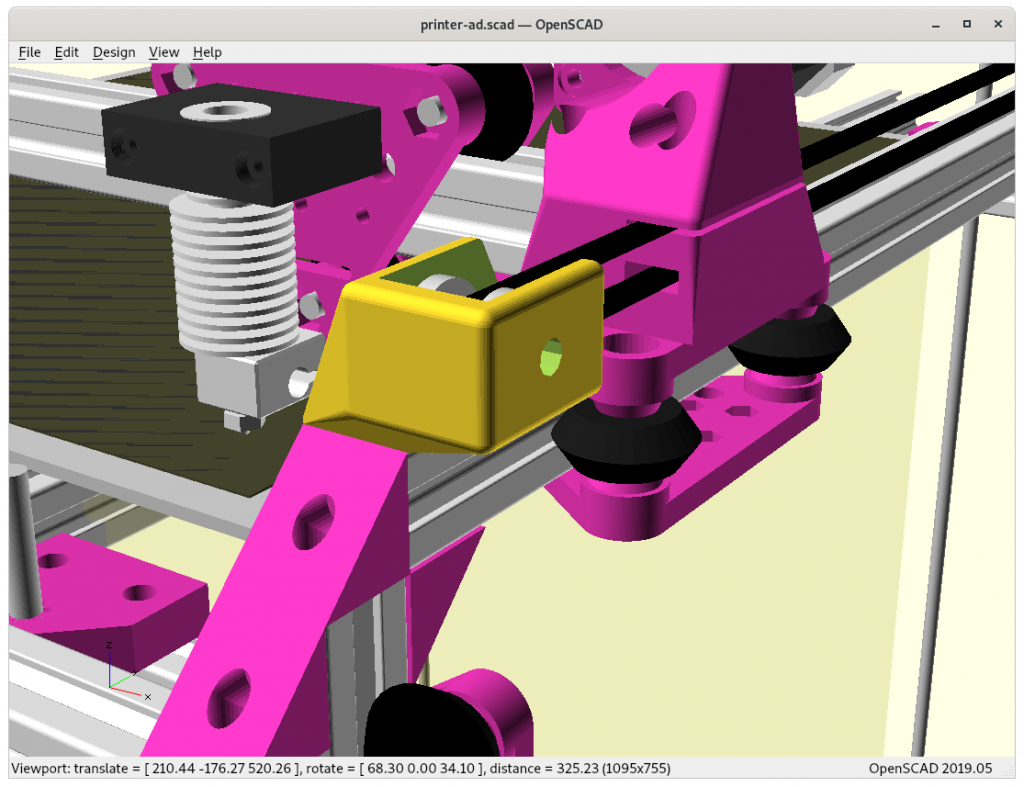

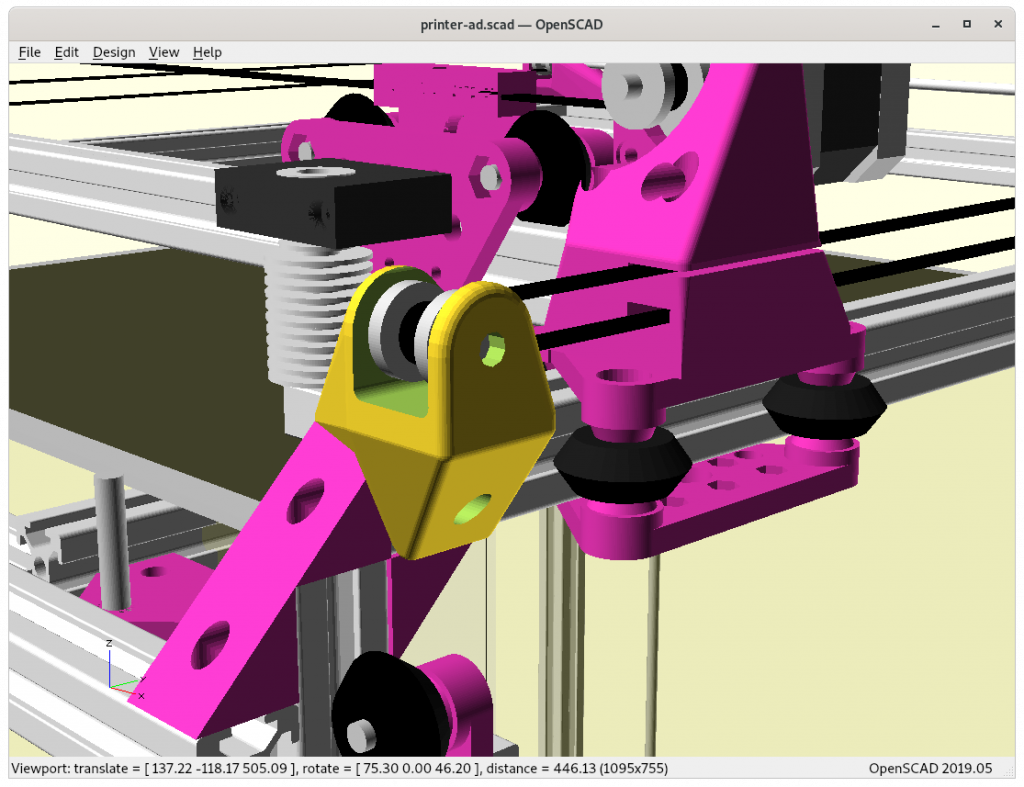

Sharp vs Rounded Edges

The round edges are achieved by replacing cube([x,y,z]) with rcube([x,y,z],r) and in conjunction with chainhull() { } the round edges propagate. Actual prints will show if any drawbacks appear, e.g. it introduces some small overhangs, but they might be disregarded at small radiuses/radii.

Toward Elegance

cube()

rcube()

cylinder() & cube()

rcylinder() & rcube()

