Updates:

- 2021/01/01: finally published with conclusion and more photos

- 2019/06/05: write up but not yet published, illustrations done

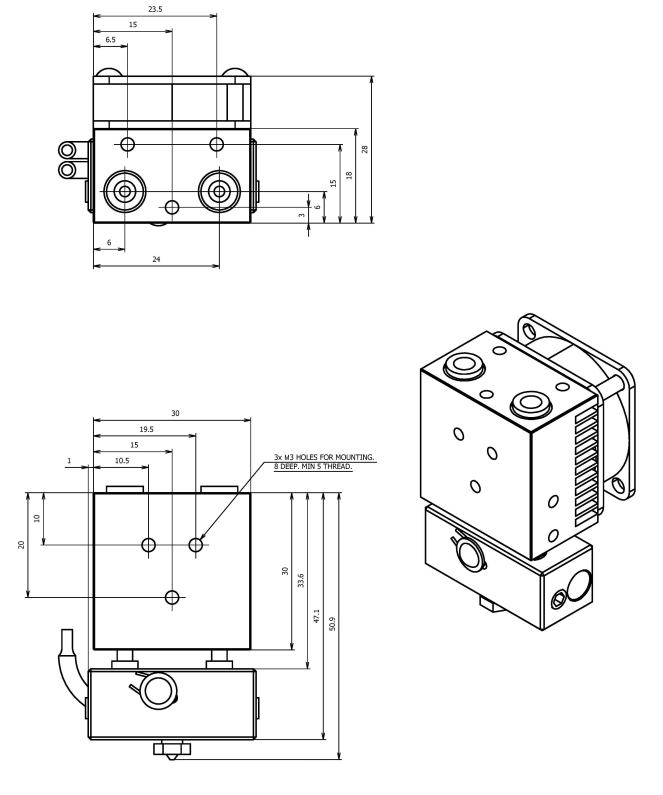

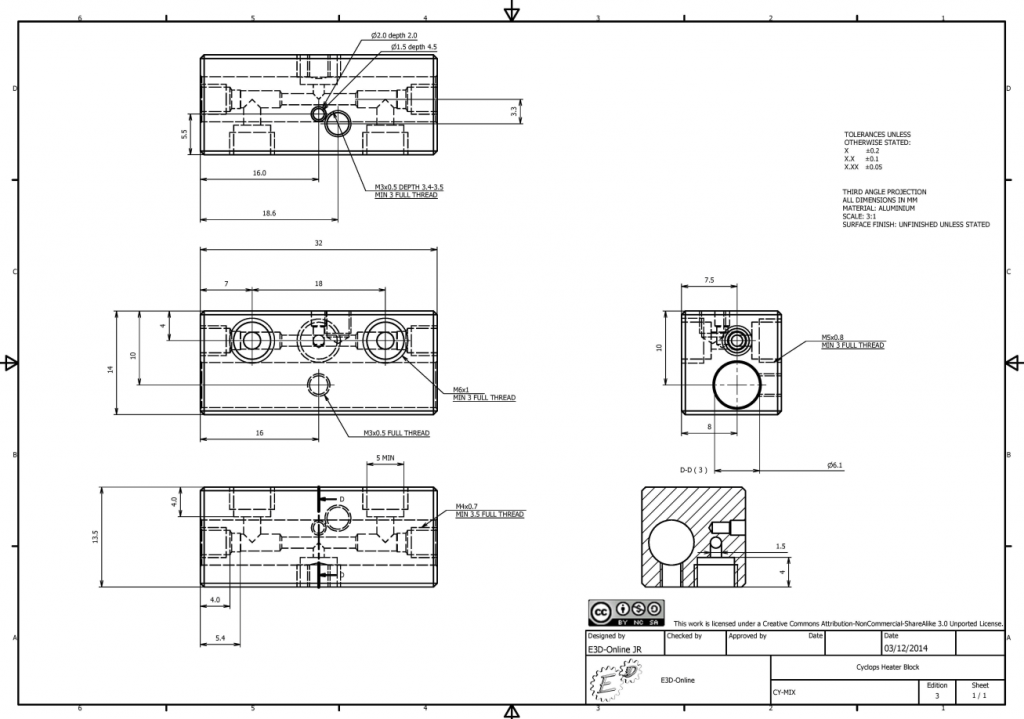

Back in May 2019 I tested a Chimera clone, based on the Open Source hardware design by E3D (UK):

and the updated 2018 design:

- E3D Cyclops/Chimera+ Drawing (PDF, 2018/02/16) GPL V3 or later

Even though I had rather unreliable experiences with the Chimera clone, I like to document it for my own sake and perhaps for you too.

