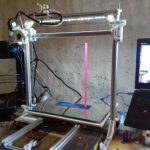

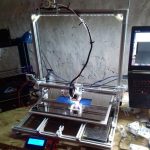

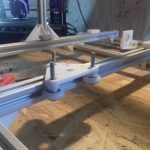

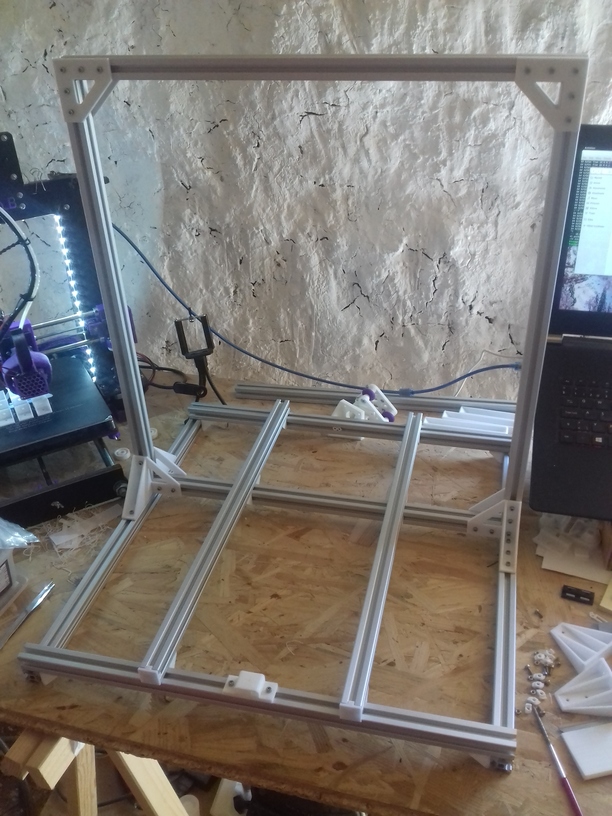

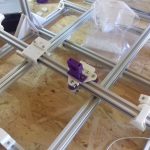

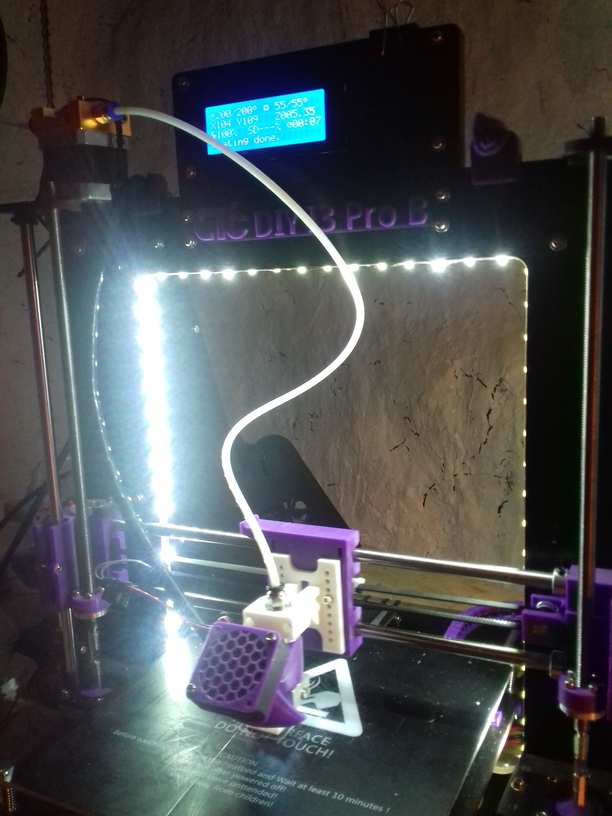

It has been a few days (2018/09/04), since Ashtar K happen to be able to print, the heat bed still unfinished, some prints illustrated below are done with no leveling screws, the mirror just taped on the Y carriage – don’t laugh – later prints I had proper carriage and leveling screws included; a proper build surface I still wait for in the mail (400×400 black sticker to be cut in shape) – anyway, here some of the early prints:

40mm XYZ Calibration Cube

The original 20mm XYZ Calibration Cube is printed in 8 mins with 0.5mm nozzle at 0.4mm layer height, and so I thought, let’s print it 2x the size with 0.4mm layer height, merely 40 mins later this:

The quality is . . . impressive, this is just tuning a single day – mostly on the extrusion factor and print temperature – and this is what I hoped for: XYZ positioning almost flawless: there is slight ghosting on X axis (which could be resolved) shown on “Y”, and Y axis shown on the “X” which is fine, given the size of the bed and its weight and inertia this is OK.

