Sourcing

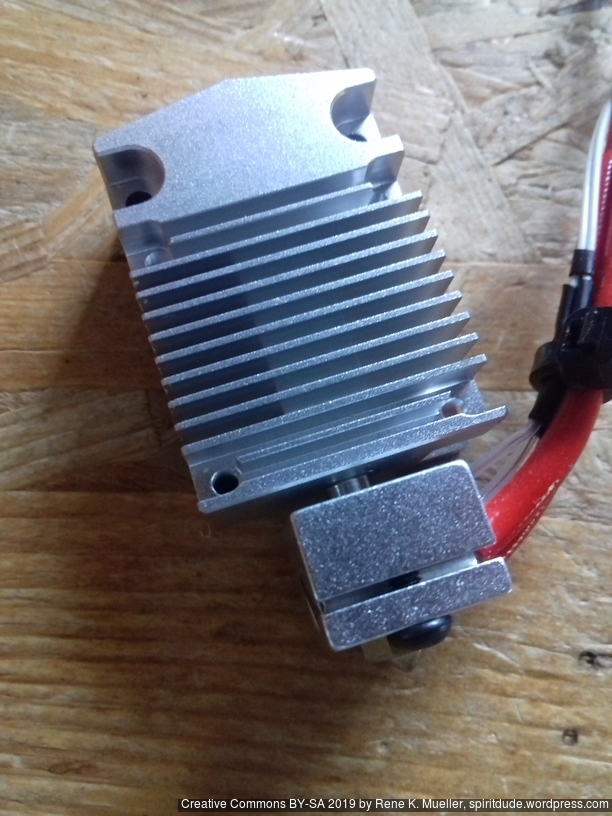

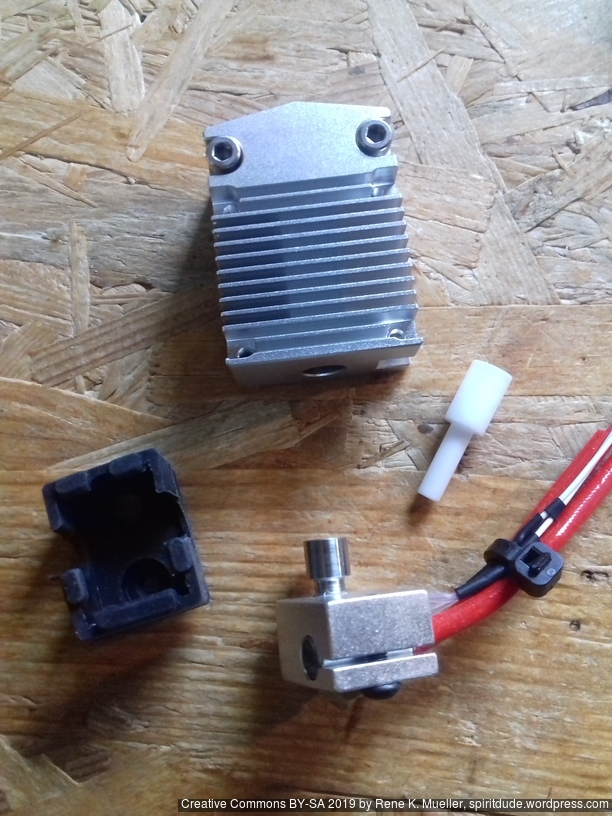

After my bad experience with the “Cyclops/Chimera” clone (2-in-1 with mixing capability), I purchased (June 2019) the improved “Cyclops” which resembles the “Cyclops NF 2-in-1” or “LERDGE 2-in-1 V2” , so I name this variant “Cyclops NF 2-in-1“:

which can be ordered at AliExpress (affiliate links):

