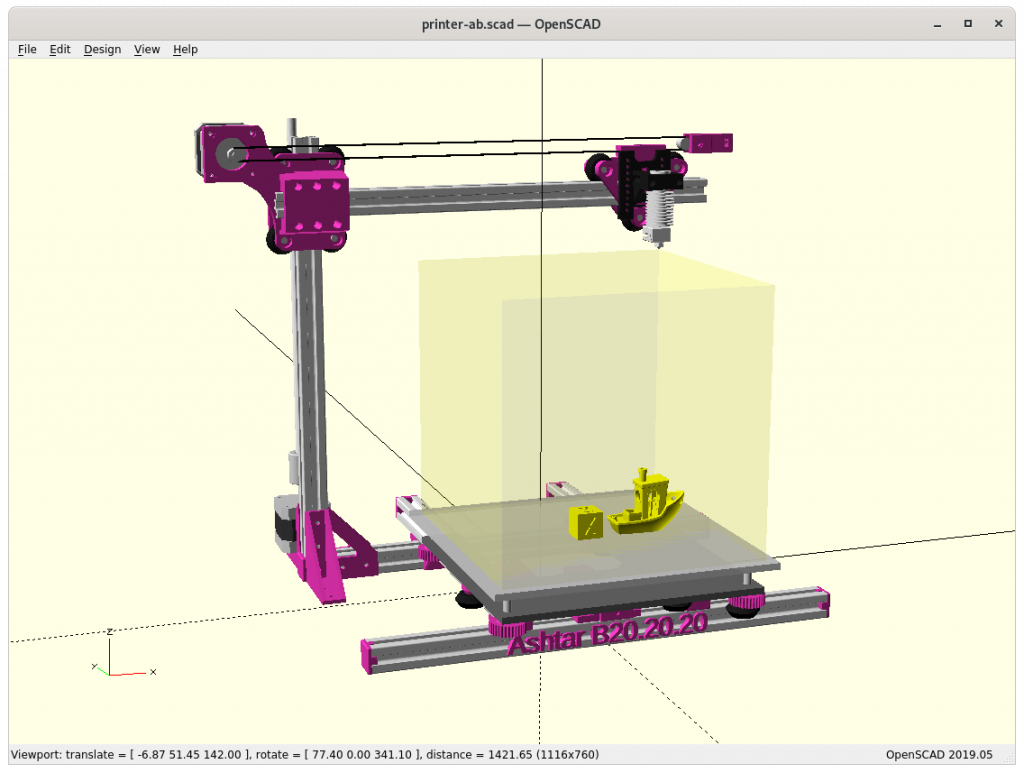

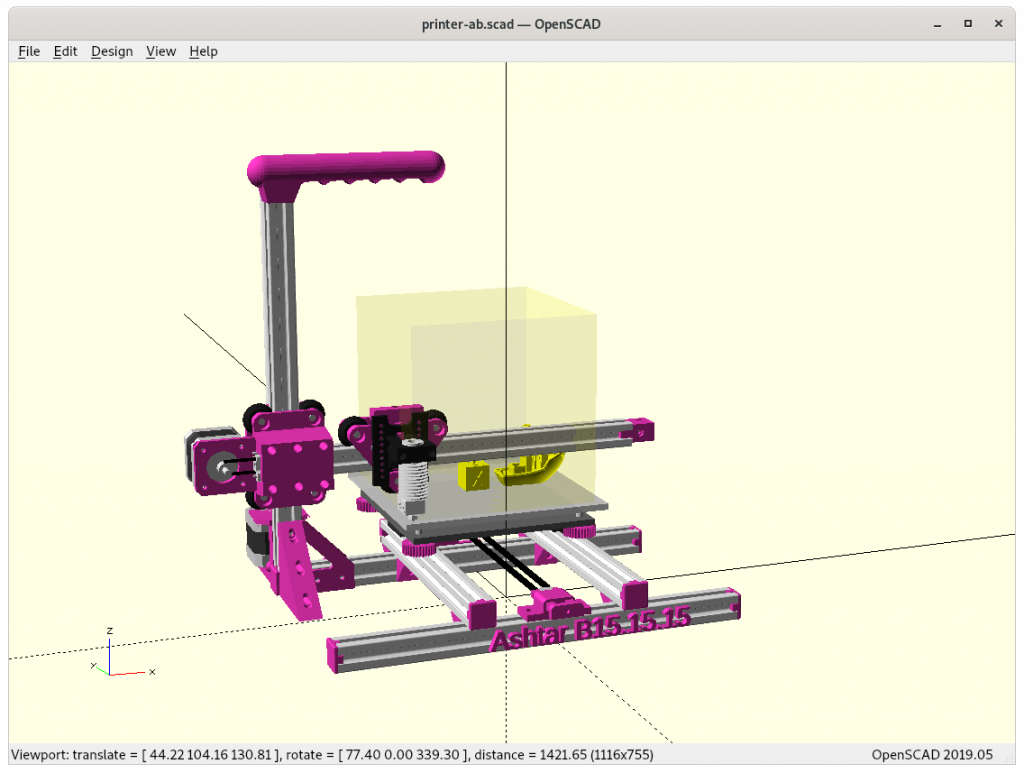

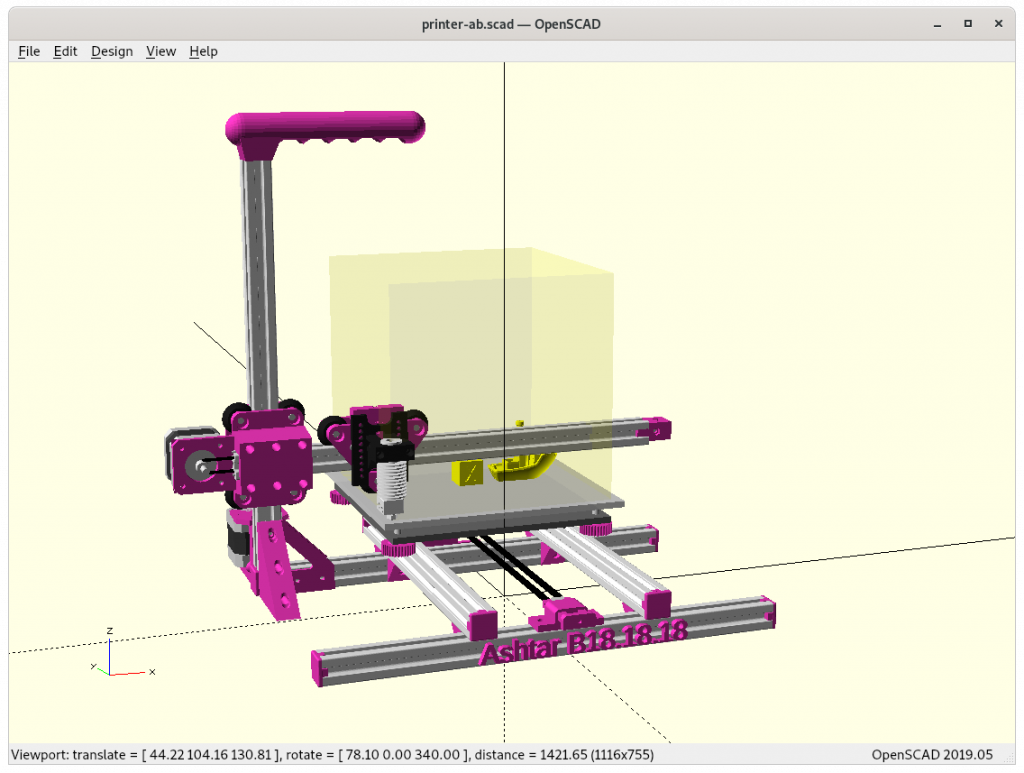

