State: Work in progress

As I finished the frame, I focused on the carriages:

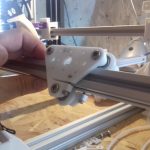

- X carriage: moving left to right with the hotend with Bowden setup to keep it light: Wheel-based Carriage

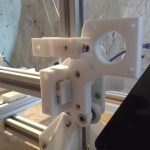

- Y carriage: moving bed forward and backward, relatively heavy with 400×300 bed with a mirror to ensure flatness: leaning toward Sliding Carriage

- Z carriage: moving up and down with X carriage: Wheel-based Carriage

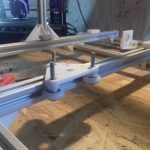

XZ Frame with X- and Z-Carriages

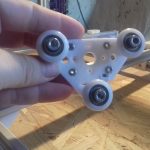

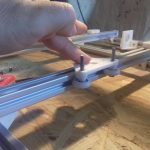

I made some tests with sliding carriage (composed with PTFE tubes), and finally the Nylon wheels arrived and I began to review two kinds of wheels:

- 23mm OD, 7.3mm width: even it’s wider it sits better in the T slot 2020 alu extrusion

- 23mm OD, 7.0mm width: is bit more narrow, but doesn’t sit well on the extrusion

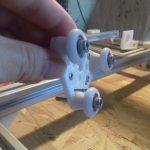

So, I put the 23/7.3 nylon wheel on the V plate to compose a V carriage, and applied to X and Z axis:

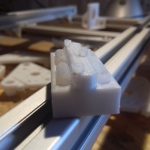

Y Carriage

The nylon wheels work very well, given the fine-tuning capability, whereas the sliding approach with 2 axis support (PTFE tubes in sliding direction plus vertical to stay in line) doesn’t give tuning capability.

- 3D printed slider with PTFE tubes

Currently I lean toward the more simple slider (white PLA) with 2 axis stabilization, as with the wheel-based carriage too much vertical force will be applied to the wheel in a perpendicular manner and wear the wheels rather fast.

One of the challenges is to mount three such sliders on the bed – two can mounted quite freely (with margin of 1-2mm) whereas the 3rd slider needs to be mounted very precise.

I update this post as I progress.