A few OpenSCAD sketches I’m currently work on, and later will publish as well:

Simple Compact Extruder

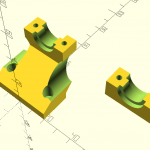

I used some aluminium MK8-based extruders but realized I required my own parametric extruder using 625ZZ bearing and I looked around and found “Compact Bowden Extruder“ and adapted the overall design but coded it from scratch again:

It’s “right handed” by default, but filament can go both directions. The handle is pushed from “inward” with a spring, not so elegant, yet it saves space and filament does not have to go through the handle this way, which I prefer.

simple_compact_extruder() takes following parameters:

type:"base": the base attached to the Nema 17 stepper motor"handle": the push handle with the spring"indicator": small indicate to put on the axis of the stepper motor

mount:"none": (default) just attaches to Nema 17 stepper motor"mount": simple mount (center)"2020": extends flat (lower left version)

btd: Bowden tube diameter (default: 0mm), if4mm is used, then Bowden tube can be inserted on both sides as guides for flexible filament close to the hobbed gear as shown below.

I use PC4-M6 push fit connector with PTFE tube 4mm OD / 2mm ID as guides, and began to use it right away on 3x printers for first tests:

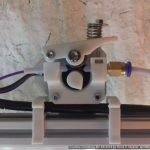

- Assembled Simple Extruder (M5 inset)

- Assembled Simple Extruder (M5 inset)

Later I likely will integrate this design, once proven reliably working, with a Direct Drive Extruder design as well.

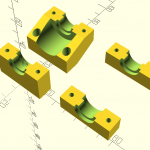

Dual E3D V6 Mount on 30mm X Carriage

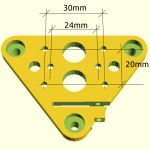

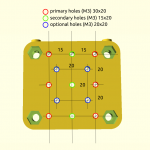

My X carriage maintains 30mm horizontally distanced M3 mounts x 3 rows 20mm apart – the v_plate() (3 wheels) and h_plate() (4 wheels) as example:

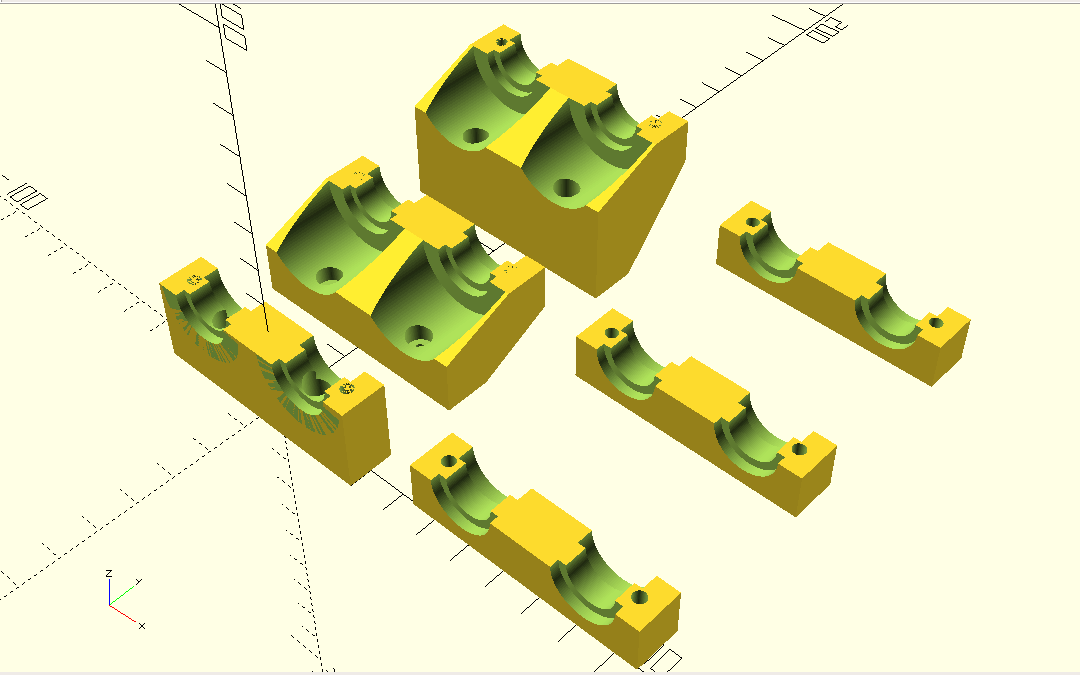

and wanted a parametric dual E3D V6 hotend mount to print dual colors or materials for the Ashtar C #1:

