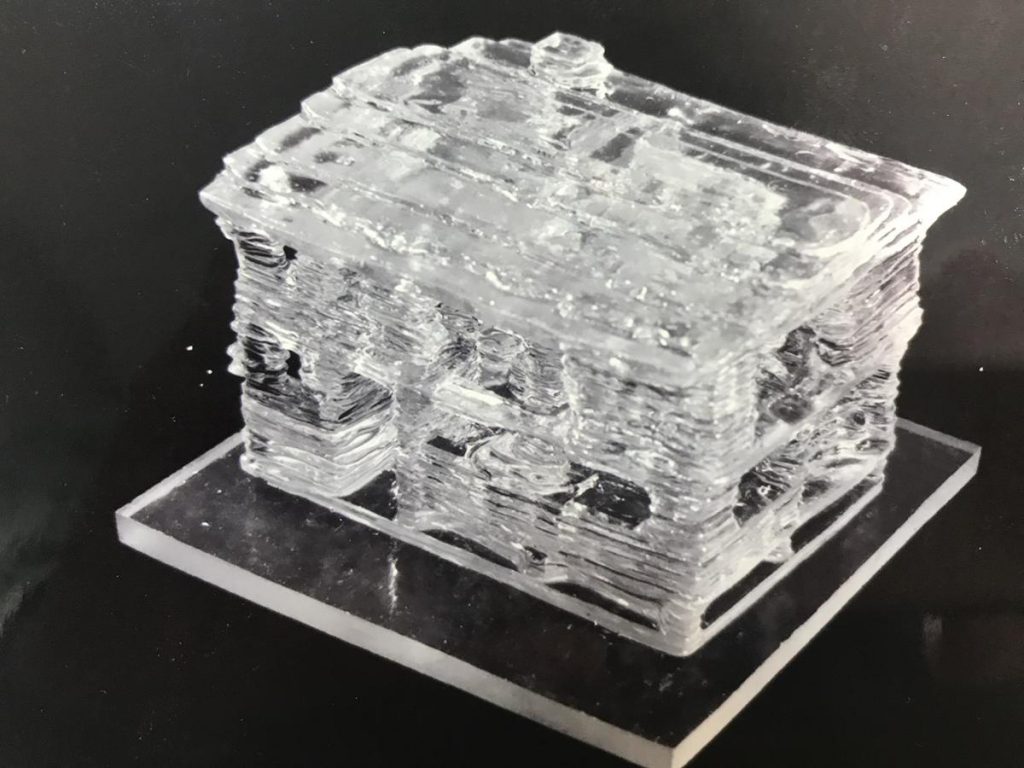

Back in 1980’s the concepts of 3D printing were invented and implemented with

- Stereolithography Apparatus (SLA) by Hideo Kodama (1980),

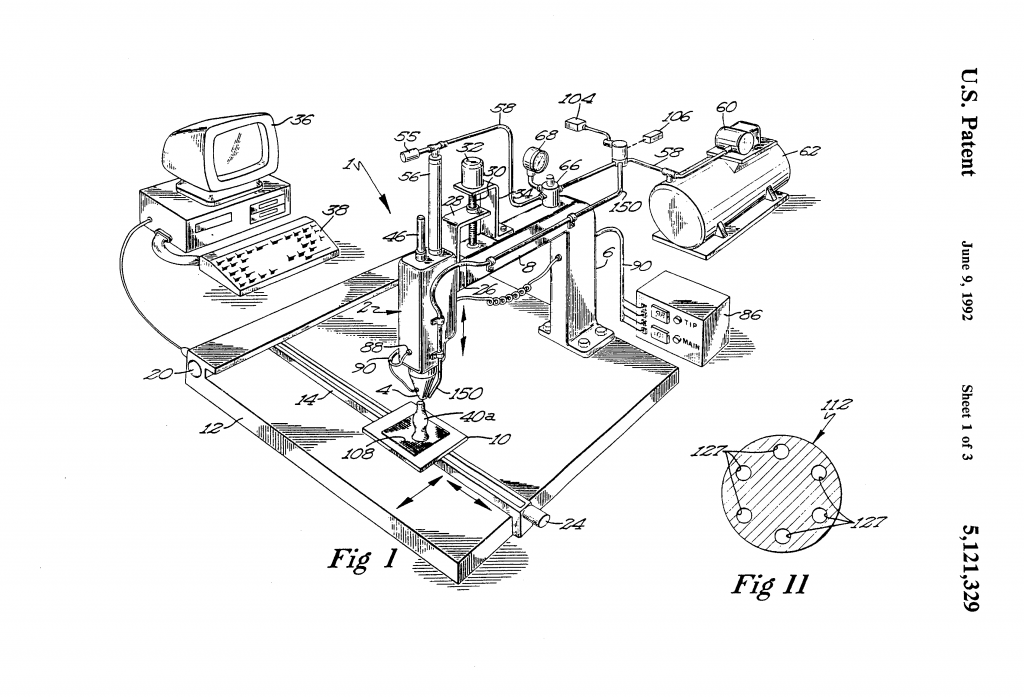

- Fused Deposition Modelling (FDM) by Scott Crump (1988), who later founded Stratasys, and

- Selective Laser Sintering (SLS) by Carl Deckard (1988).

Kodama developed the first 3D printer using UV light and curing resin, and filed a JPS56144478A patent (1980).

(source Meidai Watch: 3D Printing & Nagoya University)

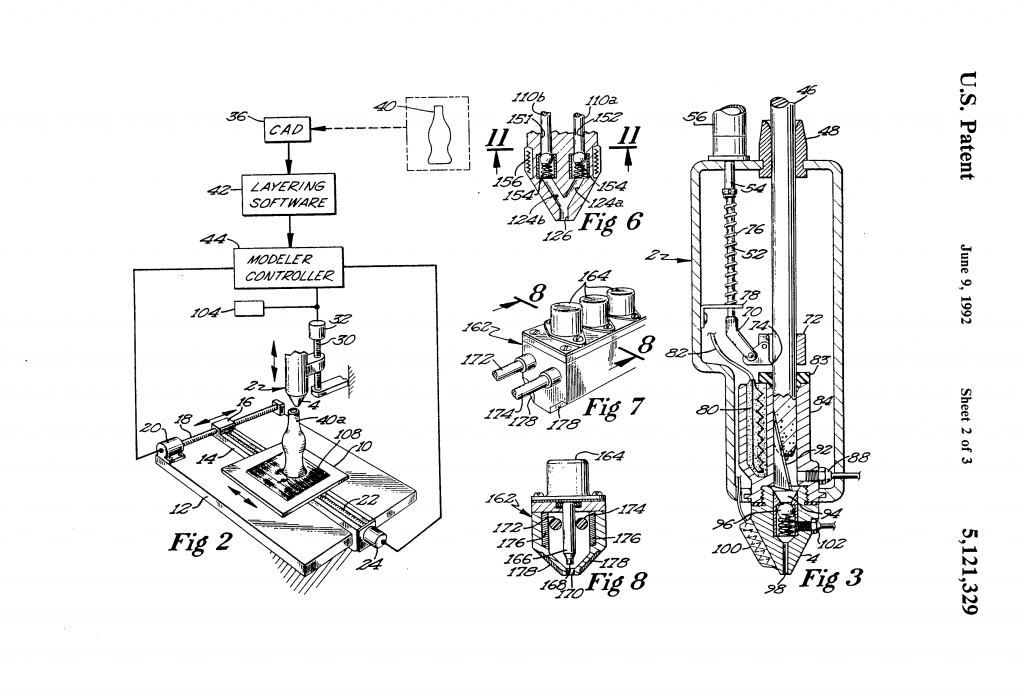

And so most approaches were secured with patents by companies like Stratasys, like the famous US #5,121,329: Apparatus and Method for Creating Three-Dimensional Objects (applied 1989, granted 1992) and others were thereby inaccessible for innovation outside of the patent holders and due the high pricing also inaccessible for users – a period of stagnation happened.