- SANBrother Improved Cyclops (my source) or

- LERDGE 2-IN-1 V2 (slightly different screws holes to fasten heatbreak),

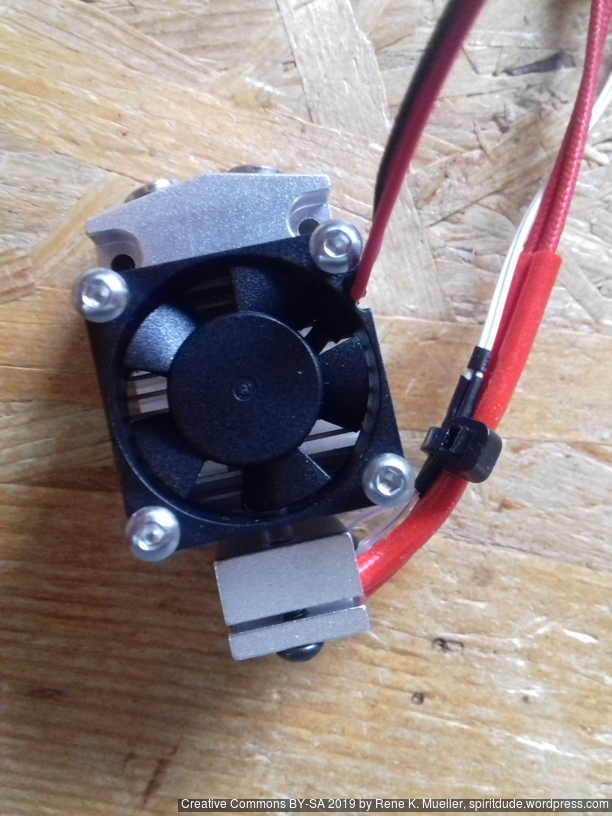

and uses E3D V6 nozzle (clone) and 30x10mm fan on top. The two mounting holes are 24mm apart and fit the Prusa i3 X-carriage.

Further, the two filaments cannot be mixed like the original Cyclops but either filament A or B can be fed into the nozzle, but not both at the same time. Also, one can print with one filament solely, a 2nd filament must not be present.

Pros:

- affordable

- simple setup

- single filament printing possible without 2nd filament being present

Cons:

- cannot mix colors

- long retraction required for tool change (>34mm)

- long transition purge (~55mm)

- custom PTFE or nylon piece in the heatbreak (not easy to source)

