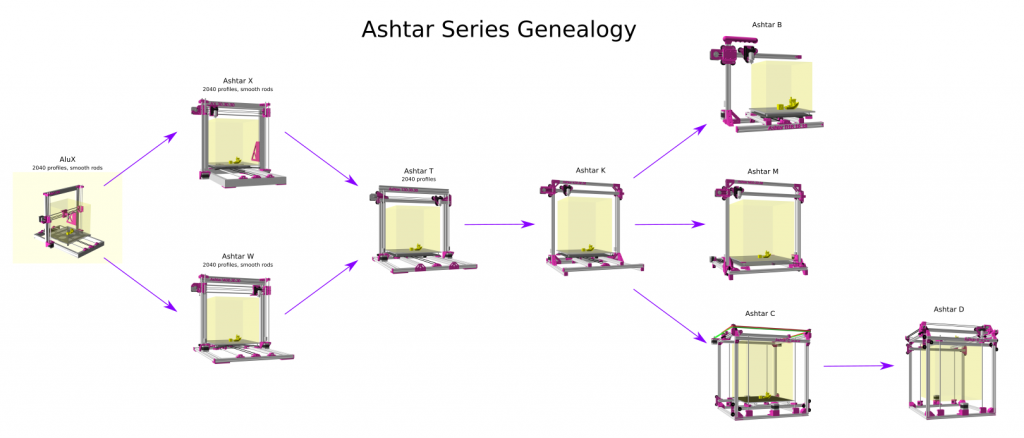

A brief history of “Ashtar K“, my first designed 3D printer I actually built – documented also for my own sake:

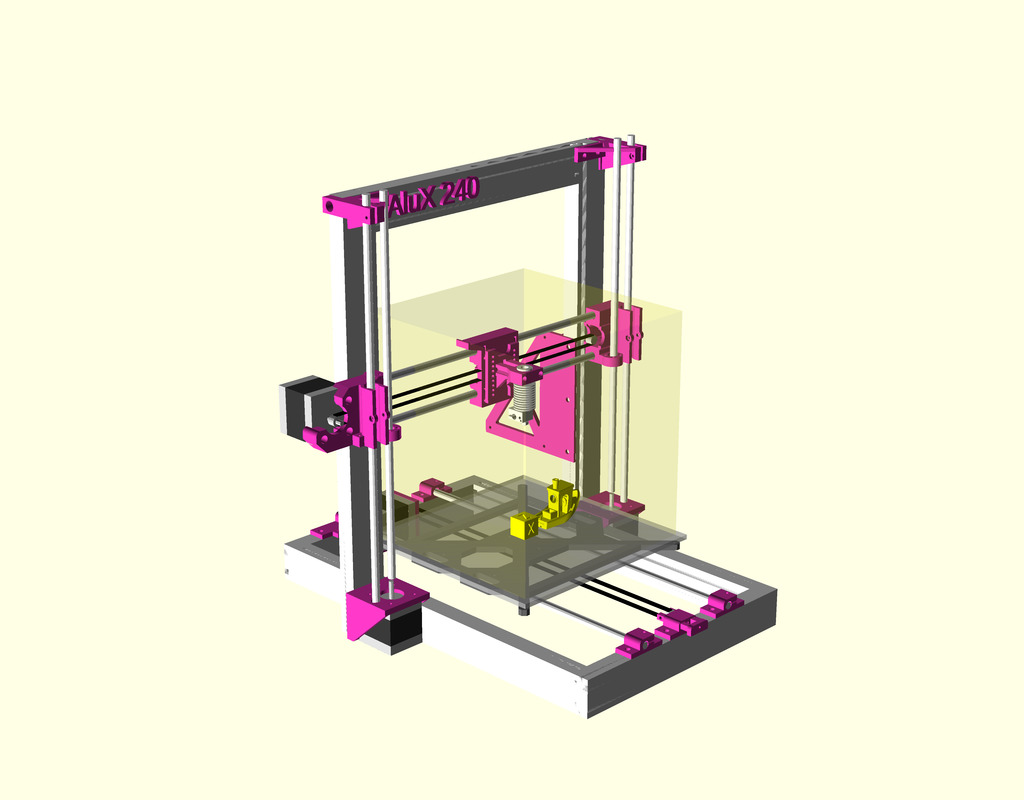

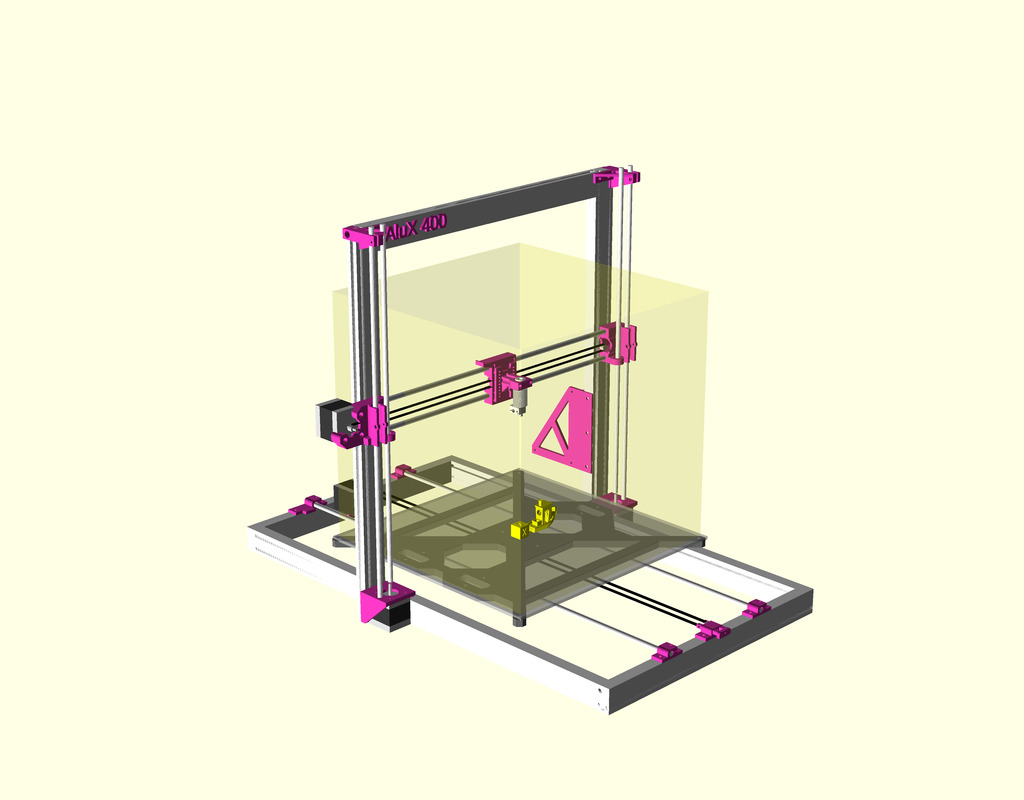

AluX: Prusa i3 Clone

It started with AluX (abbreviation of ALU-extrusion eXtendable) early June 2018, which used CTC i3 Pro B / Prusa i3 Clone pieces as the X carriage, X motor mount and X idler all in STL format. I coded the frame parametric using 2040 alu extrusions/profiles and using smooth rods as rails:

I realized then quickly I need to design and code my own pieces, every single piece I need to control and make it parametric if it makes sense, and not rely on existing STL files, as editing meshes of the STL seemed a waste of time but rather design the piece in OpenSCAD right away and derive new variants if necessary from the geometry itself.