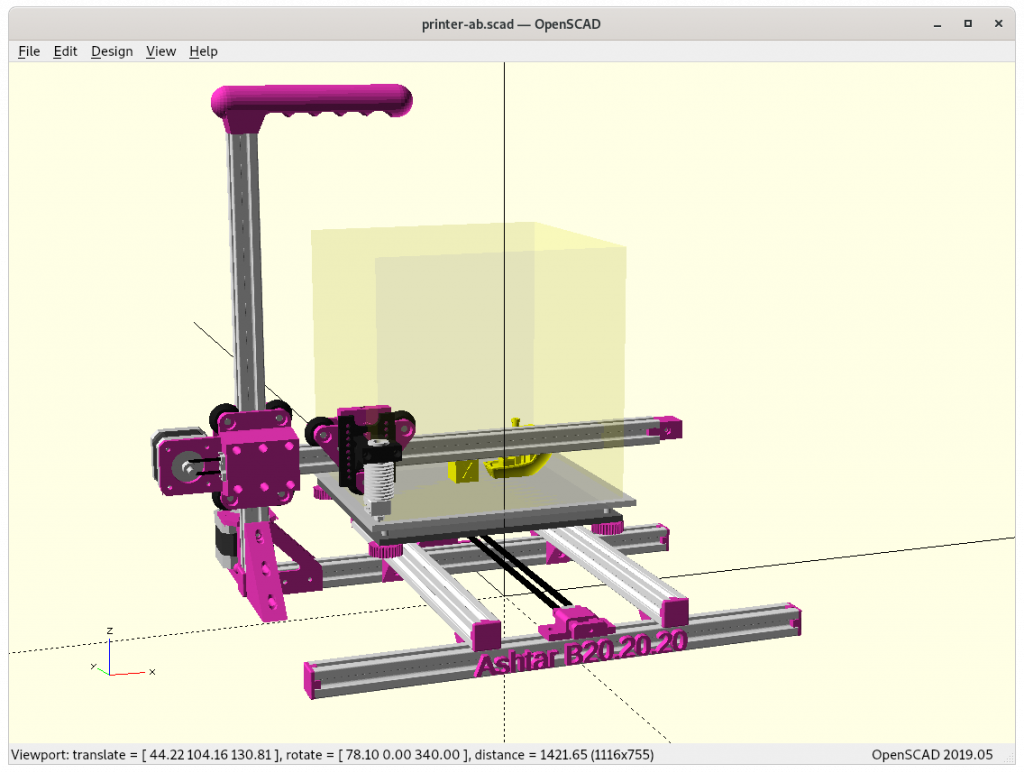

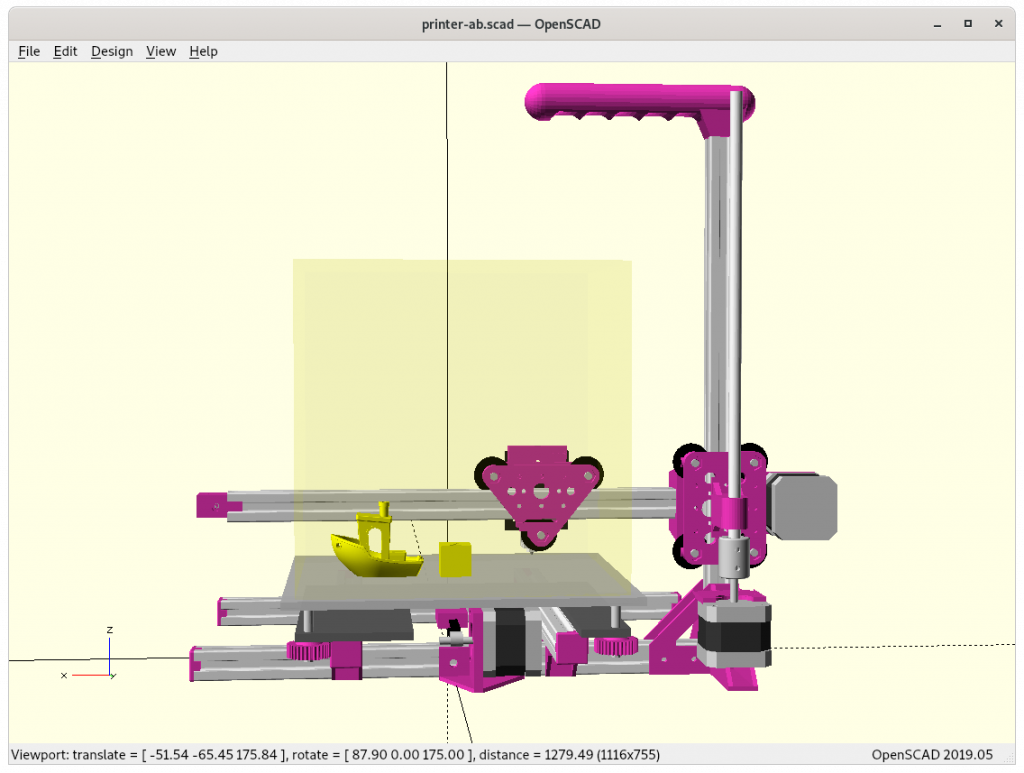

It has been on my mind for quite a while to do a 2020 alu extrusion based Cantilever 3D printer, and so I started in December 2020 with a rough design, starting from the existing Ashtar K design and cut away parts:

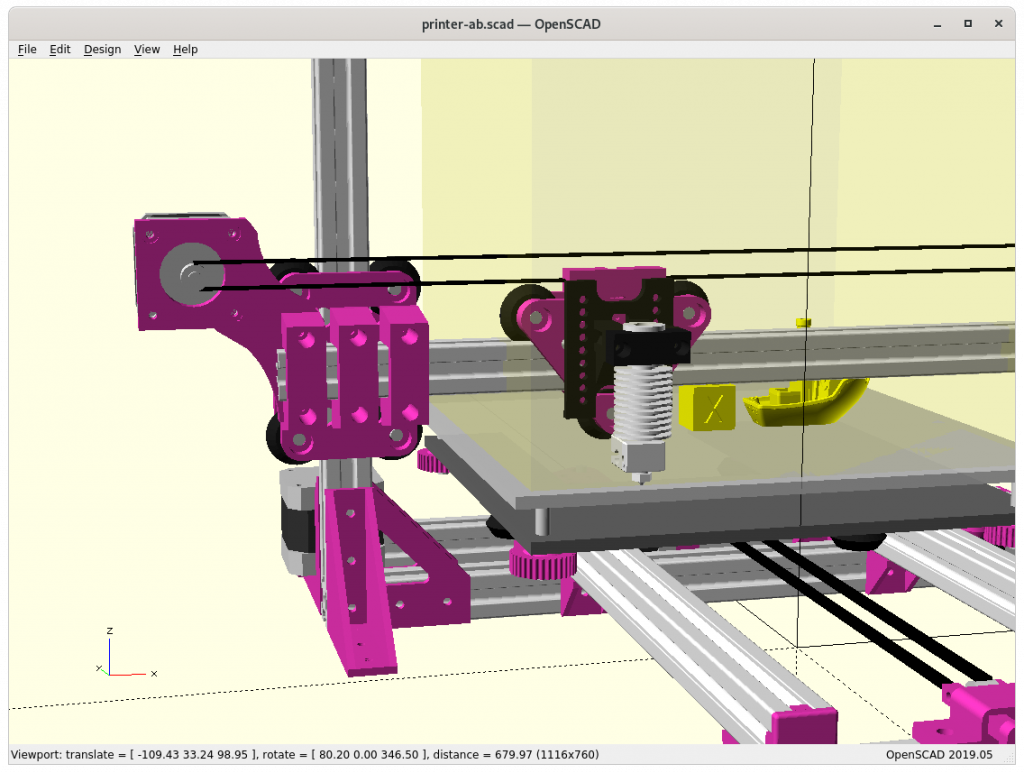

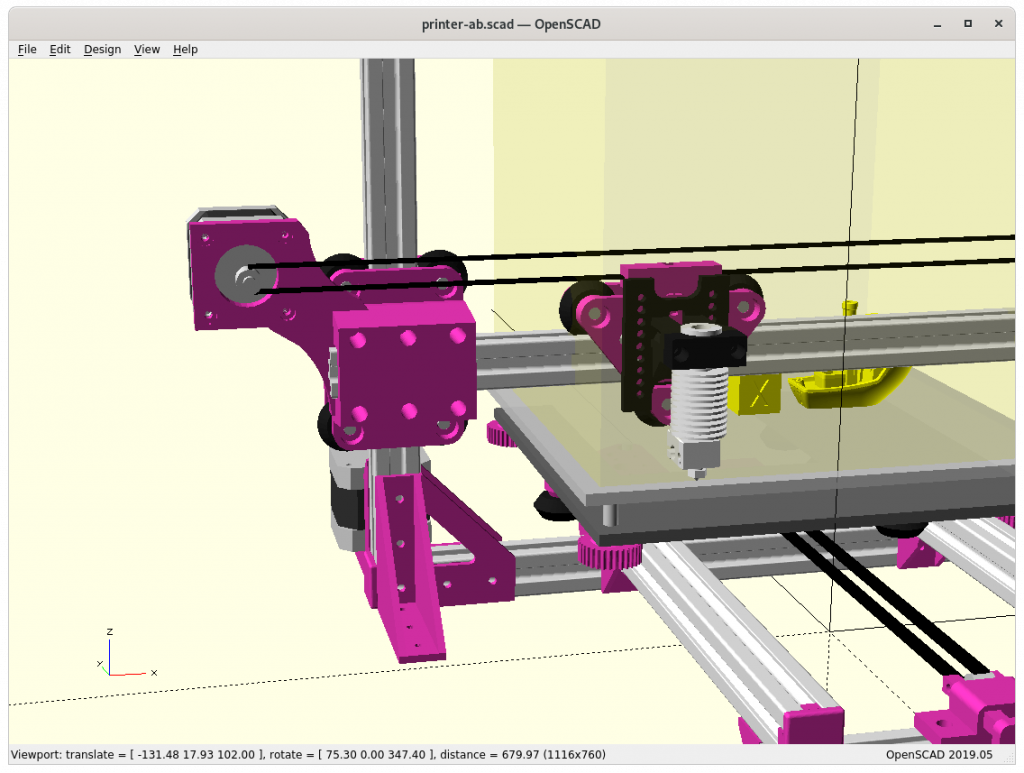

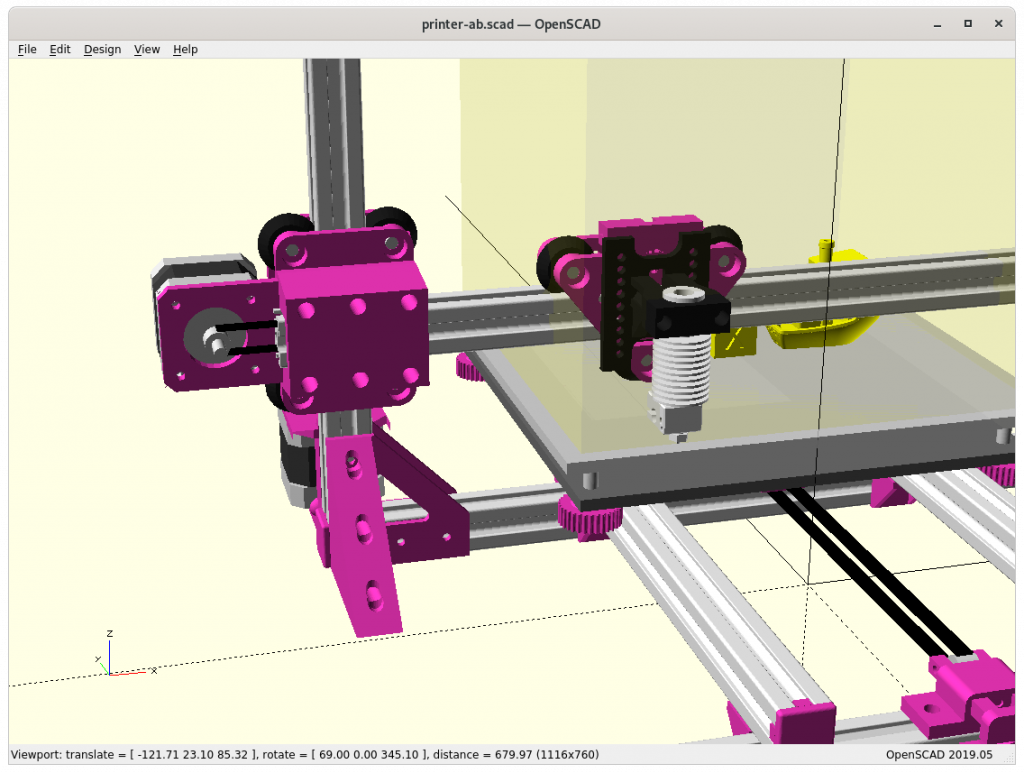

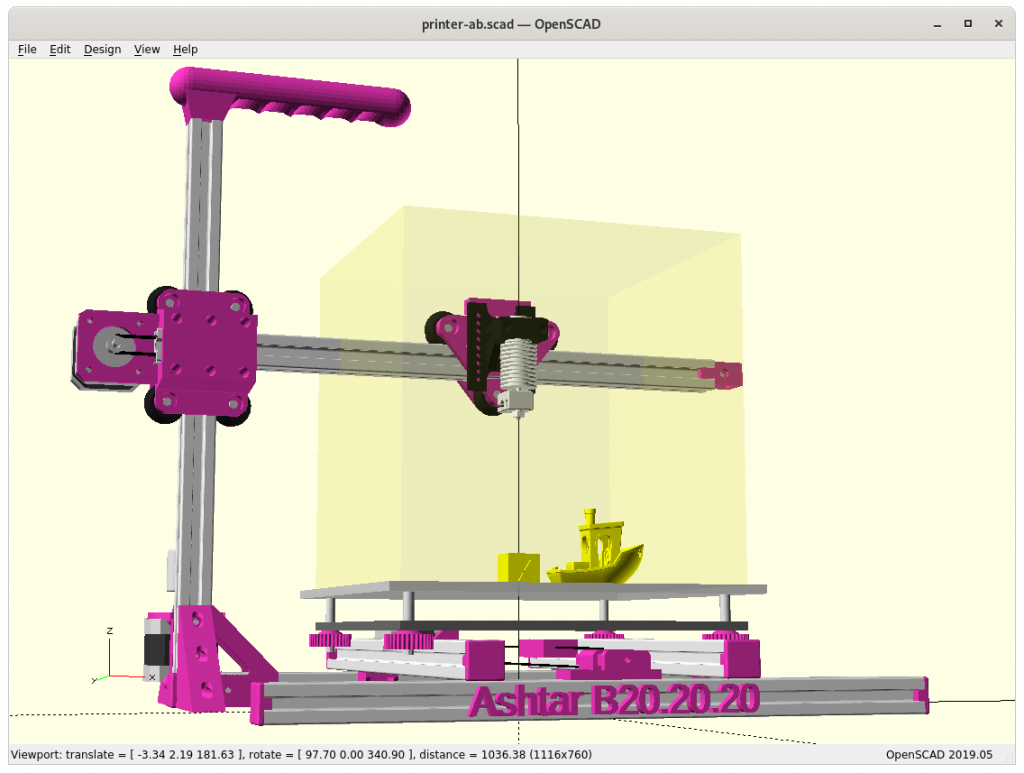