Chimera Clone as sold by IdeaFormer:

- 2-in-1 non-mixing due steel balls, called E3D Cyclops/Chimera+

- Price: EUR/USD 110 (2021/01)

- 2-in-1 no steel balls inside therefore mixes

- 2-in-1 leaks

- 2-in-2 heatbreaks in heatsink wiggle

- Price: EUR/USD 10 (2021/01)

- Rating: ★★☆☆☆

There are also “Cyclops NF” sold on Aliexpress, those are not compatible with E3D Cyclops/Chimera either – you have to study the photos carefully and not rely on the product title.

Chimera Clone 2-in-1 (mixing)

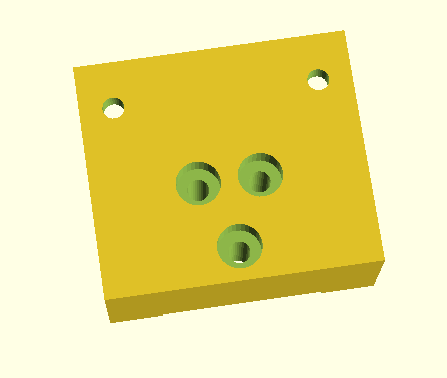

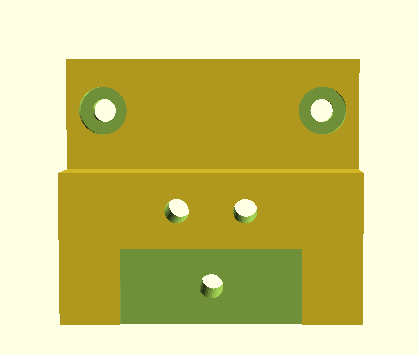

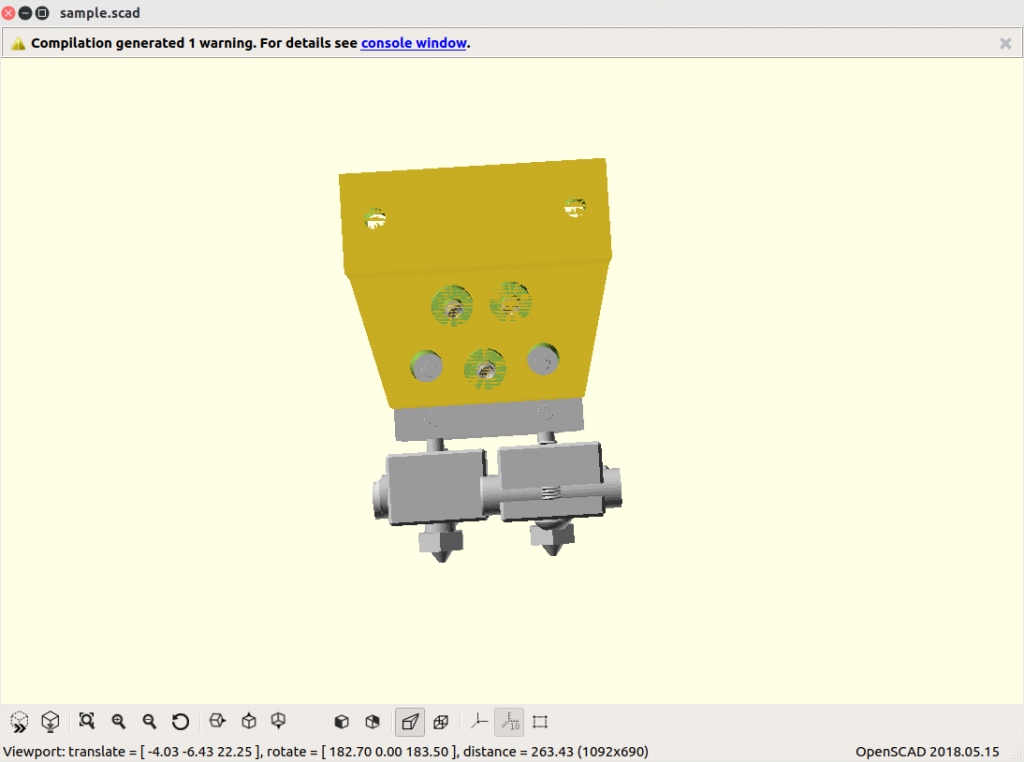

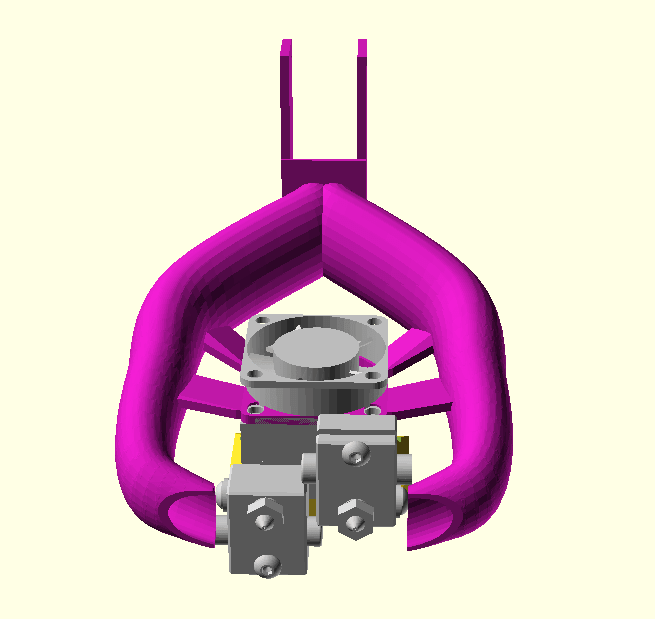

Let’s focus first on the 2-in-1 mixing mode, the large mixing heatblock with a single heat resistor – I made a basic mounting plate for my V-carriage (30mm distant M3 holes):

