Introduction

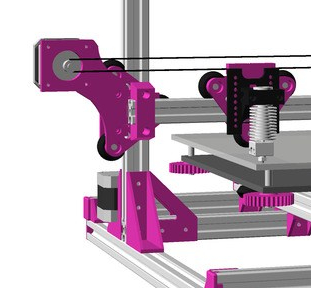

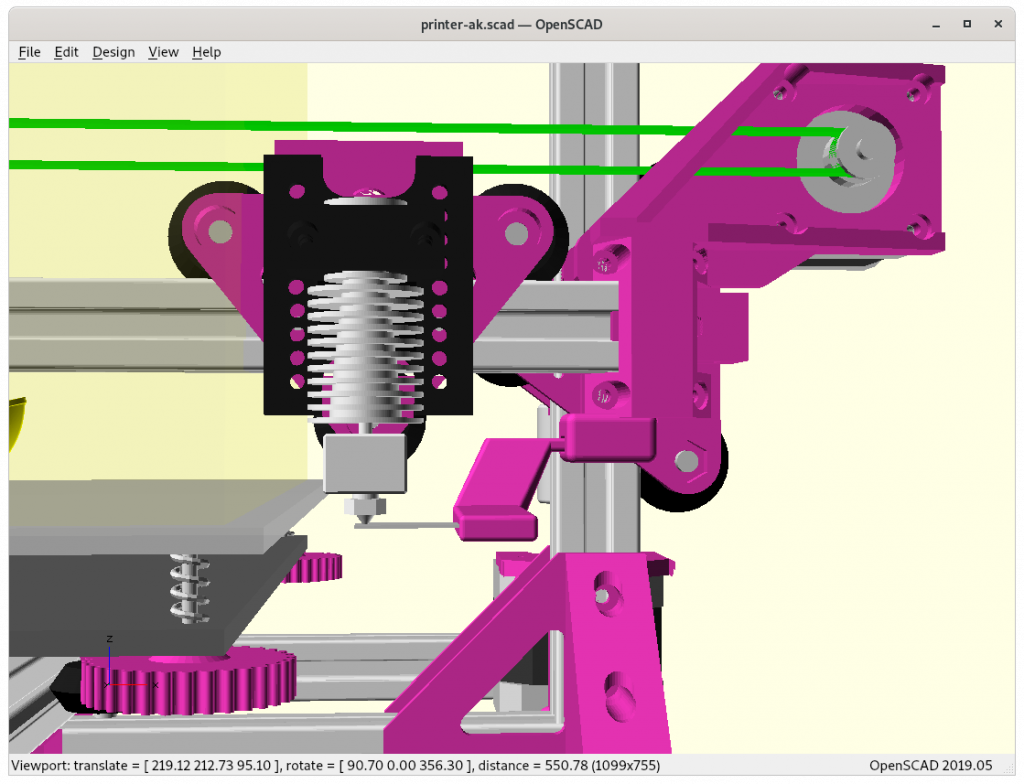

For the past 9 months (2019/08) I printed with two Ashtar K printers, where the X belt was routed above the 2020 extrusion:

Routing Above (Old)

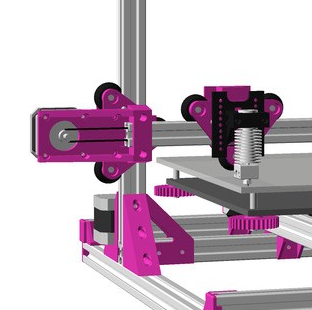

Routing Within (New)

Pro:

- easy access (X motor & X carriage belt mount)

- stabilizes the X carriage vertically

Cons:

- bending of the mount

And the bending of the mount became an issue more and more, as I kept tighten the belt and bend the mount more; time to redesign the part.

Update 2021/01/19: I resurrected the piece for the Ashtar K/M IDEX and improved the strength for its use-case.

