Updates:

- 2020/12/29: published finally, also released files on Thingiverse

- 2019/09/24: initial draft (not yet published)

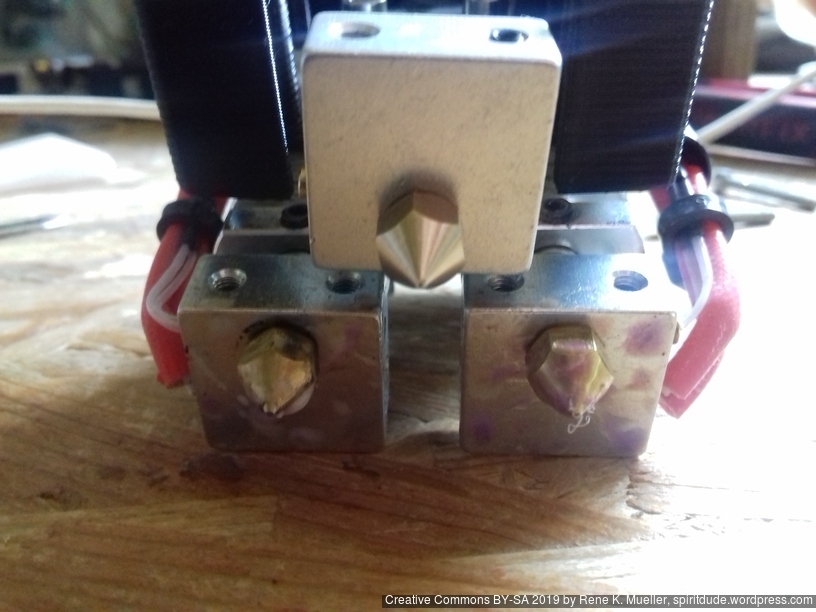

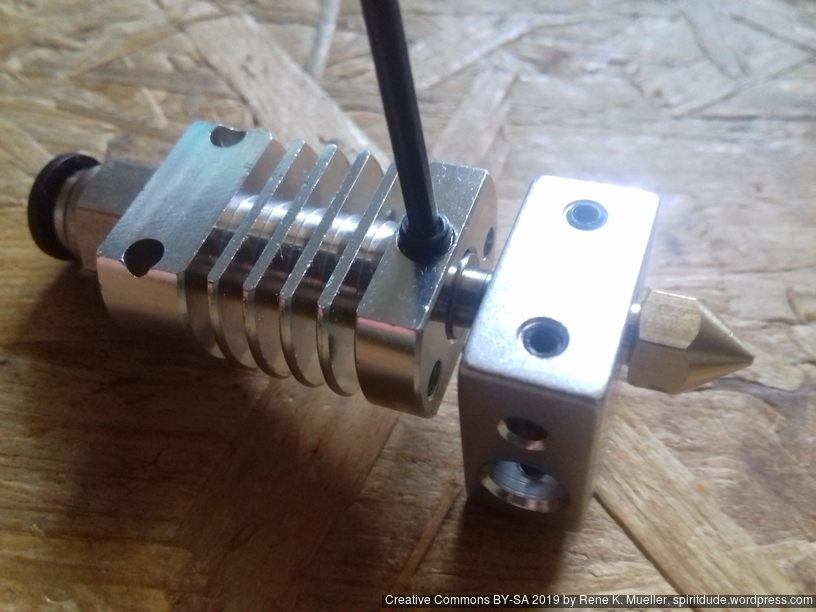

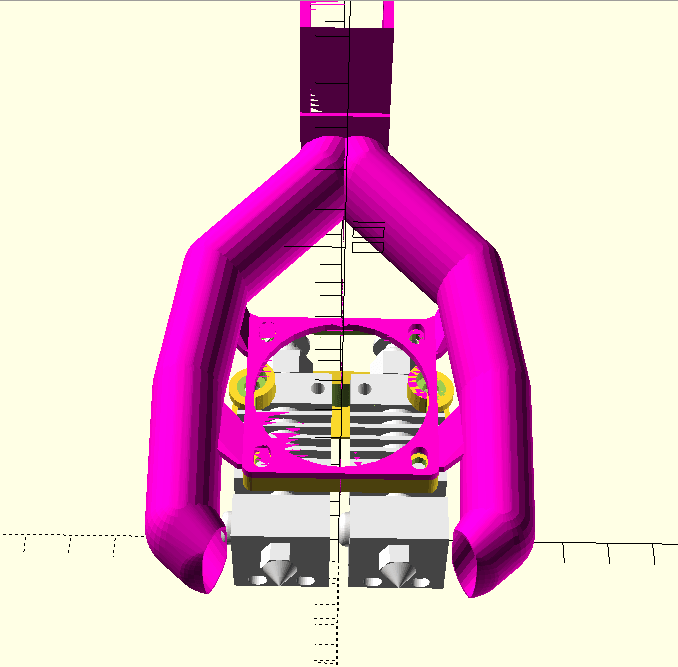

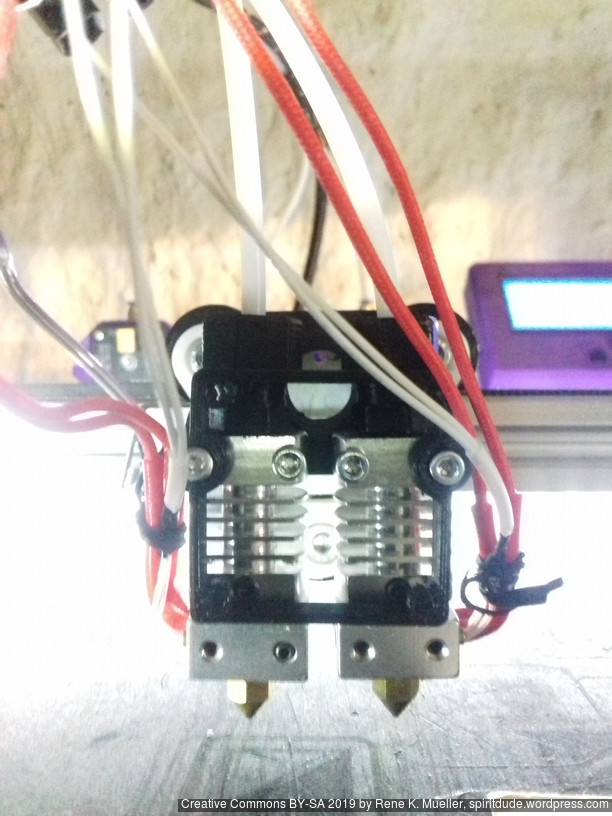

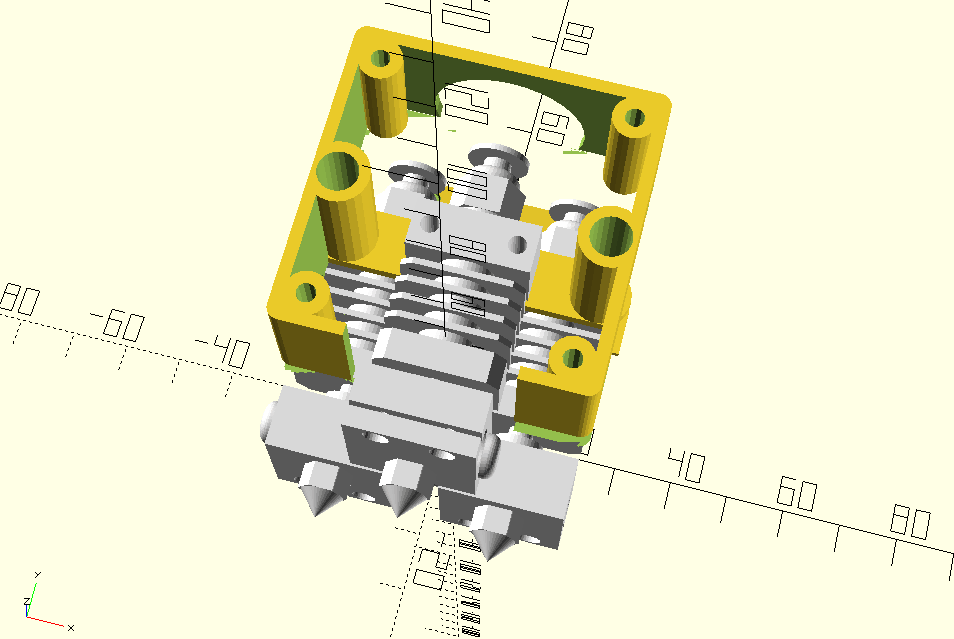

After working on dual CR10 nozzle / Micro Swiss nozzle setup, I considered to add a third nozzle:

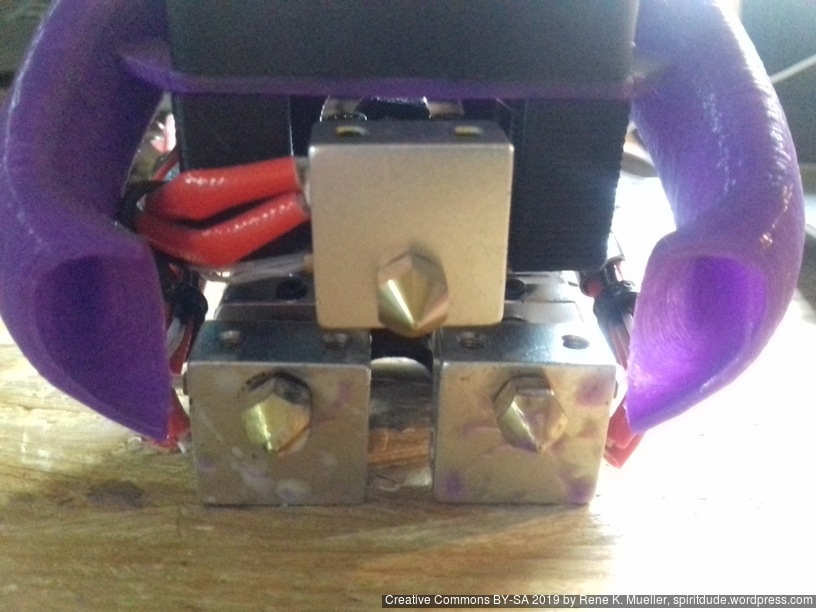

Triple CR10 Hotends / Micro Swiss Hotends

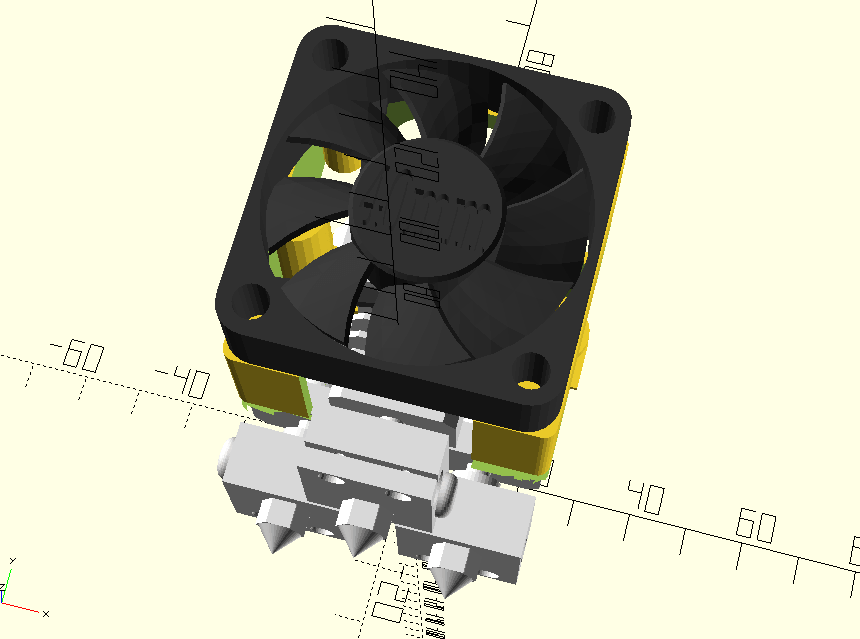

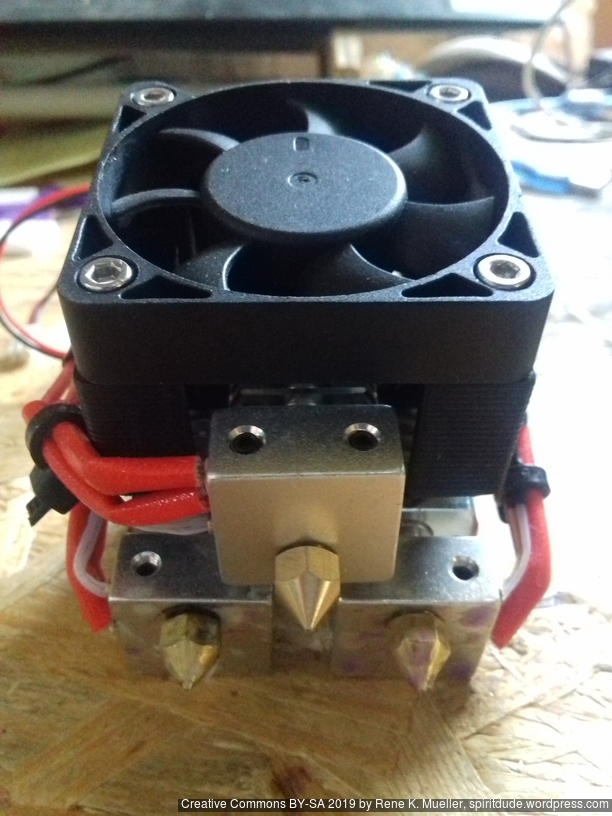

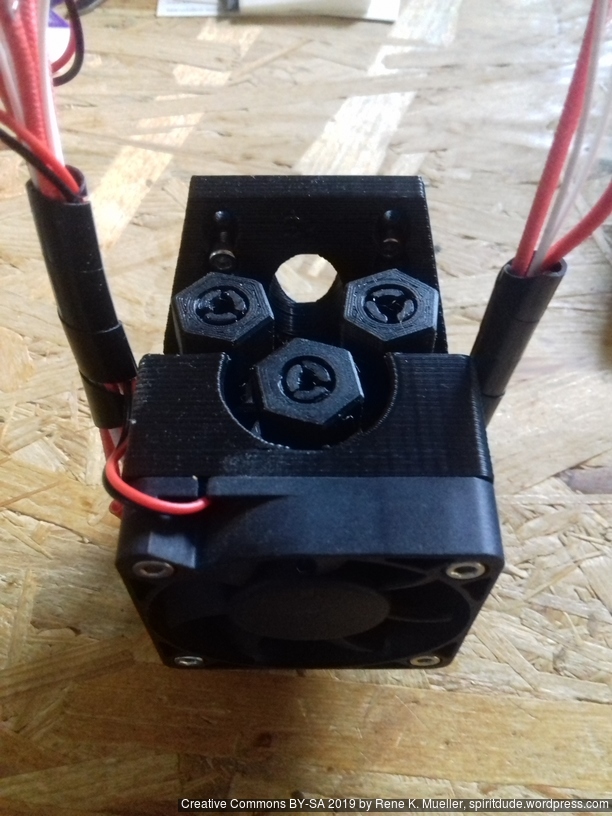

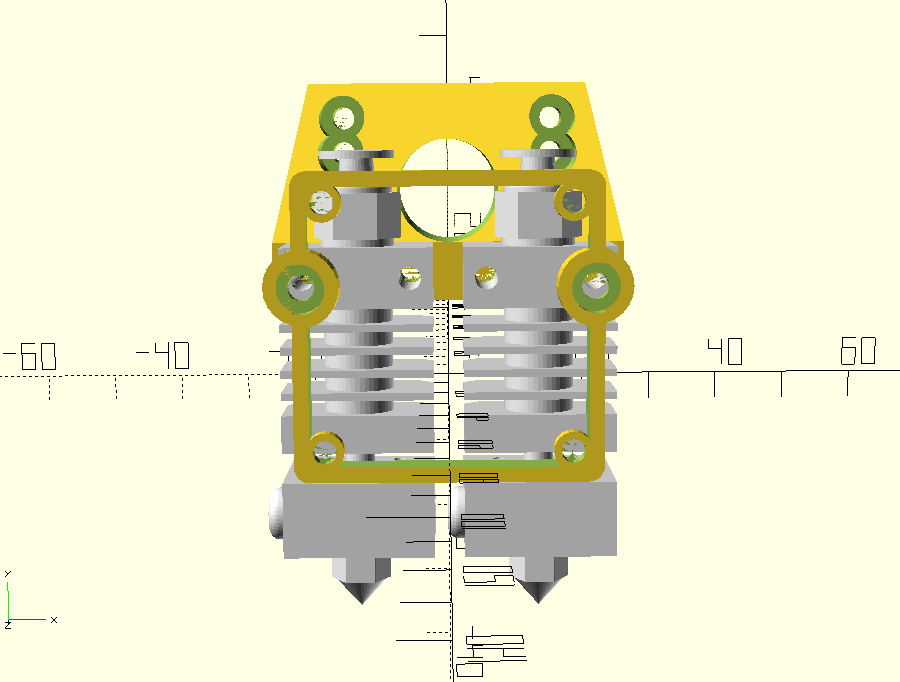

