Status: fully tested, but not yet released

Updates:

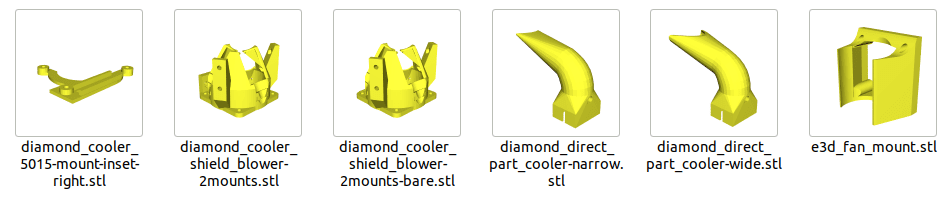

- 2020/12/27: individual renderings for each application

- 2020/12/21: improve documentation, with application variables

- 2019/06/16: design solidified, multiple variants tested (Triple Micro Swiss, Dual Micro Swiss, Chimera, Cyclops NF, Dual V6, Single V6)

Introduction

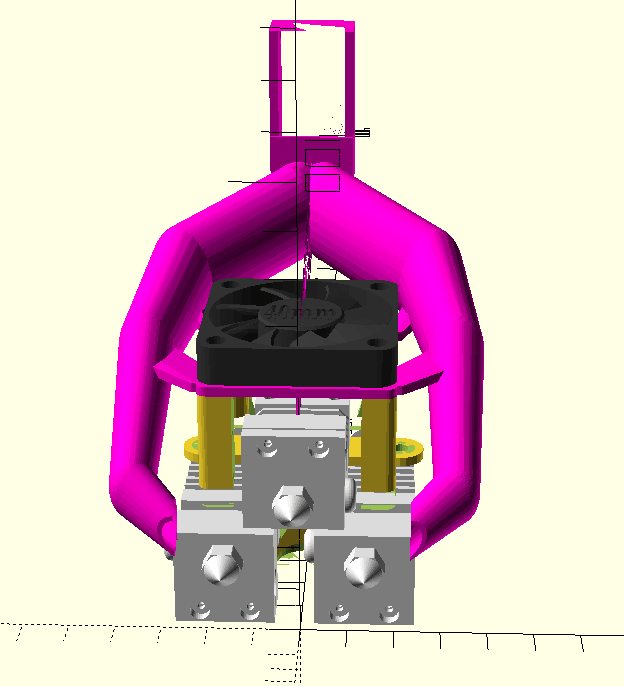

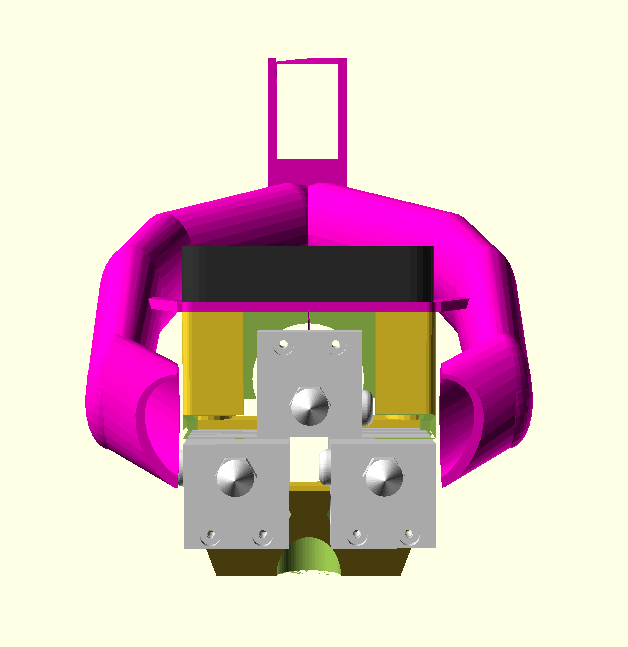

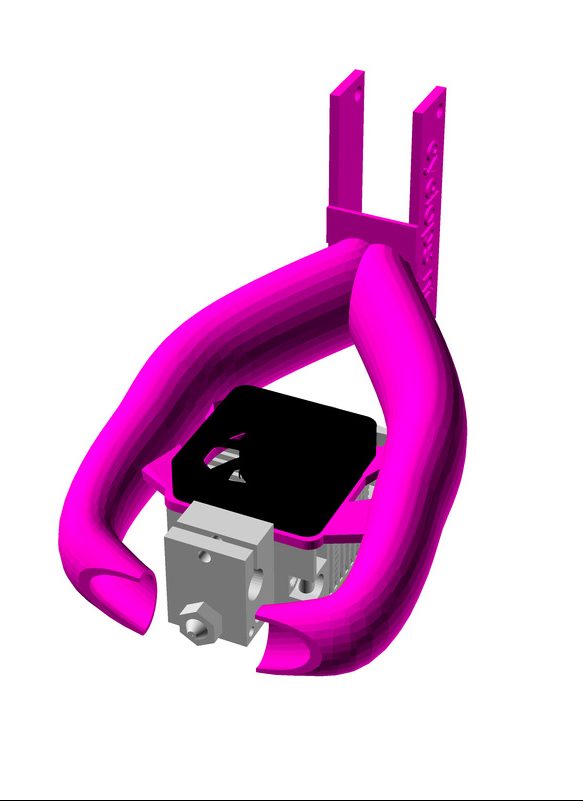

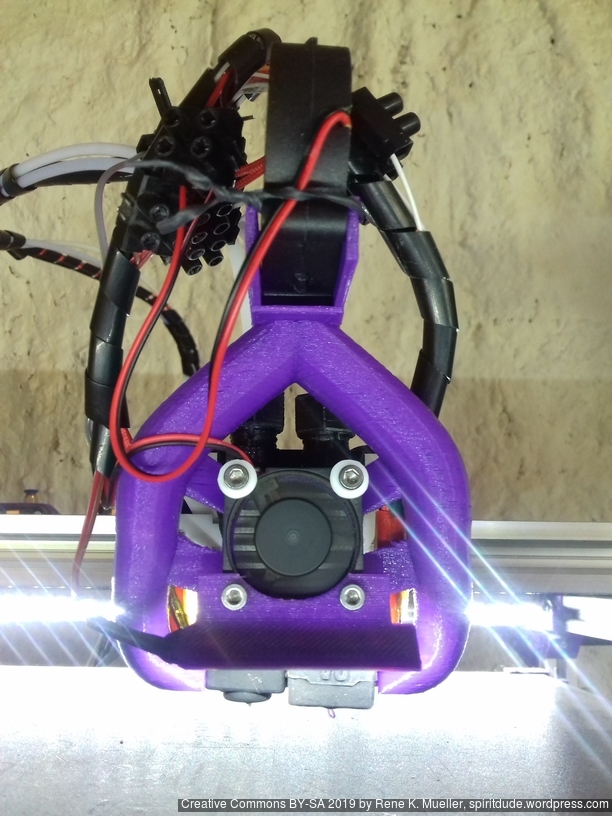

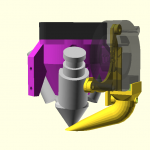

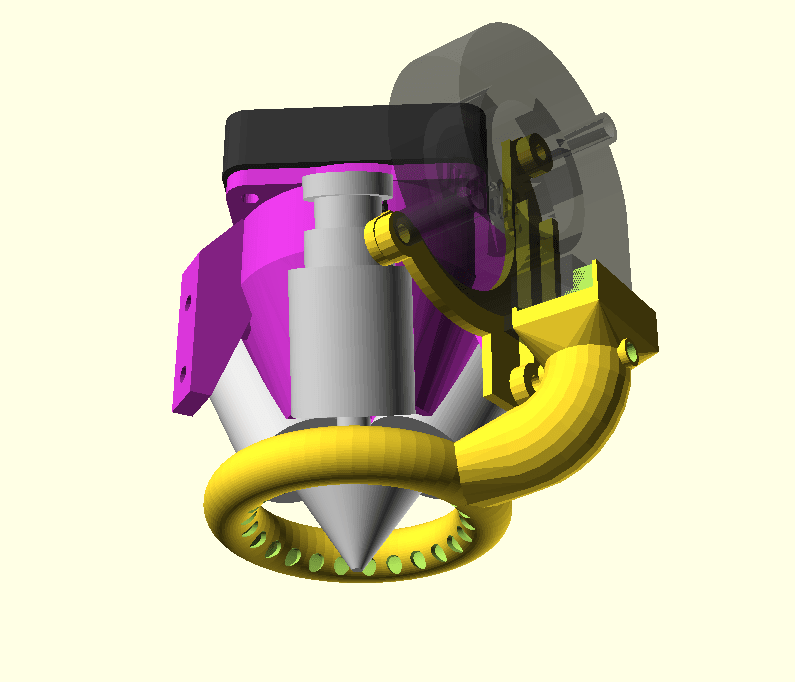

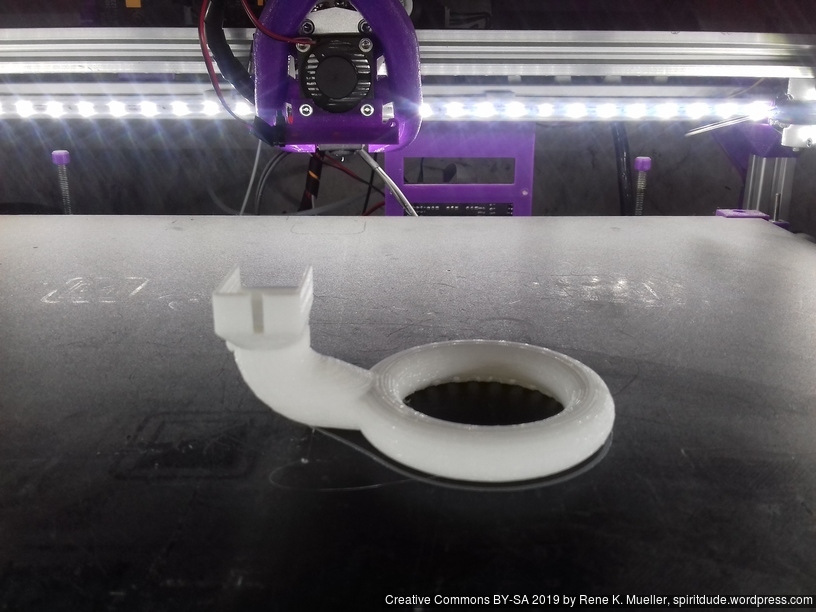

