Updates:

- 2021/01/31: added comparison regarding Multiple Switching Extrusions (MSE)

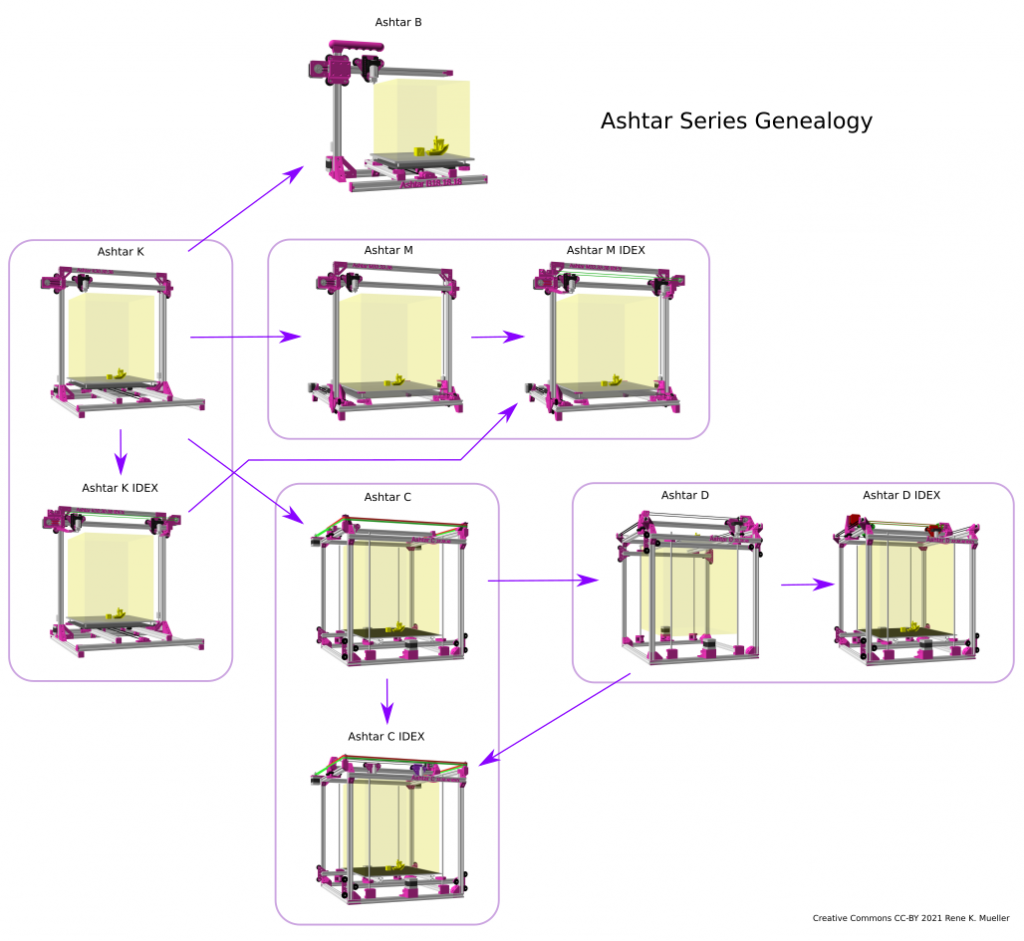

- 2021/01/18: added IDEX Features with Pros/Cons, Ashtar Series Genealogy, Comparison Dual Material approaches, and brief Hardware Requirements