I had to increase print temperature +20C from 200C to 220C for 80mm/s infill while printing with the 0.5mm nozzle, I otherwise would hear clicking from the extrusion stepper motor missing steps. I still use the classic E3D V6 (clone) heat block, not the Volcano heat block.

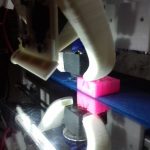

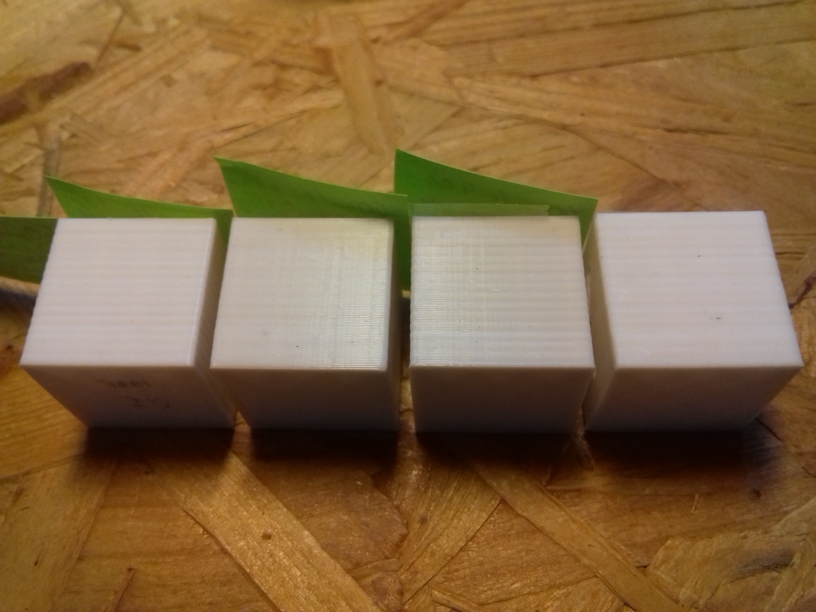

20mm Calibration Cube: Different Layer Heights

Printed with 0.5mm nozzle, left-to-right: 0.1mm, 0.2mm, 0.3mm and 0.4mm layer height, 60mm/s (80mm/s infill), 200C first layer, rest with 210C, pink glowing PLA by Sienoc.