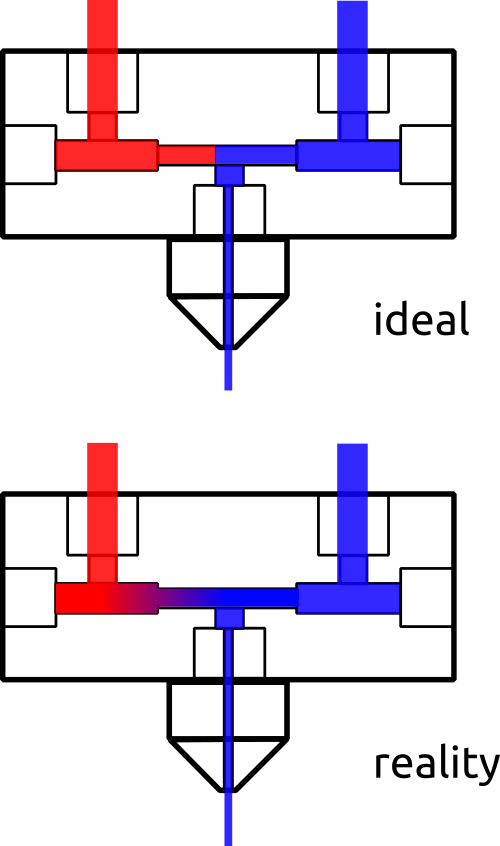

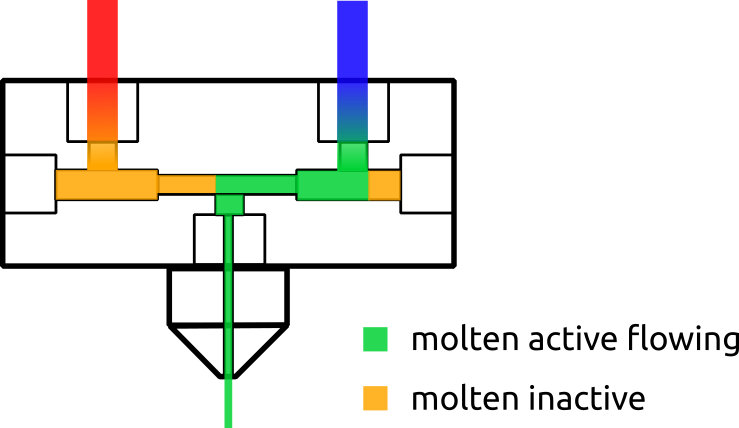

Based on the plans as shown on the top of this post, let’s illustrate the actual flow of the two filaments:

The main problem is that there is inactive molten filament, and I realized, there is a minimum of flow required of the “inactive” filament, e.g. 5%, in order to have reliable printing either mixed or single filament.