- 2021/01/15: first version with overview side-by-side

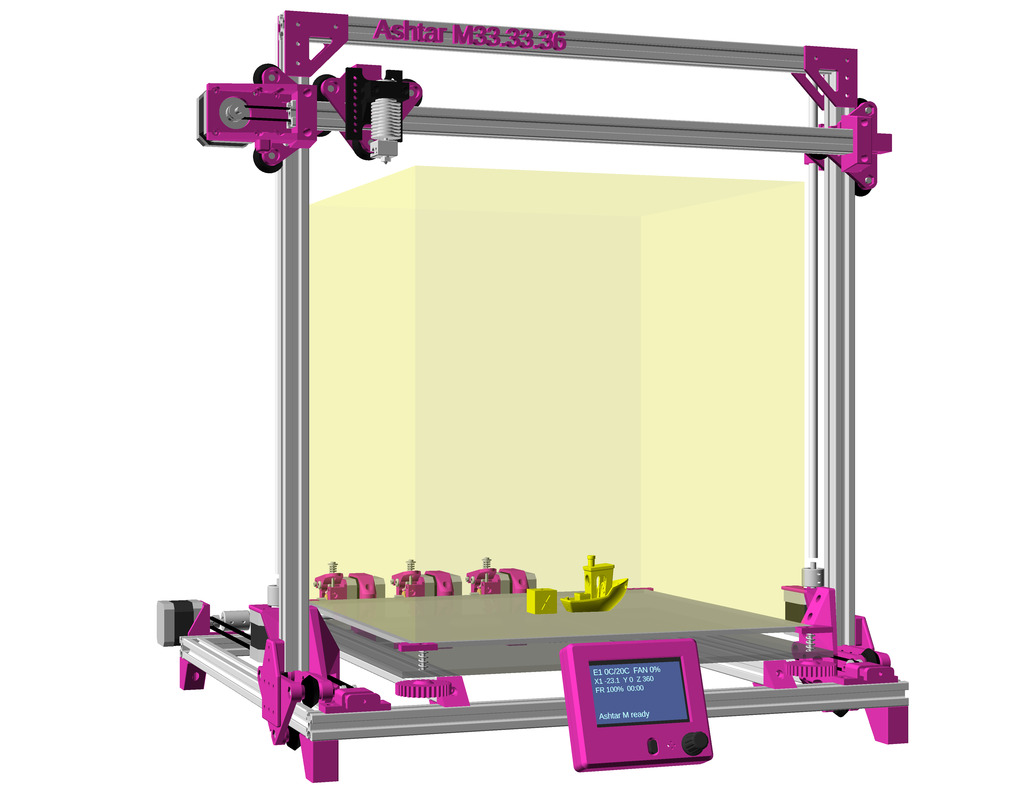

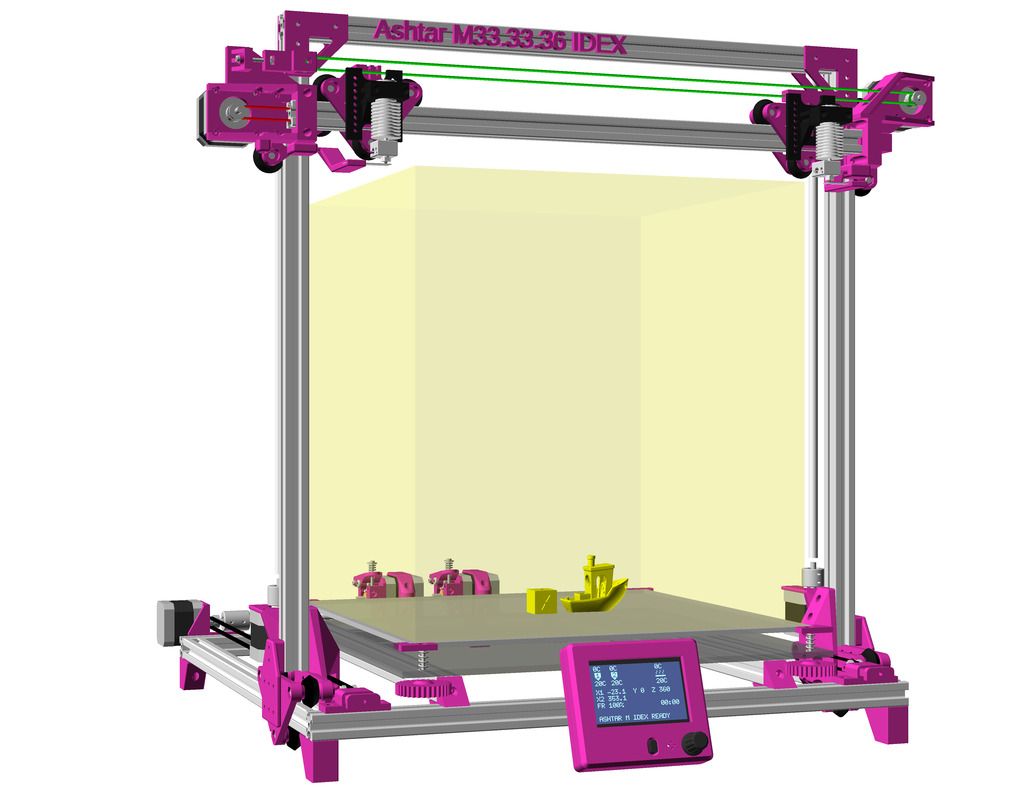

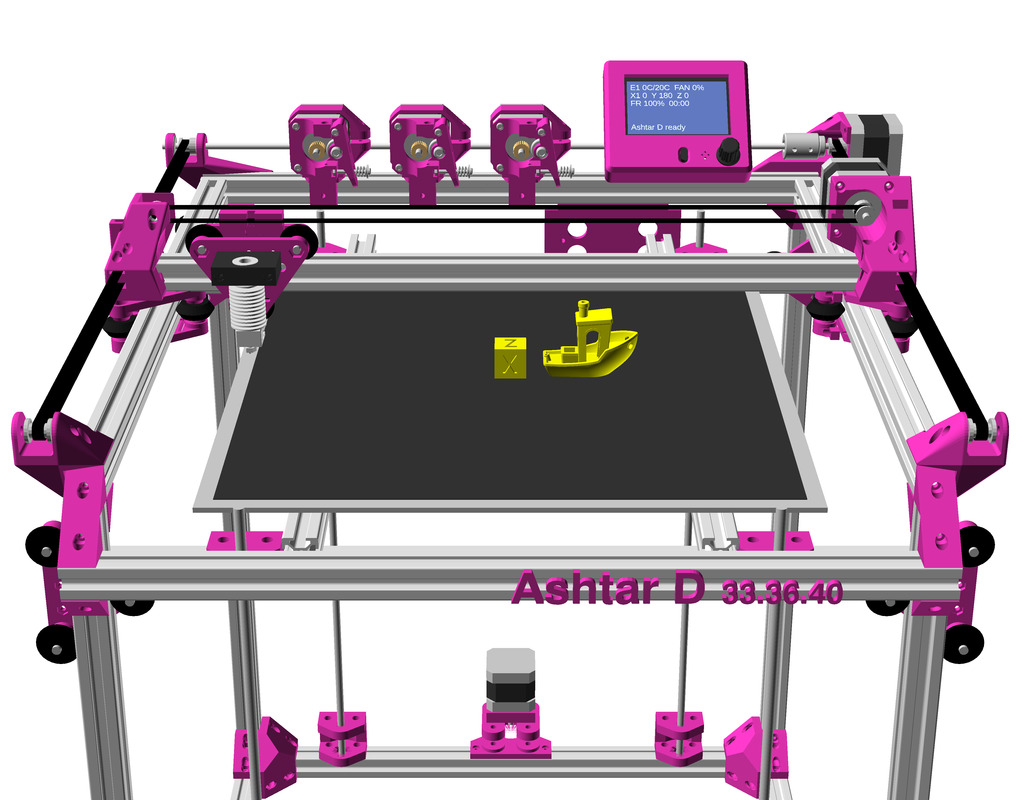

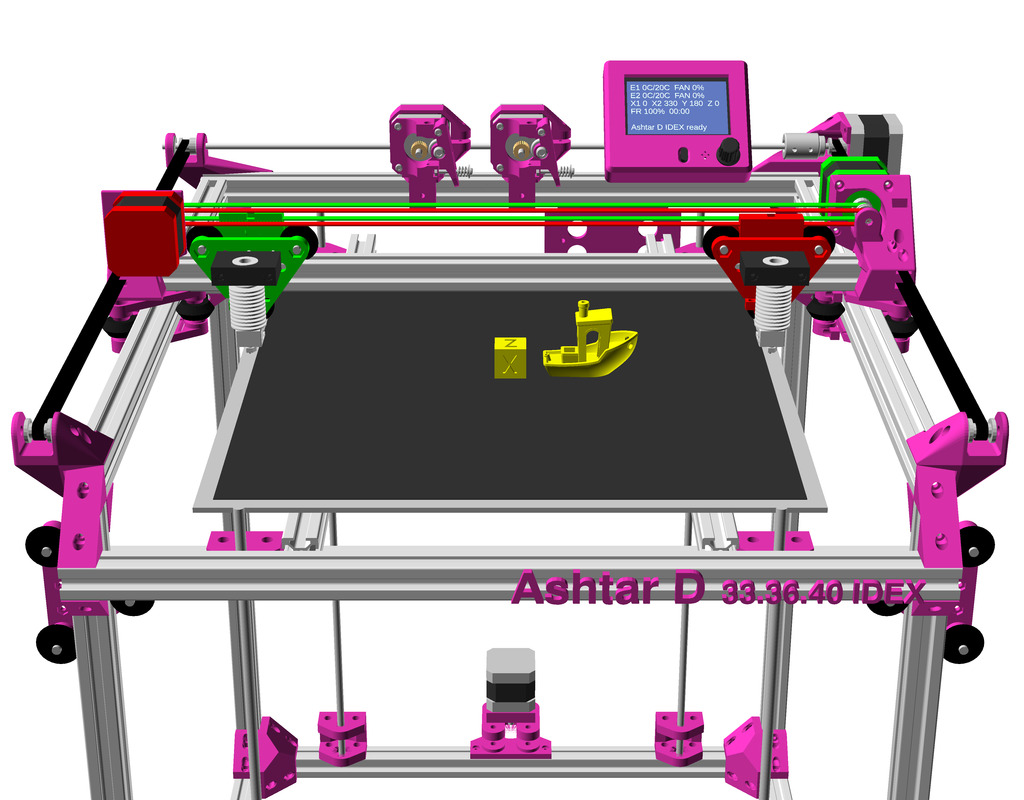

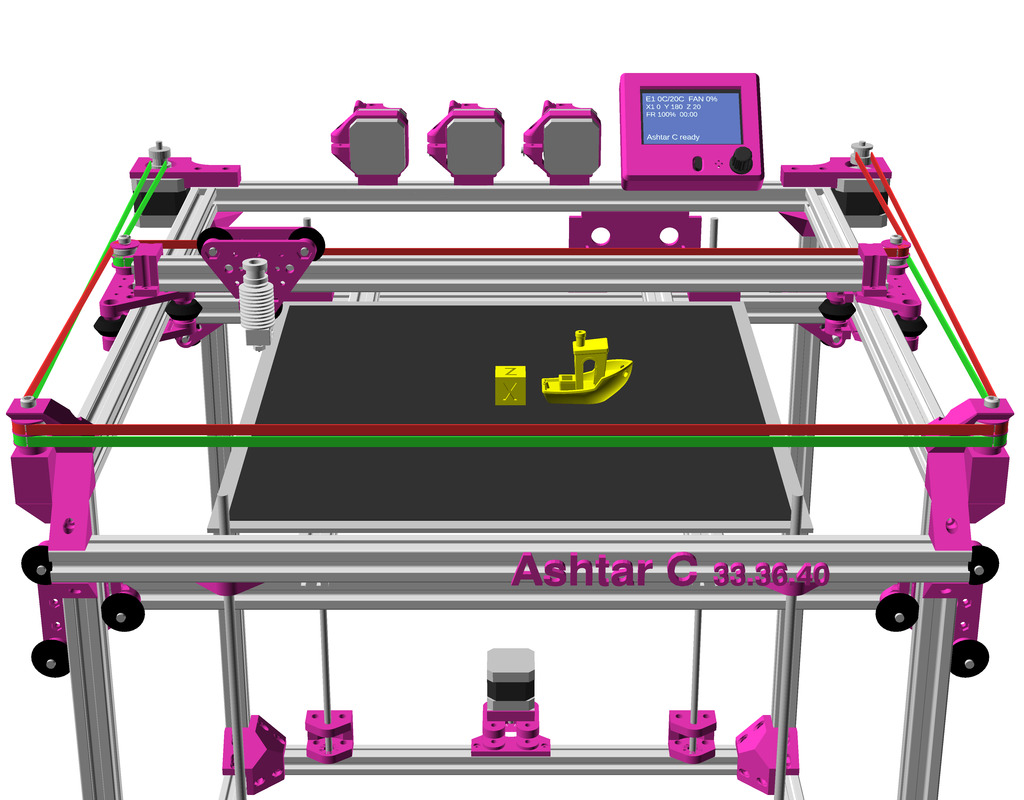