- uncoordinated retraction can cause one filament blocking another

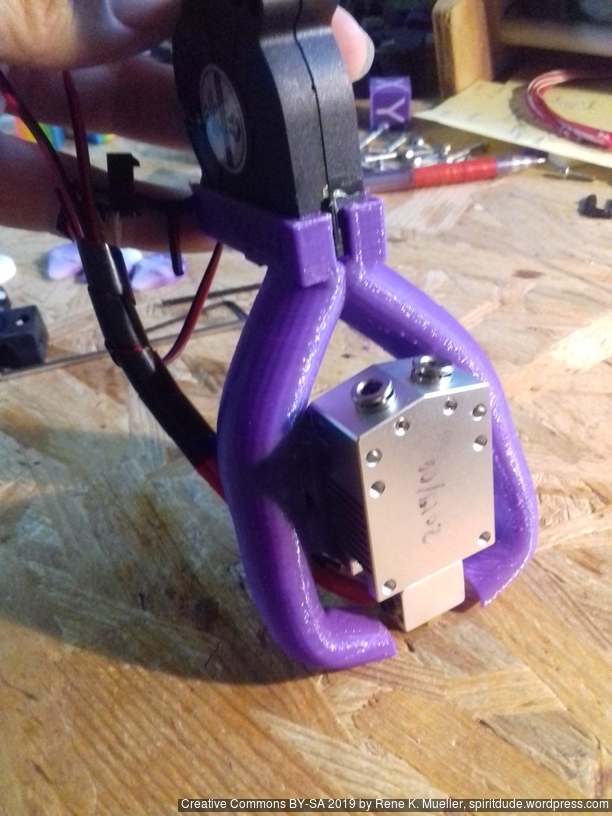

Model & Part Cooler

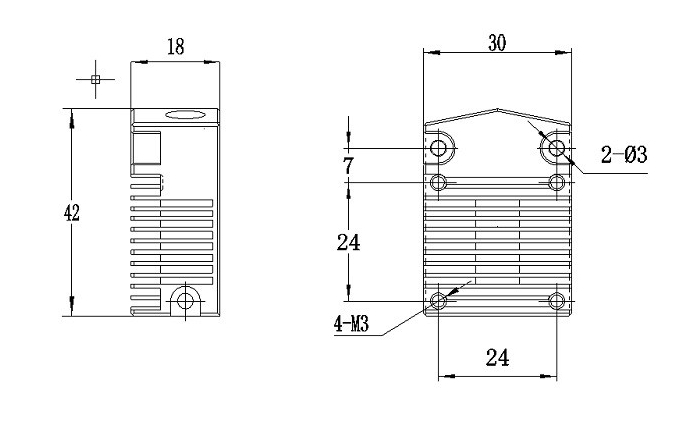

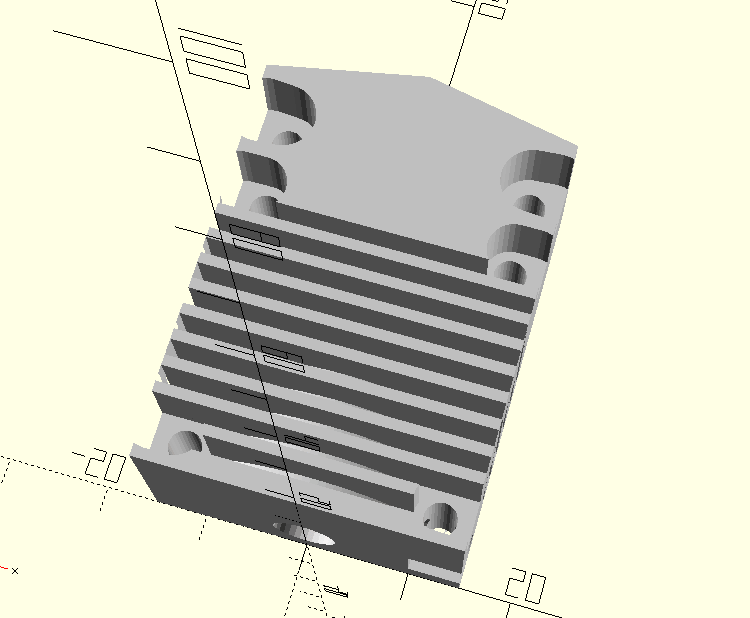