Once the patents expired (~2009), and that’s truly a lesson against patents, a surge of innovation occured and the prices for 3D printers fell from 100K+ USD range below 3K USD for the same functionality and print quality.

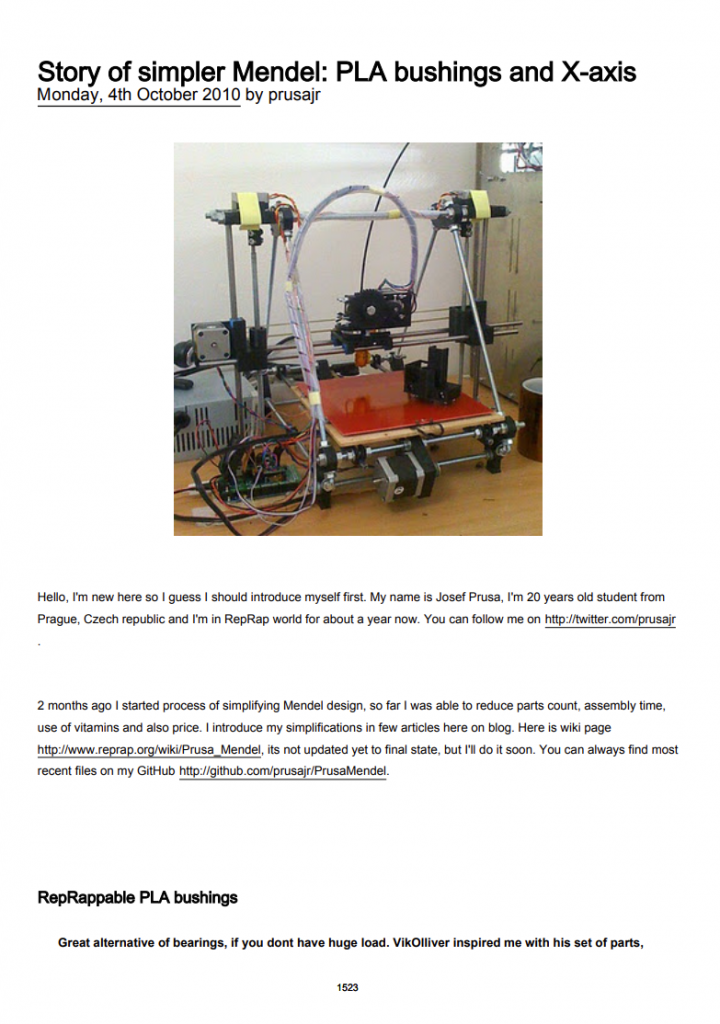

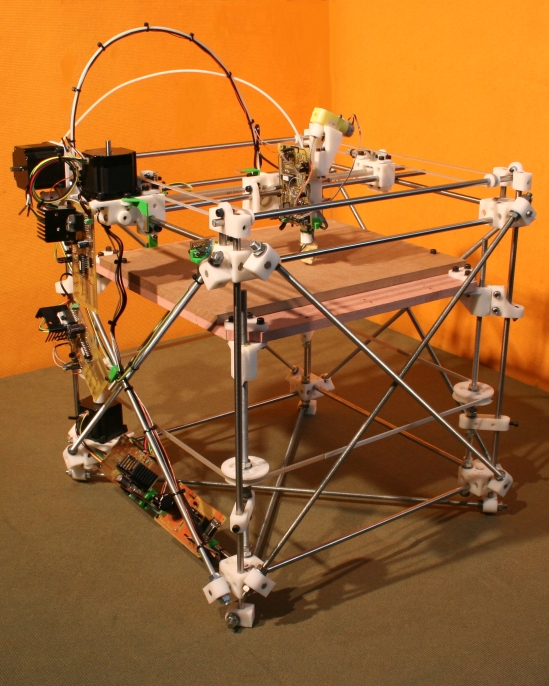

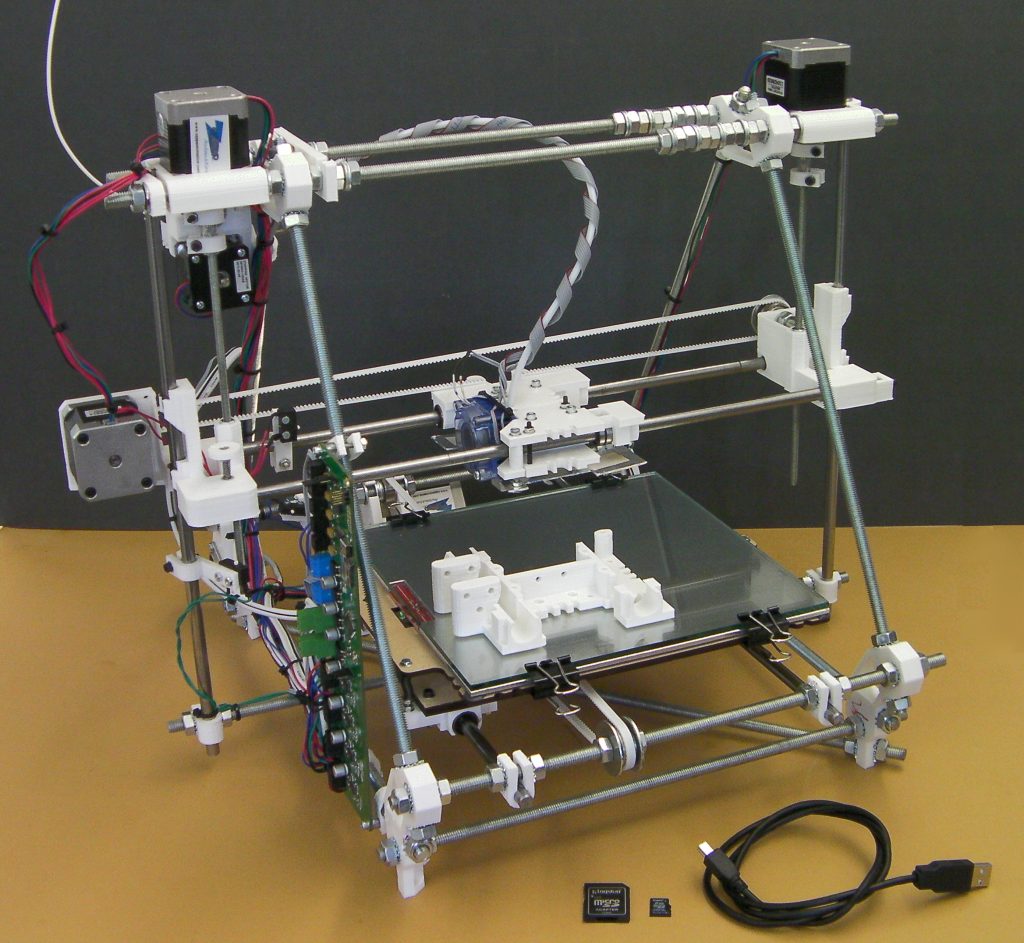

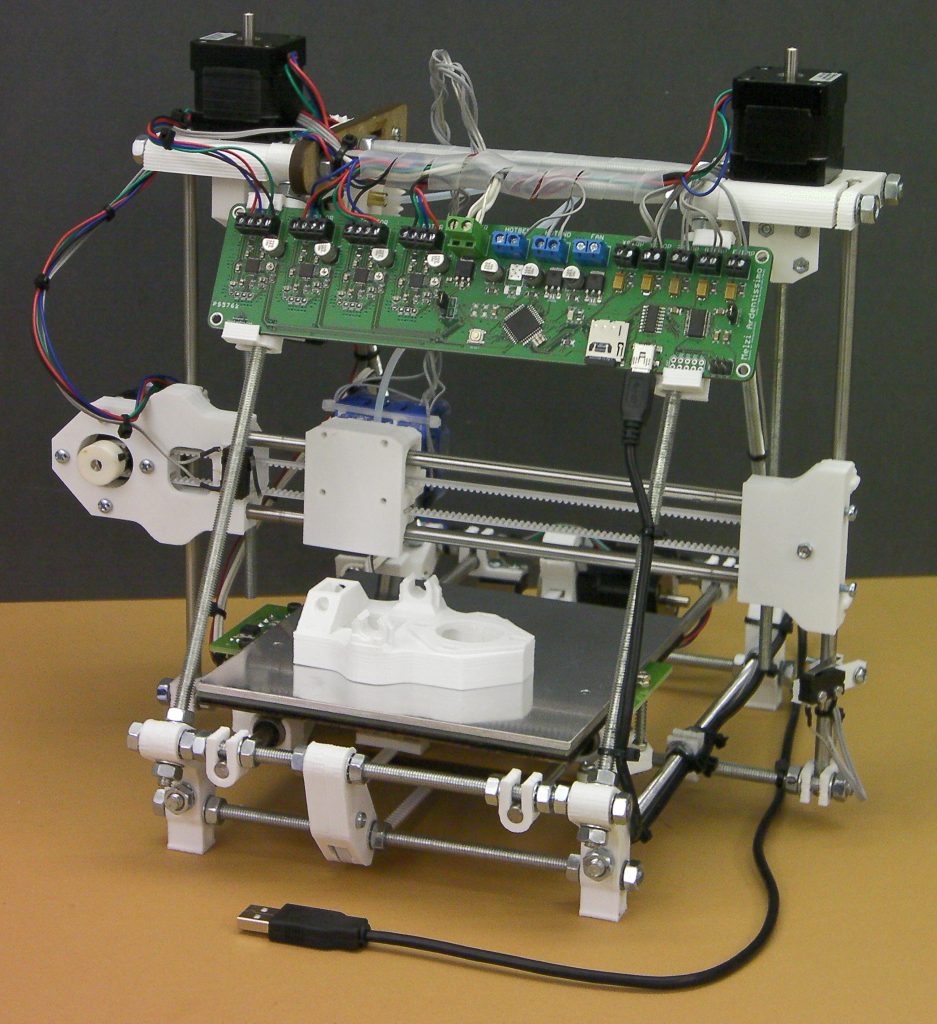

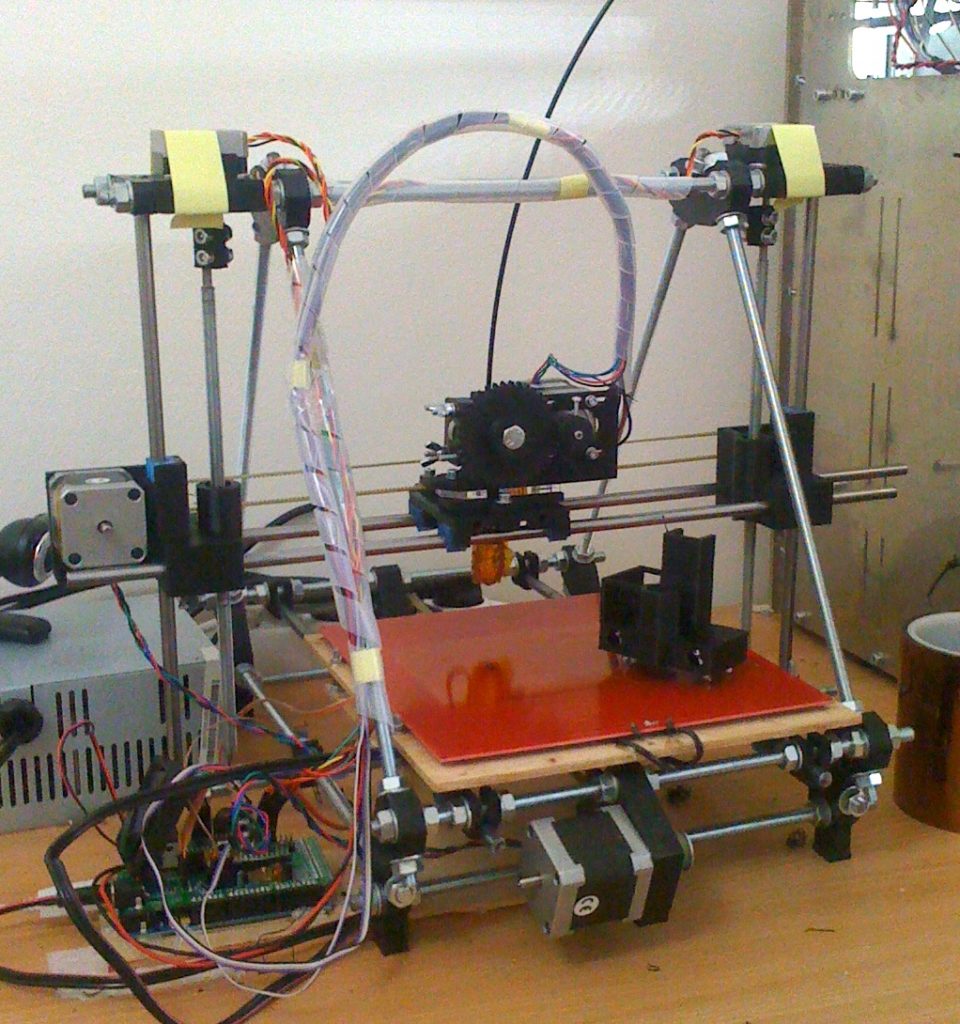

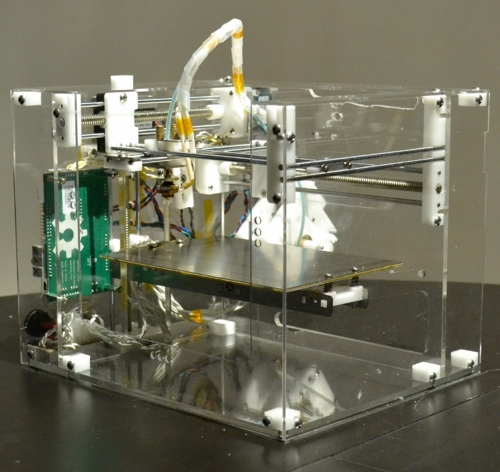

Adrian Bowyer, a british academic, coined the term of RepRap (2005), the replicating rapid prototyping and designing 3D printers which can print parts for itself: self-replication. Hobbyists started to adapt the design and push it further, since all plans were Open Source aka Open Source Hardware, it was easy to improve and iterate the designs. Eventually the Prusa Mendel as developed by Josef Prusa and reduced overall complexity and his next iteration was most significant: Prusa i3 (2012). This third iteration became quasi standard for low cost 3D printers for the next years and his Prusa Research company surged. See also RepRap Principle and RepRap.org Blog Archive.

- RepRap Darwin: XY head and Z bed, threaded rods based

- RepRap Mendel & Huxley: XZ head and Y bed, threaded rods based

- Prusa Mendel: XZ head and Y bed, threaded rods based

- Prusa i3: XZ head and Y bed, laser cut XZ frame

Josef Prusa summarizing his history 2010-2019, representing part of the spirit of the RepRap movement:

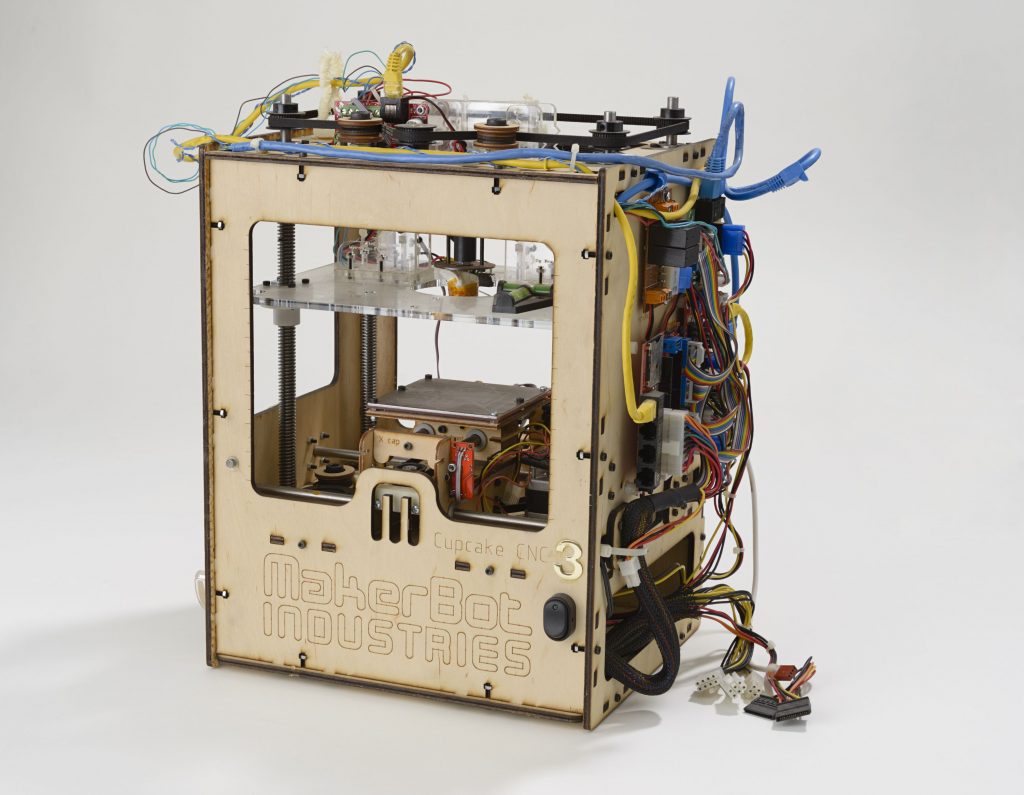

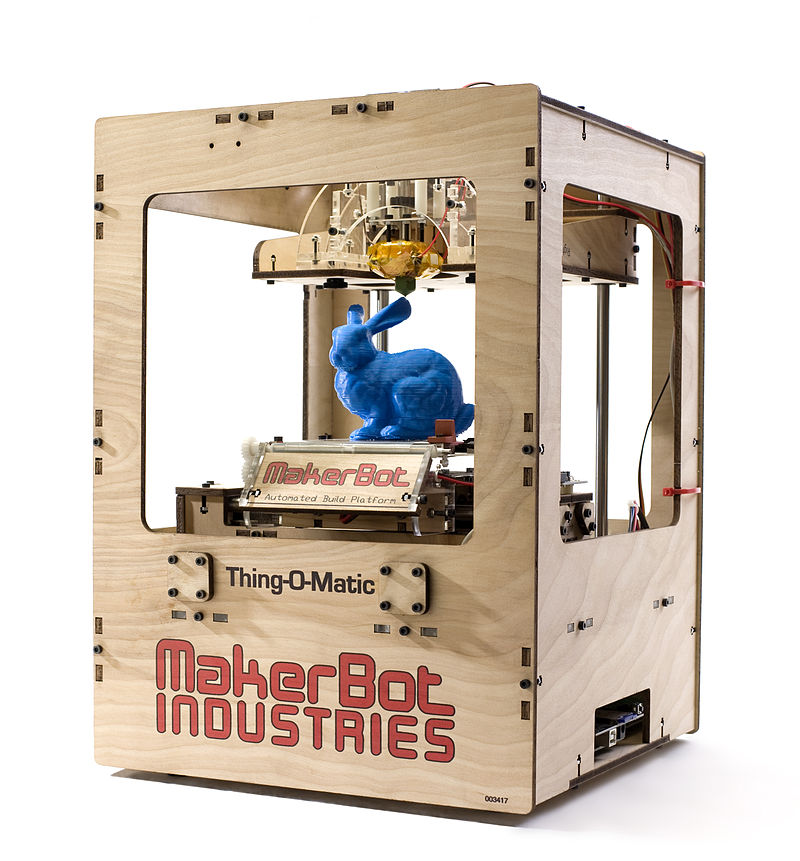

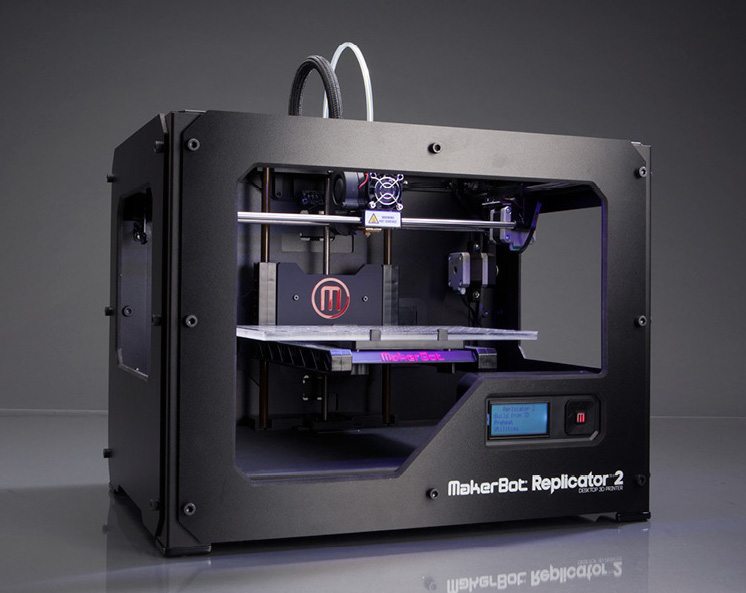

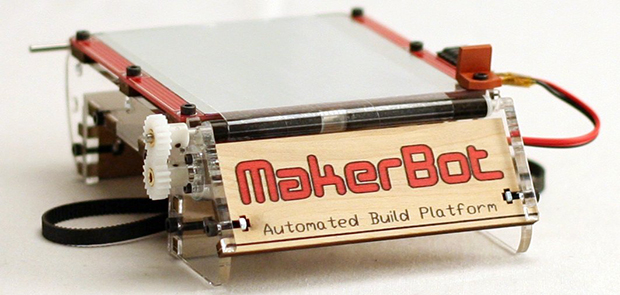

2009-2013: MakerBot & Thingiverse

US-based MakerBot was at the beginning (2009) a major driving force to the Open Source 3D printing community as partially funded also by Adrian Bowyer and his wife. MakerBot also runs Thingiverse, the major repository of free 3D models and designs for 3D printing. As MakerBot struggled with sales, after receiving Venture Capital and later bought by Stratasys (2013) it left the Open Source principle at the same time Thingiverse struggled since to stay functional (2019). In 2020 Thingiverse was given some attention, it seems now taken care of better.