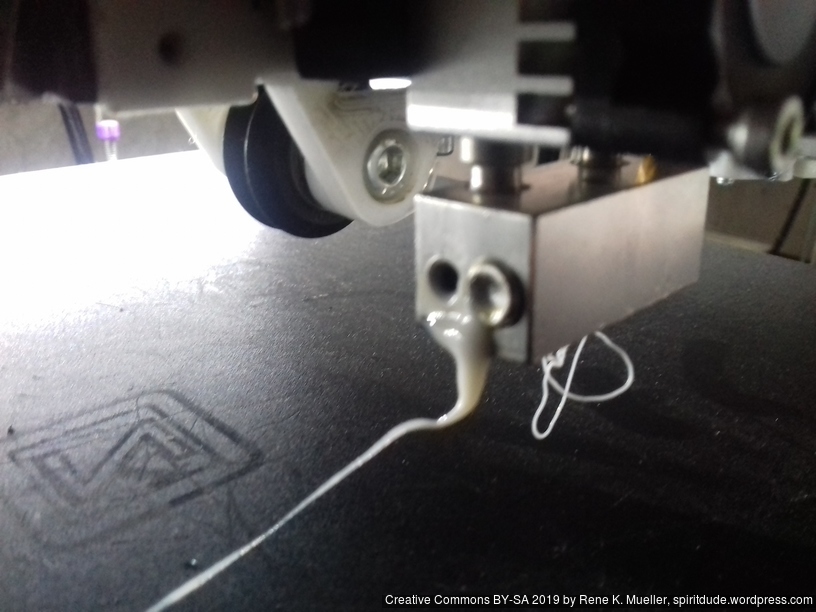

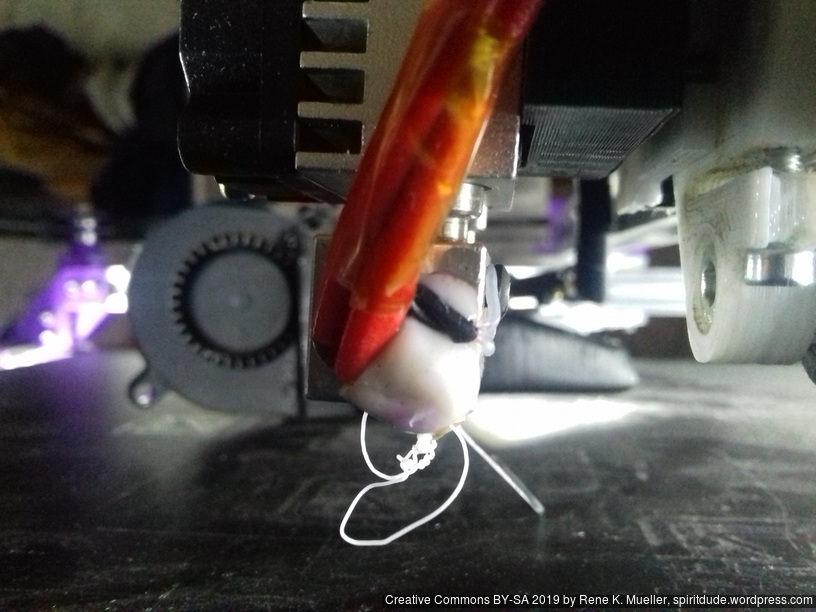

Further, I experienced massive leaks on the sides, and I was not able to patch or fix it, perhaps too wide margins of the worm screws on the side:

Eventually I gave up on printing with Chimera clone 2-in-1 mixing mode because of the clogging and leaks (which likely are related to each other).

It might have been a good to insulate the heatblock with Kapton tape and some thermal insulator to prevent the part cooler cooling down the heatblock too much and nozzle with it.

