Note: As of 2023 I started a rewrite Prynt3r in Python, reimplementing Print3r (Perl).

Print3r or print3r (pronounced print-three-r) is a command line tool (CLI) which supports:

- multiple different slicers (Cura, Slic3r, PrusaSlicer, Mandoline, KiriMotoSlicer) with same unified settings

- multiple 3D formats more than what each slicer supports:

- STL, OBJ, OFF, AMF, 3MF, 3MJ and also

- OpenSCAD (.scad), OpenJSCAD (.jscad), ScriptCAD (.sccad)

- FCStd, IGES, STEP and Brep (using FreeCAD2Any helper)

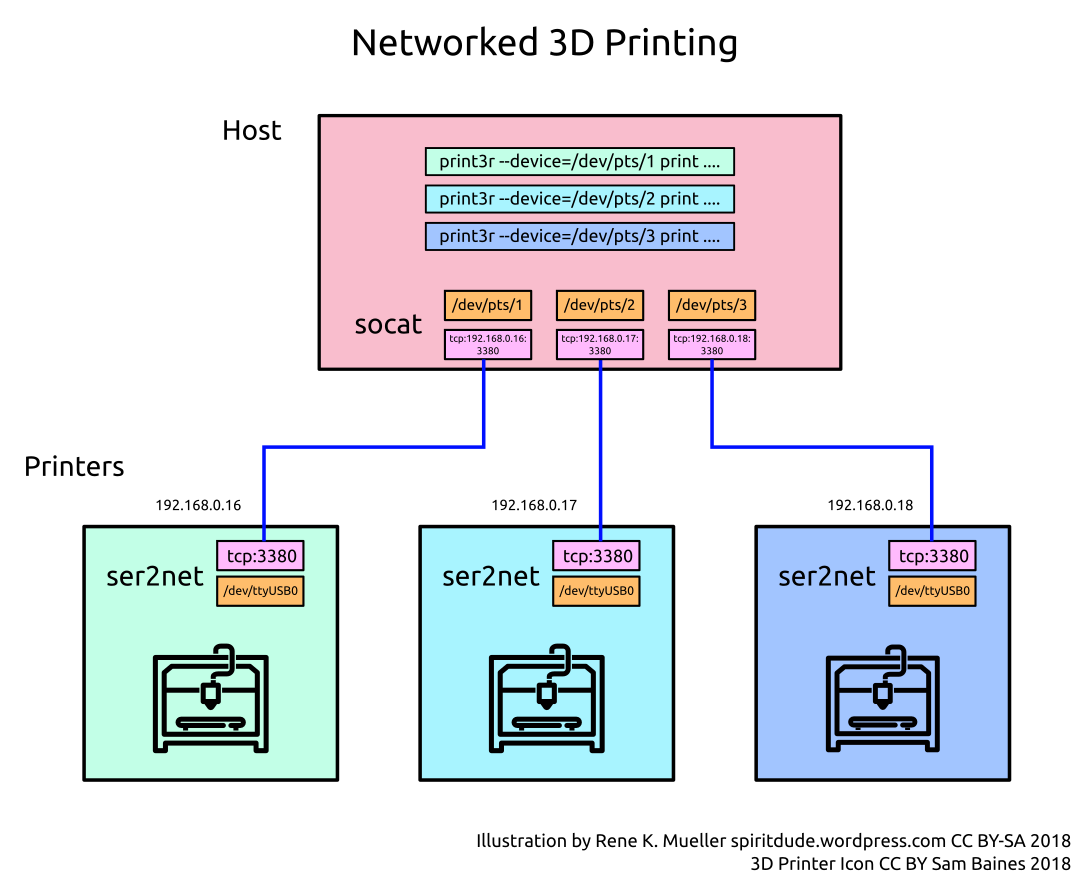

- networked/cloud printing built-in with multiple 3D-printers

Usage

% print3r [<options>] <command> <file1> ...

commands:

print: print the part (and perform necessary conversions to achieve print)slice: just slice the part to gcode with slic3r, slic3r-pe, cura, cura-legacy or prusapreview: preview print as gcoderender: render image of printgcode: send Gcode from command-linegconsole: start Gcode console to interactively send commandsclient: enable remote printing (start client mode)log: query past logged prints

Print (Convert & Slice & Print)

% print3r print cube.scad

% print3r print cube.stl

% print3r print cube.gcode

% print3r --scad print "cube(20)"

Slice (Without Printing)

Just slice the part to Gcode:

% print3r --output=cube.gcode slice cube.scad

% print3r --output=cube.gcode slice cube.stl

Preview (Without Printing)

Preview the resulting Gcode:

% print3r preview cube.scad

% print3r preview cube.stl

% print3r preview cube.gcode

% print3r --scad preview "cube(20)"