- CupCake CNC: Z head, XY bed, laser cut wood frame

- Thing-o-Matic: Z head, XY bed, laser cut wood frame

- Replicator 2: XY head, Z bed, metal frame

2011-2016: Kickstarter Hype

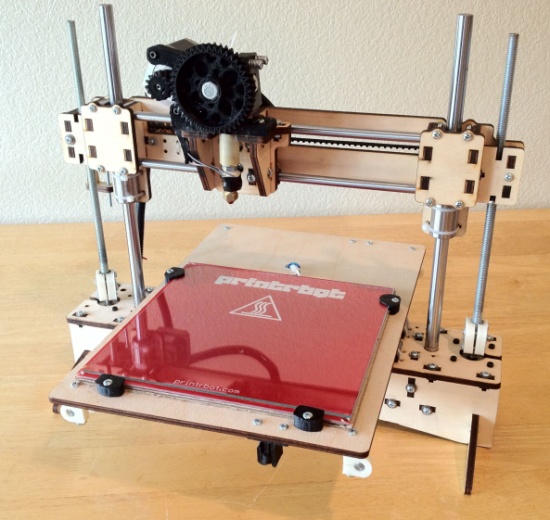

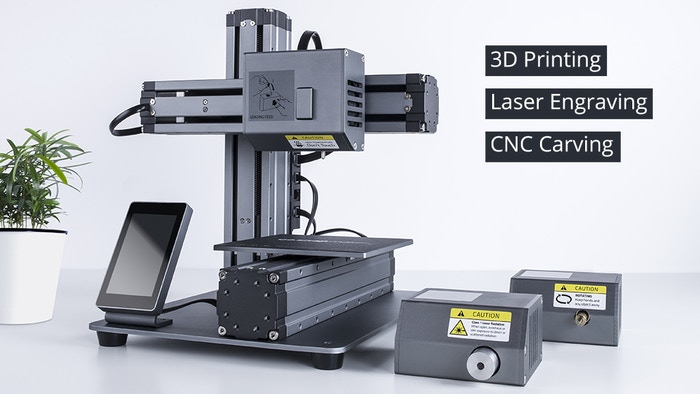

With the expiration of patents held by Stratasys and other companies (2009-), the surge for Kickstarter-based 3D printers began, sub 1000 USD printers became widely available, but also many failures and plain scams happened. Printrbot started as Kickstarter and thrived for a few years as US-based 3D printer company, also Snapmaker and FORM 1 by Formlabs made a successful debut, while sub 100 USD 3D printer like MakiBox, metal Eventorbot or slick Buccaneer failed at different stages.

