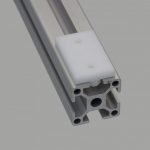

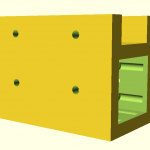

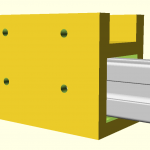

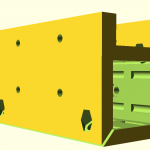

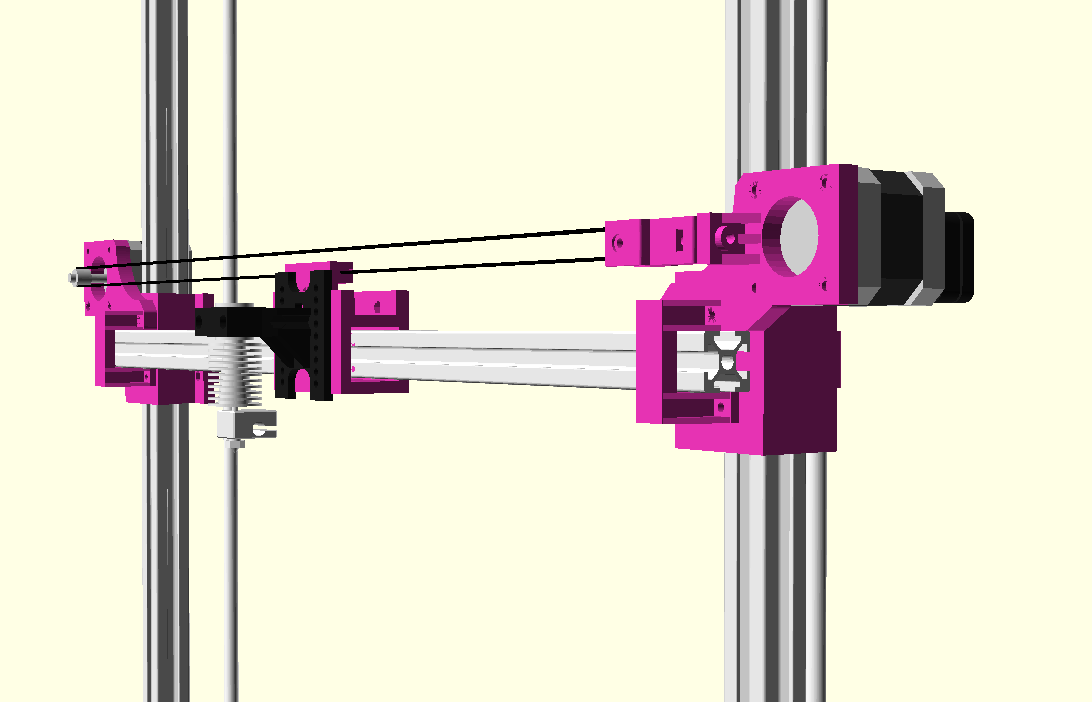

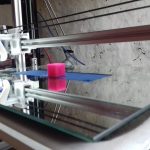

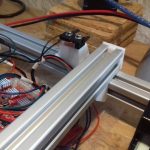

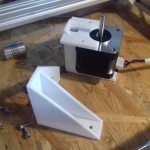

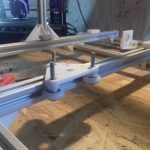

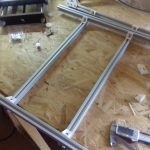

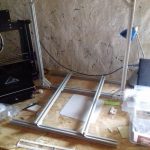

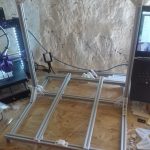

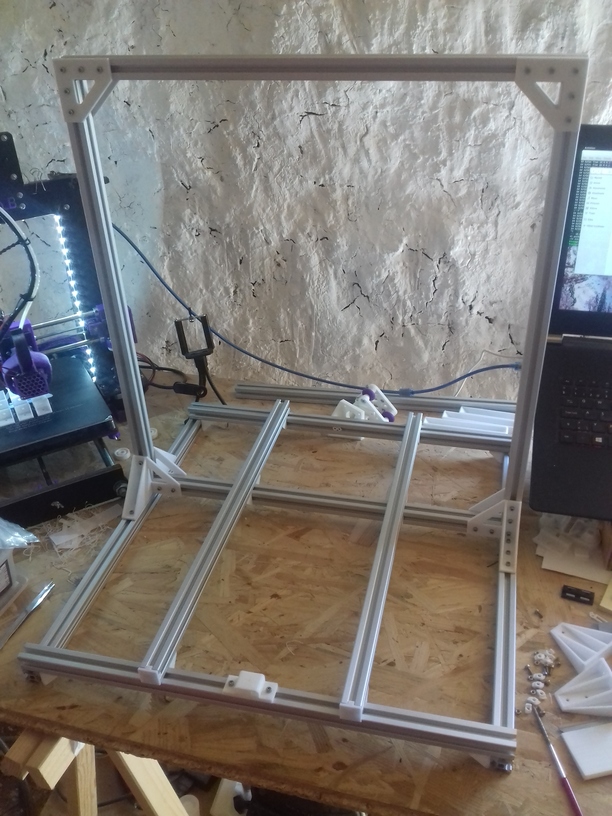

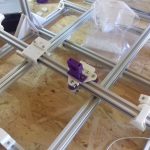

Well, after merely 3 months (2018/06/06) when I started to code the first lines of OpenSCAD to develop a series of parametric Prusa i3-like designs, and few weeks ago decided to go with the “K” series with 2020 alu profiles: simple 11x 500mm beam T slot (B-Type) alu profiles – the 1st prototype happen to print the 20mm XYZ Calibration Cube as of 2018/08/27:

- Ashtar K 38.30.33

The bed is very temporarly fasten with tape, as I haven’t decided on the actual details of the bed mounting yet and leveling details – but I wanted to see how well the mechanics already works – and it performed quite well so far.

1st print came out mediocre, when I realized I had to tighten X and Y belts more, 2nd print came out much better; 0.5mm nozzle with 0.4mm layer height, merely printed in 8mins with 60mm/s print speed and 80mm/s 20% infill:

And just for the fun of it, 0.2mm layer height with 0.5mm nozzle, at 70mm/s:

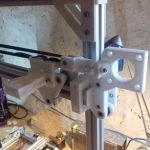

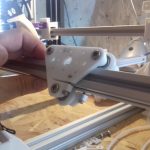

Incredible quality: X and Y surface very good, some inconsistency at “X”, on the “Y” side some slight ghosting; but most surprising is the edges on the Z axis – I operate with a simple M6 threaded rod and M6 nut – that’s all – moving nylon wheel-based carriage up and down – sure, I require to print more tests, in particular larger prints to really see how well all axis print up to 300mm.

I had to use blue tape on the mirror otherwise PLA would not stick – eventually I will use the black sticker as I used for the CTC DIY printer which worked quite well.