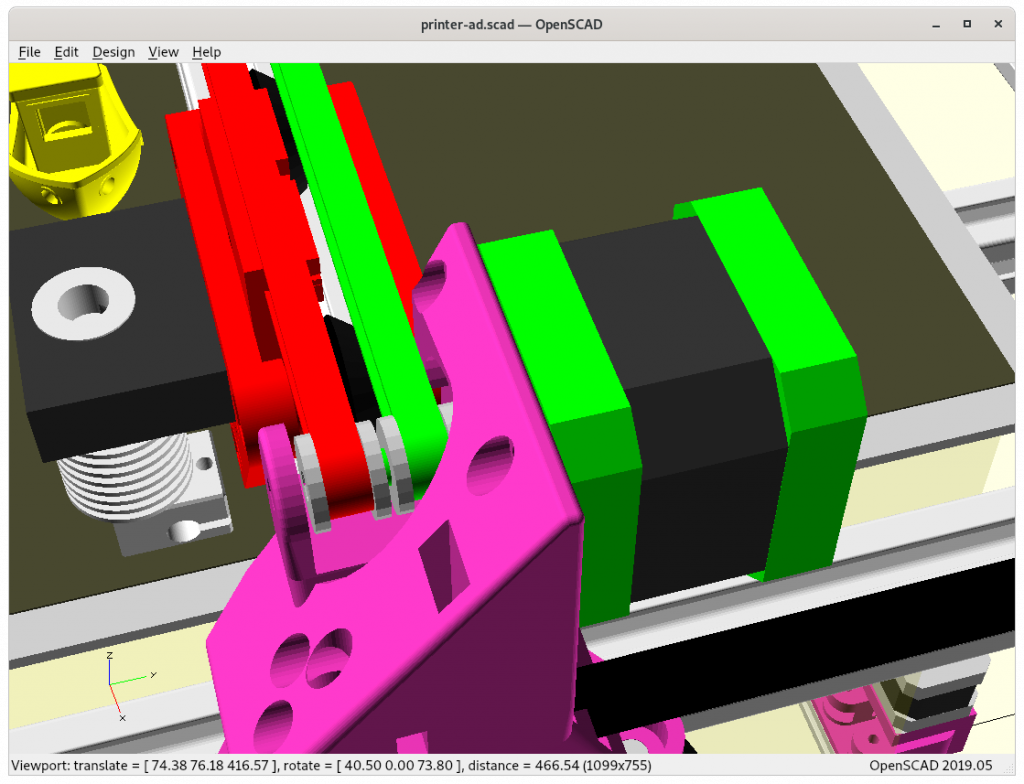

rcylinder() and rcube()IDEX Option

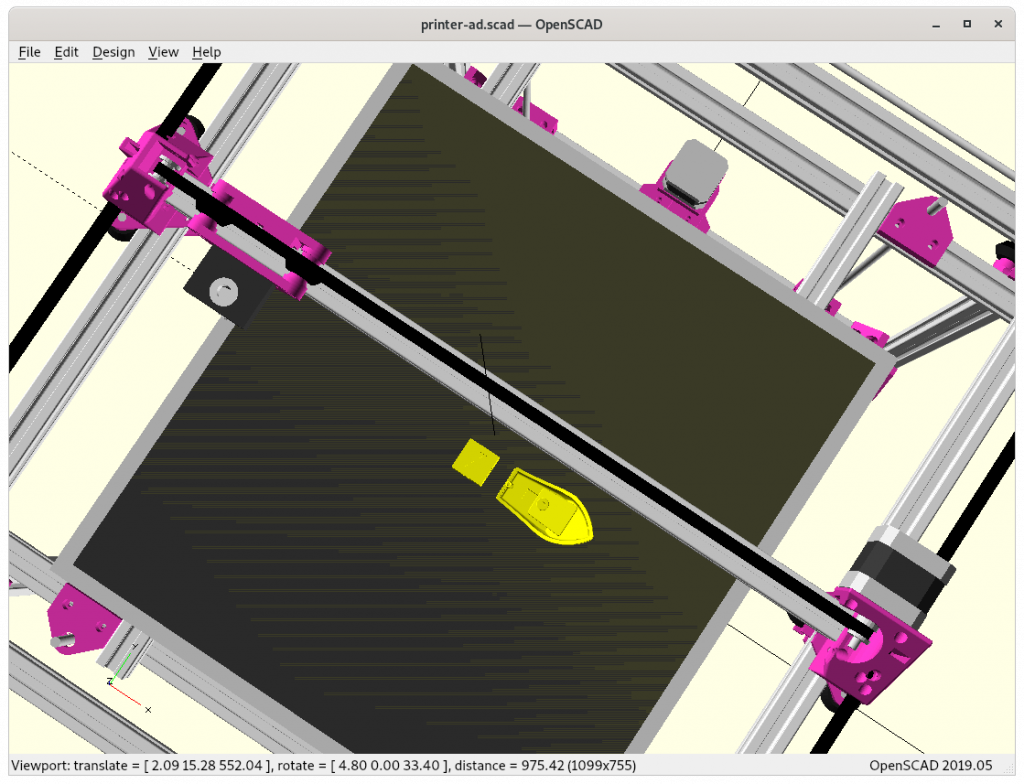

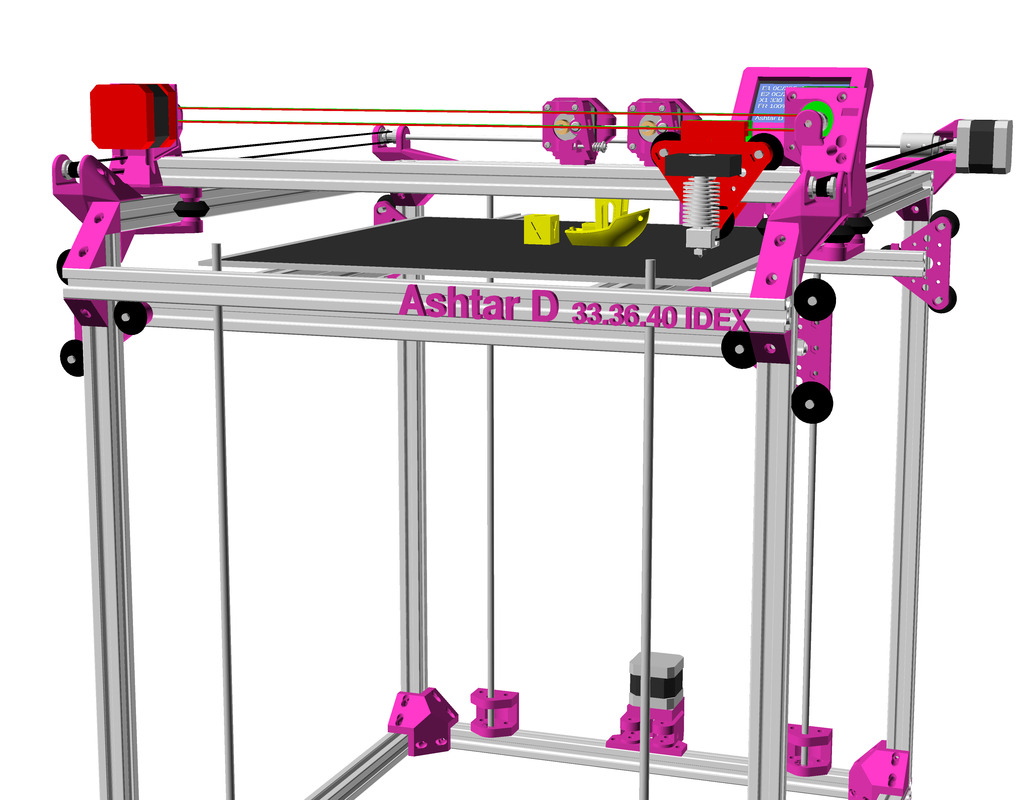

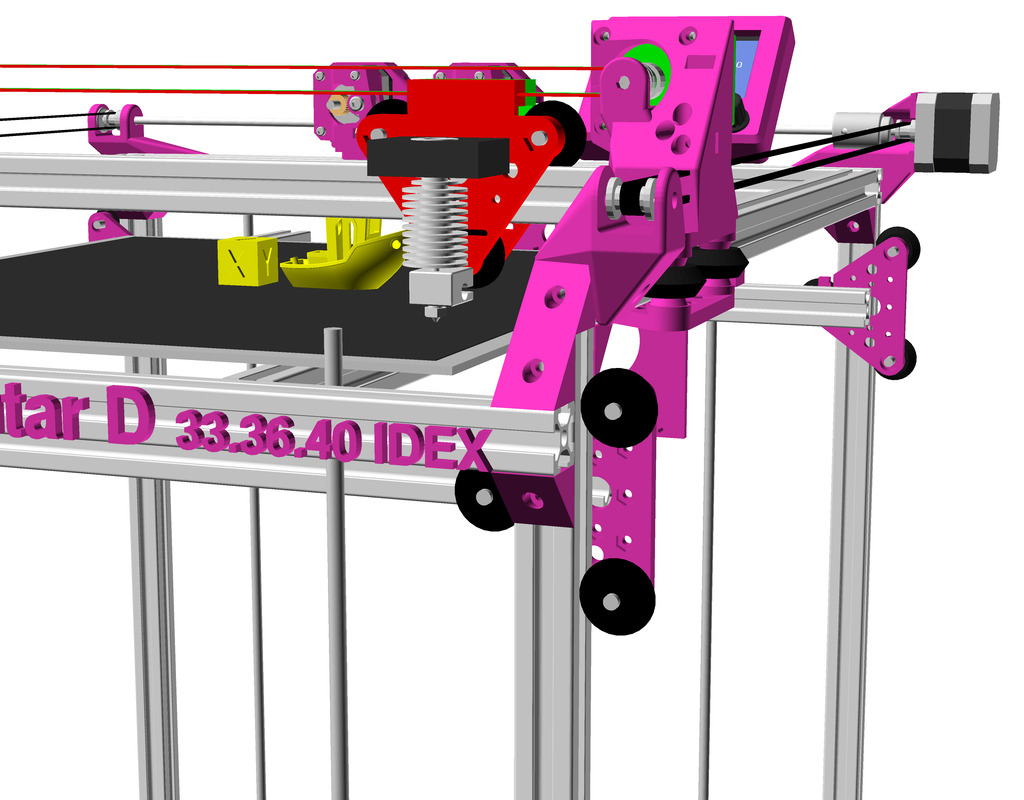

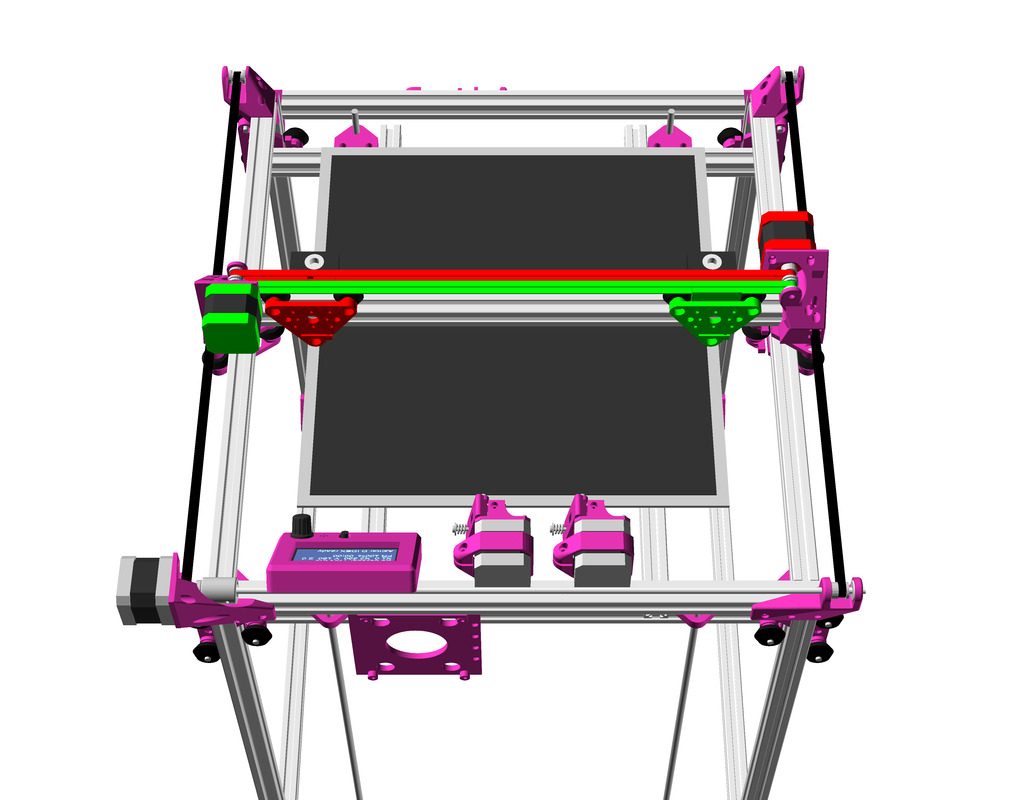

In order to provide Dual Independent Extrusion (IDEX) a 2nd belt and motor is required, yet, the Y carriage is quite delicate in this current setup but after some pondering I think I came up with an elegant solution: the main idea is to utilize the NEMA 17 shaft as axis for 2nd belt idler:

and then rotate the same Y carriage on the other side:

Since the entire Ashtar D design is still just a draft, this IDEX setup is also very experimental in nature and only actual build will tell if it’s feasible.

Gallery

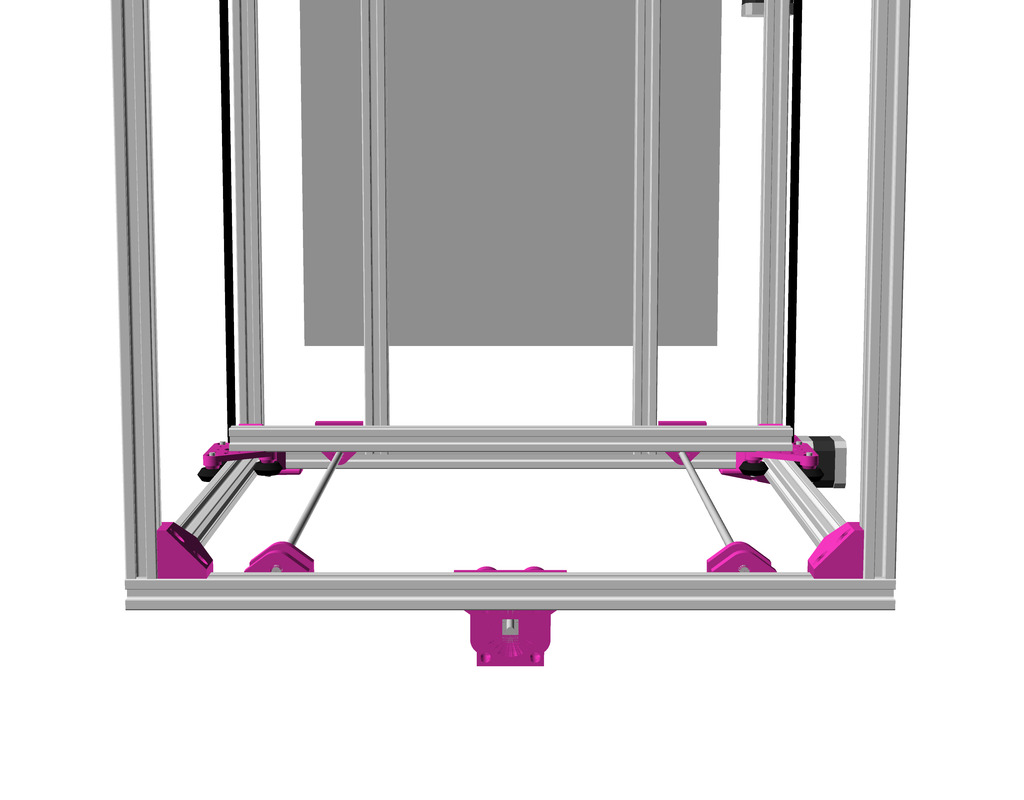

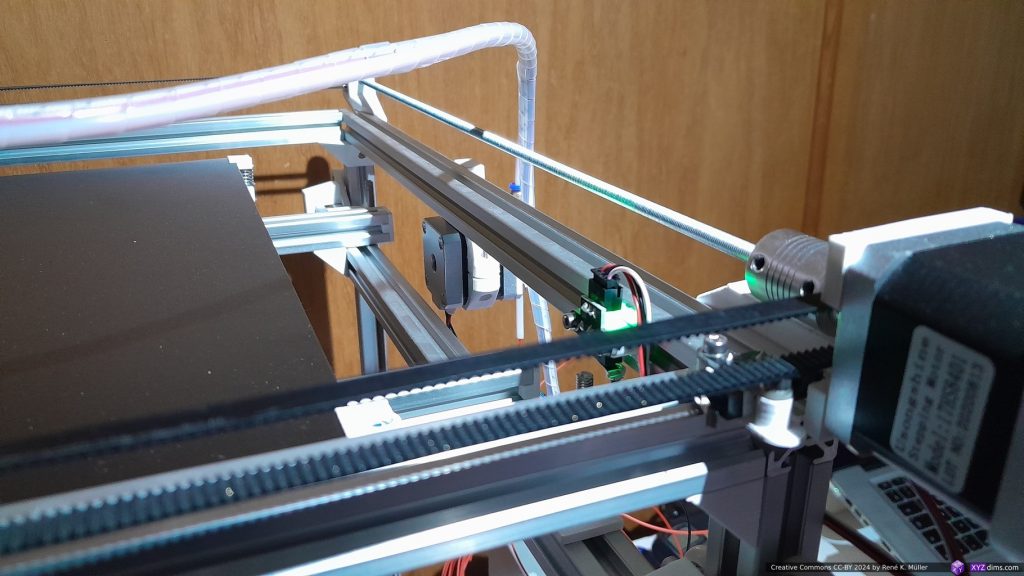

Z Axis & Motors

It has been tested successfully with Ashtar C, so I use the same setup again:

Parts

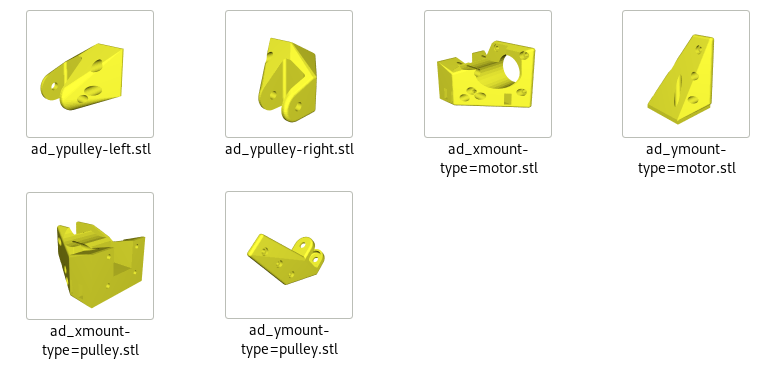

Printable Parts

- 1x

ad_xmount-type=motor - 1x

ad_xmount-type=pulley - 1x

ad_ymount-type=motor - 1x

ad_ymount-type=pulley - 1x

ad_ypulley-left - 1x

ad_ypulley-right

Note: the new parts aren’t released yet until I used them in a test setup.

Non-Printable Parts

- 2x 625ZZ bearings ID=5mm

- 2x for 1x

ad_ymount-type=pulley

- 2x for 1x

- 12x 629ZZ bearings ID=6mm

- 8x for 4x Z thread holder (2x bottom)

- 4x for 4x Z thread holder (top)

- nx pulleys (dimension not yet determined)

- 2x (5mm hole) for 2x Z motors

- 1x (5mm hole) for 1x X motor

- 2x (5mm hole) for 1x Y motor, 1x

ad_ymount-type=pulley - 4x (6mm hole) for Z threaded rods

- nx idlers (with 3 or 5mm hole)

- 2x (3mm hole) for 1x

ad_ypulley-left, 1xad_ypulley-right

- 2x (3mm hole) for 1x

- ~520 mm M5 smooth or threaded rod (Y shaft extension)