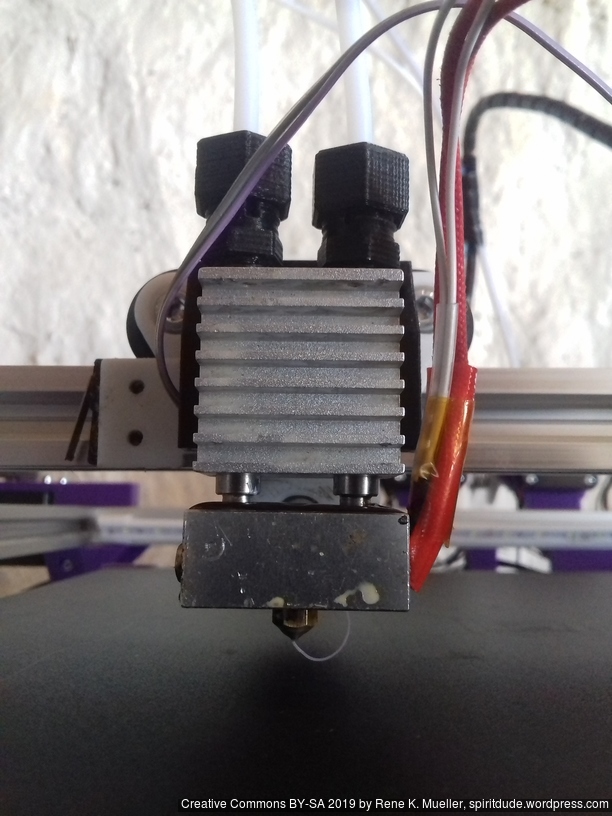

Chimera Clone 2-in-2

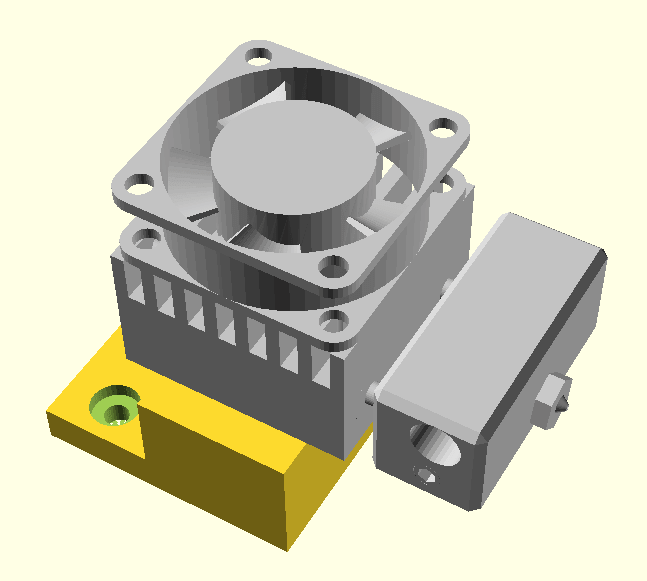

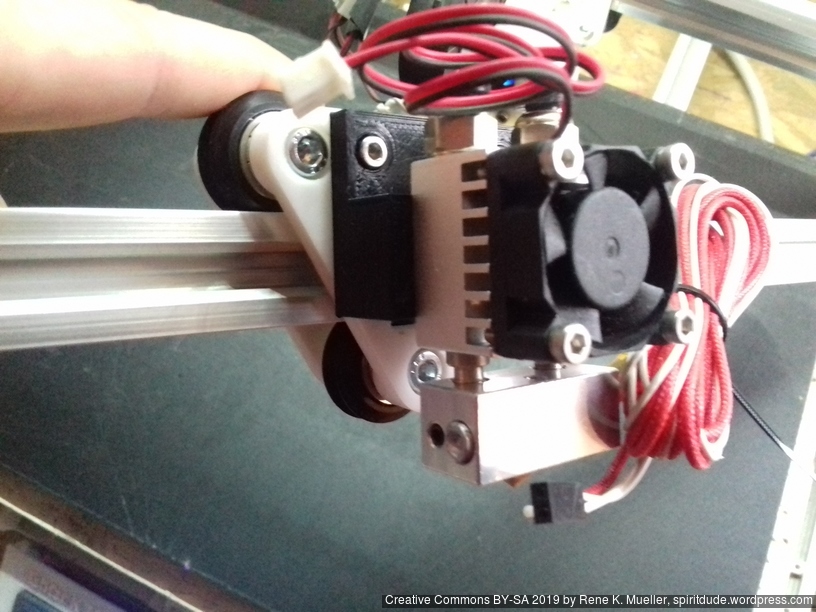

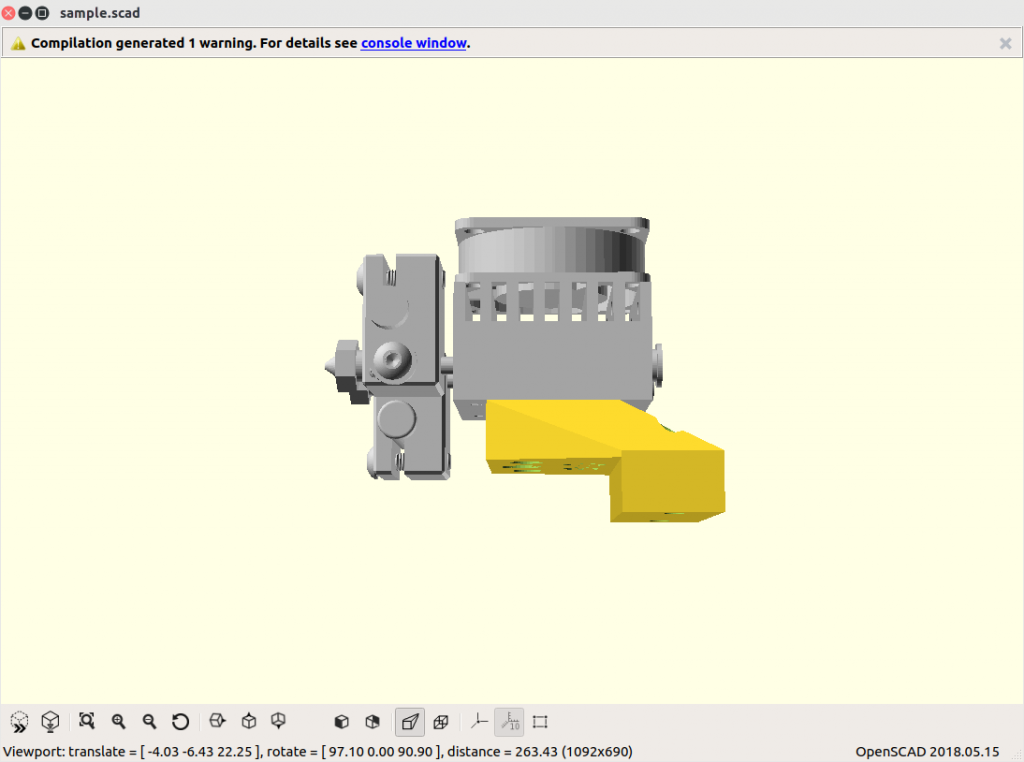

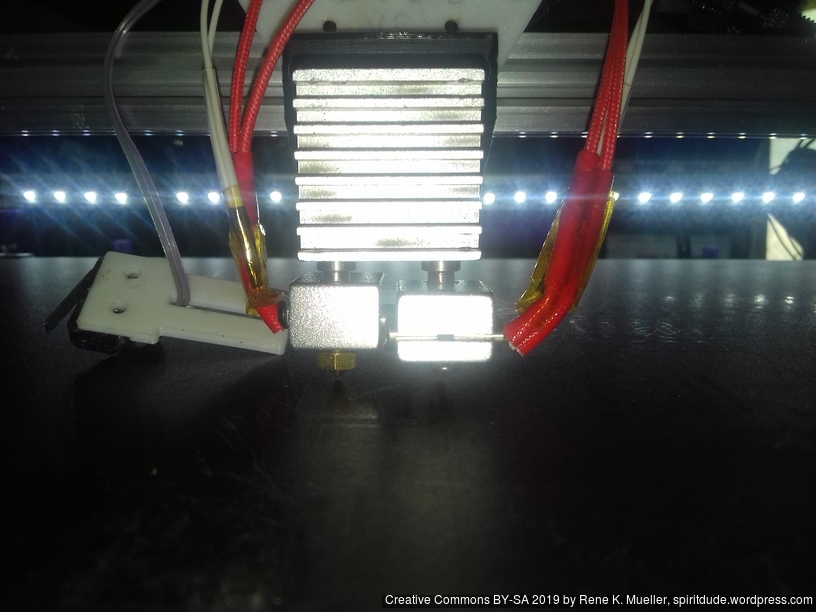

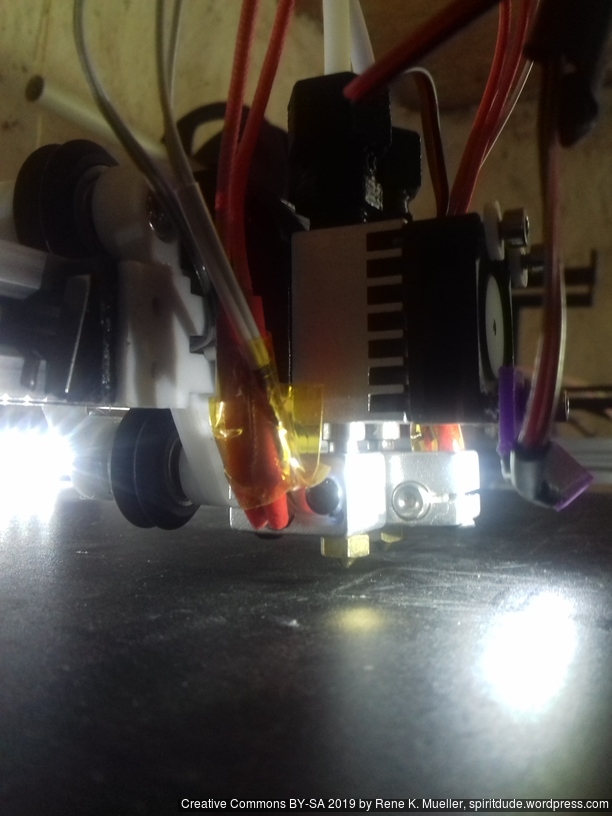

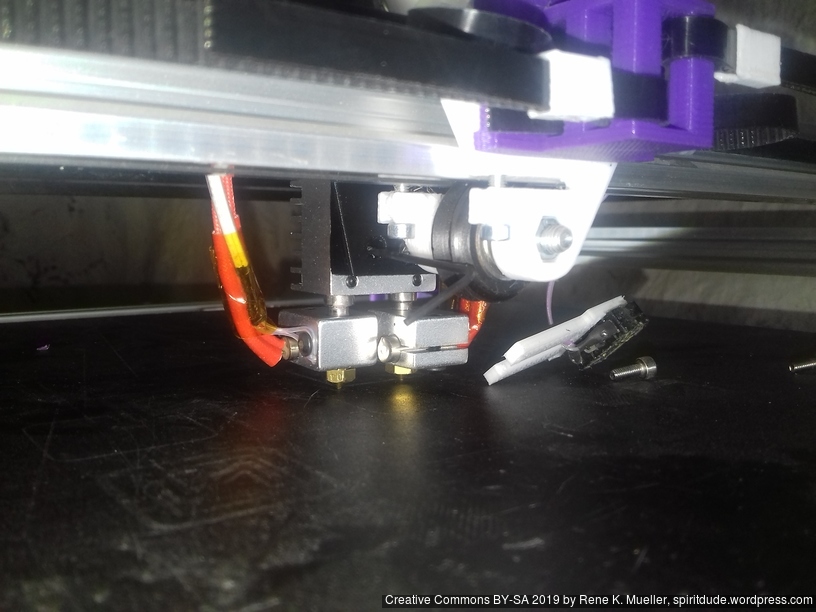

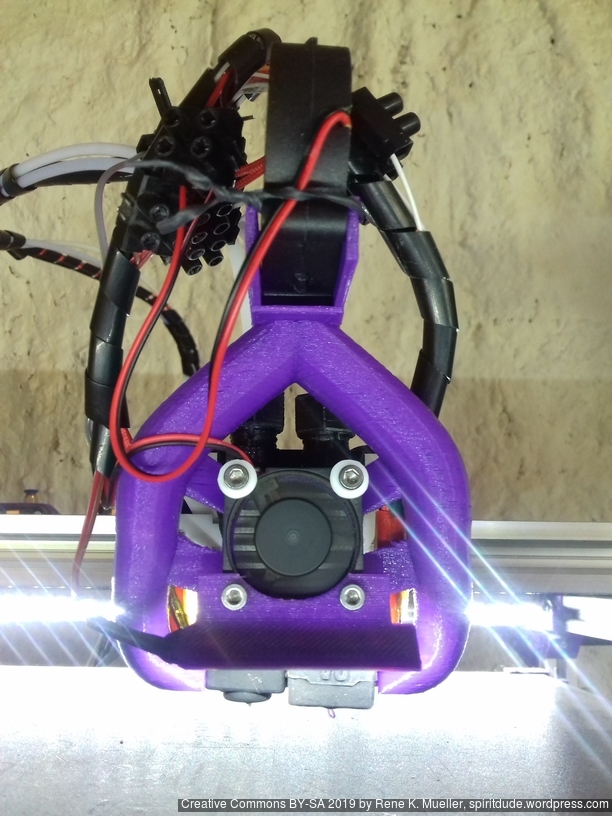

The two heatblocks with single heatsink mode, aka 2-in-2, again made a simple mounting plate this time with additional holes to adjust