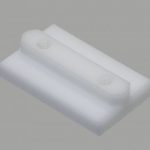

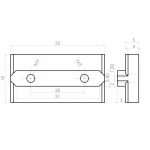

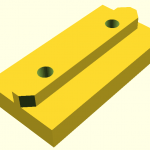

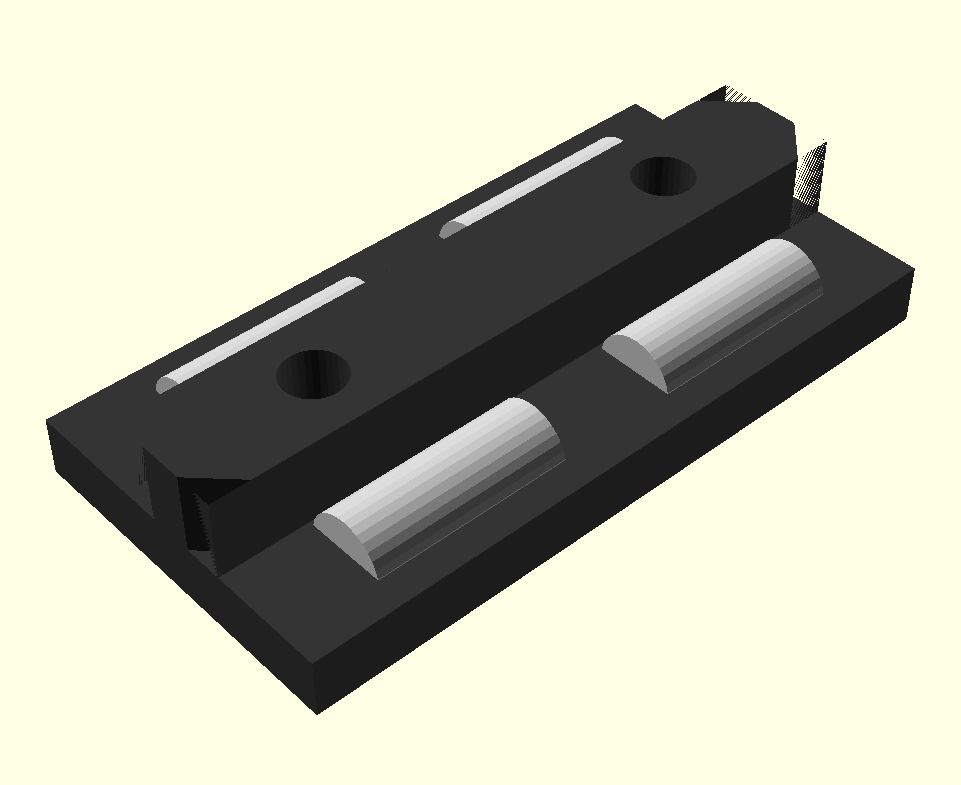

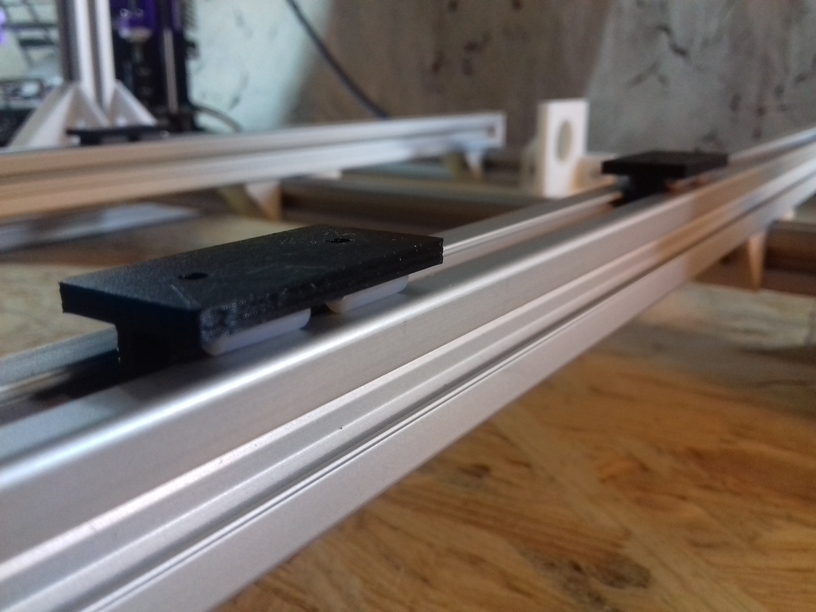

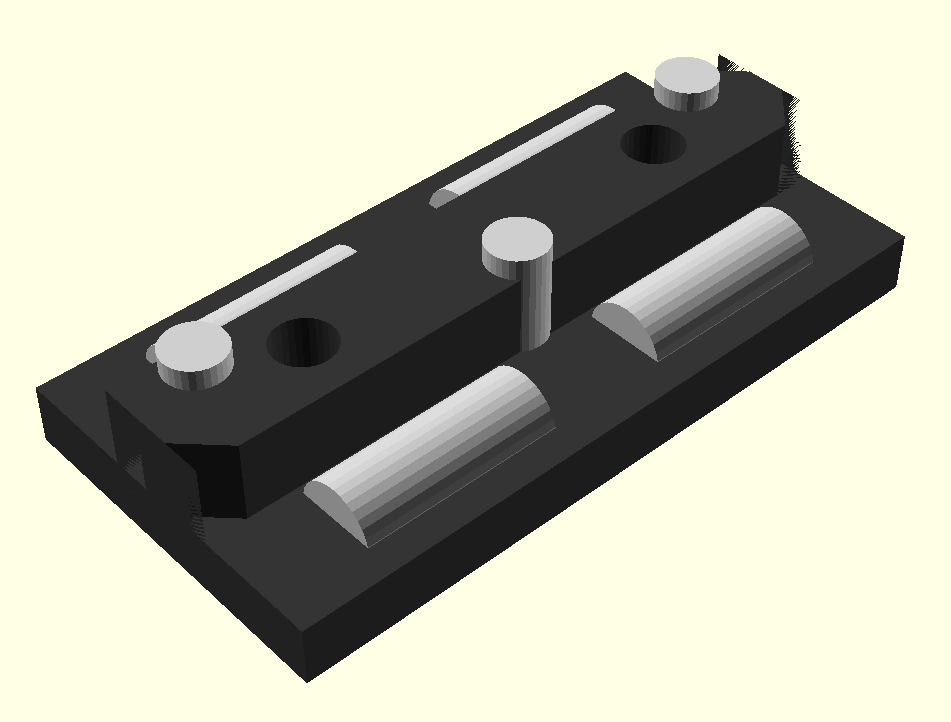

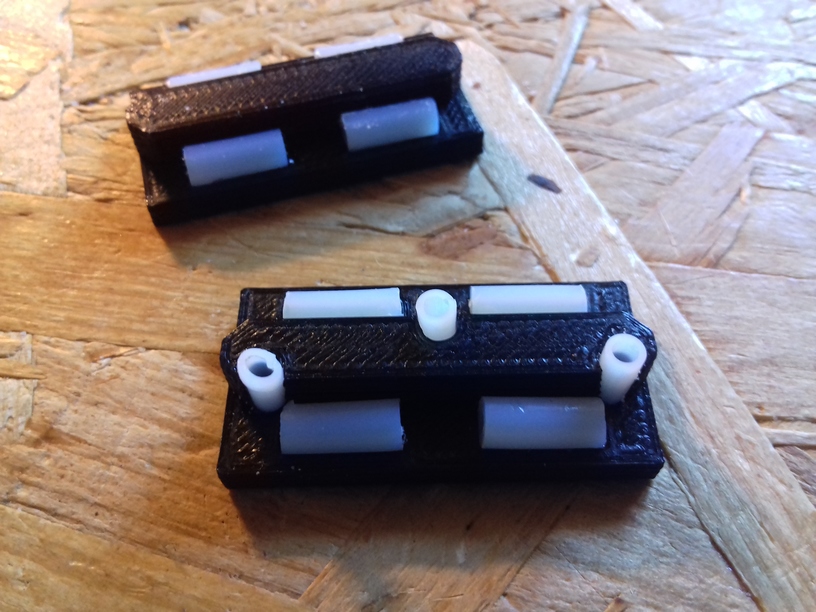

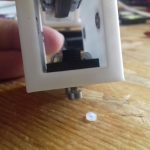

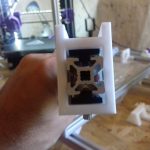

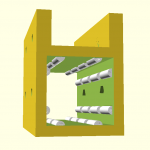

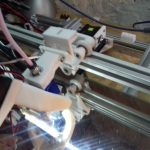

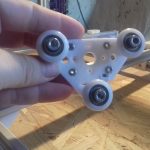

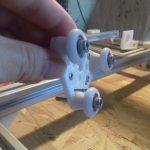

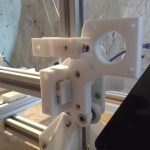

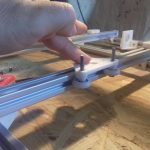

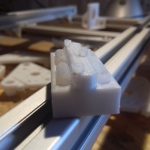

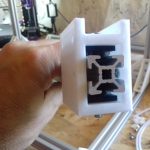

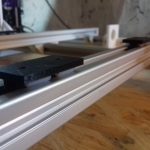

Nylon Wheels vs Sliders

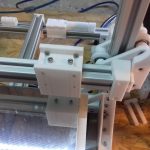

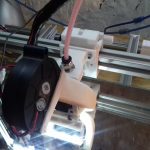

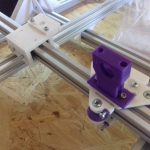

The past 2-3 weeks, while waiting the nylon wheels to arrive, I decided to check alternatives such as sliders with PTFE tubes – and this paid off: the nylon wheels 23.0mm OD with 7.3mm width sit quite nicely into the T slot (B-type) but when used in real life, like with X carriage, I had some sinus wobble in the vertical – apprx. 