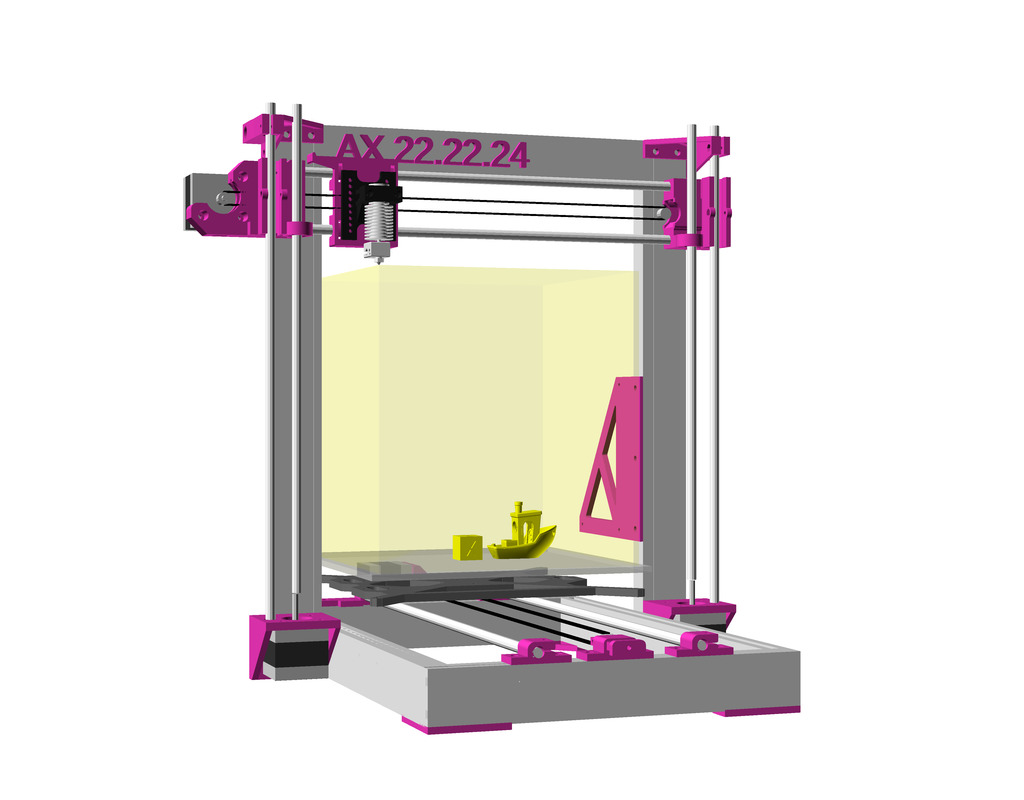

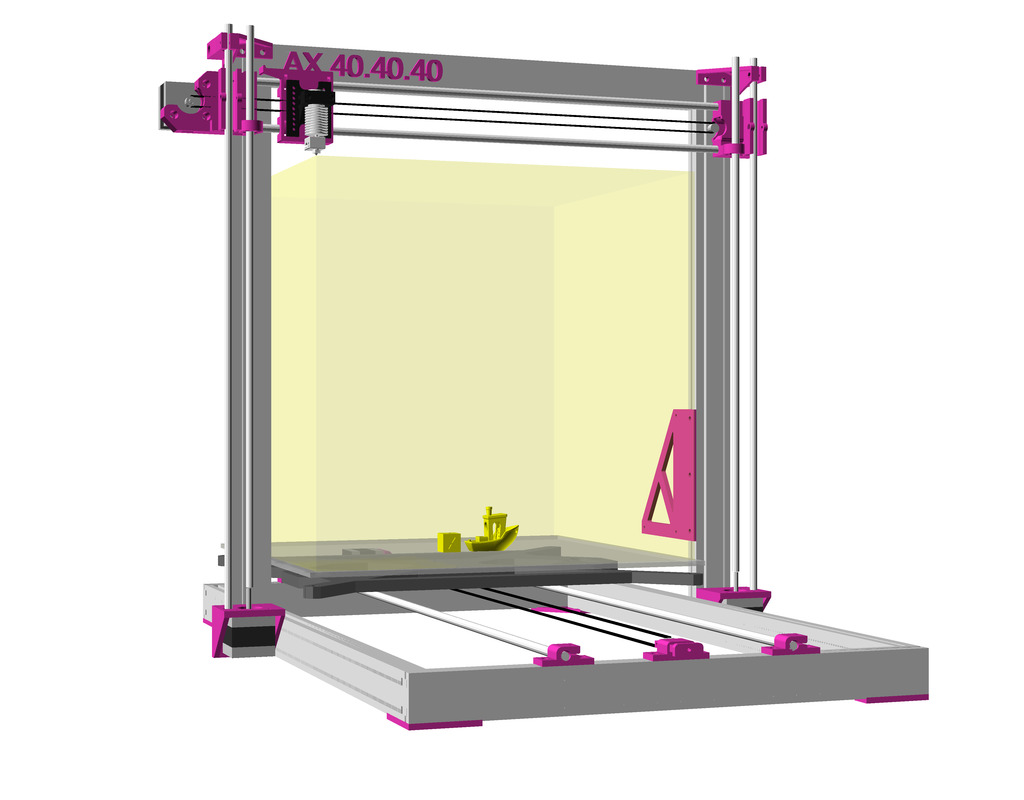

Ashtar X & W Series: Riding on Smooth Rods

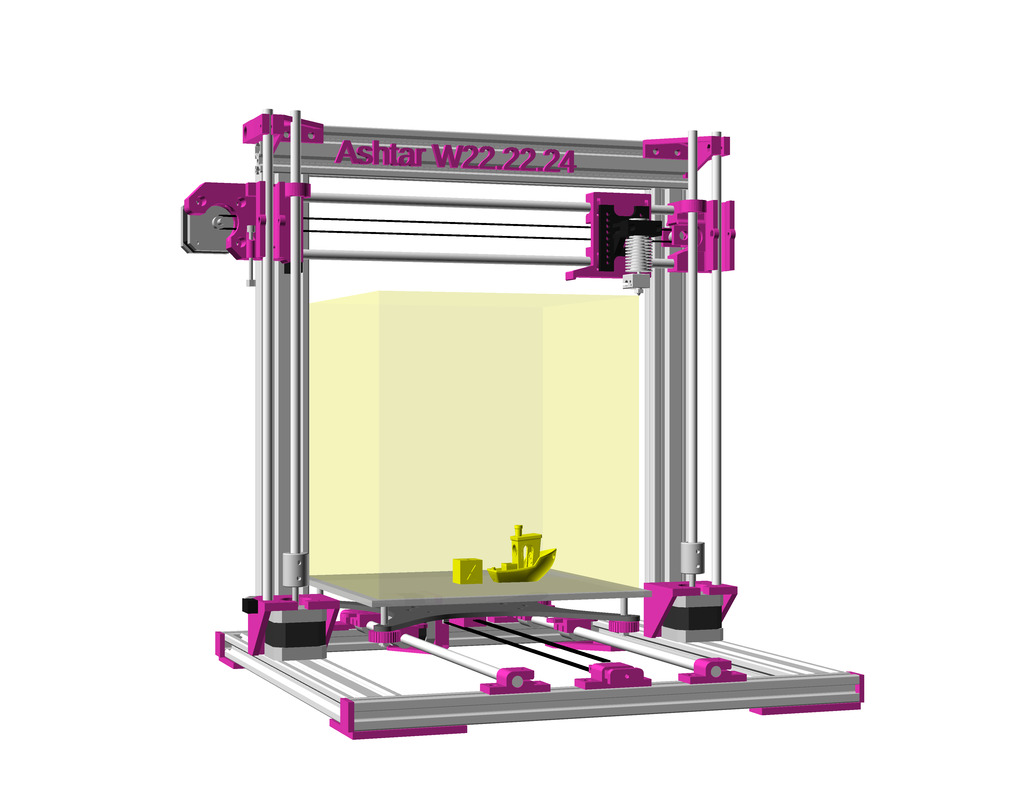

Mid June 2018, AluX became Ashtar X (abbreviated as AX), and Ashtar W were using 2040 alu extrusions but differently oriented at the base, still using smooth rods as rails:

At this point I got sufficient experience of the parametric approach and it was obvious to use the frame as rails.