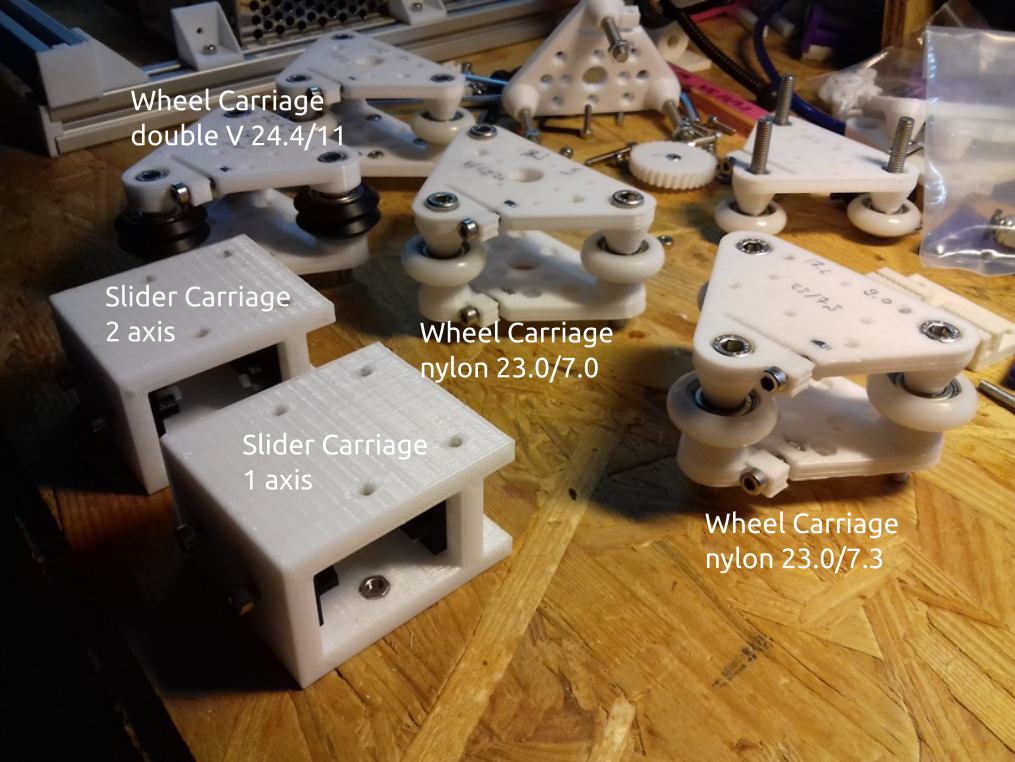

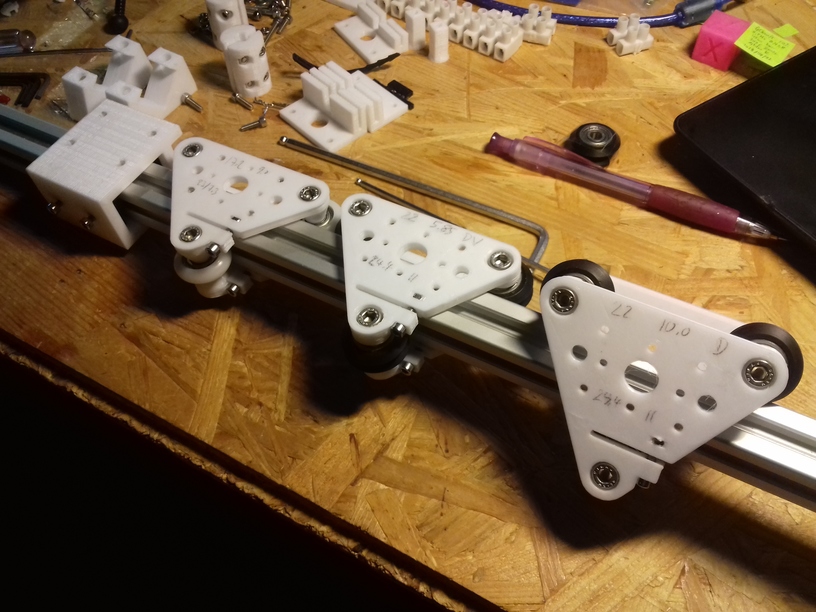

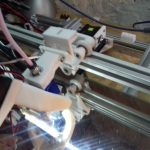

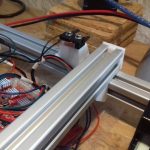

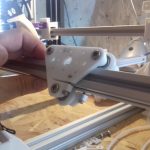

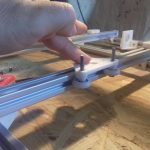

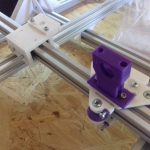