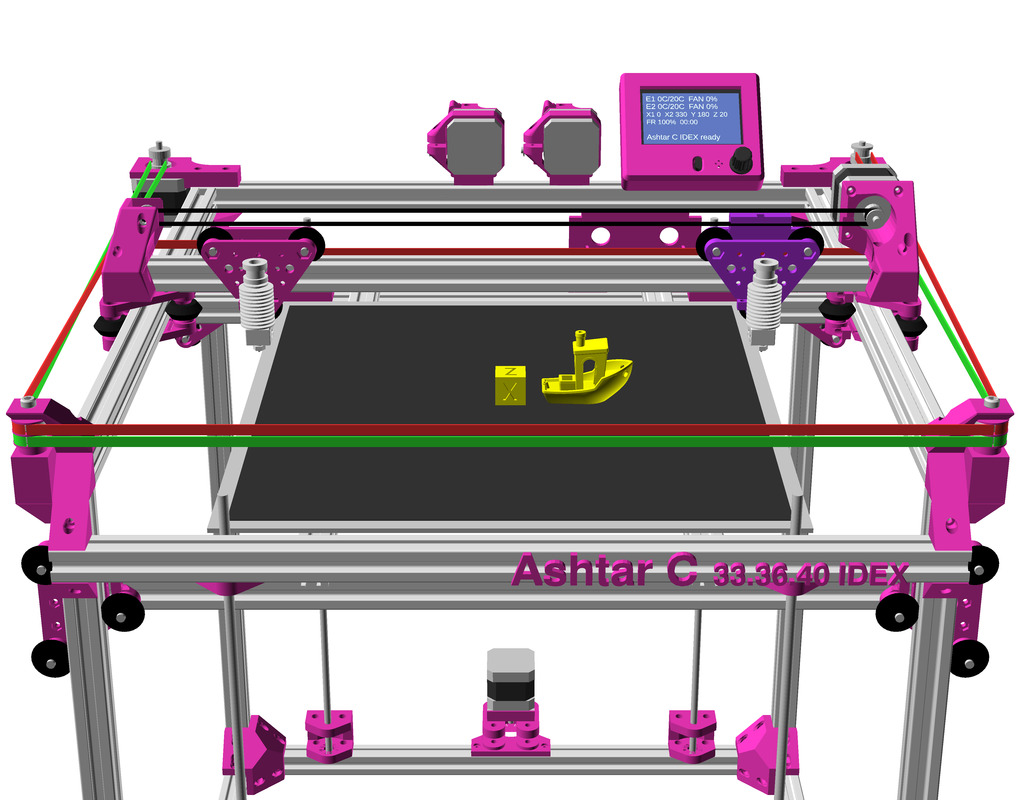

Mid of January 2021 (01/12 – 01/14) I added IDEX (Independent Dual Extrusion) option to 4 designs, all still in early draft stage – here as a summary side-by-side:

Ashtar K IDEX has been fairly easy, as I was using an improved “old” design of the X motor mount for the 2nd motor and 2nd belt, and since Ashtar M IDEX is using the same XZ frame, it was a matter of a few minutes to port that option as well.

Ashtar D IDEX with Classic XY belt routing was more tricky as there was little space left to add another motor, so I realized I need to utilize what’s there and take advantage of it – result is a very space saving solution, but it needs to be verified in real life first.