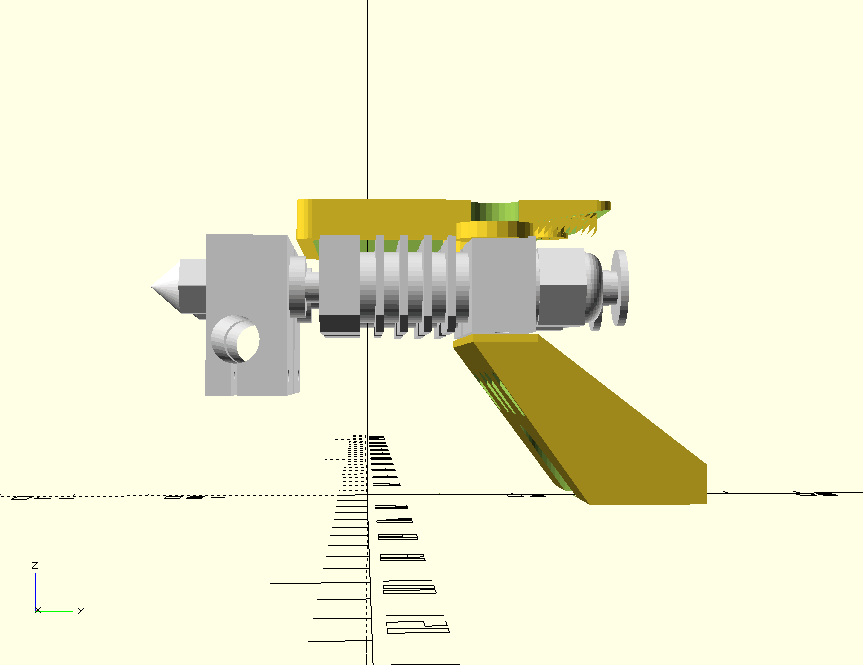

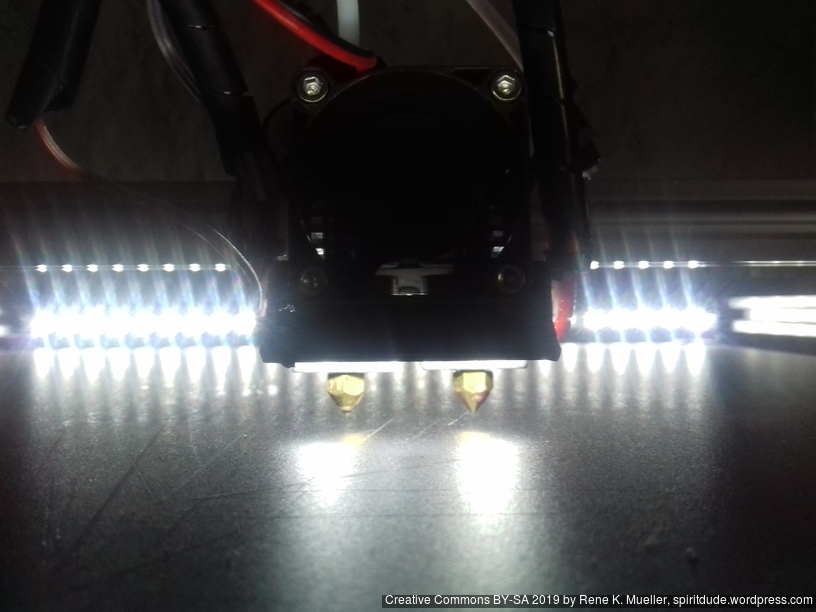

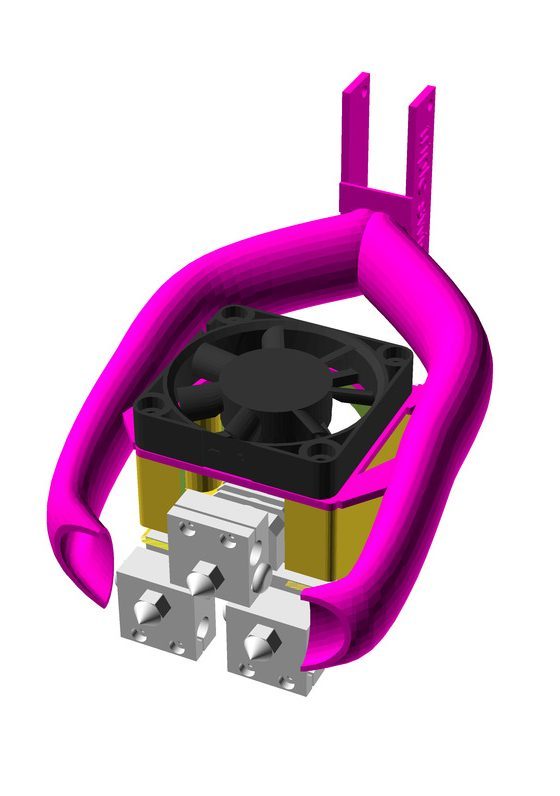

In order to pack the 3rd nozzle, I put it in front of the dual setup, and use one heatsink fan cooling all three heatsinks:

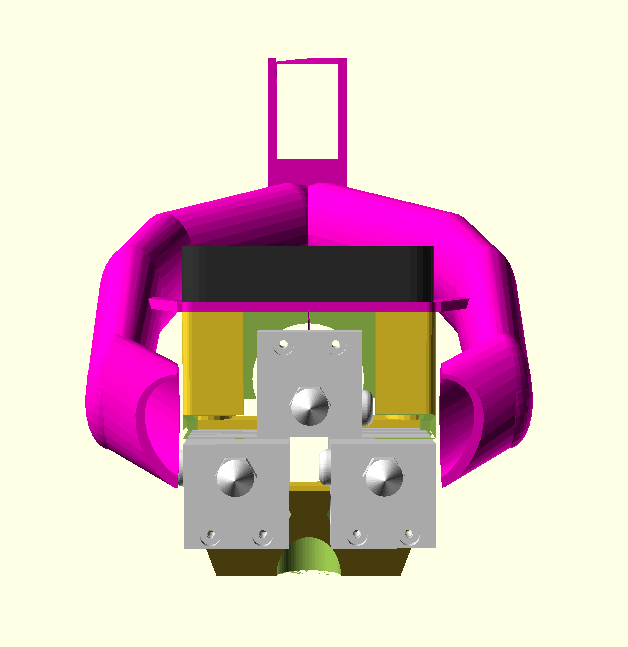

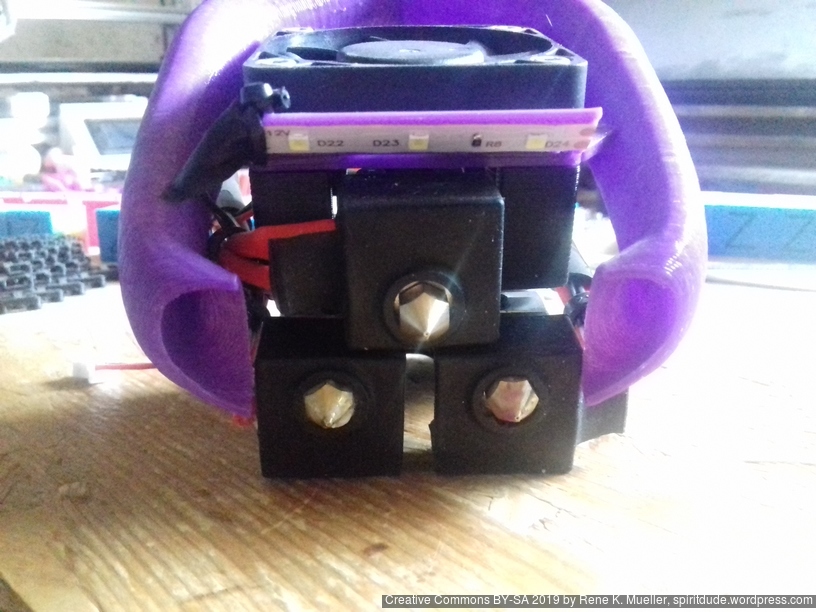

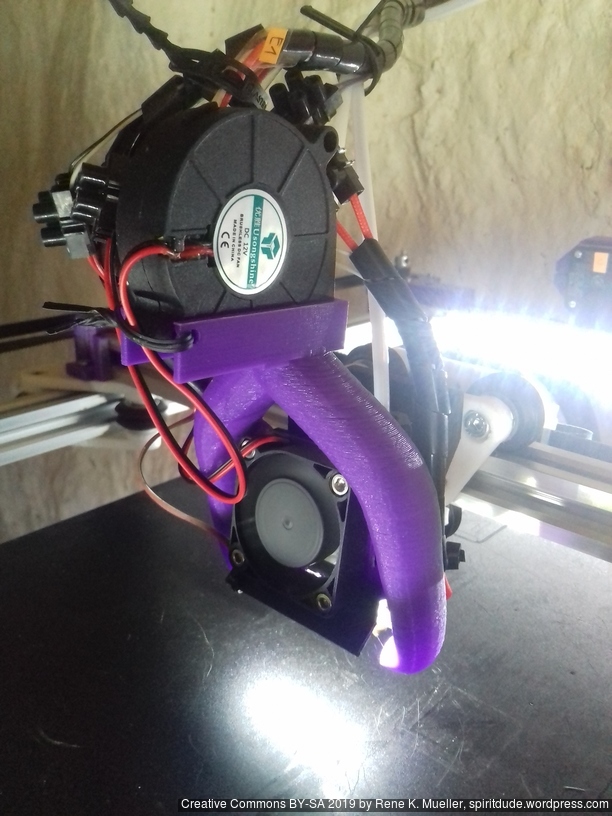

The Parametric Part Cooler has the settings part_cooler(m=50,wx=50,yoff=17,sq3=1,wx=54).