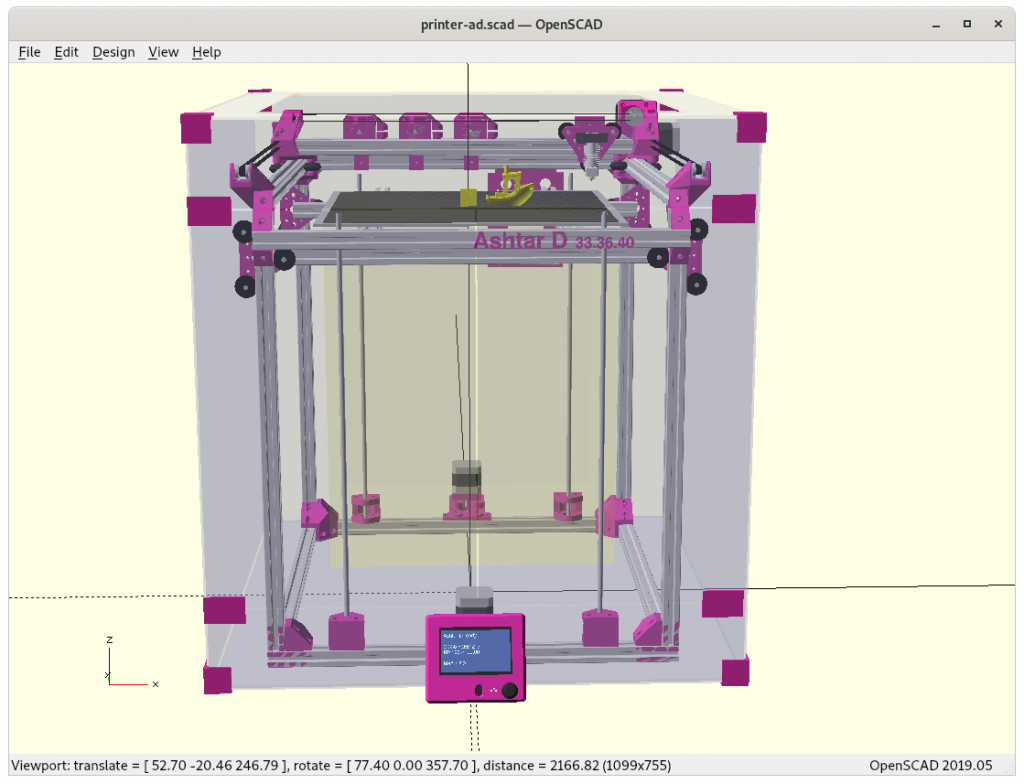

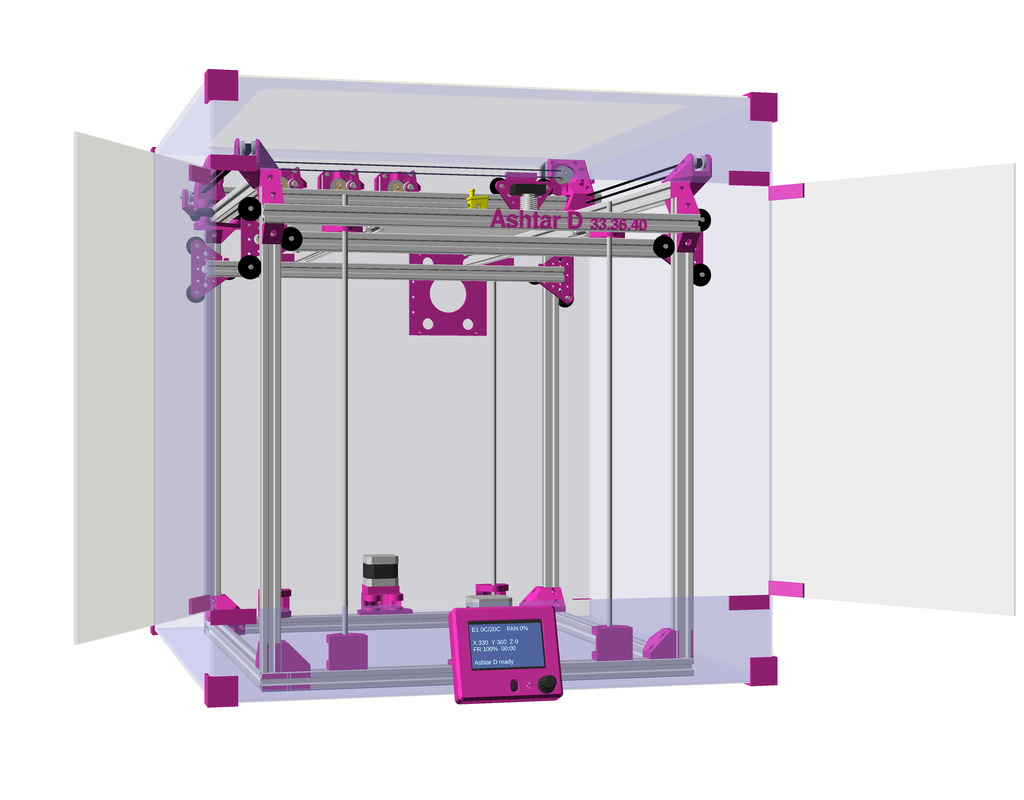

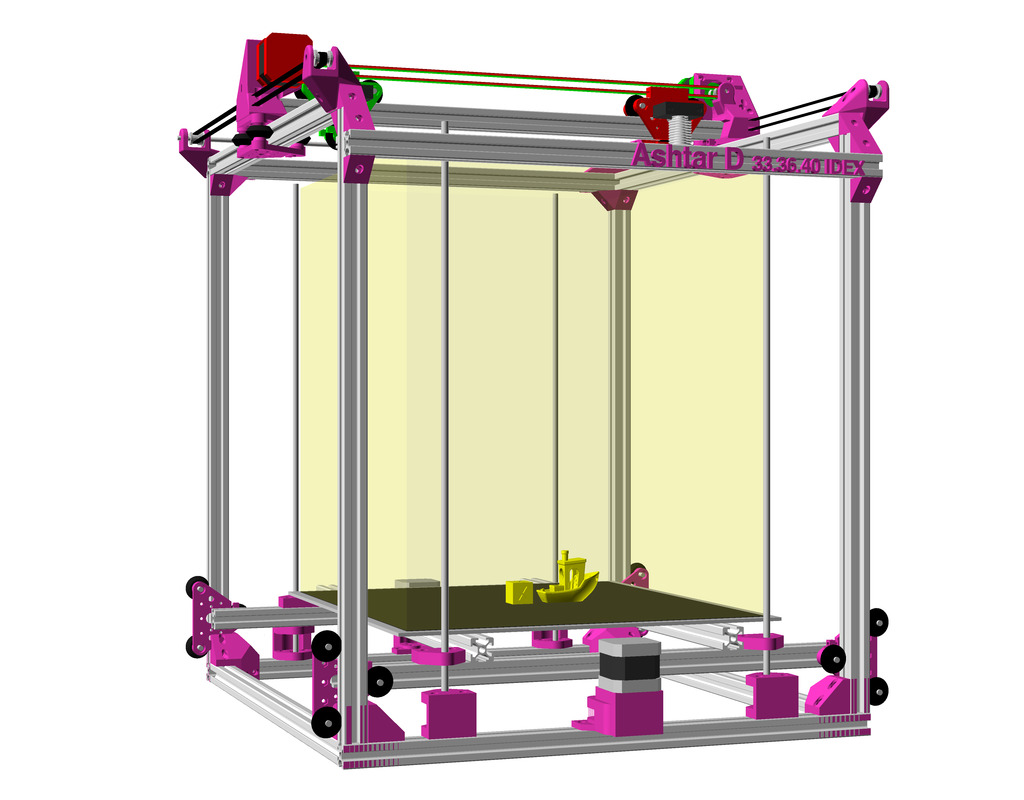

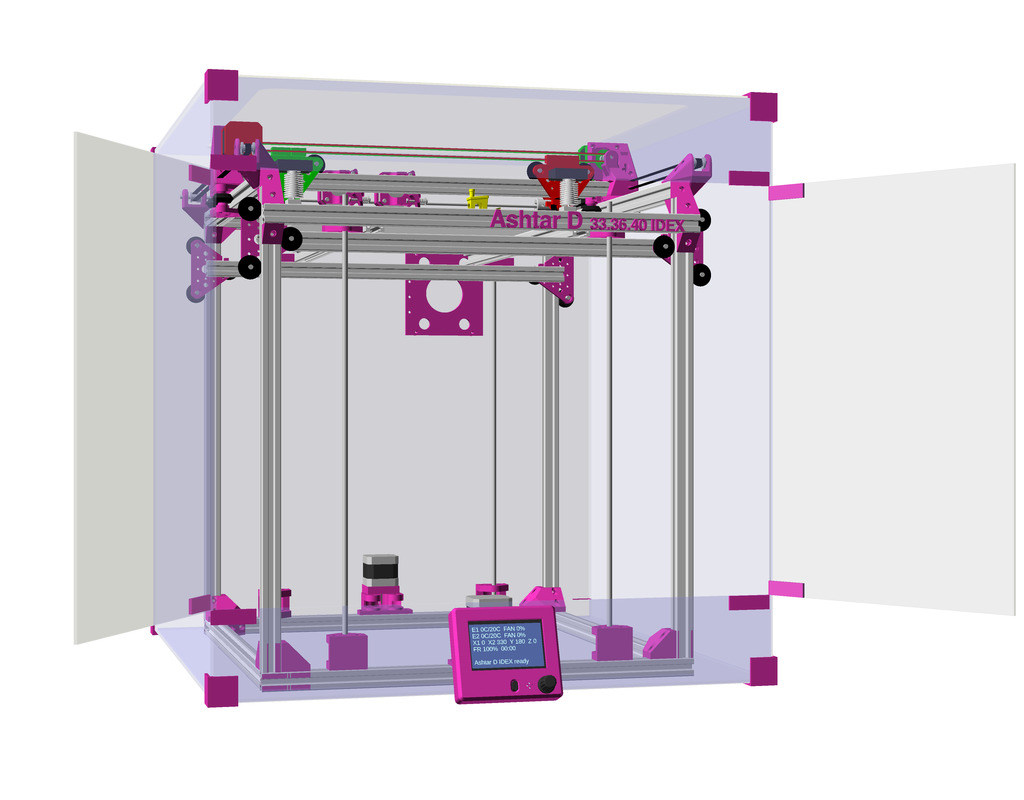

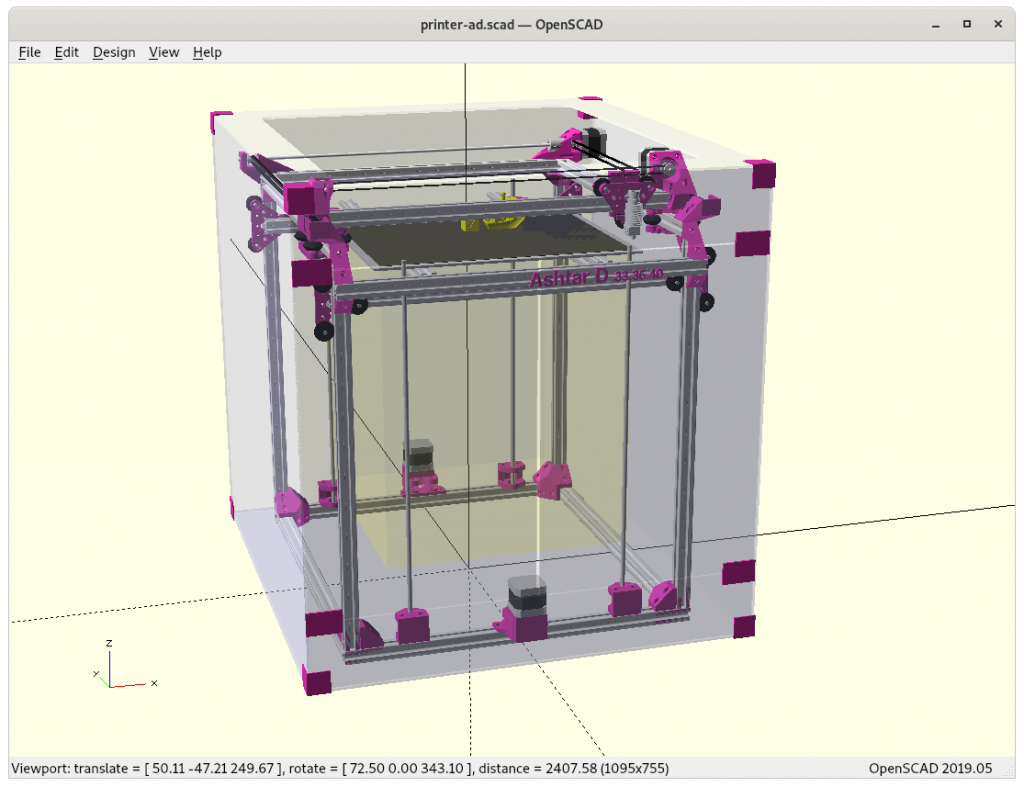

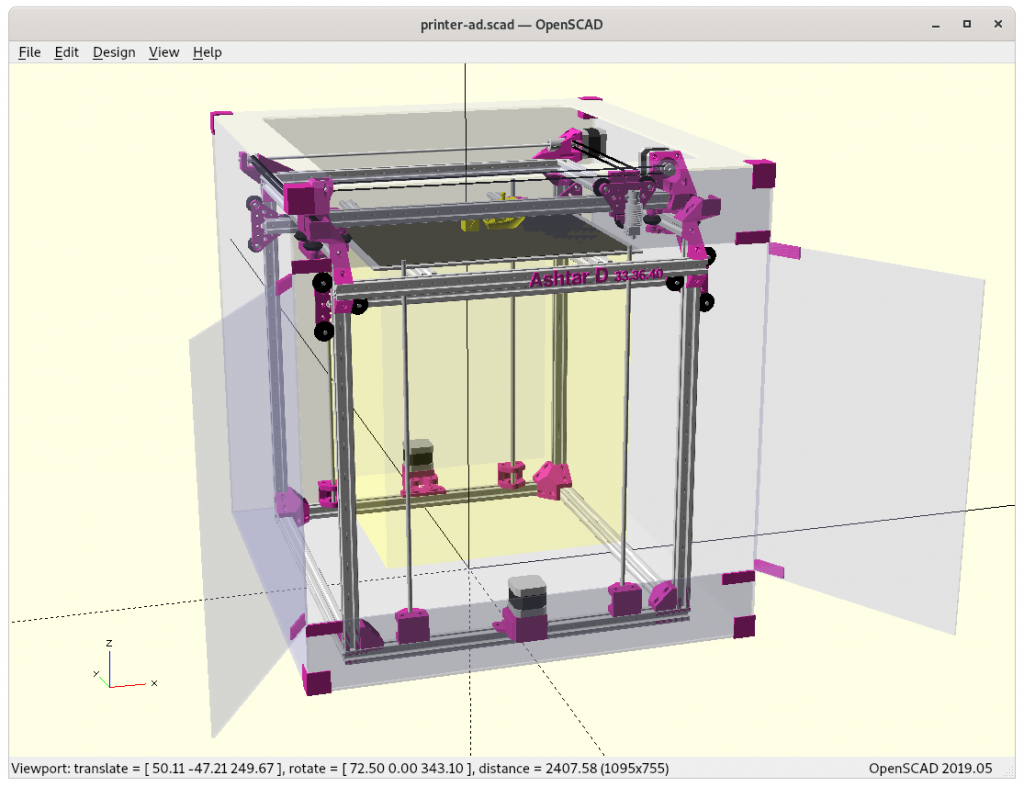

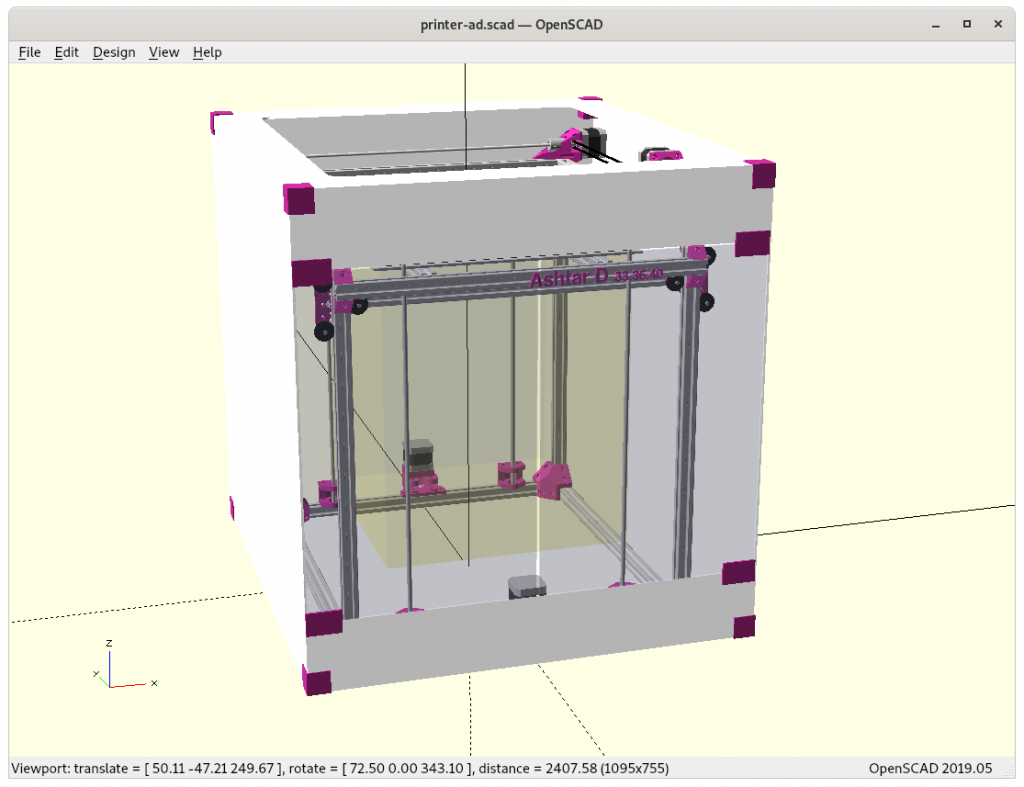

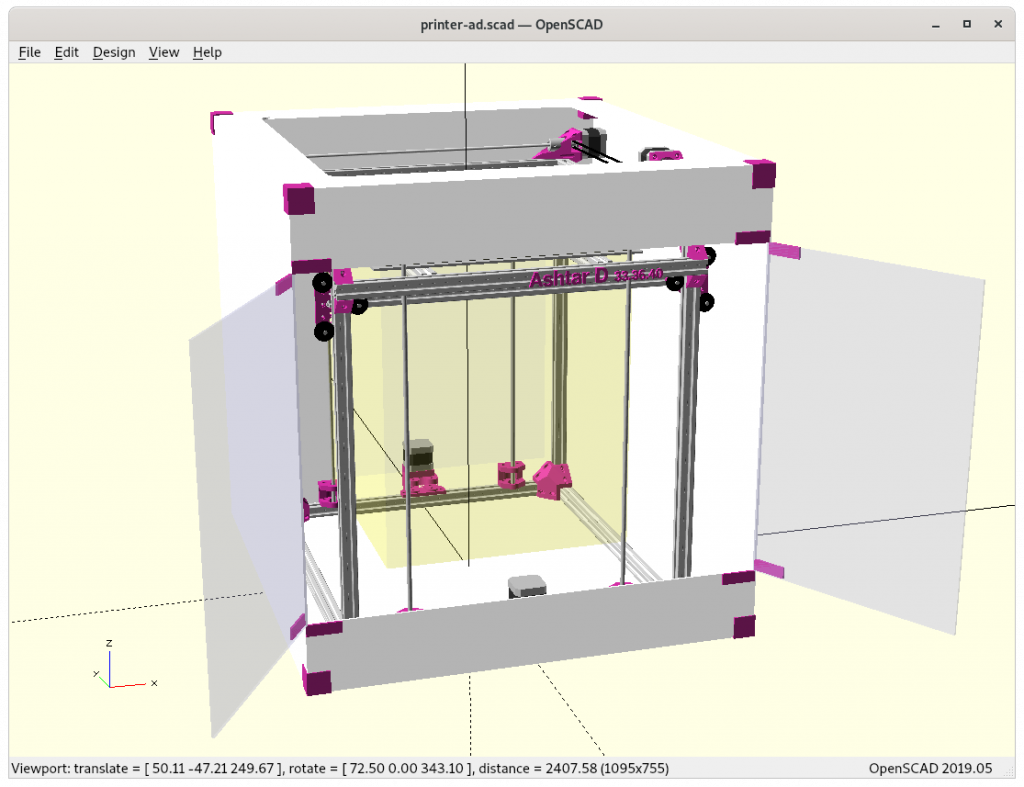

Enclosure

Developing some enclosure, either attach to the Z beams – as one side is free to fasten pieces and use acrylic sheets – or enclose entire frame, like with

- Printer Enclosure, parametric enclosure, 2.5mm thick acrylic

or doing my own approach, something like this:

With the enclosure the display must be reachable, and therefore likely be on the front and longer wires from the controller board, which most likely resides on the back right side as with Ashtar C.