Back in May 2019 I started to customize dedicated printheads, e.g. combining CR10 hotends / Micro Swiss Hotends in dual and triple mode – and thereby required a dedicated Part Cooler. This lead me to develop my own Parametric Part Cooler in OpenSCAD, adapting the design of Radial Fan Fang by Lion4H as I used that one successful for E3D V6 – now a general approach coded entirely in OpenSCAD:

I started with the central heatsink fan in the geometric center, and route the pipes (symmetrically) around it, back to the nozzle; on top using 5015mm fan blower – after a couple of hours the basic form was defined.

As long I am in edit or tune mode, the part cooler is rendered with a few corners – yet, when exporting STL format, the pipe is calculated with refined spline and smooth surface:

Variables

part_cooler() takes following variables with their defaults:

m=40: size of heatsink fant=2: thickness of fan mountzoff=17: z-offset of air outputsyoff=8: y-offset of air outputsws=12: extra width spacewx=35: cutout width X at the bottomsq2=0.6: relative squeeze Y-wise at air outputssq3=0.6: relative squeeze Z-wise at air outputszb=0.5: relative Z bendsmooth=false: switch of smooth pipe rendering (false: fast rendering / editing mode,true: export to STL)name="noname": label on both sidestscale=1: text/label x/y scale

Needless to say, to set or alter those variables you require the fan and the hotend as a model so you can model the part_cooler() around it.