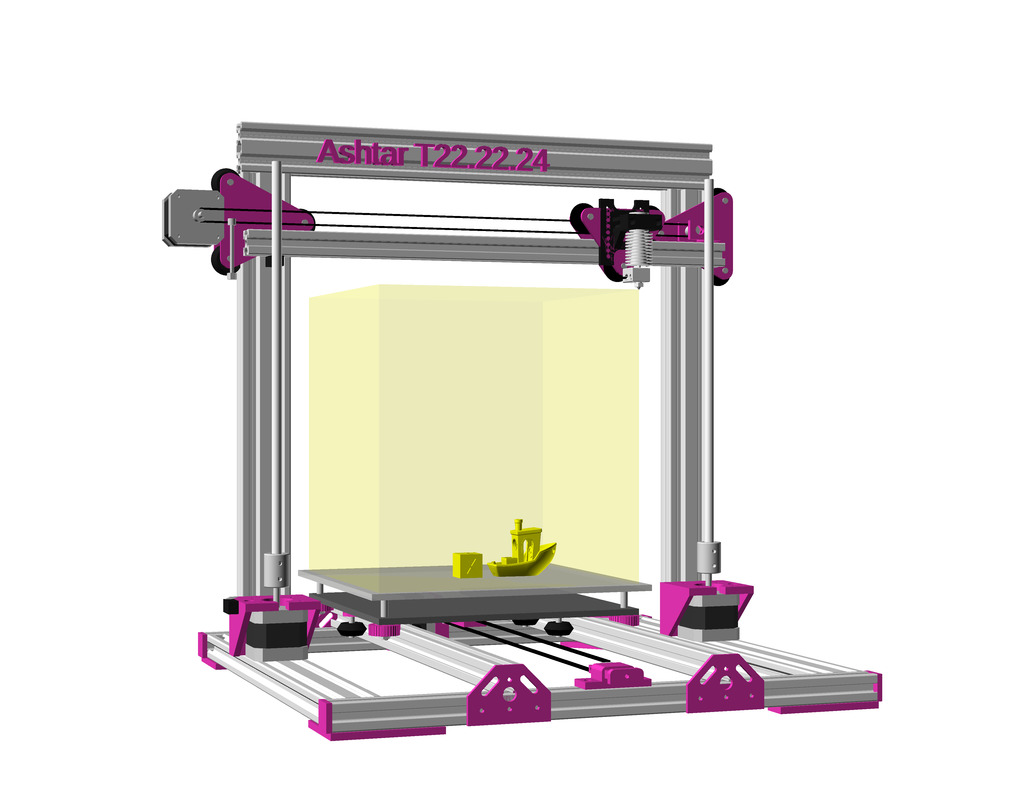

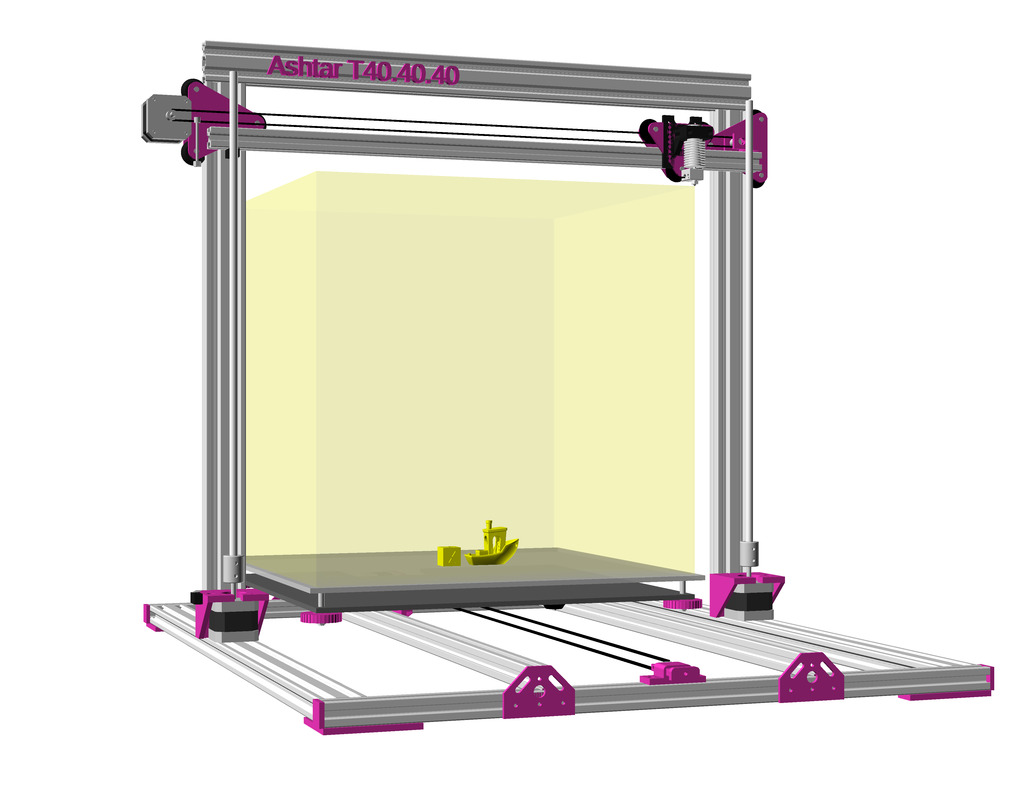

Ashtar T Series: Riding Alu Profiles

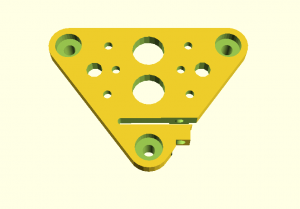

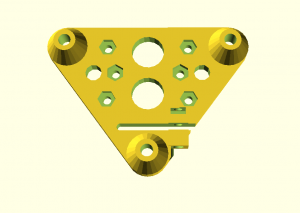

Beginning of July 2018, with the Ashtar T series I began to use the frame as rails itself, utilizing 2040 alu extrusions, it also started with the parametric V module (due its shape) composed by 2x V-plates, using 3 wheels which ride on the alu extrusion:

V plate (outer side)

V plate (inner side)

With the parametric V modules the X, Y and Z frame beams became rails as well, simplifying the overall construction compared to earlier designs:

The dual Z motors still residing in the front for sake of accessibility, but then I realized I want them in the back and keep the front dedicated to the printhead.