- using Head XZ and Bed Y

- aiming common build volume (e.g. easy to source print bed)

- 140mm to 190mm each axis

- tried 6, 7 and 9 beams options, settling with 6 beams for now

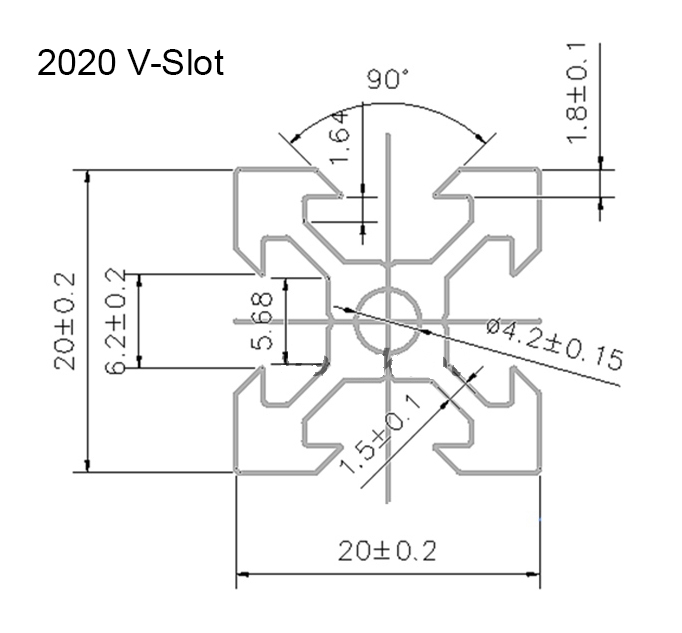

- aiming for uni-length 2020 alu extrusions, T-slot and V-slot where a carriage rides (X & Z axis) with V wheels.