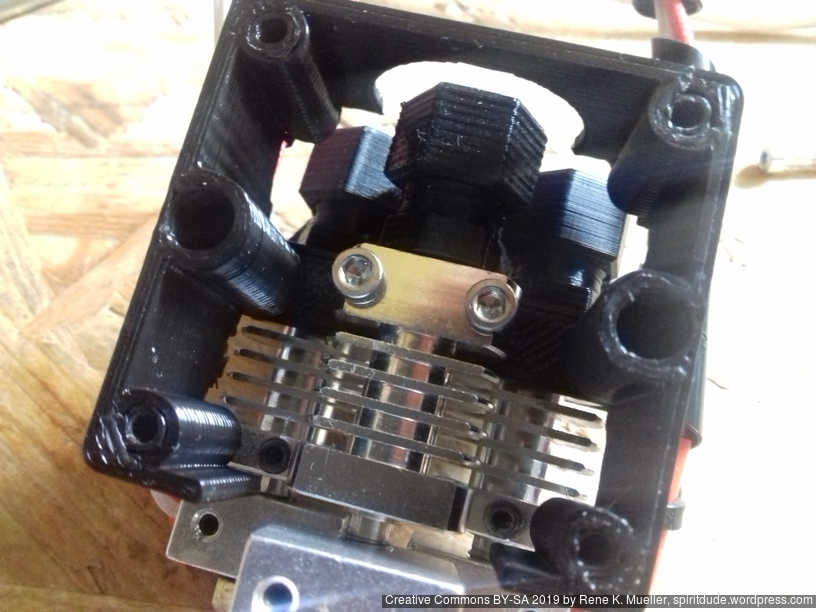

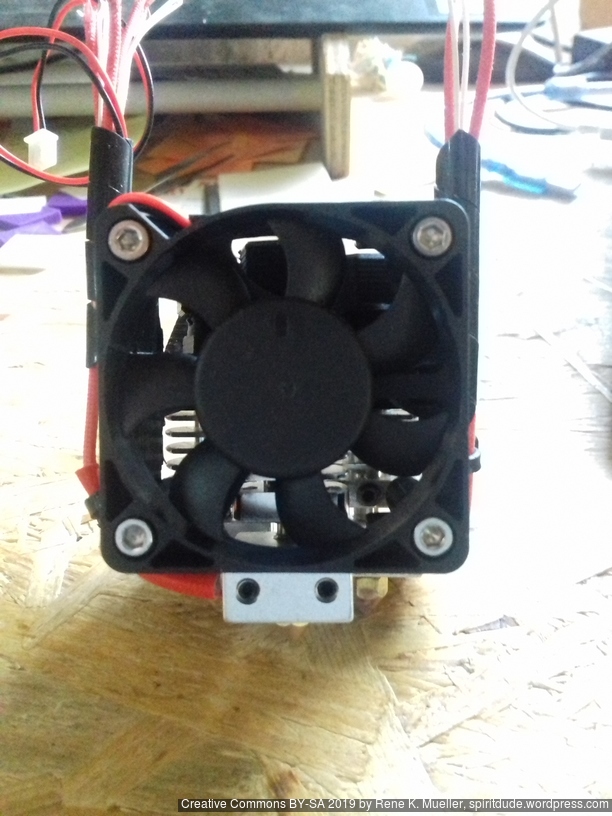

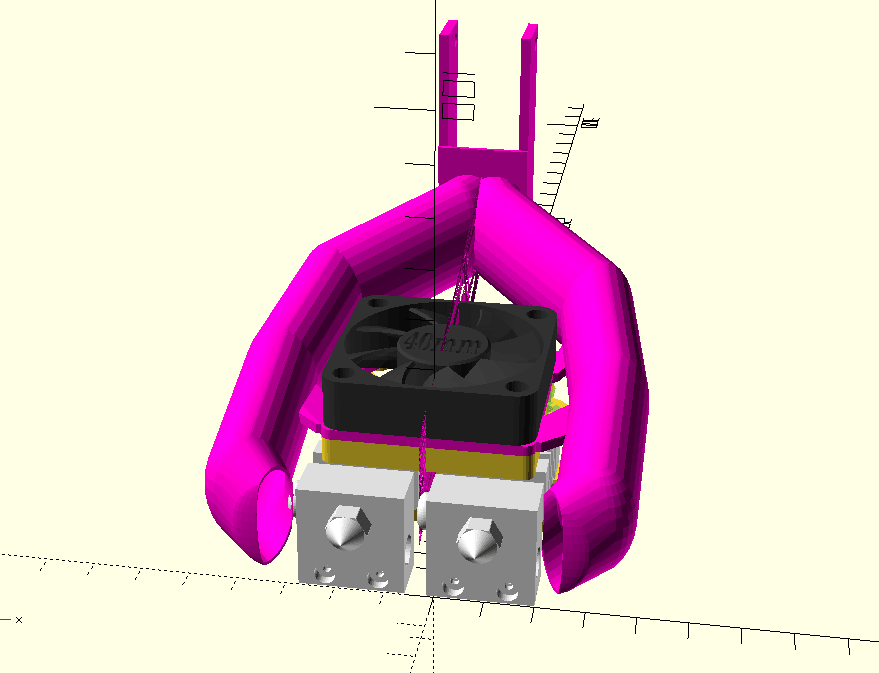

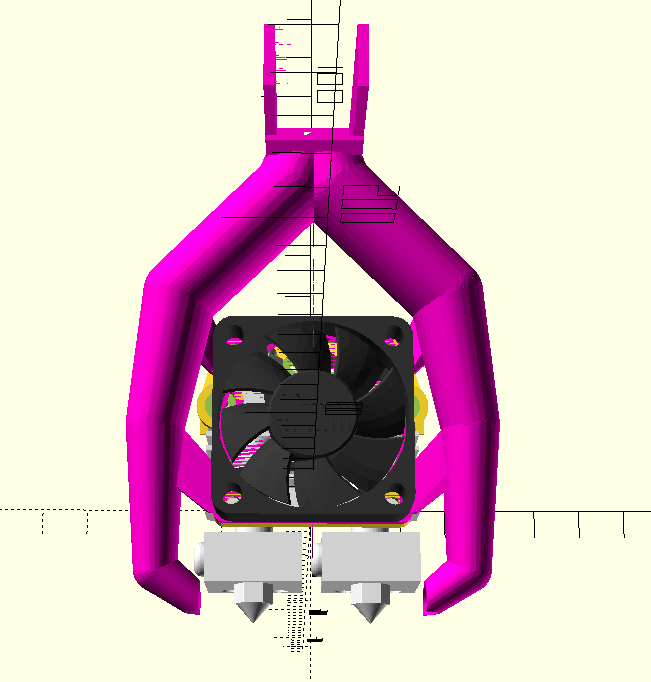

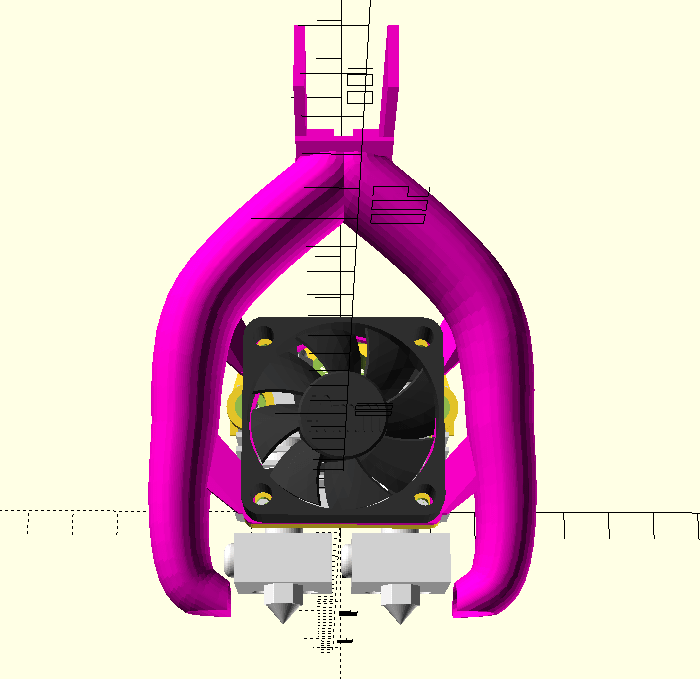

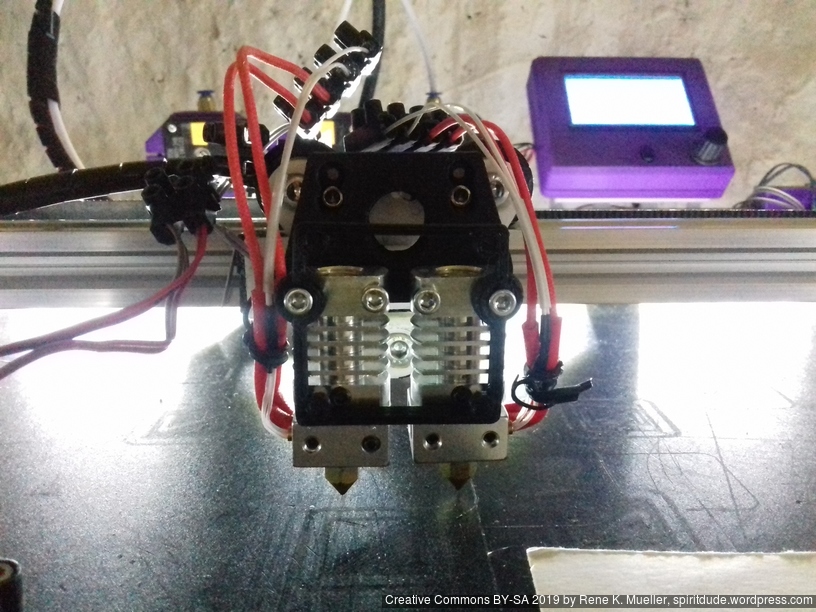