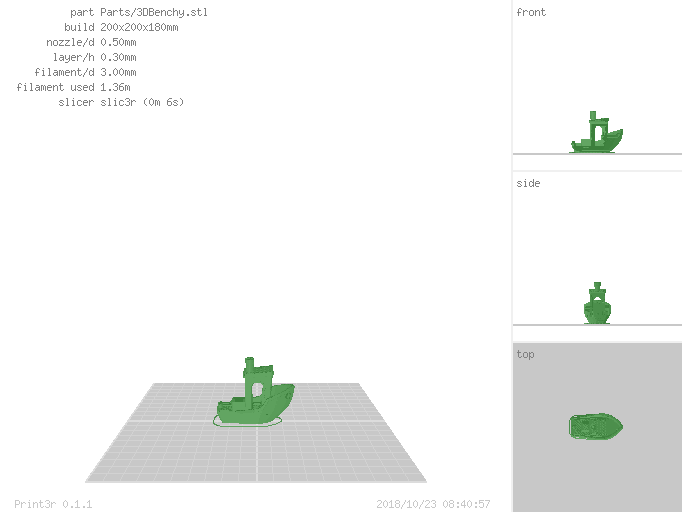

Render

Render the Gcode into an image:

% print3r --output=test.png render cube.scad

% print3r --output=test.png --scad render "cube(20)"

% print3r --output=test.png render cube.stl

% print3r --output=test.png render cube.gcode

Cloud Printing (Server/Client)

Create a printhub by starting print3r in client-mode:

% print3r --device=/dev/ttyUSB0 client &

% print3r --device=/dev/ttyUSB1 client &On the another host you can address the printhub(s):

% print3r --device=tcp:192.168.0.23:0 print benchy.stl

% print3r --device=tcp:192.168.0.23:1 print calibrationCube.stlUsage Overview

Print3r (print3r) 0.2.0 USAGE: [<options>] <cmd> <file1> [<...>]

options:

--verbose or -v or -vv increase verbosity

--quiet or -q no output except fatal errors

--baudrate=<n> set baudrate, default: 115200

--device=<d> set device, default: /dev/ttyUSB0

--slicer=<slicer> set slicer, default: slic3r

slic3r, slic3r-pe, cura-legacy, cura, prusa

--printer=<name> config of printer, default: default

--version display version and exit

--output=<file> define output file for 'slice' and 'render' command

--scad consider all arguments as actual OpenSCAD code (not files)

--scadlib=<files> define OpenSCAD files separated by "," or ":"

part preprocessing:

--random-placement place print randomly on the bed

--auto-center place print in the center

--multiply-part=<n> multiply part(s)

--scale=<x>,<y>,<z> scale part x,y,z (absolute if 'mm' is appended)

--scale=<f> scale part f,f,f

--rotate=<x>,<y>,<z> rotate x,y,z

--translate=<x>,<y>,<z> translate x,y,z

--mirror=<x>,<y>,<z> mirror x,y,z (0=keep, 1=mirror)

--<key>=<value> include any valid slicer option (e.g. slic3r --help)

commands:

print <file> [...] print (convert & slice & print) part(s) (.scad, .stl, .obj, .gcode)

slice <file> [...] slice file(s) to gcode (.scad, .stl, .amf, .obj, .3mf)

preview <file> [...] slice & preview (.scad, .stl, .obj, .gcode)

render <file> [...] render an image (use '--output=sample.png' or so)

gcode <code1> [...] send gcode lines

gconsole start gcode console

client map USB connected printer to network (per device)

help

examples:

export PRINT3R "printer=my_printer" --OR-- setenv PRINT3R "printer=my_printer"

print3r slice cube.stl

print3r --layer-height=0.2 --output=test.gcode slice cube.stl

print3r --printer=ender3 --device=/dev/ttyUSB1 print test.gcode

print3r --printer=corexy --device=/dev/ttyUSB2 --layer-height=0.3 --fill-density=0 print cube.stl

print3r --printer=ender3 --device=tcp:192.168.0.2 --layer-height=0.25 print cube.stl

print3r print cube.scad

print3r --scad print "cube(20)"

print3r gcode 'G28 X Y' 'G1 X60' 'G28 Z'

print3r gconsole

== Print3r: Gcode Console (gconsole) - use CTRL-C or 'exit' or 'quit' to exit

for valid Gcode see https://reprap.org/wiki/G-code

conf: device /dev/ttyUSB0, connected

> M115

...

Slicers

Following slicers are supported via --slicer=<slicer>:

slic3r: Slic3rslic3r-pe: Slic3r Prusa Editioncura-legacy: CuraEngine 15.04 with old profilescura: CuraEngine 3.x or laterprusa: PrusaSlicer

/usr/share/print3r/slicer/<slicer>/base.ini contains the base settings for a particular slicer.

print command converts, slices and sends the resulting Gcode to the USB port of your choice.