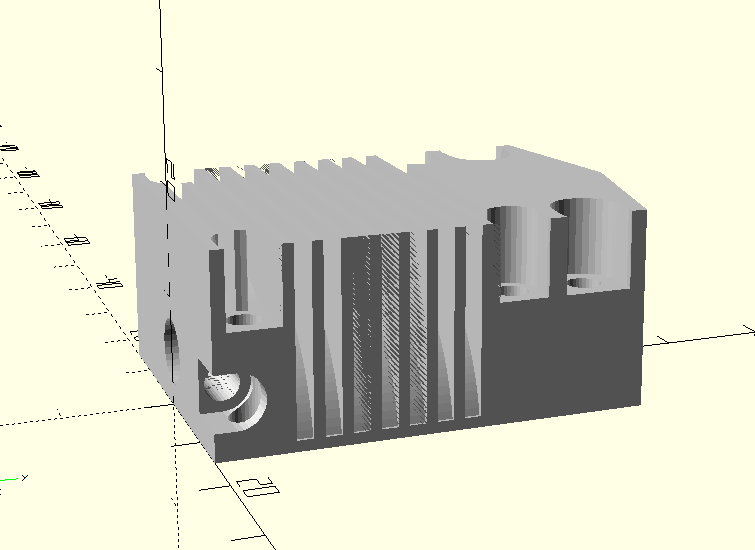

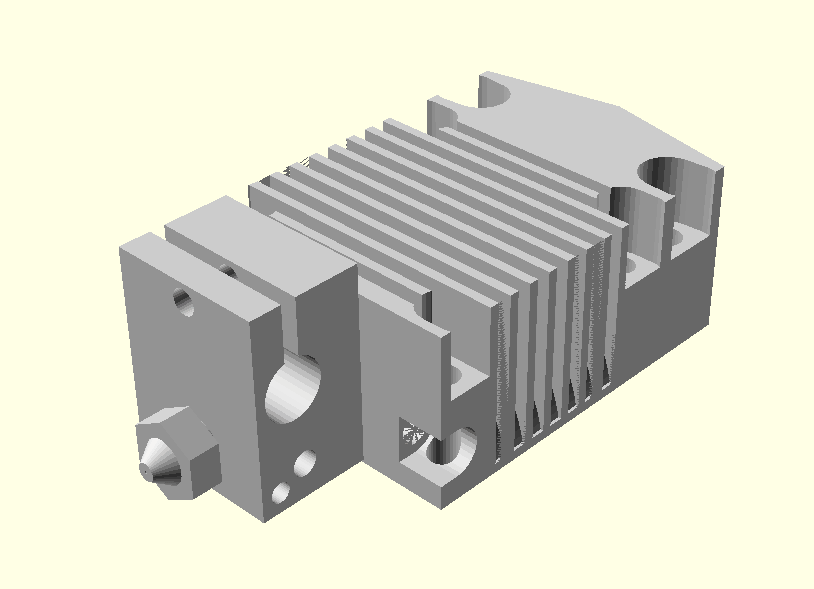

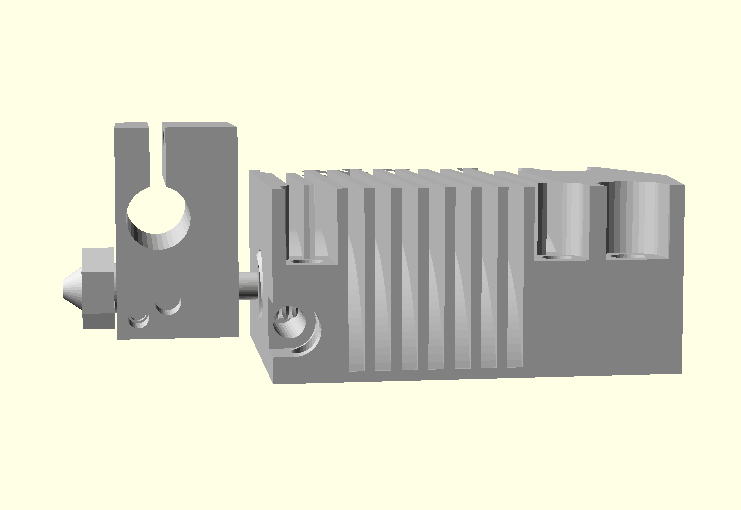

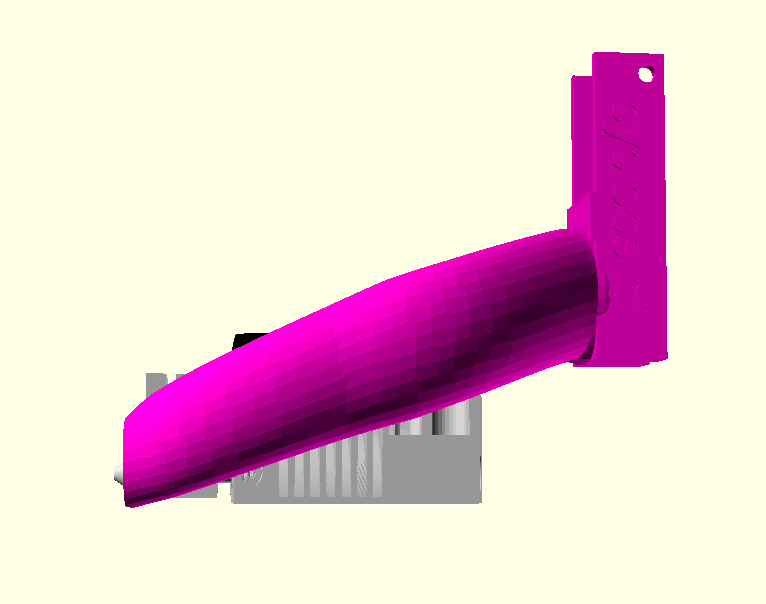

I quickly modeled the heatsink in OpenSCAD:

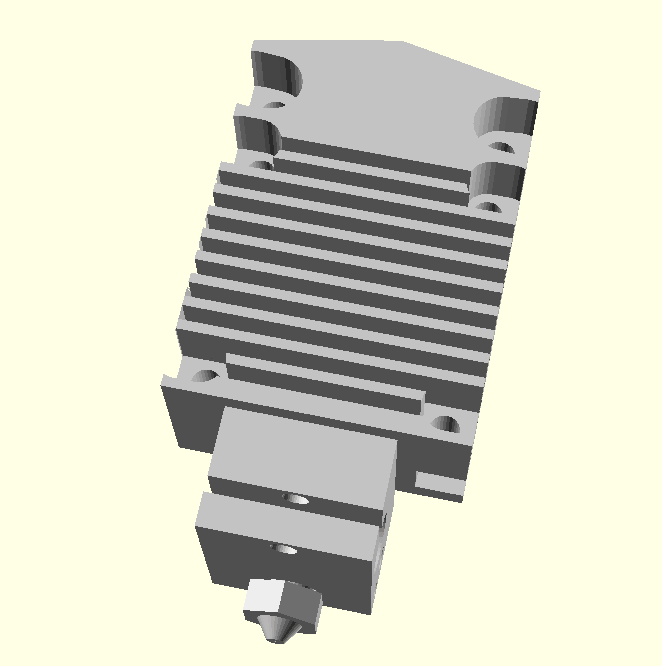

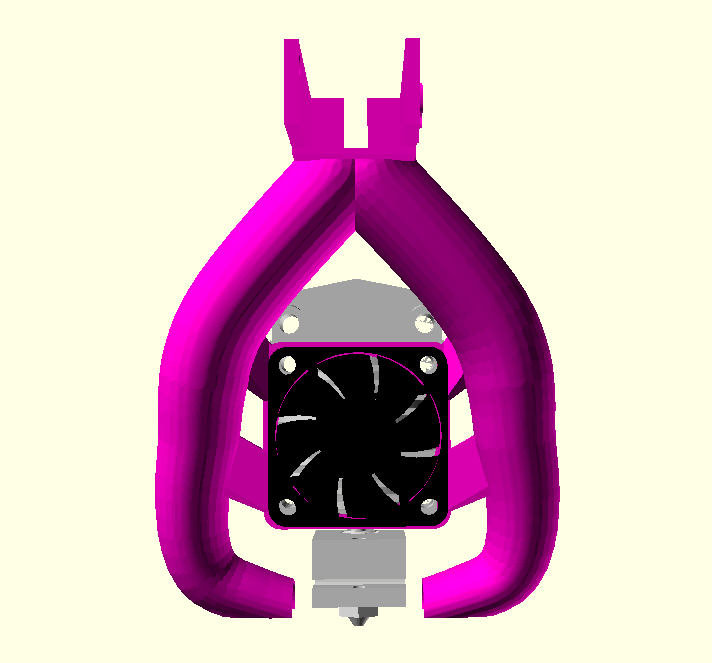

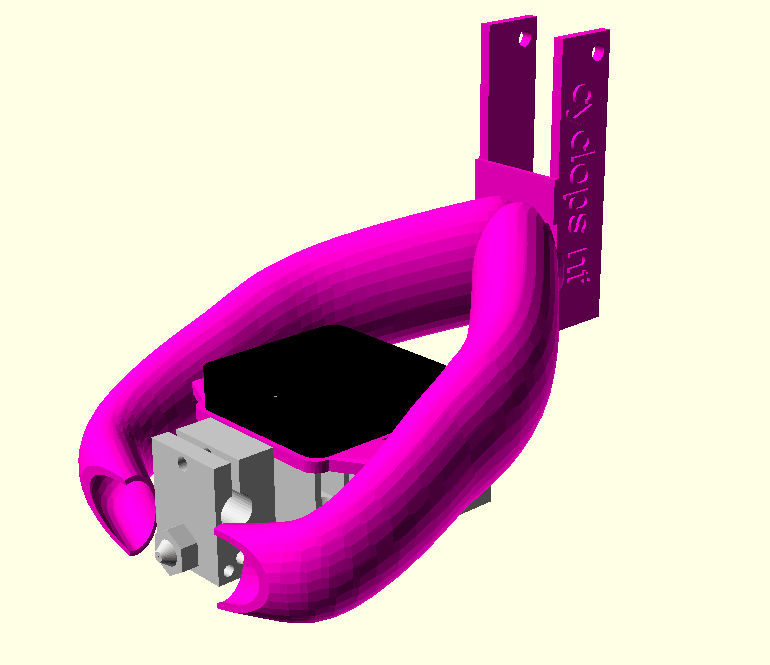

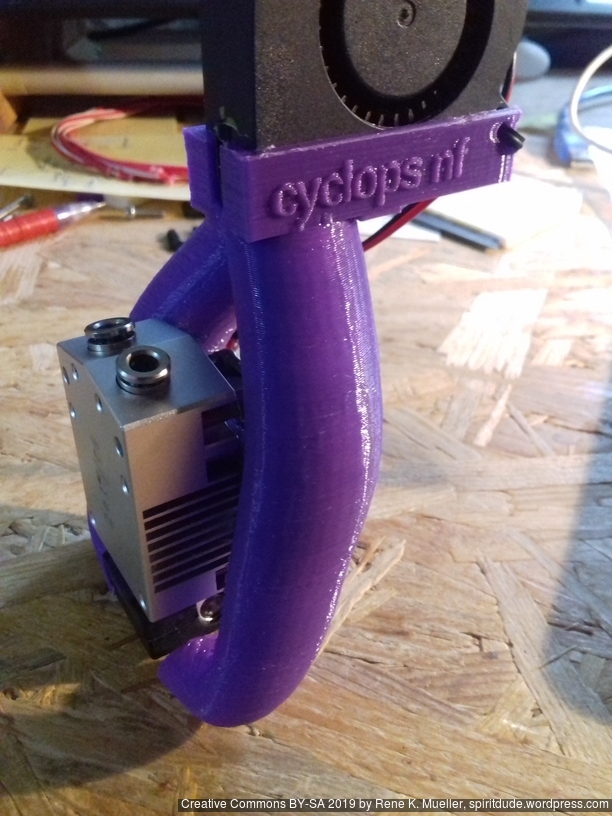