Ashtar D (Classic XY)

- Build Volume: 380 x 400 x 380mm (57.7Kcm3 / 57.7L) = 100%

- Device Dimension: 590 x 650 x 620mm (237Kcm3 / 237L)

- Build vs Device Volume: 4.11

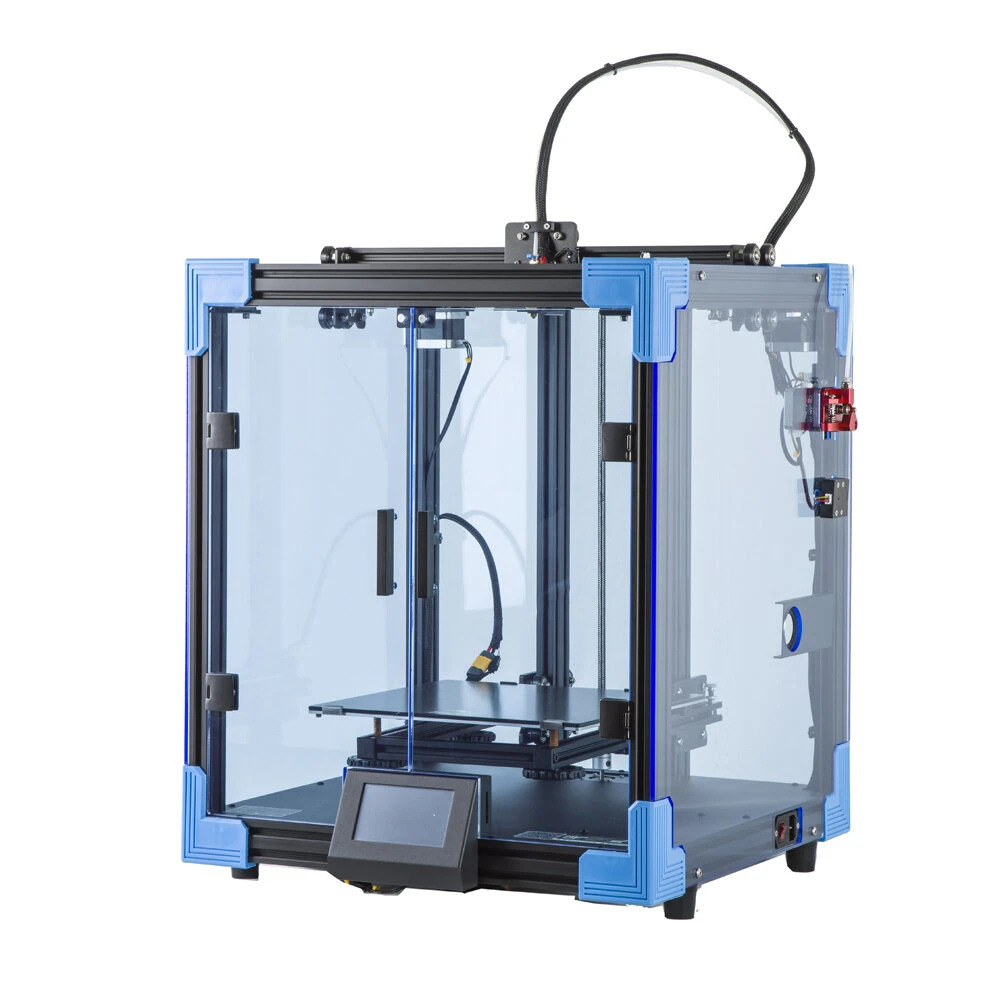

Creality CR5

- Build Volume: 300 x 225 x 380mm (25.6Kcm3 / 25.6L) = 44%

- Device Dimension: 530 x 487 x 621mm (160Kcm3 / 160L)

- Build vs Device Volume: 6.25

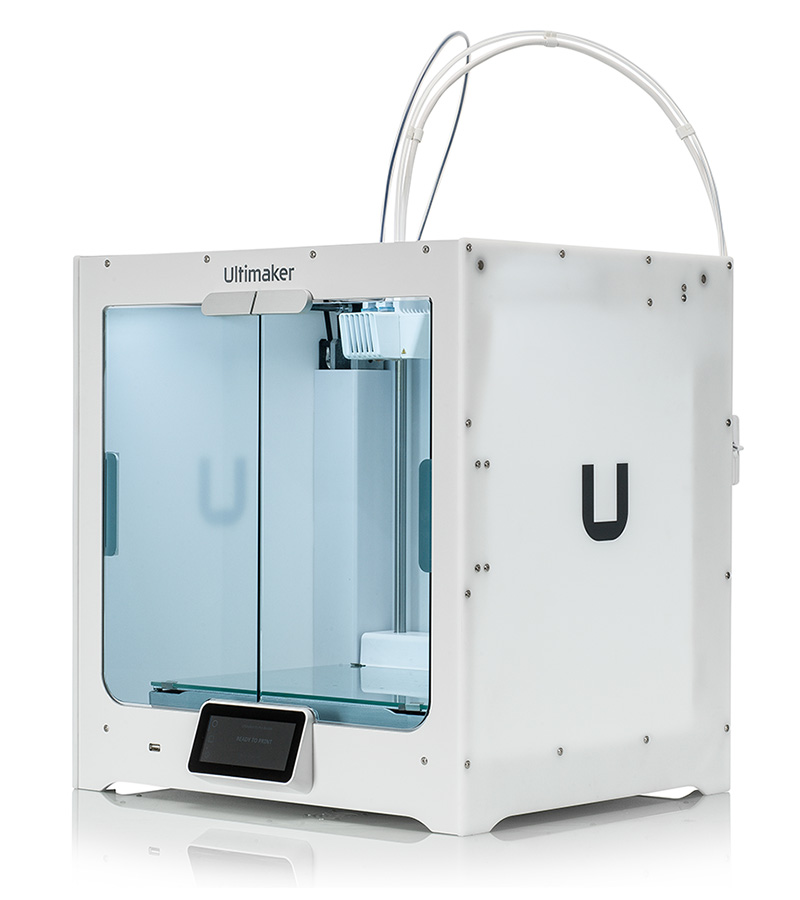

Ultimaker S5

- Build Volume: 320 x 240 x 300mm (23.0Kcm3 / 23L) = 40%

- Device Dimension: 495 x 585 x 780mm (225Kcm3 / 225L)

- Build vs Device Volume: 9.78

Creality Ender 6

- Build Volume: 250 x 250 x 400mm (25.0kcm3 / 25L) = 43%

- Device Dimension: 495 x 495 x 650mm (159Kcm3 / 159L)

- Build vs Device Volume: 6.36

Ashtar D and Ultimaker S5 device volumes are nearly the same, 237Kcm3 vs 225Kcm3, but Ashtar D would print more than the double of the volume – so it would be volume-wise more efficient. Creality CR5 and Creality Ender 6 are more volume efficient than the Ultimaker S5, but not as good Ashtar D. Let’s see if I can keep this advantage for the final implementation.

