Diamond Hotend Part Coolers Design Reviews:

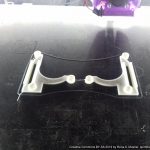

- Diamond Hotend Dual Short Fan Shrouds

- Diamond Hotend Ring Cooler

- Diamond Hotend Directional Part Cooler

This is the 3rd option for a Part Cooler for Diamond Hotend I designed, a pointy directional approach using again 5015 blower:

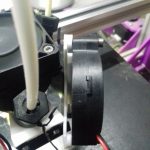

Assemble

Functional Setup

Parts

Printable:

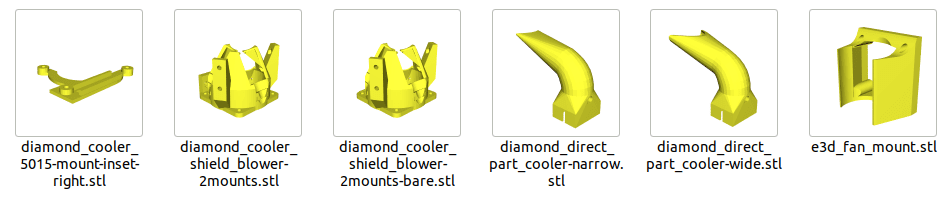

diamond_cooler_shield_blower-2mountsdiamond_cooler_5015-mount-inset-rightdiamond_direct_part_cooler- print without support but with additional brim to increase adhesion of 1st layer

- print with 0.4mm nozzle / line-width, with a good slicer this gives 3 perimeters for the model with 0.2mm or 0.25mm layer-height

-narrow: use ~50% fan cooling, position as low to the nozzle height as possible (e.g. 2mm above, not less, not more)-wide: use ~80% fan cooling: more tolerant on vertical position / height

- optional:

e3d_fan_mount& LED Strip mount

- optional (recommended):

- printable 3x PC4-M10 PTFE

Vitamins (Non-Printable):

- 5010 fan (main heatsink fan)

- 5015 blower

- 3x M3x20

- 2x M3 nuts

Download

https://cults3d.com/en/3d-model/tool/diamond-hotend-directional-part-cool

https://www.thingiverse.com/thing:3855947

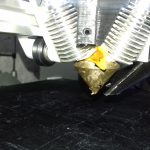

Throttle Fan & Positioning

Even though the air output is close to the nozzle tip, you might reduce the fan

-narrow: use ~50% fan cooling, position as low to the nozzle height as possible (e.g. 2mm above, not less, not more)-wide: use ~80% fan cooling: more tolerant on vertical position / height

to avoid cooling the nozzle and run into “THERMAL RUNAWAY” error – or you use a Diamond Hotend silicon sock, then you likely are able to use 100% cooling fan.

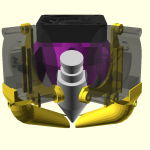

XYZ Hollow Calibration Cube with 3 Colors Mixed

The actual success of this setup is seen in this test cube (printable with 0% infill):

The “X” and “Y” junctions are quite well printed, not as good with a “bull horn” part cooler as with E3D V6 setup.

Addendum: Dual Directional Cooler

Although this looks like a nice setup, the overall output of air to the nozzle is overpowering and cools off the nozzle too much. The cooling fan, in my case, required reduction to 20% to avoid “THERMAL RUNAWAY ERROR”, but at 20% the cooling effect on the extruded filament was less optional than with a single directional cooler – therefore this option isn’t recommended, unless you have a silicon sock over the nozzle.

That’s it.