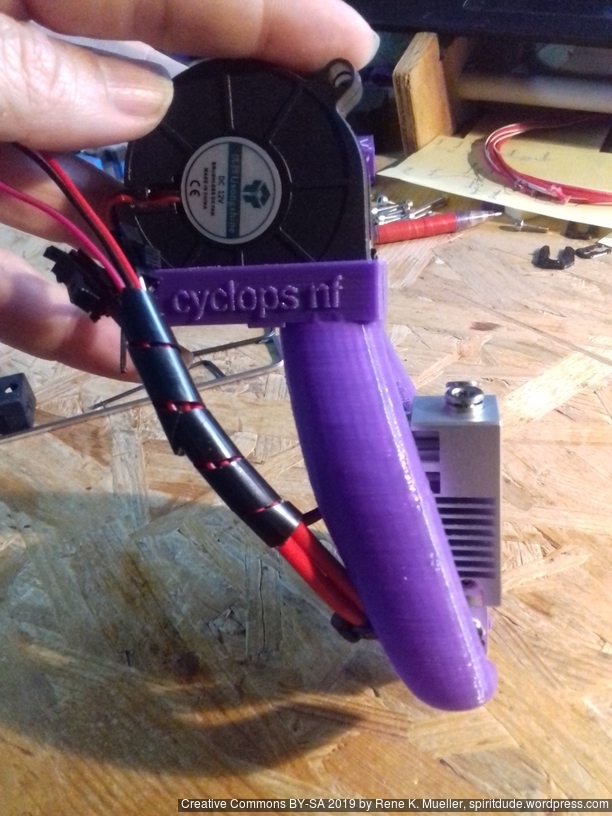

so I was able to adapt my Parametric Part Cooler with following settings part_cooler(name="cyclops nf",m=30,wx=25,yoff=10):