0.5mm to 1mm – way too much. So, I exchanged the wheel-based X carriage with the slider-based carriage, remounted the hotend with Bowden setup, and after 5mins the exchange was done:

- X carriage with white nylon wheels (23.mm OD / 7.3mm width)

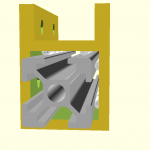

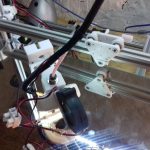

Current setup:

- X axis: slider-based carriage, holding on top and bottom side with 2 tightening screws

- Y axis: simple sliders (just sitting on the groove)

- Z axis: nylon wheel (23.0/7.3mm) based carriage

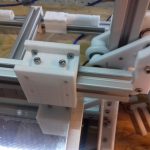

The next days and weeks I will review my options:

- slider-based carriage with

- 1 axis support or

- 2 axis support

- wheel-based carriage with

- nylon wheels 23.0/7.3 and 23.0/7.0

- double V wheels

both on T slot alu extrusion – I know ideally would be proper V slot alu extrusions, but I like to find out how good it works with the easily available T slot extrusions. Worst case is, I have to use on X and perhaps Z axis proper V slot alu extrusions, on the Y axis it seems the simple sliders (just a block) work fine.

0.5mm Nozzle

Since I deal with nearly 3x the bed surface compared to 200×200 I thought I have to use a bigger nozzle as well, as a bigger build volume would imply larger objects to be printed. The increase from 0.4mm to 0.5mm diameter also implies 1.5x or +50% more material being extruded and I still desire to print with 60mm/s average with 80mm/s infill – this means I have to test well the hotend performs with that speed and higher throughput of material.

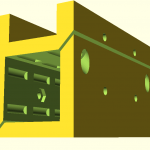

Specifications

Current specifications of Ashtar K 3d printer:

- 380 x 300 x 320 mm build volume (400 x 300 bed)

- E3D V6 clone hotend

- 0.5mm nozzle

- Anet 1.0 controller board

- 210 x 210mm 12V heatbed

TODO

- bed mounting & leveling

- 300×300 or 400×300 220V heatbed

- proper print surface (likely black sticker 300×300 or 400×300)

- improving cable management:

- Y carriage and heatbed with proper cable chain

- deciding on position of LCD display

Commercially manufactured, apprx. cost EUR 2.50 per piece, sold in 10 pieces bag.

Commercially manufactured, apprx. cost EUR 2.50 per piece, sold in 10 pieces bag.