Updates:

- 2021/01/01: sufficiently tested, finally published

- 2018/12/20: starting with write-up

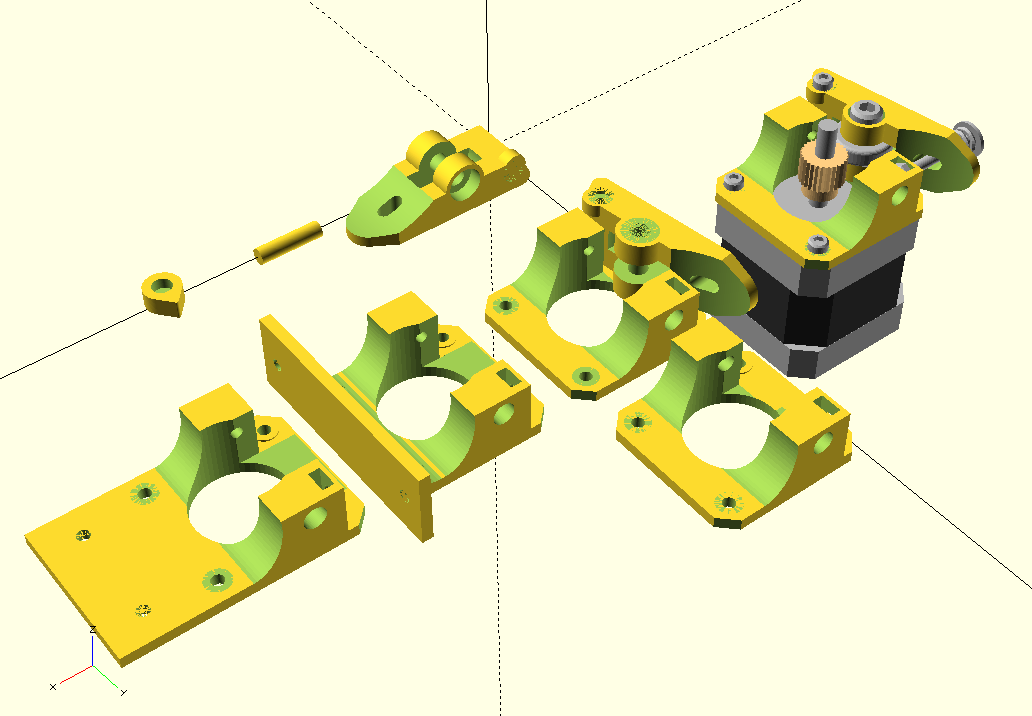

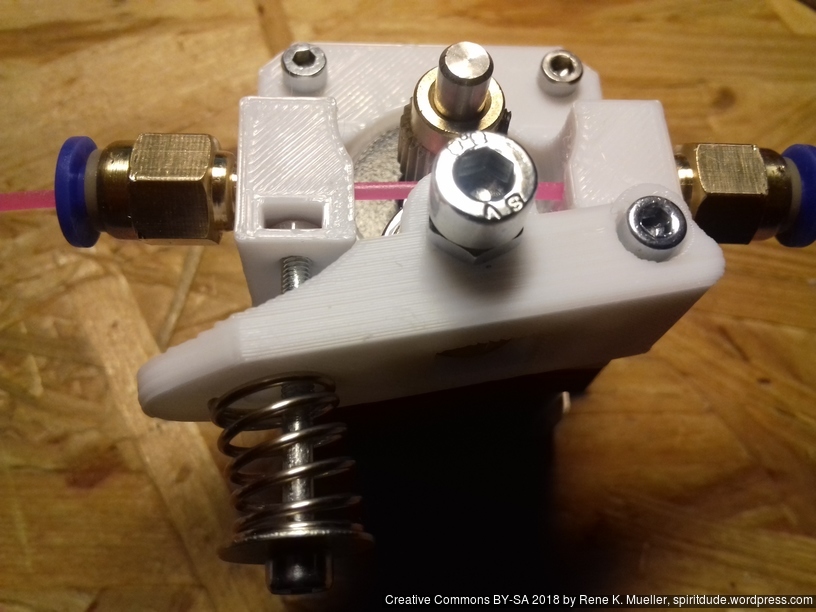

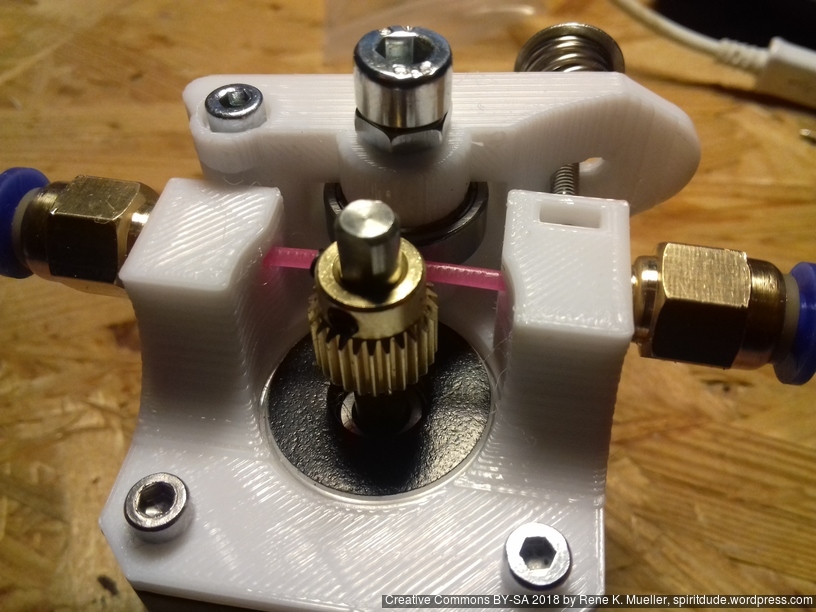

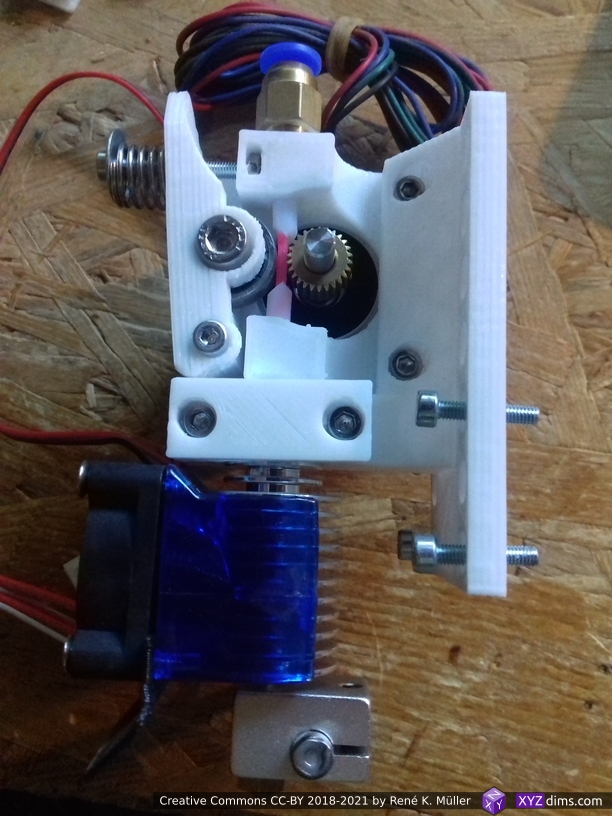

I used some aluminium MK8-based extruders but realized I required my own parametric extruder using 625ZZ bearing and I looked around and found Compact Bowden Extruder by Dominik Scholz which uses 608ZZ and adapted the overall design but coded it from scratch again in OpenSCAD with 625ZZ bearing for the Ashtar Series:

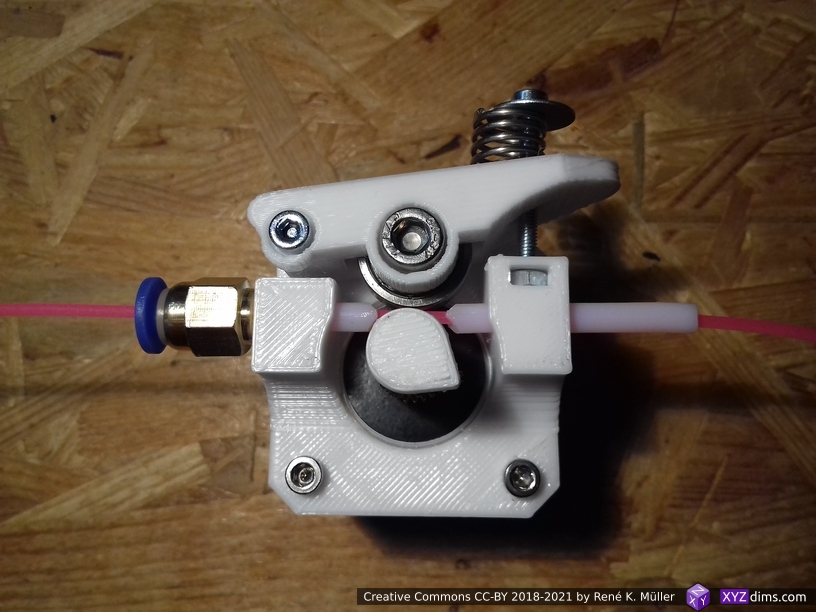

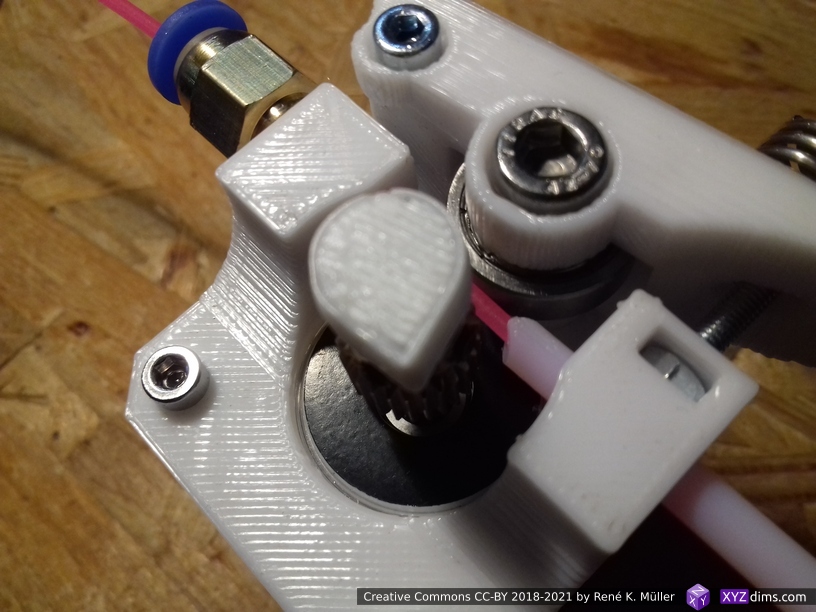

It’s “right handed” by default, but filament can go both directions. The handle is pushed from inside out with a spring, not so elegant, yet it saves space and filament does not have to go through the handle this way, which I prefer.

Bill of Materials (BOM)

- M5x14 or M5x16: mounting bearing

- 2x M3x8: mounting base to stepper motor

- 2x M3x25: mounting handle and spring

- M3 nut: insert into slot

- M3 washer (or print it): hold spring

- 20-25mm long soft spring (ID 3.2-8mm) or alike

- hubbed gear OD 11mm (MK8)

- 625ZZ bearing

Recommended further:

- PTFE OD 4mm, ID 2mm

- PC4-M6 straight fitting

Building

Software

compact_extruder() takes following parameters, in case you like to recreate the pieces:

type:"base": the base attached to the NEMA 17 stepper motor"handle": the push handle with the spring"indicator": small indicator to put on the axis of the stepper motor

mount:"none": (default) just attaches to NEMA 17 stepper motor"mount": simple mount (center)"2020": extends flat (lower left version)

btd: Bowden tube diameter (default: 0), if4mm is used, then Bowden PTFE OD 4mm/ID 2mm tube can be inserted on both sides as guides for flexible filament close to the hobbed gear as shown belowm5can be redefined, e.g.14then it sinks in

Hardware

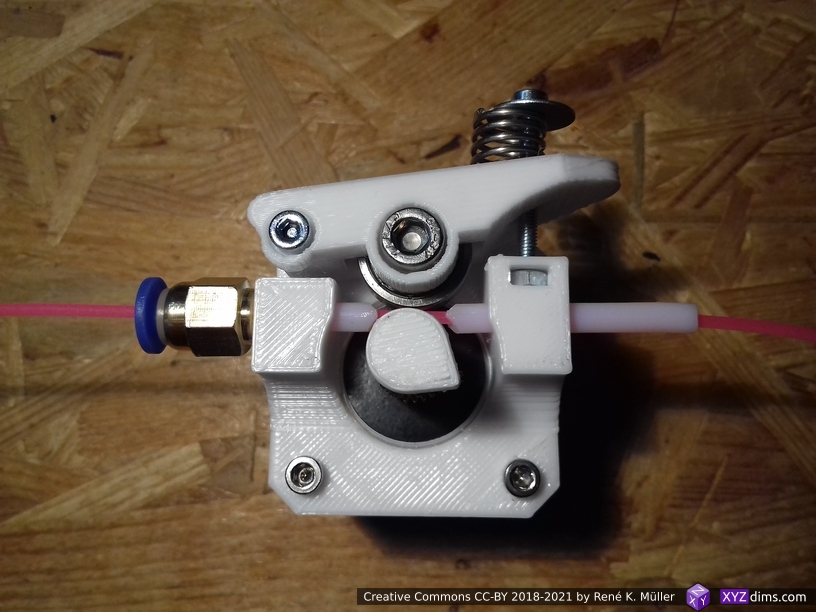

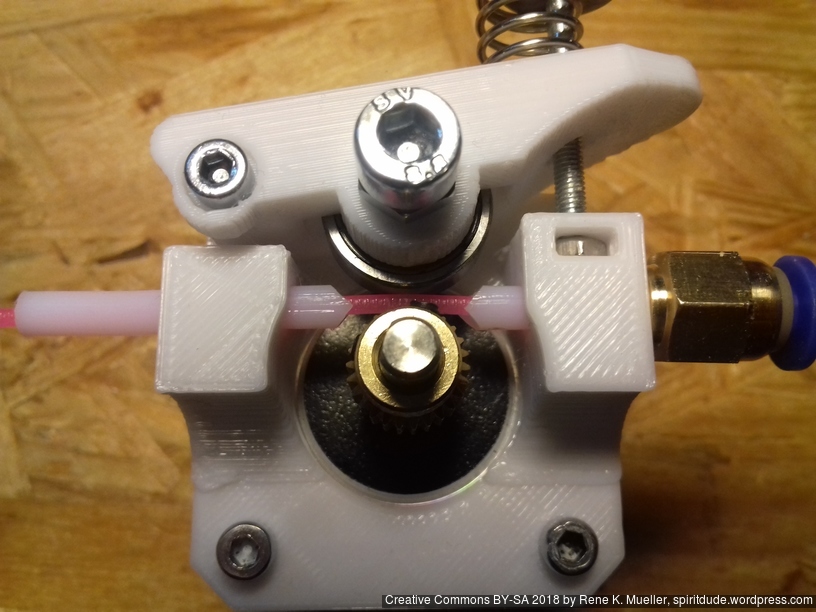

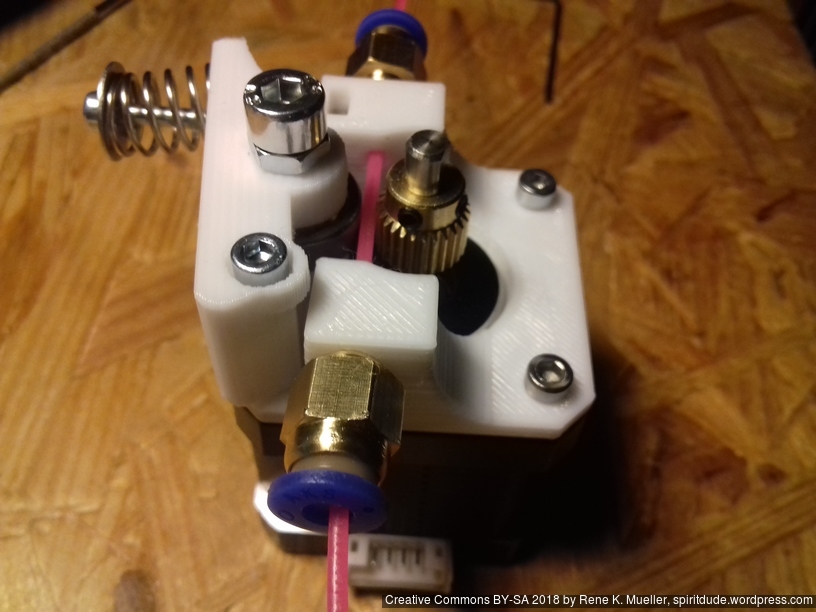

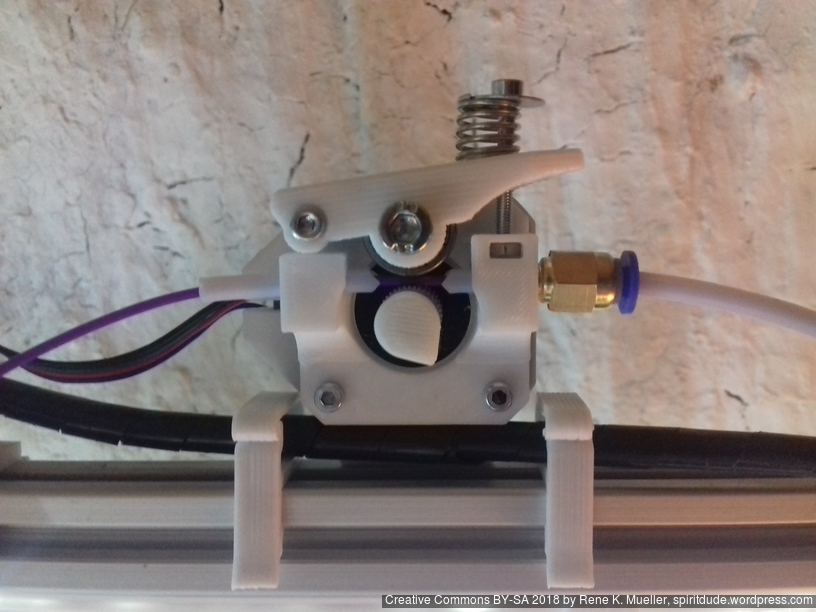

I use PC4-M6 push fit connector with PTFE tube 4mm OD / 2mm ID as guides, and began to use it right away on 3x printers for first tests:

Download

https://www.thingiverse.com/thing:3265864

includes STLs and OpenSCAD source code of the module

Applications

Direct Drive Extruder

A small adapter allows to mount the Compact Extruder close to the printhead to use it as Direct Drive Extruder:

I did not test the Direct Drive approach as I prefer the Bowden setup on my printers, but have it ready when needed, e.g. for flexible filament.

References

- Compact Bowden Extruder 608ZZ Bearing by Dominik Scholz, adapted his overall design but coded it from scratch

- Compact Bowden Extruder 625ZZ Bearing by Jake D, uses 625ZZ but had no OpenSCAD source

See Also

- Parametric Part Cooler

- Cyclops NF, 2-in-1 non-mixing

- Dual Micro Swiss