- trying to keep as simple as possible

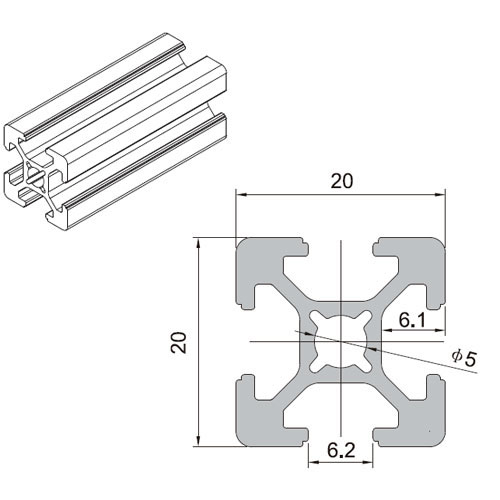

20×20 aka 2020 Alu Extrusion T-Slot Profile

2020 V-Slot Profile

V wheel

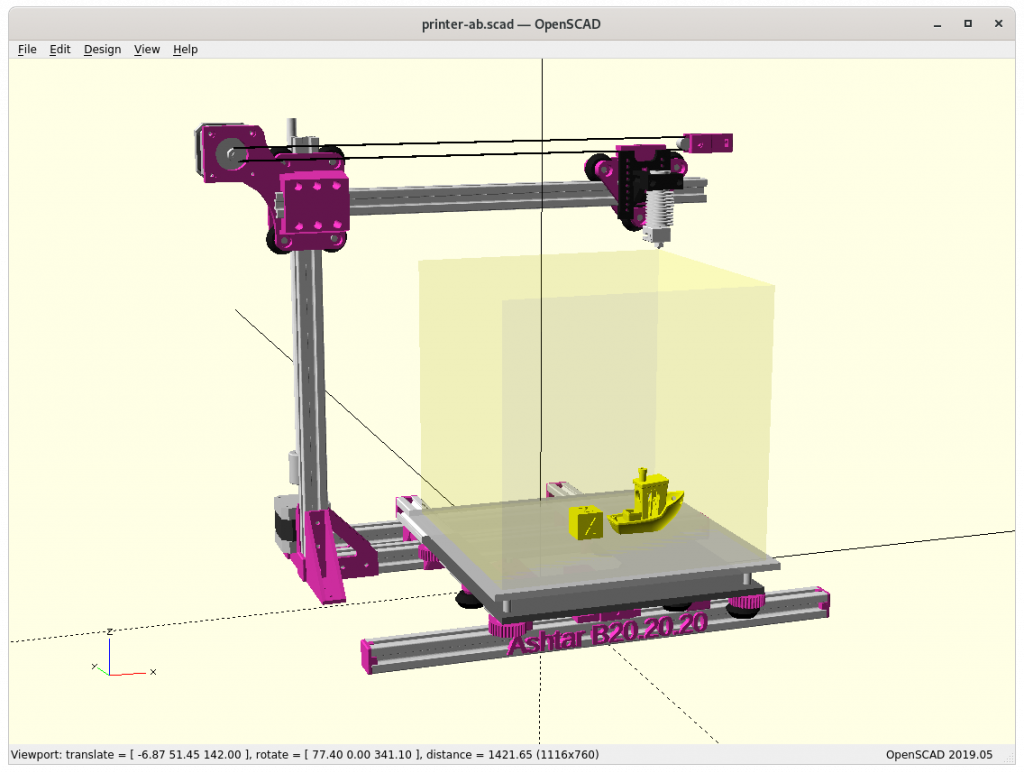

Frame: 6 vs 7 vs 9 beams

The 9 beams give an overall better sturdiness, but not sure how essential at small building volume (less than 220mm each axis). I might be able to remove beam, the last beam at the back at the bottom reducing to only 6 beams, in that case the Y motor is mounted on the remaining beam in the back.