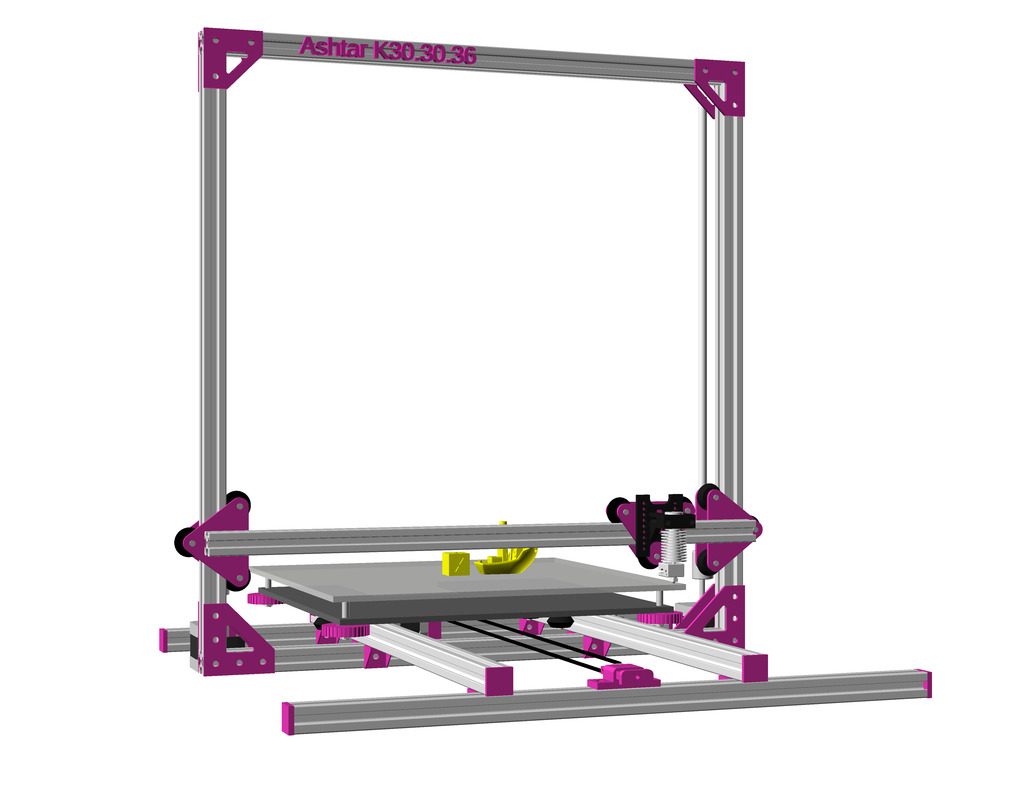

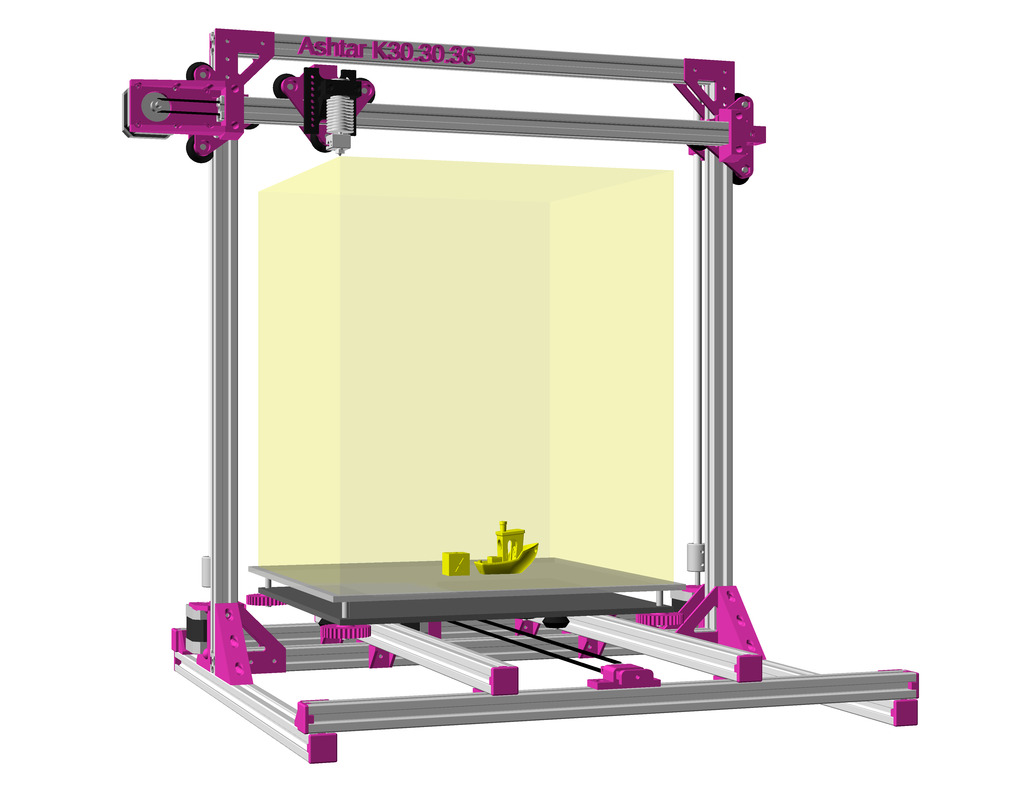

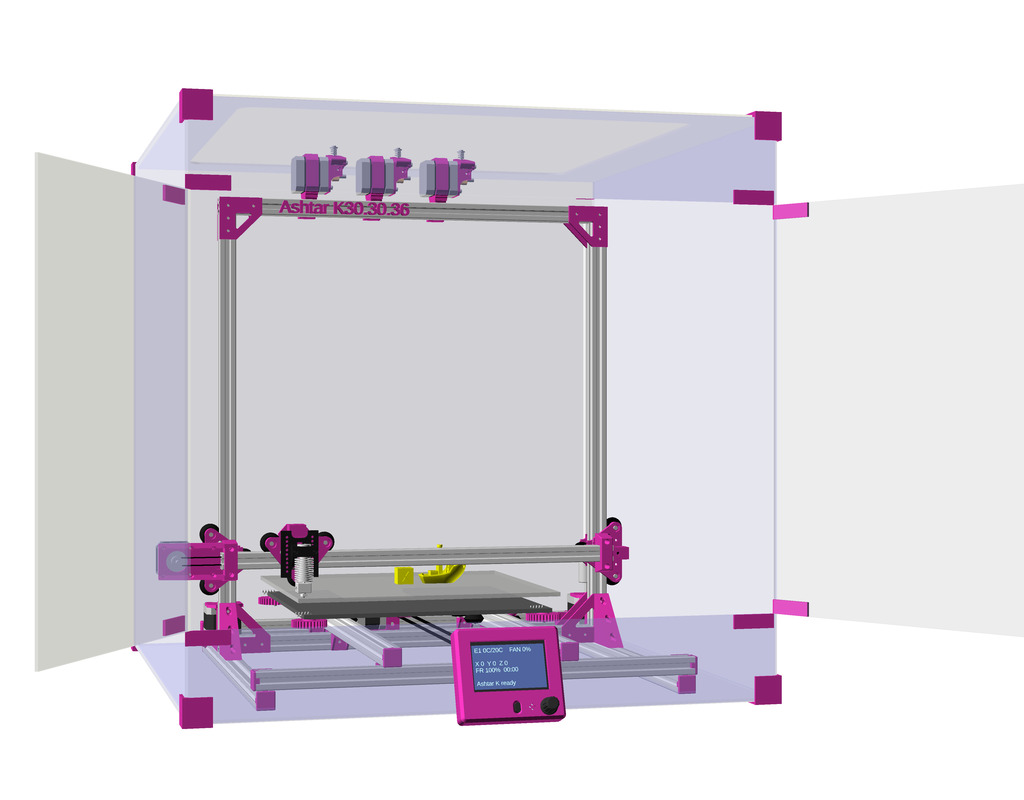

Ashtar K Series: Riding Alu Profiles, Uni-Length Beams

Mid of July 2018 I started the Ashtar K series, I decided to use 2020 alu profiles and focused on the single length of alu profiles, uni-length so I could reuse the beams for other future designs and since all the designs were parametric, it was easy to attain to find an optimum of single length beams and a common build-plate or build-volume:

The 9 beams design turned out too weak when I actually built the printer, so I added two beams back on left and right, and lift up the 9 beam design.

Eventually I decided to use 500mm alu 2020 profiles to achieve ~380x300x360 build volume; Ashtar K #1 used 400×300 build-plate, and Ashtar K #2 300×300 build-plate. Ashtar K #1 was functional in August 2018, and since then became my working horses together with Ashtar K #2, reliably printing.

See more at Ashtar K project page of the current state.

Next Steps

After the Ashtar K I did the Ashtar C Core XY cubic frame also with 2020 alu profiles. Late 2020 I started to design Ashtar M, a derivative of Ashtar K but with a moving gantry and static bed, and Ashtar D with Classic XY alike Ashtar C; and also a draft of a parametric enclosure as well to be adaptable to all of my 3D printer designs.

That’s it.