the heatbreaks individually – as we are operating now with two nozzles; and I even adapted my Parametric Part Cooler piece for it:

The leveling of the two nozzles worked well, given your mount allows to reach at least one worm screw which controls the heatbreak and thereby the nozzle distance to bed.

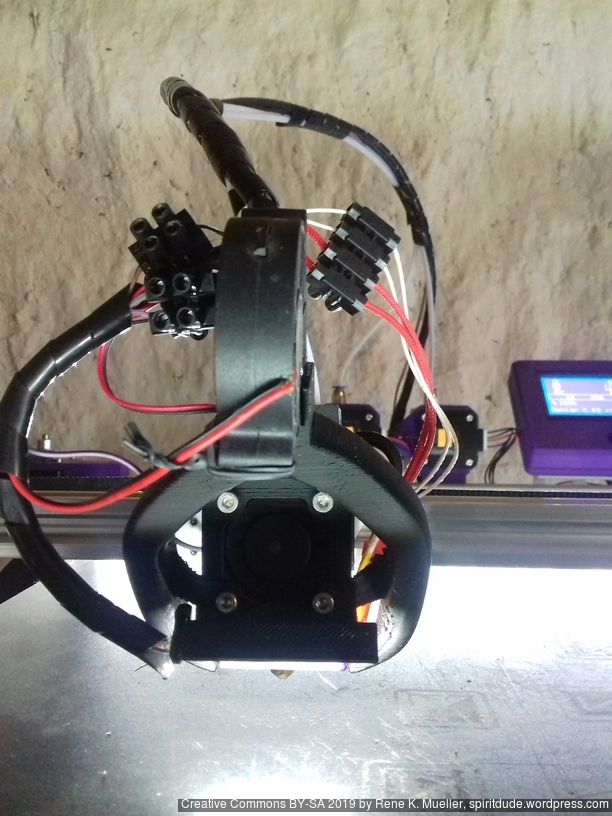

Chimera 2-in-2 with part cooler & nozzle socks

Chimera 2-in-2, fully assembled on Ashtar C (Core XY)

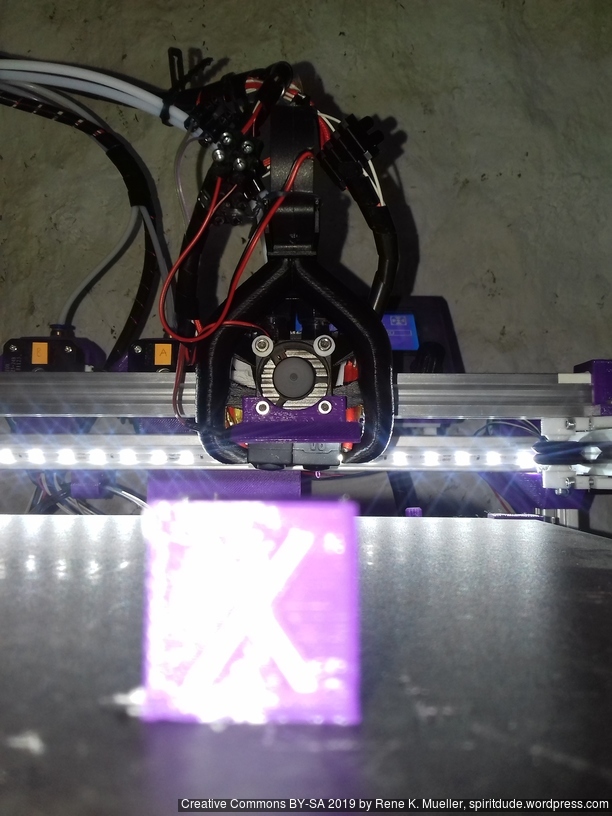

Chimera 2-in-2 printing XYZ Dual Color Hollow Calibration Cube

The 2-in-2 operation worked better, the X-offset between the two nozzles needed to be measured and calibrated with test prints, as well slight Y-offset as the holes in the heatsink have too much margin for the two heatbreaks, so they wiggle a bit – so every leveling between the two nozzles changed X- and Y-offset between the nozzles. This happens when an Open Source hardware design is implemented without care of the details.