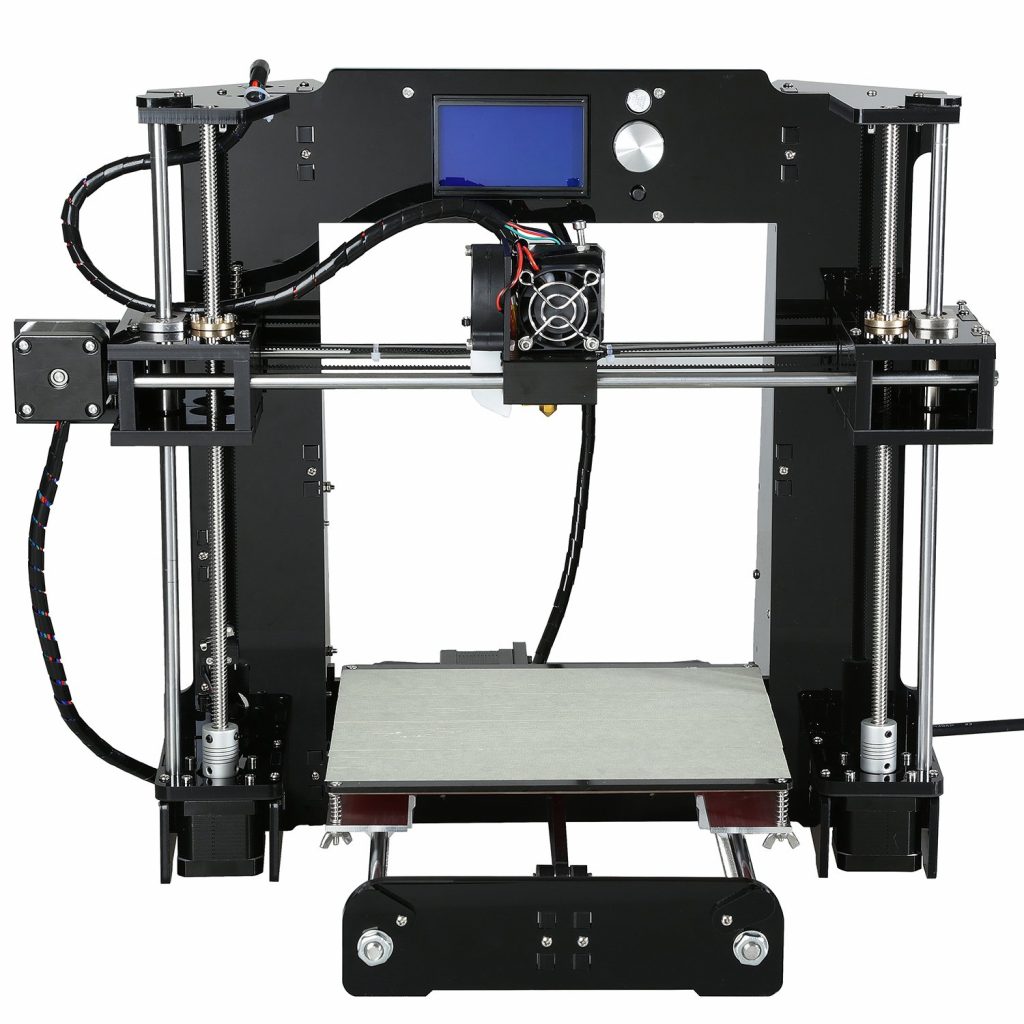

2018: Year of Chinese 3D Printers

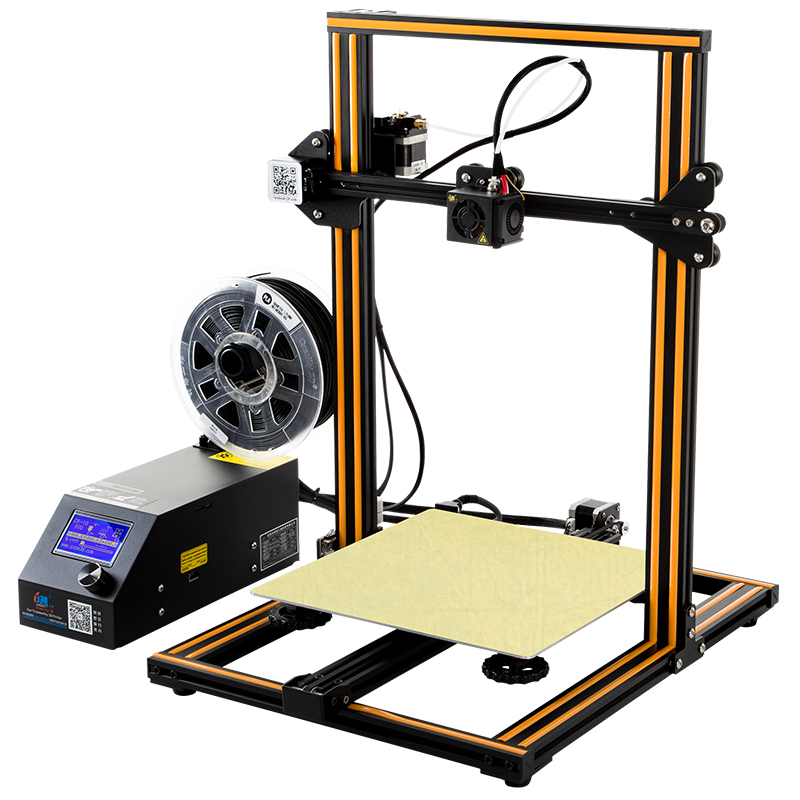

In 2016-2018 chinese manufacturers (Geeetech, Creality, Anycubic, FLSUN, TEVO, CTC etc.) started to develop Prusa i3-like machines and the companies started to copy each others parts and improvements at a rapid pace. As a result, many small US companies, like Printrbot, which contributed significantly to the Open Source movement, closed doors for good (2018).

A big game changer was Ender 3 as manufactured by Creality, priced at USD 150-200 incl. shipment, providing excellent printing quality, at a price which was hard to compete by anyone else. Notable was, Creality open sourced Ender 3 entirely, as the Open Source community built up pressure to chinese manufacturers which spit out each month a new Prusa i3 derivative (e.g. different build volumes, slight improvements of extruders etc) back in 2018/2019.

As a side note, the chinese manufactured 3D printer broke the RepRap principle and used other means to produce their parts, while Prusa Research has a 3D printer farm to manufacture their parts.

Western Innovation & Chinese Manufacturing

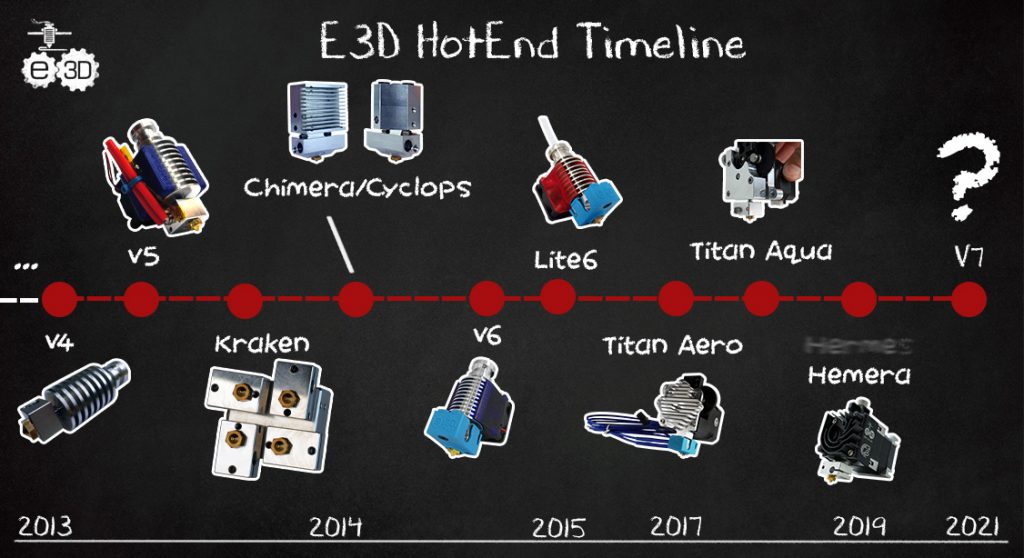

It became obvious the past years (2010-2019), that true innovation still remained in the west, Czech-based Prusa Research, Denmark-based RepRap.me with Diamond Hotend (3-in-1 and 5-in-1), or UK-based E3D or US-based Slice Engineering with their hotends and extruder technology, and the chinese manufacturer which cloned or copied the Closed- and Open-Source designs within weeks and sold at fraction of the price as by the original inventors. Often chinese manufactures tried to simplify hotend designs and compromised significant features – to copy a design didn’t mean the design was understood.

As pointed out, Creality, one of the big chinese 3D printer manufacturer, started to adapt and join the Open Source Hardware movement, with the release of the Ender 3 source files and get properly certified – time will tell – as of end of 2019 – if they stay true to their commitment, and whether other chinese 3D printer manufacturer follow and become also actual innovators.