dual_e3d_mount(): there are plenty parameters, but the most important ones:

type:"base"(left) or"clamp"for the clamp (right)yoff: Y offset (when mounted the Z offset up), default: 0 (front one), 20 (middle and top)nd: nozzle distance (Y-wise), default: 22 (most close possible), 35 (top one)

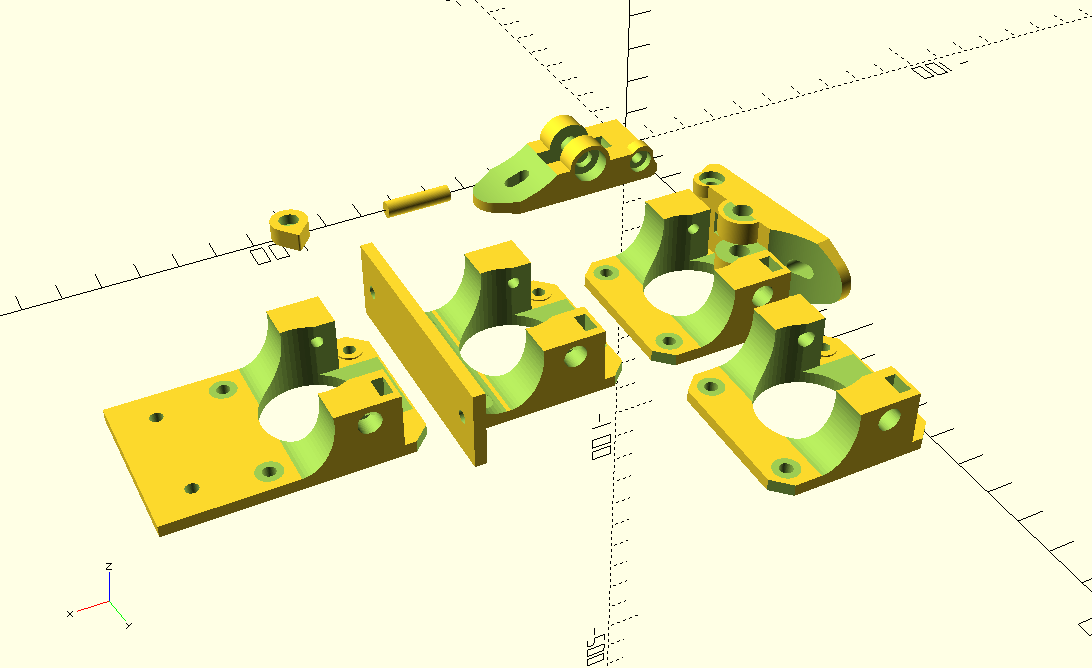

Example

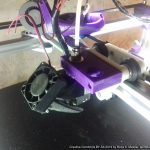

First attempt to use it:

This design has been not yet printed but not yet in use, but soon as alternative to Chimera (dual hotends) or Cyclops (dual to one / mixing) hotends – two main issues:

- part cooler needs to be narrow enough to sit aside of each other

- part cooler should extend too much Y-wise too much, as the routing belt of the Ashtar C come into the way

The “Dual E3D V6 mount” was derived from preview designs as used for the Ashtar K:

- Static Hotend Mount (Y Offset: 35mm, Z Offset: 20mm)

- Simple Parametric Hotend Mount (Y-Offset: 0,20)

The first one used two pairs of M3 screws, whereas the other more simple one requires in its base version just one pairs of M3 to mount the E3D V6 hotend and the mount itself to the X carriage; in case a slight Y offset is used, two pairs of M3 are required again.

I will update this post once the designs are published, after thorough testing in real life.