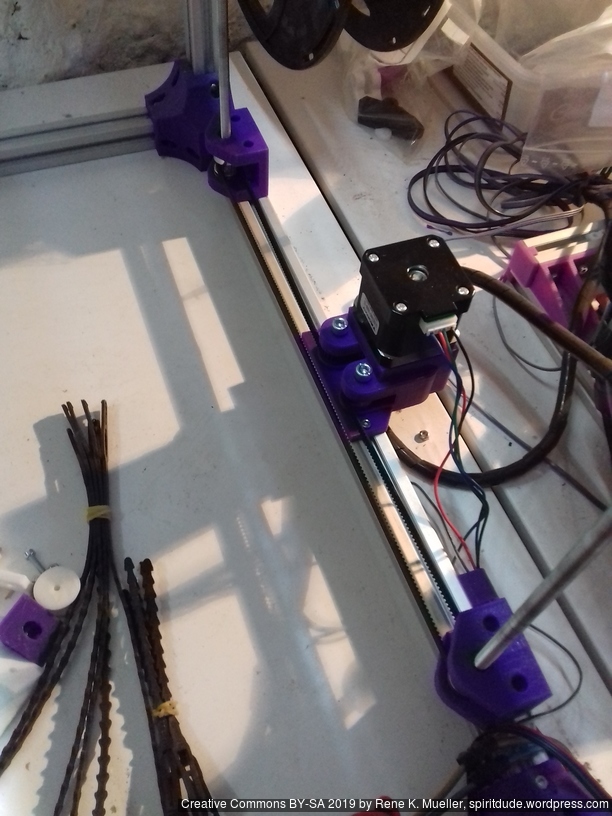

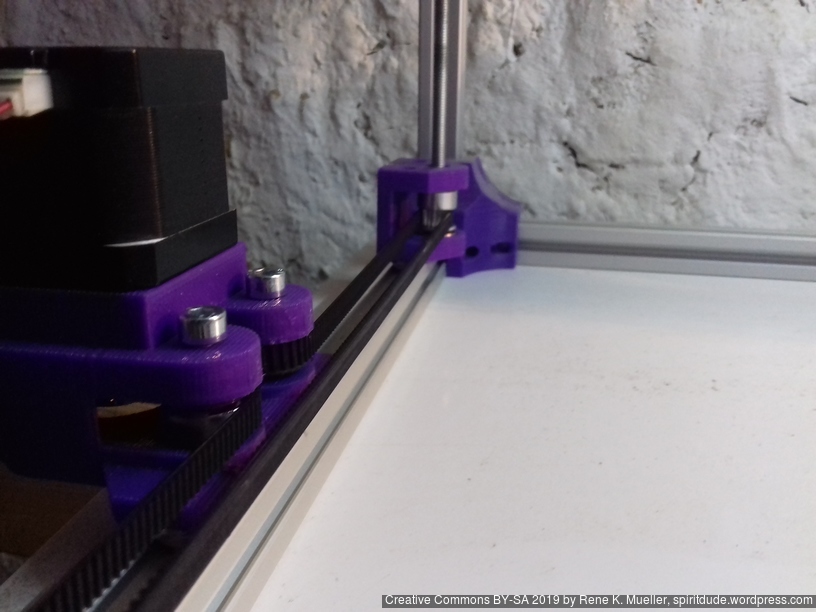

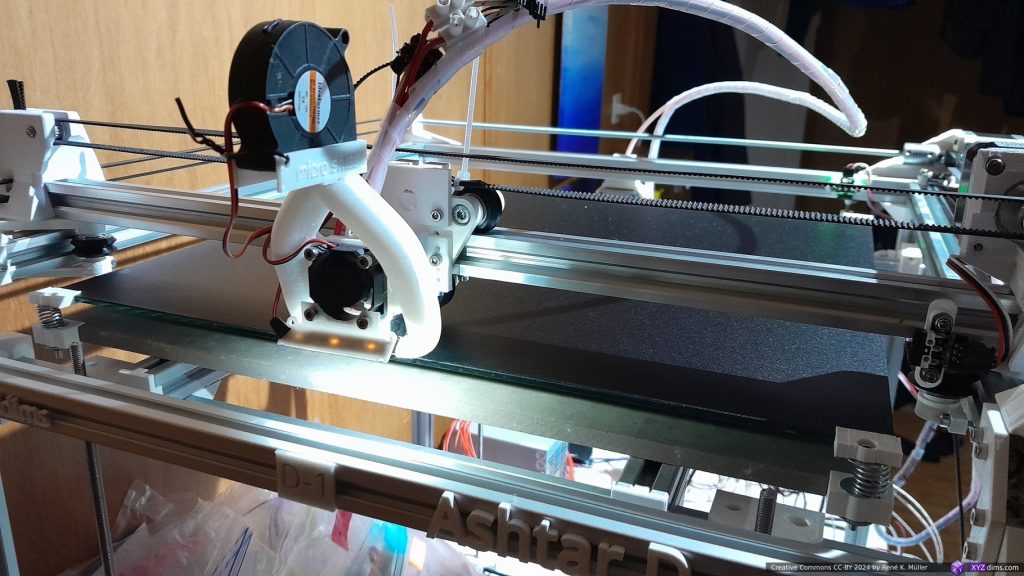

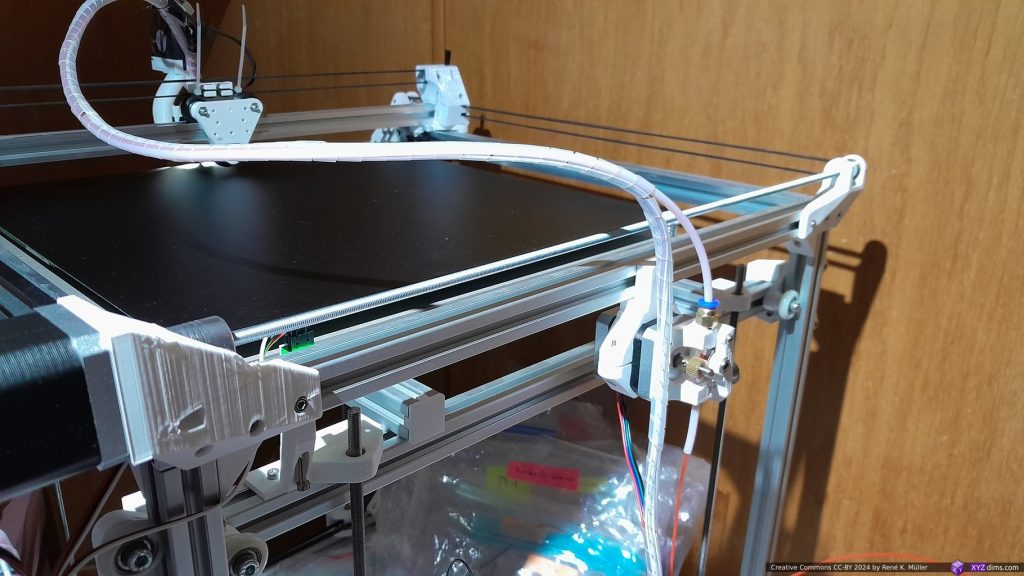

Building Ashtar D

It took a while to build the Ashtar D #1 as the other variants like Ashtar K and Ashtar C worked so well – here some of the early tests in 2022/12/09:

References

- Ultimaker S5: different XY head design using smooth rods, head: XY, bed: Z, build volume: 330 x 240 x 300mm, swapable hotends/printcores; priced at EUR/USD 6,500+ (2020/12)

- Makerbot Replicator: head: XY, bed: Z, build volume: 295 x 195 x 165mm, priced EUR/USD 2,400 (2020/12)

- Creality CR5: blatant copy of Ultimaker 2, S3 & S5 case design, head: XY, bed: Z, build volume: 300 x 225 x 380mm, priced EUR/USD 1,500 (2020/12)

- Creality Ender 6: low cost Core XY, head: XY, bed: Z, build volume: 250 x 250 x 400mm, priced EUR/USD 500 (2020/12)