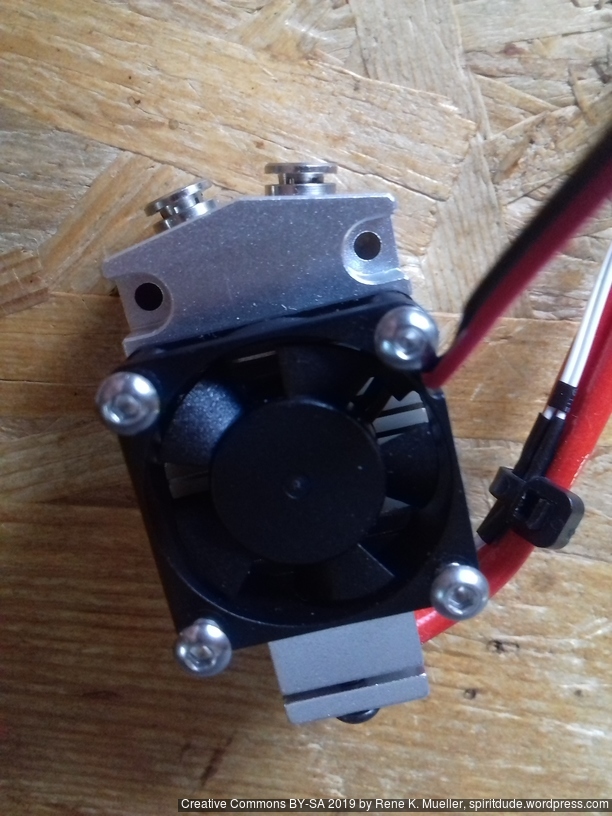

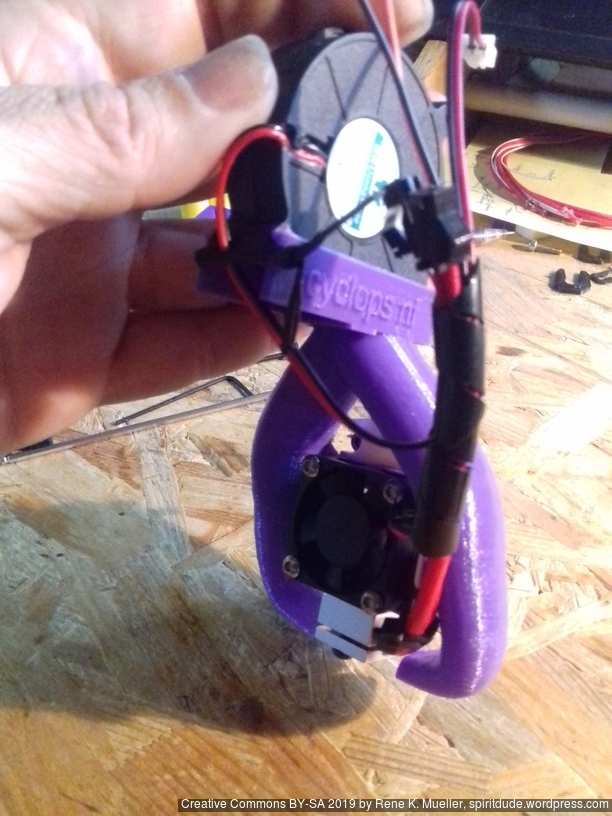

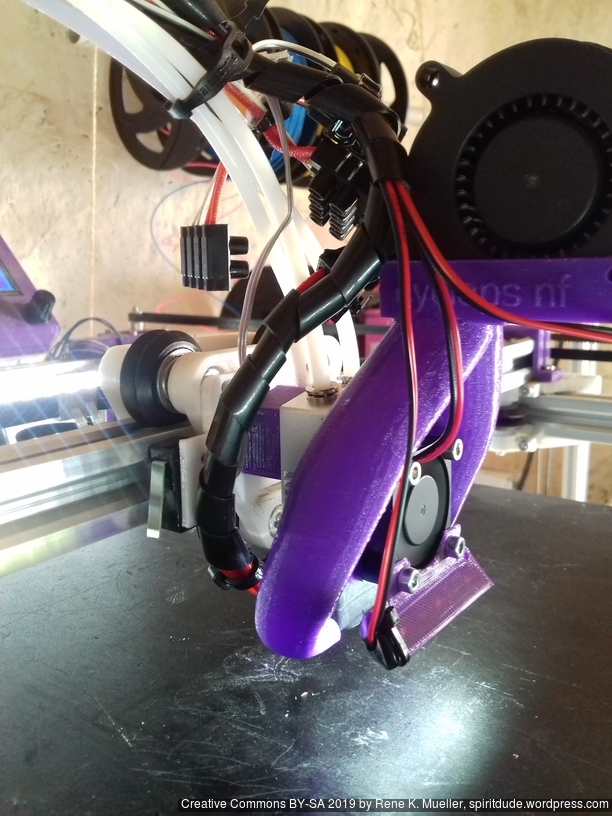

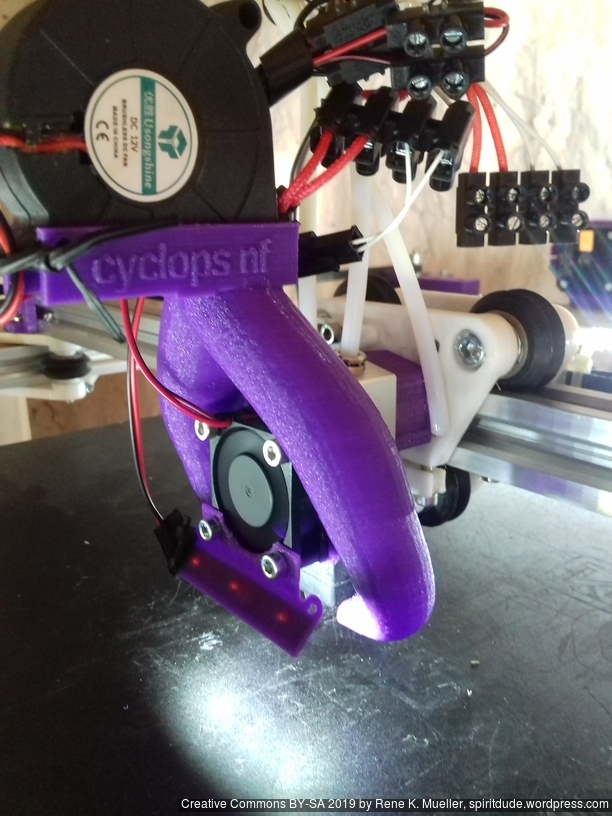

and the printed assembly:

Download

https://www.thingiverse.com/thing:3680090

Full Assembly

I finally turned the heatblock around (from the default orientation), so I could see the nozzle better and the LED strip shining more direct on the nozzle and bed.

Operation

The long tool switching retraction of > 34mm imposes quite additional risk of jamming combined with temperature sensitivity: depending on the temperature the pulled back of end of filament changes shape, and may not able to re-enter at next tool switch – so I’m a bit skeptical on the reliability – time will tell.