Download

Even though my Chimera clone experience was not convincing, you might have better one with another supplier or the original E3D Cylcops/Chimera+ with more precise machining – let me know if you do so.

https://www.thingiverse.com/thing:4704047

Conclusion

The Chimera clone from IdeaFormer did not convince me, as

- the 2-in-1 mixing mode leaked and

- the 2-in-2 was harder to calibrate the X- and Y-offset

For 2-in-2 application I rather use the more simple Dual Micro Swiss Setup which turned out more feasible, reliable and easier to handle. I eventually used the Cyclops NF (non-mixing) more reliable, but still not as reliable as single nozzle operation as with E3D V6 or Volcano.

The problem for 2-in-2 is also about the inactive nozzle to leak out the nozzle, e.g. you need to retract a bit, and then push forward but you lack building up pressure, so every switch of tools (nozzles/filament) decreases the print quality. The independent X dual nozzles (IDEX) setup you can move the inactive nozzle aside and brush off leaking filament.

For the mixing mode 2-in-1, I had more reliable experiences with the Diamond Hotend with 3-in-1, where all three filaments must be present (and ideally have 2-5% use even when not desired).

Comparison Dual/Multi Color/Material Extrusions

blue = relevant positive

red = relevant negative

Independent Dual Extrusions (IDEX)

- complex setup

- moderate cost

- non-mixing

- dual nozzles

- dual heatblocks

- dual heatsinks

- normal retraction

- no purge block 1)

- no oozing over print

- no inactive nozzle traveling

- reliable 2)

★★★★★

Dual Hotends 2-in-2

- simple setup

- low cost

- non-mixing

- dual nozzles

- dual heatblocks

- dual heatsinks

- normal retraction

- no purge block

- inactive nozzle oozing over prints

- inactive nozzle travels over print

- moderate reliability

★★★★★

Chimera 2-in-2

- simple setup

- clone: low cost

- original: high cost

- non-mixing

- dual nozzles

- dual heatblocks

- single heatsink

- normal retraction

- no purge block

- oozing of inactive material

- inactive nozzle travels over print

- moderate reliability

★★★★★

Cyclops 2-in-1

- simple setup

- clone: low cost

- original: high cost

- mixing

- single nozzle

- single heatblock

- single heatsink

- normal retraction

- purge block required

- no oozing of inactive material

- clone: unreliable

★★★★★ (clone)

Cyclops NF 2-in-1

- simple setup

- low cost

- non-mixing

- single nozzle

- single heatblock

- single heatsink

- complex retraction

- no oozing of inactive material

- moderate reliability

★★★★★

Diamond Hotend 3-in-1

- complex setup

- clone: low cost

- original: high cost

- mixing

- single nozzle

- single heatblock

- 3 heatsinks

- tricky retraction

- purge block required

- no oozing of inactive material

- moderate reliability

★★★★★

Multiple Switching Extrusions (MSE) 2-in-2, 3-in-3, 4-in-4

- moderate complex setup

- requires additional servo or motor

- extendable 2, 3, or 4 colors/materials

- low cost

- non-mixing

- multiple nozzles / heatblocks / heatsinks

- normal retraction

- no purge block 1)

- no oozing of inactive material

- no inactive nozzle touching print

- reliable 2)

(rating comes later)

Y Splitter x-in-1

- simple setup

- extendable 2, 3, or 4 or more colors / materials

- low cost

- non-mixing

- single nozzle

- single heatblock

- single heatsink

- complex retraction

- purge block required

- no oozing of inactive material

- moderate reliability

★★★★★

Tool Changer

- complex setup

- extendable to n-colors or materials

- moderate cost

- non-mixing

- multiple nozzles / heatblocks / heatsinks

- normal retraction

- no oozing of inactive material

- no inactive nozzle touching print

- moderate reliability

(rating comes later)

Footnotes

- in theory no purge block, but if ooze shields are shared among switching extrusions (more than 2 extrusions) there may be cross-contamination between colors/materials

- the printheads individually are proven to be reliable

Hints:

- single heatblock = same print temperature

- dual heatblock = different print temperatures possible

- dual nozzle = different nozzle sizes possible

See Also

- Cyclops NF, more reliable 2-in-1 (non-mixing) experiences