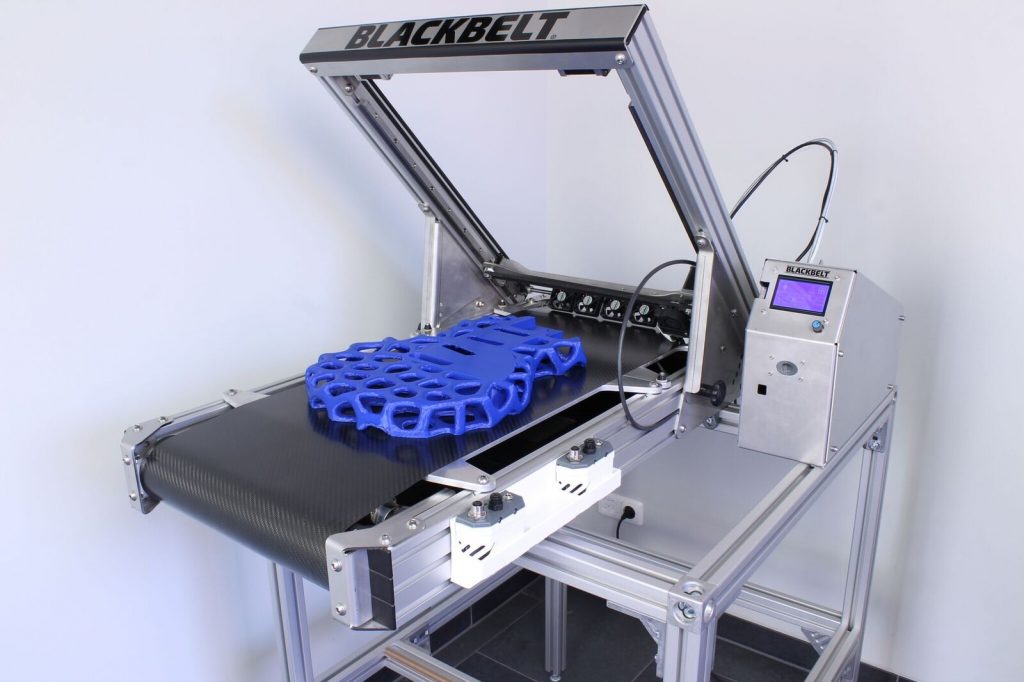

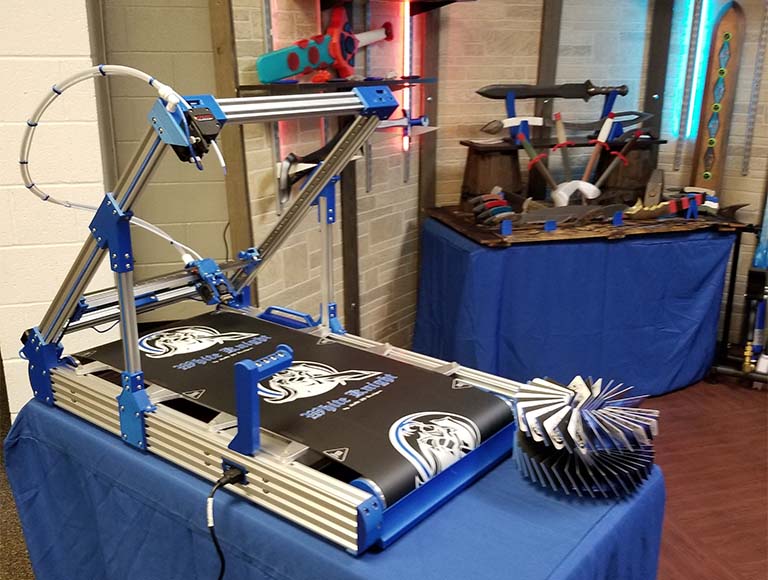

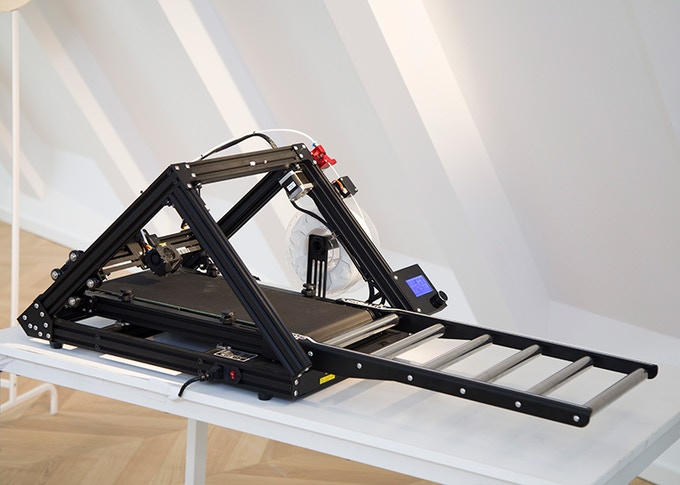

In late 2020 Creality announced a belt-based printer named CR-30 aka 3DPrintMill as a result of collaboration with Naomi Wu and acknowledging all the previous research of developers like Bill Steele and Karl Brown (White Knight Belt) the printer is based on – and renewed their commitment to Open Source the CR-30 – a nice development.

2021: Voron, Prusa XL, E3D Revo

A loosely organized Maker group developed various 3D printers under the brand Voron Design which gained momentum in the Maker community:

- CoreXY (Voron 0.x, 2.x, Trident) or CoreXZ (Voron Switchwire)

- sturdy well engineered frame design

- tuned toward reliable and fast printing

- properly documented (CAD models, bill of materials)

- fully open source

- no commercial frontend (no single store to buy assembled Vorons, only kits)

Voron printers became well-known in 2021 and widely adapted among people who wanted to build their own printers.

Various skillful Makers tuned the printer design toward very fast printing, high motion speeds and acceleration, to achieve 3D Benchy prints below 10mins at acceptable quality aka “Speed Benchy”.