% print3r print cube.scad

% print3r --scad print 'cube(20)'

% print3r print cube.stl pyramid.obj

% print3r print cube.gcodePart Preprocessing

All part-preprocessing operations can be used in combination of print, slice, preview and render command:

Placement

--random-placementplace print randomly on the bed to evenly use the entire bed--auto-centerplace print in the center (default)

% print3r print cube.scad

% print3r --auto-center print cube.scad

% print3r --random-placement print cube.stlMultiply Part

--multiply-part=<n> multiply part(s)

% print3r --multiply-part=2 print cube.stl

% print3r --multiply-part=2 print cube.stl dodecahedron.stl

% print3r --multiply-part=2 preview cube.scad pyramid.stleach part is multiplied, --multiply-part=1 is redundant.

Scale

--scale=<x>,<y>,<z>scale part x,y,z (absolute if ‘mm’ is appended)--scale=<f>scale part f,f,f

whereas each value can be:

<float>= multiplier, special case 0 = scale proportionally<float>% = multiplier in percent<float>mm = force to x mm absolute length and scale all axis set to 0 proportionally

% print3r --scale=2 preview cube.scad

% print3r --scale=200% print cube.stl

% print3r --scale=2,1,0.5 print cube.stl

% print3r --scale=20mm,0,0 print box.stl

% print3r --scale=20mm,2,1 print box.stl

% print3r --scale=300mm,30%,1 print box.stlRotate

--rotate=<x>,<y>,<z> rotate x,y,z where is each angle 0 .. 360 deg

% print3r --rotate=90,0,0 preview toy.scad

% print3r --rotate=90,0,0 print toy.stlTranslate

--translate=<x>,<y>,<z> translate x,y,z whereas each value in [mm], disables --auto-center and --random-placement.

% print3r --translate=-40,20,0 print cube.stlMirror

--mirror=<x>,<y>,<z> mirror x,y,z (0=keep, 1=mirror), the same can be achieved with --scale= by using -1 (mirror) and 1 (keep):

% print3r --mirror=1,0,0 print toy.stl

% print3r --mirror=0,1,0 print mount.stl

% print3r --scale=1,-1,1 print mount.stl Slice

slice command converts and slices the model to Gcode file, best set --output=file.gcode to define the filename.

% print3r slice cube.scad

% print3r slice cube.stl

% print3r --output=cube.gcode cube.scad

% print3r --slicer=cura --output=cube.gcode cube.scad

% print3r --slicer=slic3r-pe --output=cube2.gcode cube.scadPreview

preview command converts, slices and display the resulting Gcode with yagv Gcode viewer.

% print3r preview cube.scad

% print3r --slicer=cura preview cube.scad

% print3r --slicer=cura --printer=prusa-i3 preview cube.scad

% print3r --slicer=slic3r-pe --printer=ashtar-k-1 preview cube.stl pyramid.stlRender

render command converts, slices and renders the resulting Gcode into a PNG image, best set --output=test.png to define the filename.

% print3r render cube.scad

% print3r --slicer=cura render 3DBenchy.stl

% print3r --slicer=cura --printer=prusa-i3 render cube.scad

% print3r --slicer=slic3r-pe --printer=ashtar-k-1 --output=set.png render cube.stl pyramid.stl

Gcode

gcode command allows to send Gcode in the command line directly:

% print3r gcode 'G28 X Y' % print3r gcode 'G28 Z'

Gcode Console (gconsole)

gconsole command launches an interactive console to send Gcode and custom commands to USB connected printer:

== Print3r: Gcode Console (gconsole) - use CTRL-C or 'exit' or 'quit' to exit

for valid Gcode see https://reprap.org/wiki/G-code

conf: device /dev/ttyUSB0, connected

>

Commands

- any valid Gcode line

- in

gconsole/commandsreside a few gcode script which simplify handling:home,homex,homey,homez,hx,hy,hz: homing all or individual axisleft <n>,right <n>move left or right (X-axis) relativelyup <n>,down <n>move up or down (Z-axis) relativelyforward <n>,back <n>move forward or back (Y-axis) relativelyx <n>,y <n>,z <n>move each axis absolutelynozzle <temp>set nozzle temperaturebed <temp>set bed temperatureoffturn everything off (motors, nozzle, bed)

> homex

send <G28 X>

-----

X:0.00 Y:0.00 Z:5.00 E:0.00 Count X:0 Y:0 Z:16000

ok

.

> right 10

send <G91>

-----

X:0.00 Y:0.00 Z:5.00 E:0.00 Count X:0 Y:0 Z:16000

ok

.

send <G1 X10>

-----

ok

.

> _Download & Install

Visit https://github.com/Spiritdude/Print3r or choose the latest release.

More Information & Details

- Github: Print3r Wiki: the “official” documentation and in-depth examples

- My Blog with Print3r: on-going development with examples

Orange Pi Zero

Orange Pi Zero