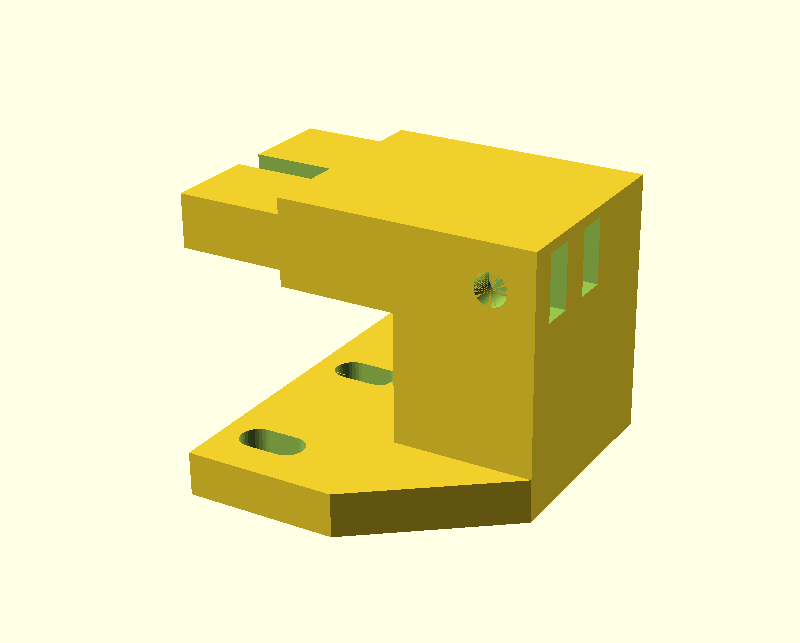

Old “routed above” X motor mount

Improved “routed above” X motor mount

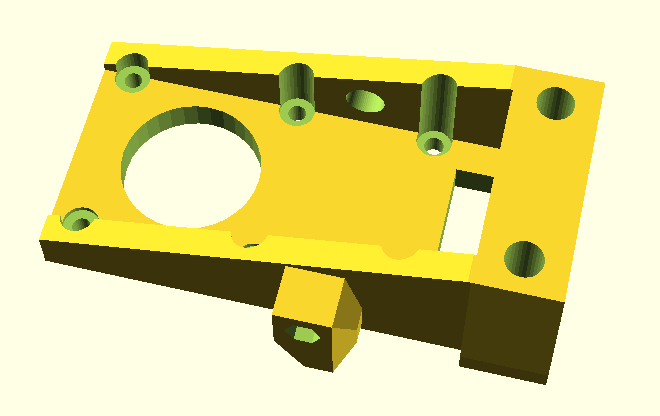

New Option: Routing Belt inside groove of 2020 Profile

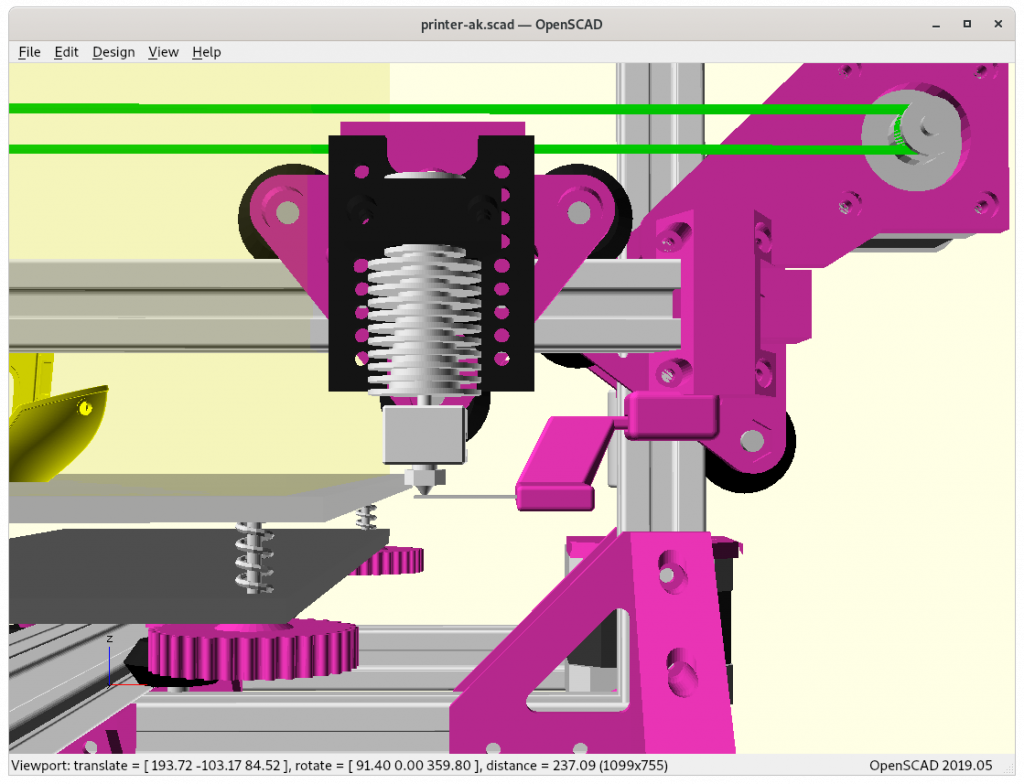

First I used T shaped 2020 aluminium profiles and the nylon wheels did have little surface to ride, hence, I wanted the belt also function as vertical stabilizing. Once I replaced the X beam with V shaped 2020 profile, and V shaped wheel in the V modules riding on the profiles, I thought to reposition the belt into the groove of the V 2020 profile, and so reposition the X motor mount. So I merged the horizontal 2020 mount with the motor mount in one, plus adjustable Z stopper:

which gave the desired stiffness of the part I sought.