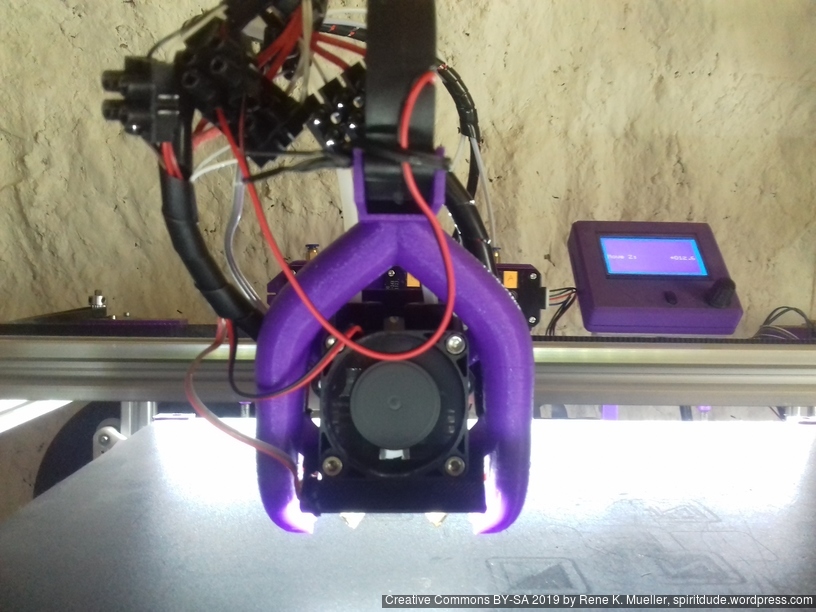

Final smooth part cooler and fully assembled:

Download

https://www.thingiverse.com/thing:3865972

Assembly

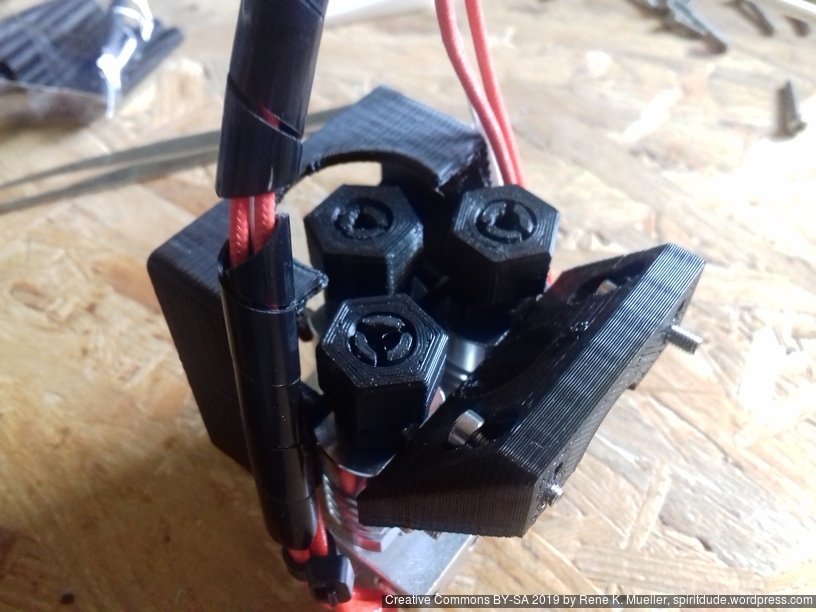

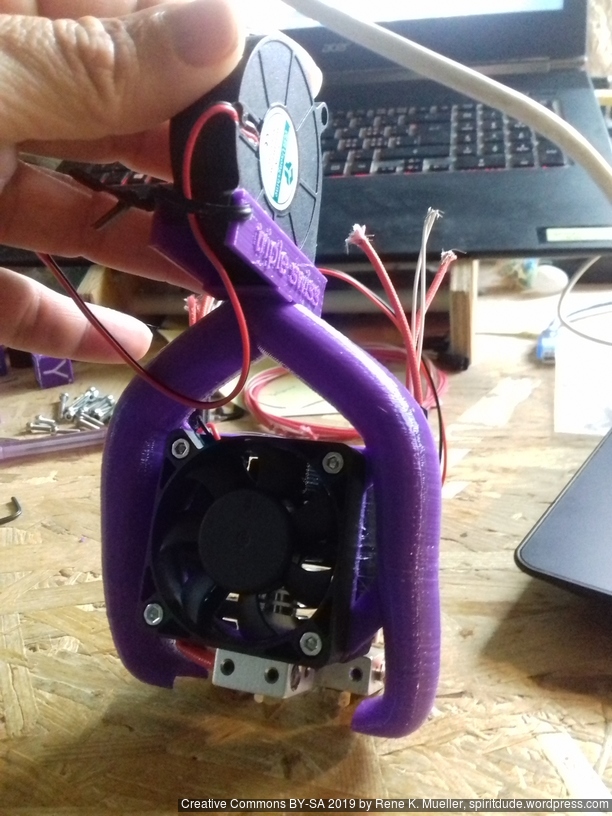

Assemble 3 nozzles in one go, and adding heatsink fan mount:

adding 50mm fan on top:

and with the dedicated Part Cooler using 5015 fan blower:

I recommend cover all nozzles with silicon socks when using the part cooler. Optionally LED strip mount in case you want some light on all three nozzles.