Applications

After a couple of weeks the part_cooler() was designed for various hotends:

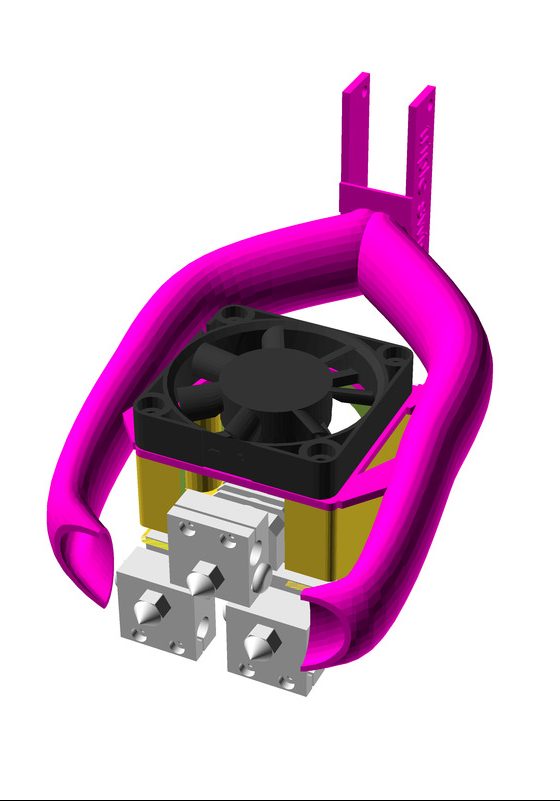

- Triple Micro Swiss (3x CR10 Hotends): largest part cooler, and first application

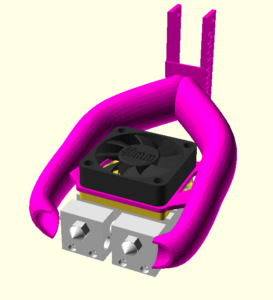

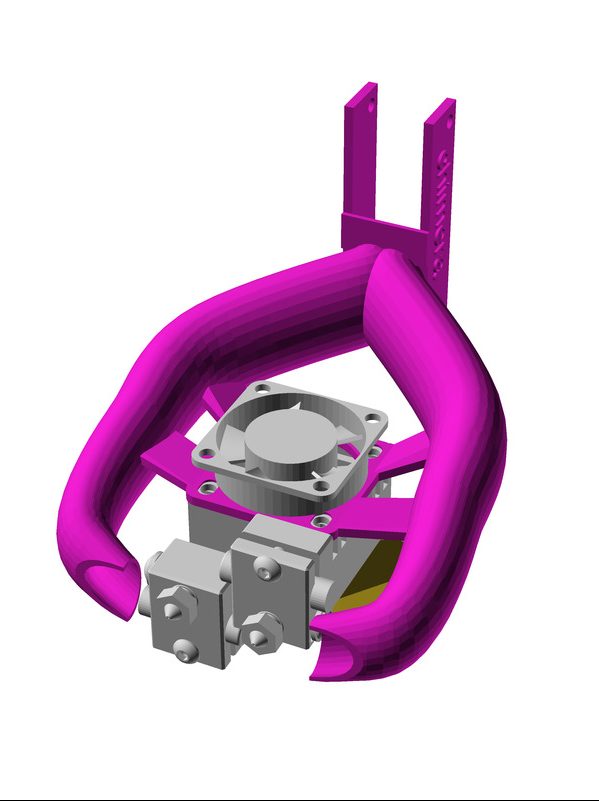

- Chimera 2-in-2: two filament/material and two nozzles, yet, a small common heatsink with E3D V6 nozzles