Pro:

- remains stiff

- easy to mount & accessible (belt, Z stop screw)

Cons:

- larger part, 2020 mount and motor mount combined

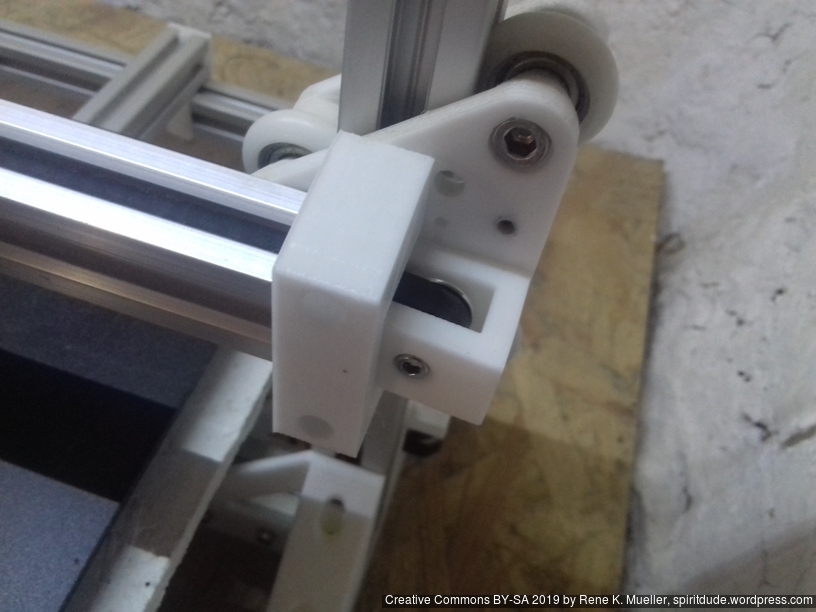

X Carriage Beltmount

In order to route the belt in the groove of the 2020 profile for the X carriage itself, a rather delicate piece was required, mounted at the backside of the X carriage V-module; I use a M3 to fasten the belts:

Assembled

Part names with variables:

xcarriage_short_hmount_motor_2020(zstop=true): main motor mount with 2020 profile mount combinedxcarriage_beltmount_2020(th=32.7): new belt mount on the X carriage,thdefault at 32.7mm, but one needs to measure the total thickness of the V modules acting as X carriagepulley_holder_2020(): right side of the belt routing

That’s it.