As I use print3r solely (without GUI), I set following in the printer profile:

# -- slicer=slic3r, slic3r-pe and prusa only: retract_length_toolchange = 36

and a small macro named e2-nf-t1.ini for my Ashtar C #1 (380x400x380) Core XY style:

prepend_gcode="G91\nT0\nG1 E20 F100\nG1 E-36 F3000\nT1\nG1 E36 F3000\nG1 E60 F100\nG90\nG92 E0\n"

end_gcode="G1 Y{$machine_depth-10} F6000\nG92 E0\nG91\nG1 E-2 F2000\nM104 S0\nG1 E-36 F3000\nT0\nG1 E36 F3000\nM84\nG90\n"

which I use as print3r @e2-nf-t1 ... in case I like to print with 2nd filament only:

- start:

T0: purge 20mmT0: retract -36mmT1: forward 36mmT1: purge 60mm- reset E meter and go back to absolute positioning/extruding

- end:

- go back to Y380 (absolute)

T1: retract extrusion -2mmT1: retract -36mm quickT0: forward 36mm quick- switch off heating and motors

This way I keep T0 as default, and on-demand switch to T1 only with @e2-nf-t1 macro in operations. One case is not covered: if I abort a print then T1 is still active in the printhead and manually needs to be retracted (future print3r version will resolve this).

print3r --device=tcp:printhub:0 --printer=ashtar-c-1-e2 --random-placement --scad --slicer=cura print 'for(i=[0:2]) translate([50*i,0,0]) cylinder(d=5,h=40)'

Comparison Dual/Multi Color/Material Extrusions

blue = relevant positive

red = relevant negative

Independent Dual Extrusions (IDEX)

- complex setup

- moderate cost

- non-mixing

- dual nozzles

- dual heatblocks

- dual heatsinks

- normal retraction

- no purge block 1)

- no oozing over print

- no inactive nozzle traveling

- reliable 2)

★★★★★

Dual Hotends 2-in-2

- simple setup

- low cost

- non-mixing

- dual nozzles

- dual heatblocks

- dual heatsinks

- normal retraction

- no purge block

- inactive nozzle oozing over prints

- inactive nozzle travels over print

- moderate reliability

★★★★★

Chimera 2-in-2

- simple setup

- clone: low cost

- original: high cost

- non-mixing

- dual nozzles

- dual heatblocks

- single heatsink

- normal retraction

- no purge block

- oozing of inactive material

- inactive nozzle travels over print

- moderate reliability

★★★★★

Cyclops 2-in-1

- simple setup

- clone: low cost

- original: high cost

- mixing

- single nozzle

- single heatblock

- single heatsink

- normal retraction

- purge block required

- no oozing of inactive material

- clone: unreliable

★★★★★ (clone)

Cyclops NF 2-in-1

- simple setup

- low cost

- non-mixing

- single nozzle

- single heatblock

- single heatsink

- complex retraction

- no oozing of inactive material

- moderate reliability

★★★★★

Diamond Hotend 3-in-1

- complex setup

- clone: low cost

- original: high cost

- mixing

- single nozzle

- single heatblock

- 3 heatsinks

- tricky retraction

- purge block required

- no oozing of inactive material

- moderate reliability

★★★★★

Multiple Switching Extrusions (MSE) 2-in-2, 3-in-3, 4-in-4

- moderate complex setup

- requires additional servo or motor

- extendable 2, 3, or 4 colors/materials

- low cost

- non-mixing

- multiple nozzles / heatblocks / heatsinks

- normal retraction

- no purge block 1)

- no oozing of inactive material

- no inactive nozzle touching print

- reliable 2)

(rating comes later)

Y Splitter x-in-1

- simple setup

- extendable 2, 3, or 4 or more colors / materials

- low cost

- non-mixing

- single nozzle

- single heatblock

- single heatsink

- complex retraction

- purge block required

- no oozing of inactive material

- moderate reliability

★★★★★

Tool Changer

- complex setup

- extendable to n-colors or materials

- moderate cost

- non-mixing

- multiple nozzles / heatblocks / heatsinks

- normal retraction

- no oozing of inactive material

- no inactive nozzle touching print

- moderate reliability

(rating comes later)

Footnotes

- in theory no purge block, but if ooze shields are shared among switching extrusions (more than 2 extrusions) there may be cross-contamination between colors/materials

- the printheads individually are proven to be reliable

Hints:

- single heatblock = same print temperature

- dual heatblock = different print temperatures possible

- dual nozzle = different nozzle sizes possible

That’s it.