Ashtar C IDEX with Core XY with an additional X motor was easy, I just reused a slightly altered X motor/pulley mount of Ashtar D, so that was done fairly quickly as well, yet the challenge will be the firmware support, as currently (2021/01) only Duet RepRap firmware supports the CoreXYU as my design falls under.

Features of IDEX

Pros:

- double printing: duplicate or mirror mode

- double printing volume at same duration

- two materials with different melting points

- two colors (non-mixing) with

- more reliable than dual nozzle setups, as inactive nozzle does not run over existing printed piece often

- possibly different nozzle sizes

- dedicated nozzle for infill vs outline

Cons:

- slightly reduced build-volume in X-axis

- added complexity

Comparison Dual/Multi Color/Material Extrusions

blue = relevant positive

red = relevant negative

Independent Dual Extrusions (IDEX)

- complex setup

- moderate cost

- non-mixing

- dual nozzles

- dual heatblocks

- dual heatsinks

- normal retraction

- no purge block 1)

- no oozing over print

- no inactive nozzle traveling

- reliable 2)

★★★★★

Dual Hotends 2-in-2

- simple setup

- low cost

- non-mixing

- dual nozzles

- dual heatblocks

- dual heatsinks

- normal retraction

- no purge block

- inactive nozzle oozing over prints

- inactive nozzle travels over print

- moderate reliability

★★★★★

Chimera 2-in-2

- simple setup

- clone: low cost

- original: high cost

- non-mixing

- dual nozzles

- dual heatblocks

- single heatsink

- normal retraction

- no purge block

- oozing of inactive material

- inactive nozzle travels over print

- moderate reliability

★★★★★

Cyclops 2-in-1

- simple setup

- clone: low cost

- original: high cost

- mixing

- single nozzle

- single heatblock

- single heatsink

- normal retraction

- purge block required

- no oozing of inactive material

- clone: unreliable

★★★★★ (clone)

Cyclops NF 2-in-1

- simple setup

- low cost

- non-mixing

- single nozzle

- single heatblock

- single heatsink

- complex retraction

- no oozing of inactive material

- moderate reliability

★★★★★

Diamond Hotend 3-in-1

- complex setup

- clone: low cost

- original: high cost

- mixing

- single nozzle

- single heatblock

- 3 heatsinks

- tricky retraction

- purge block required

- no oozing of inactive material

- moderate reliability

★★★★★

Multiple Switching Extrusions (MSE) 2-in-2, 3-in-3, 4-in-4

- moderate complex setup

- requires additional servo or motor

- extendable 2, 3, or 4 colors/materials

- low cost

- non-mixing

- multiple nozzles / heatblocks / heatsinks

- normal retraction

- no purge block 1)

- no oozing of inactive material

- no inactive nozzle touching print

- reliable 2)

(rating comes later)

Y Splitter x-in-1

- simple setup

- extendable 2, 3, or 4 or more colors / materials

- low cost

- non-mixing

- single nozzle

- single heatblock

- single heatsink

- complex retraction

- purge block required

- no oozing of inactive material

- moderate reliability

★★★★★

Tool Changer

- complex setup

- extendable to n-colors or materials

- moderate cost

- non-mixing

- multiple nozzles / heatblocks / heatsinks

- normal retraction

- no oozing of inactive material

- no inactive nozzle touching print

- moderate reliability

(rating comes later)

Footnotes

- in theory no purge block, but if ooze shields are shared among switching extrusions (more than 2 extrusions) there may be cross-contamination between colors/materials

- the printheads individually are proven to be reliable

Hints:

- single heatblock = same print temperature

- dual heatblock = different print temperatures possible

- dual nozzle = different nozzle sizes possible

Hardware Requirements

- 1x NEMA 17 42-45Nm with wire, extra stepper motor driver on motherboard

- 100-110cm long 6mm wide GT2 belt

- 1x pulley and 1x idler

- 1x hotend (nozzle, heatblock, heat cartridge, heatbreak, heatsink), extra heating connector on motherboard

That’s it.