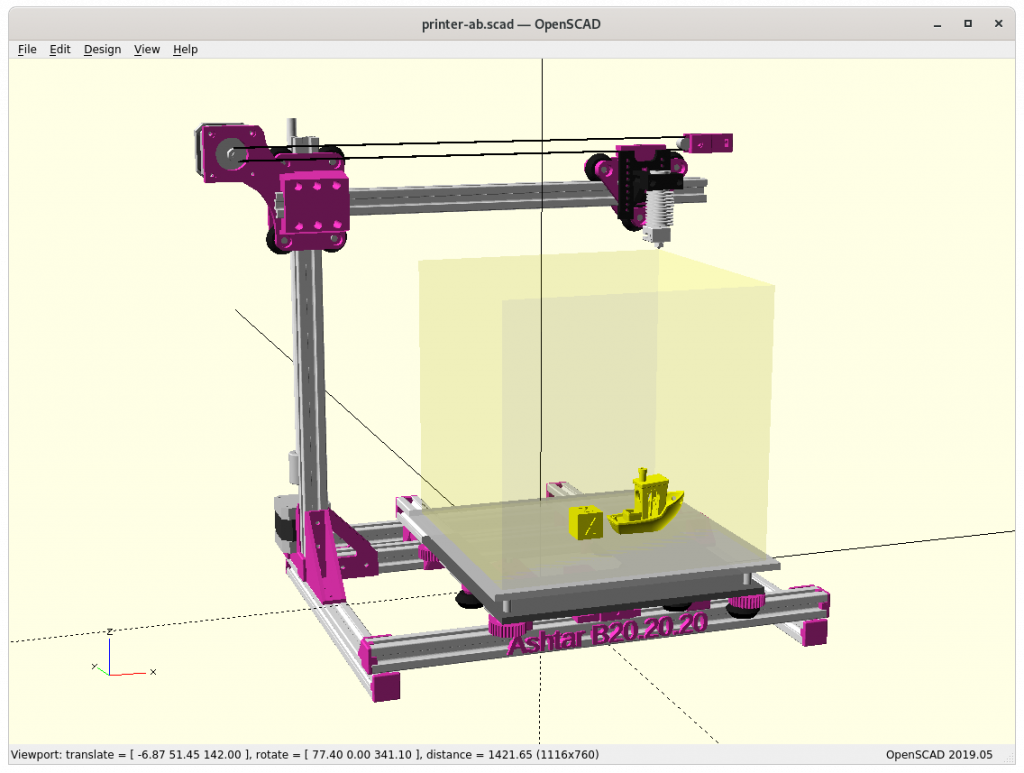

Z Carriage: 3 vs 4 wheels module

The 4 wheels looks best but it also sacrifices some of the X range by apprx. 10mm, the obvious choice is 3-wide mount – actual tests will tell if the X & Z axis are solid enough.

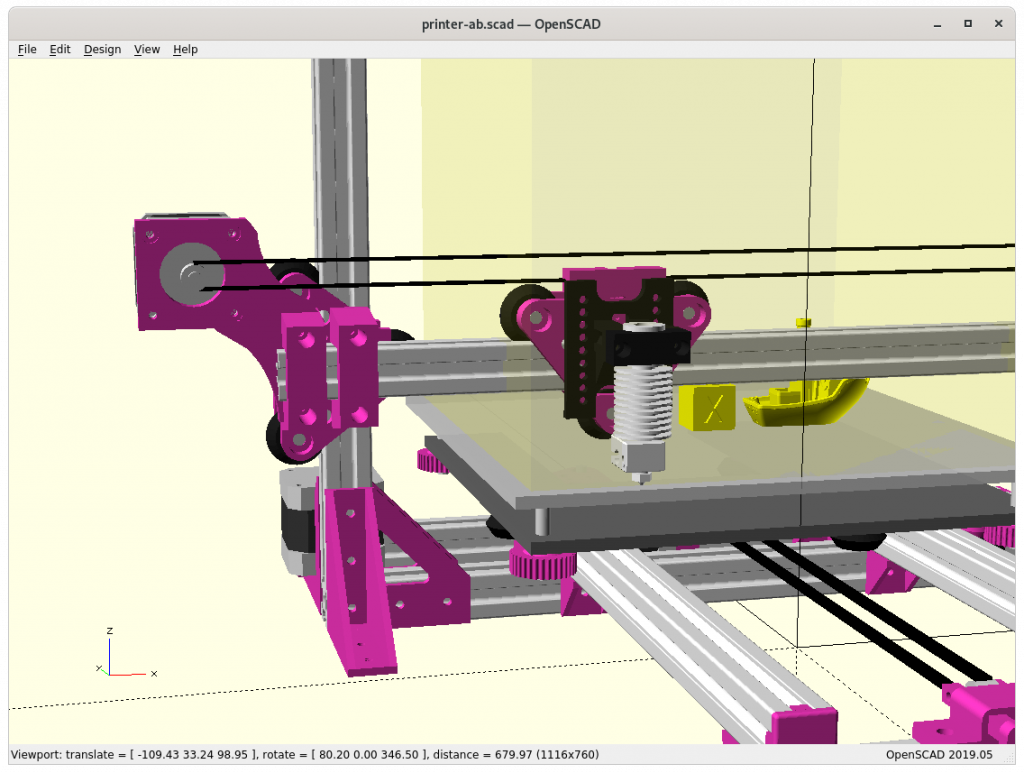

Different Sizes

The 200mm build axis length would be good, but I’m not sure if the XZ carriage will allow it as the max margin or tolerance would be half of a layer-height, e.g. 1mm layer height ⇒ 0.05mm tolerance, at X = 0 .. max the head should not flex more than 0.05mm. At this this early draft stage I don’t know which size is most suitable, I focus on 180mm build axis.

The project page on Ashtar B summarizes the current state.