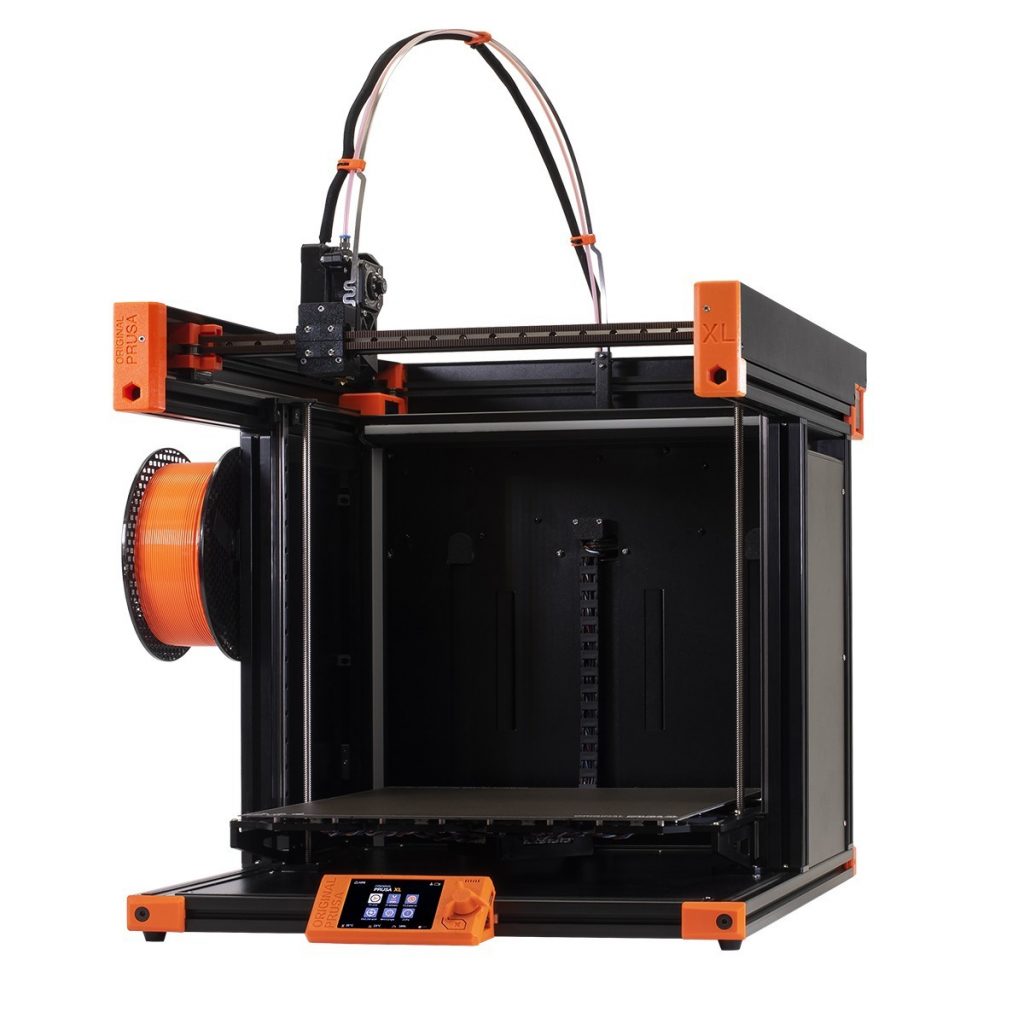

At Formnext 2021 (November 2021) Prusa Research announced the Prusa XL, a CoreXY cubic frame 3D printer, with interesting features:

- ability to sense blocked nozzle, indirectly by measuring bending of print head with a load cell

- autoleveling done mechanically via same load cell

- multiple heating zones in the build plate (only heat where part resides)

- multi-material with optional tool changer

- foldable curtain to maintain more regulated air temperature within the printer

- build-volume 360x360x360mm

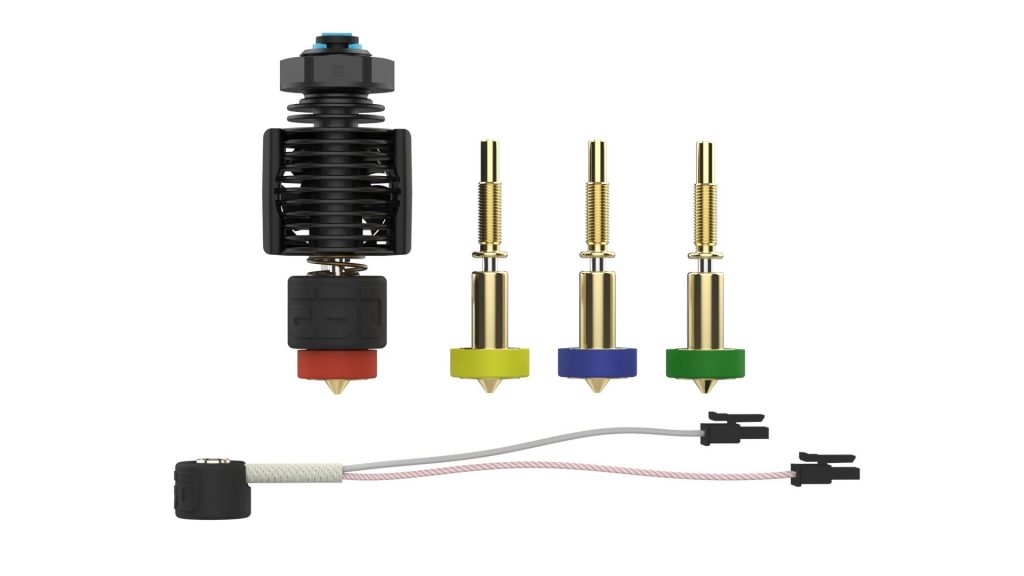

Also in fall of 2021 E3D announced its new generation of print heads, Revo:

- manual (un)mounting of print head without tools

- nozzle and heatbreak combined

- spring loaded tension of heat cartridge with nozzle

- partially patented

2022: MakerBot & Ultimaker Merge, Bambu Lab’s X1

In May 2022 MakerBot, owner of Thingiverse and part of Stratasys, announced together with Ultimaker they would merge the coming months, and in September announced to become UltiMaker. MakerBot, who plays no significant role in regards of hardware development anymore, and software development being neglected as well, incl. Thingiverse lumping since many years.

Ultimaker became monetary successful the past years is also showing inertia in hardware innovation, resting on existing hardware designs, at the same time committed to push software development with Cura slicer with fine-tuning details of the slicer, and still doing most of it under Open Source, admirably.

Another significant announcement happened in May 2022: Bambu Lab, founded by former DJI (drones) employees, worked the past two years on a new printer called “X1“, which has features hardly even seen in industrial 3D printers:

- printing fast at 400mm/s with 10,000 to 20,000m/s2 accelleration

- auto leveling (no manual calibration)

- auto tuning pressure advance with LiDAR sensor

- first layer analysis with LiDAR sensor, measure height and width of extrusions

- video analysis of failed prints using built-in camera and AI

- multiple materials (up to 16 spools/materials)

- dedicated slicer (being open sourced later)

- competitive price with USD 900-1500

The only downside is the rather moderate build-volume with 256x256x256mm, but they control that tightly unlike anyone before.

2023 & 2024: Incremental Upgrades

Formlabs resin printer series 4 switched from laser based SLA to UV-light & LCD based MSLA procedure (EUR 5,000-10,000), like the rest of prosumer and consumer resin printers. In June 2024 Micronics LLC launched a Kickstarter compaign for their SLS printer priced at USD 2,500, and after the finish of the compaign, the company was acquired by Formlabs.

Resin printing with more specialized resin types entering SLS and FDM domain (from Formlabs Keynote 2024):

Prusa Research introduced SL1S resin printer in 2021 with a tilting vat, and Elegoo followed then with Mars 5 Ultra & Saturn 4 Ultra in 2024, priced at EUR 300 & 400, also having a tilting vat / tilt release mechanism, which decreases layer printing time by ~50% from ~10s to ~5.5s, and therefore overall printing time as well, e.g. increase from 18mm/hr in Z height to 32mm/hr at 50μm or 64mm/hr at 100μm layer height.

Elegoo also introduced a massive FDM OrangeStorm Giga with a build volume of 800x800x1000mm, priced at EUR 2,500. Sovol SV08 (Voron 2.4 / CoreXY) becomes available at USD 750, with a build volume of 350x350x330mm.

Stratasys sued Bambu Lab in August 2024 about infringment of 10+ patents:

- purge towers for multi-color printing

- heated build platforms

- force detection systems

- networked printing capabilities

- filament detection/identification

It seems Bambu Lab has reached of market share where they are relevant for Stratasys, e.g. also protect their UltiMaker branded prosumer FDM series which have shown no relevant innovation since 5+ years.

2025: Price of Closed Source

Bambu Lab decided (2025/01/17) to change the way their printers are accessed, introducing “security” locking 3rd party software and hardware out, and breaking thereby workflows and trust into the company and their printers.

See also at RepRap Principle, RepRap.org Blog Archive and RepRap Magazine Archive to read about early RepRap movement (2000-2010).

That’s it.