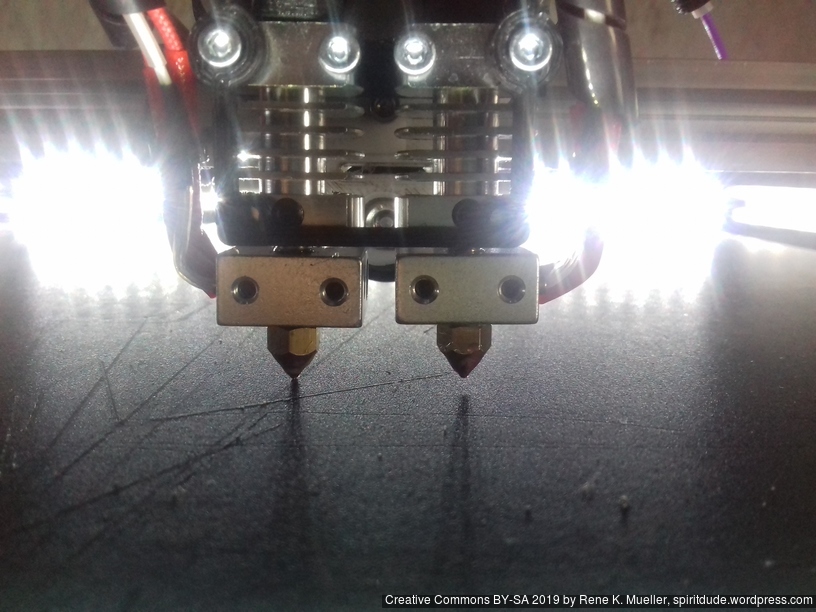

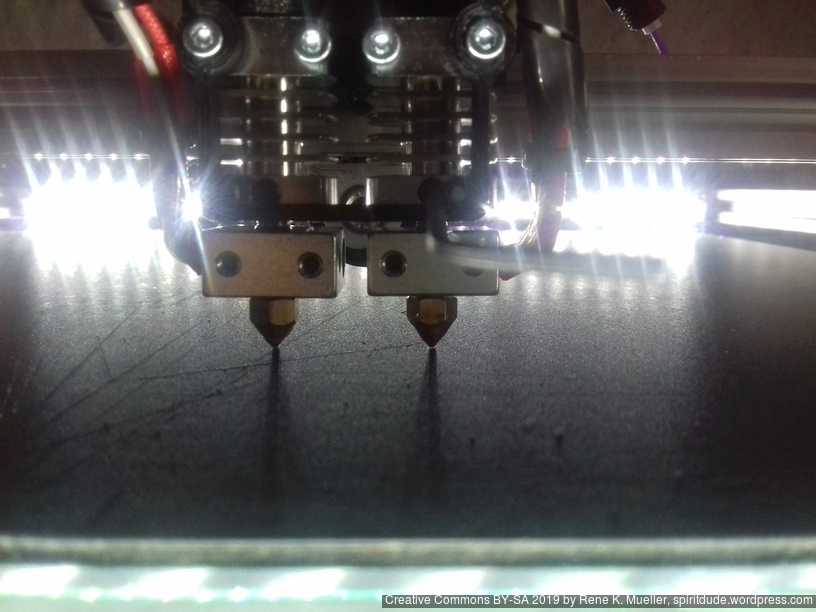

Leveling Three Nozzles

It’s essential that all three nozzles have the same distance to the bed, otherwise inactive nozzles might touch and tip-over a piece while printing. See Dual Nozzle Setup for the procedure.

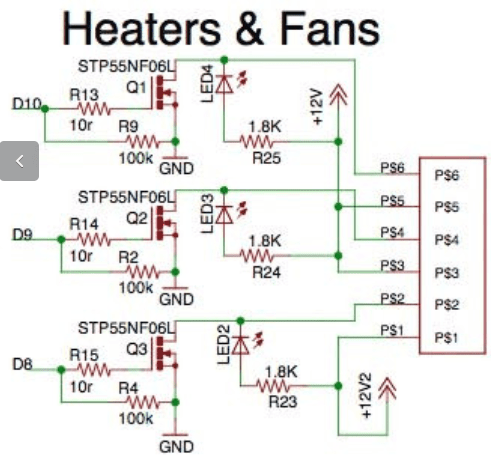

Third Hotend Wiring

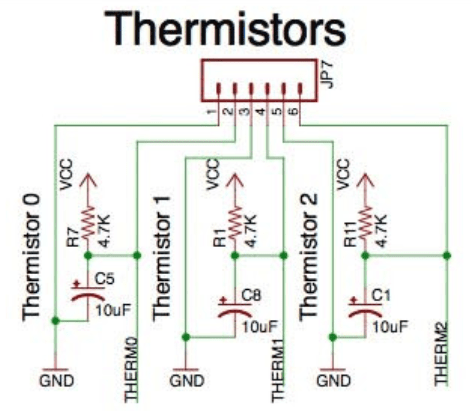

One requires a board with 3x MOSFETs to heat all three heatblocks and 3x thermistors inputs, like RUMBA or TANGO (Open Source variant of RUMBA) controller board or extend it with dedicated parts:

- per heater: STP55NF06L (MOSFET) with 10R, 100K on a Dx (digital output); LED with 1.8K is optional

- per thermistor: 4.7K with 10uF on a Ax (analog input)

for wiring see RAMPS 1.4 schematic as reference:

See Also

That’s it.