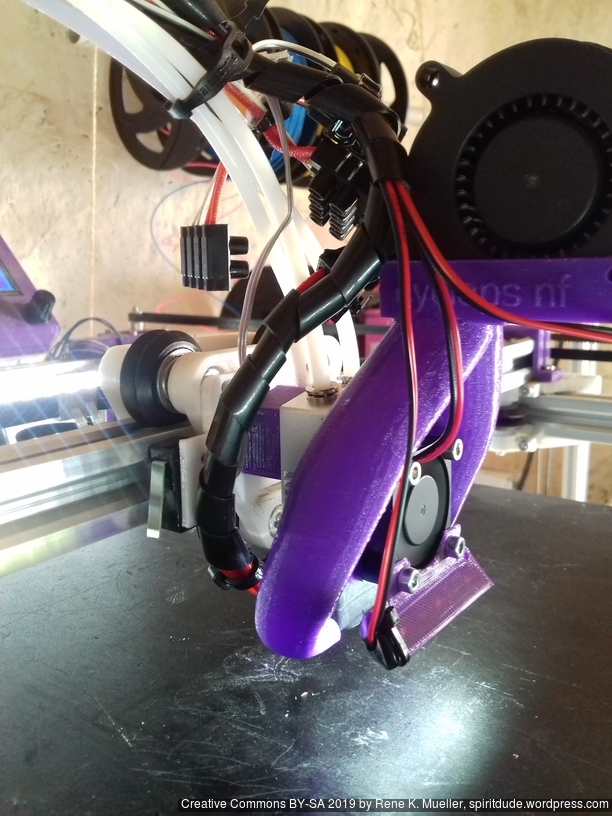

- Cyclops NF or Lerdge 2-in-1 V2: simple non-mixing 2-in-1 printhead – in use currently on the Ashtar C #1 (Core XY)

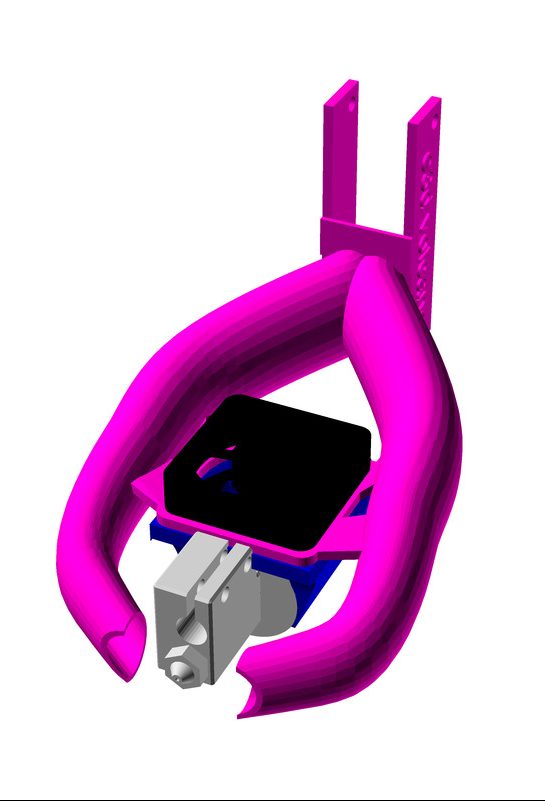

- E3D Volcano: although designs exist, I just wanted to see how my cooler performs in comparison – in use currently on Ashtar K #1 (Prusa i3-like) with 0.6mm nozzle

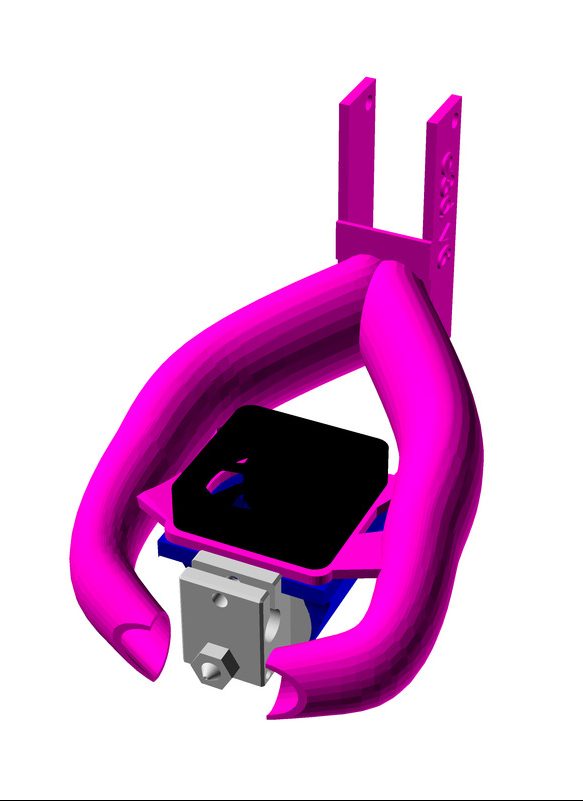

- E3D V6 Lite: just an excercise to make it work for this popular setup as well – in use currently on CTC DIY I3 Pro B Y3228

Application Variables

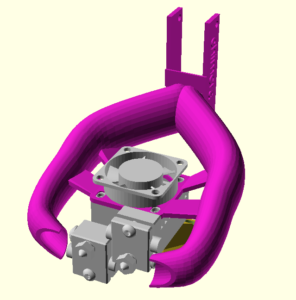

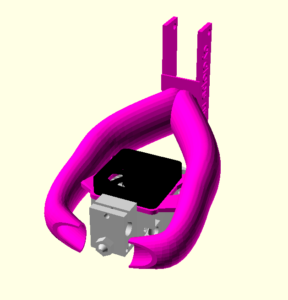

Triple Micro Swiss

name=”triple swiss”

m=50

wx=50

yoff=17

sq3=1

wx=54

* requires a dedicated fan mount: Triple Nozzle Printhead

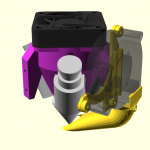

Chimera 2-in-2

name=”chimera”

m=30

yoff=10

zoff=18

ws=18

wx=42

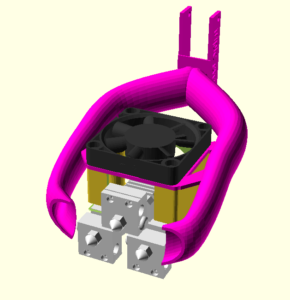

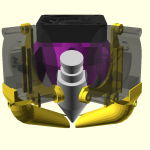

E3D Volcano

name=”volcano”

m=30

wx=24

yoff=12

zoff=21

zb=0.3

tscale=0.9

E3D V6 Lite

name=”e3d v6″

m=30

wx=24

yoff=12

zoff=14

zb=0.2

Pros / Cons

Pros:

- parametric, reusable design

- source code available (OpenSCAD) [not yet]

- modular/stack use:

- either use below or above existing heatsink fan

- e.g. add LED Strip Fan Mounts

Cons:

- other parts must be available as models in order to determine parameters of the part cooler

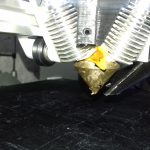

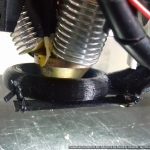

- heatblock(s) should wear silicon cover, as air outputs partially affect heatblock which should be avoided

Download

https://www.thingiverse.com/thing:3680198 (not yet released)

Currently all my parts reside in a single large parts.scad for all Ashtar 3D printers, it helps me to improve designs quickly, but hinders me to release part designs in OpenSCAD source individually – it’s all interconnected and therefore avoid split it into separate files for now. As soon it’s resolved I will release the OpenSCAD sources.

For now three part coolers I released in STL downloadable on the dedicated pages:

Impressions

I’m quite happy with the result and use this Parametric Part Cooler for all my planned use cases.

References

- Radial Fan Fang by Lion4H

See Also (Ashtar Series & Parts)

or