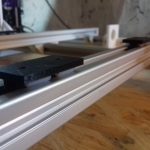

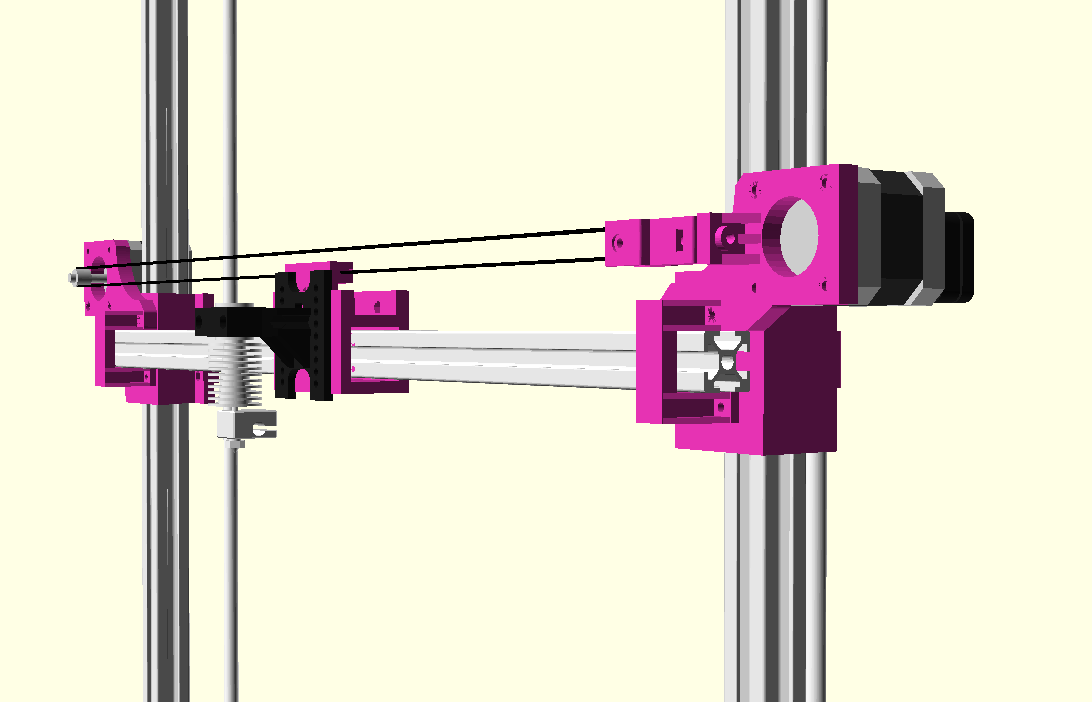

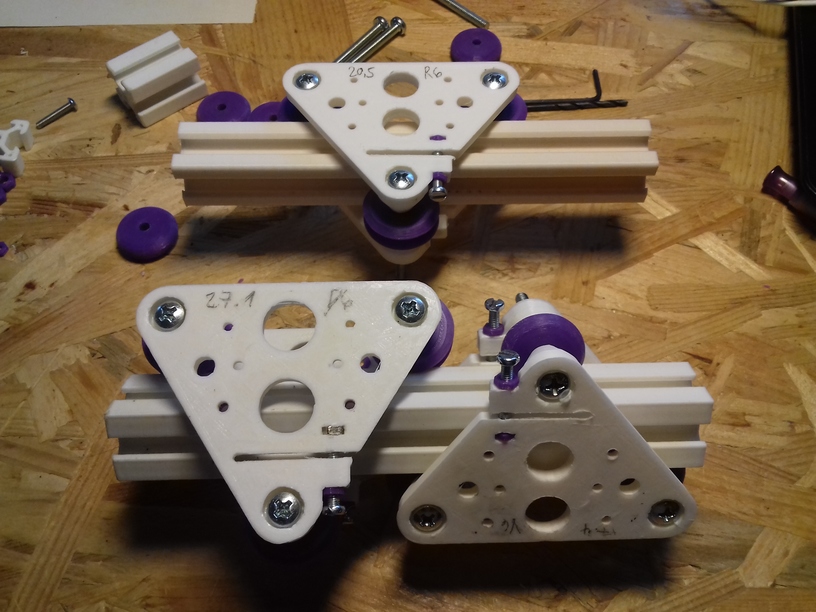

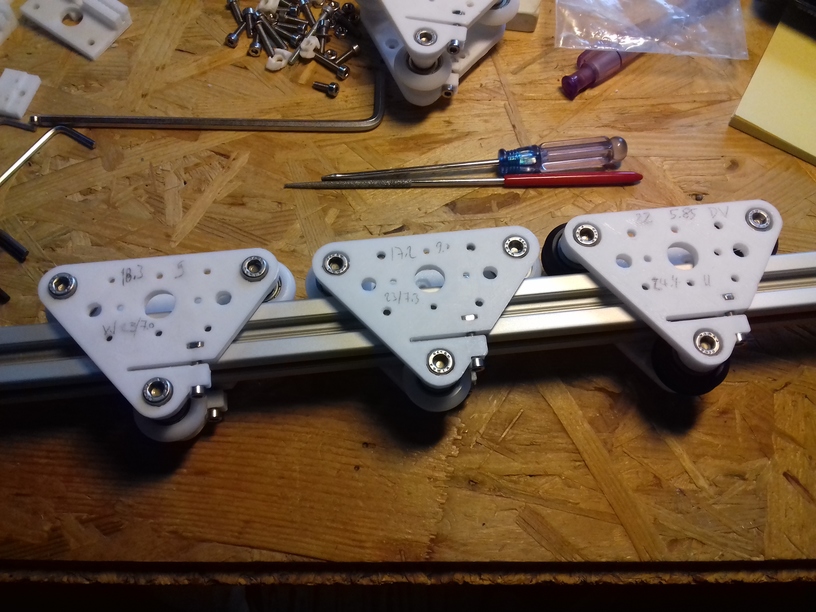

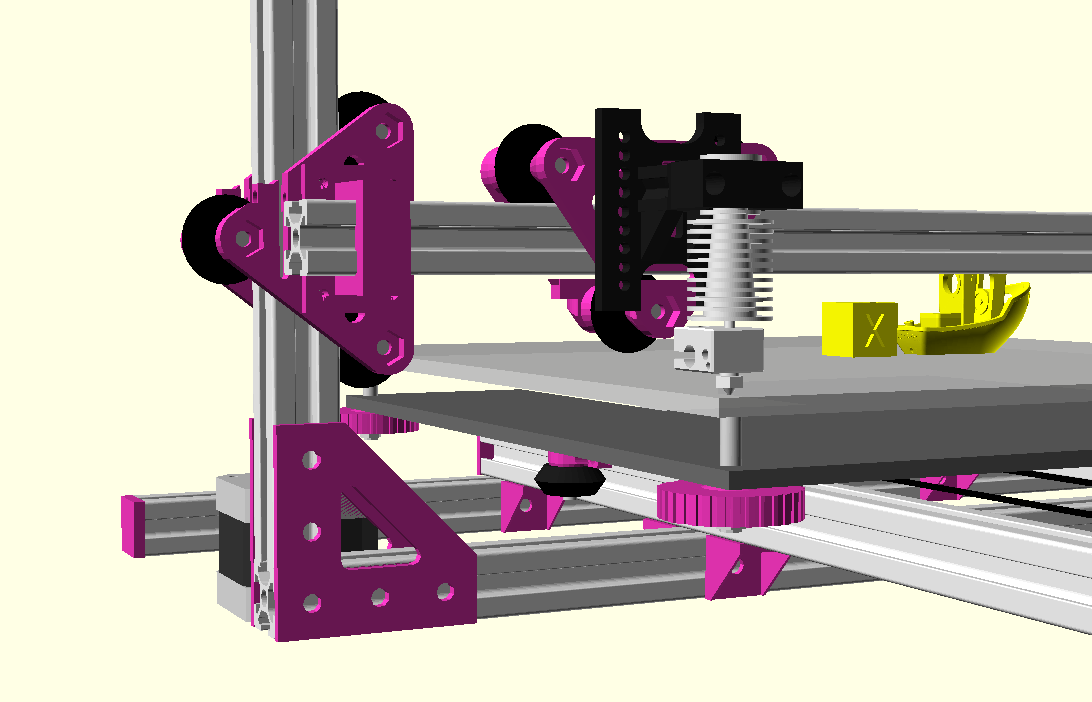

X Carriage: Sliders vs Wheels

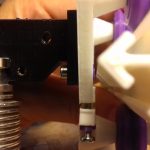

While printing with slider carriage on the X axis, I noticed increased stuttering, and regardless if I thighten or loosen the grip, the stuttering remained, and slight horizontal tilt occured when changing direction on the X axis resulting in too narrow prints in X dimension.

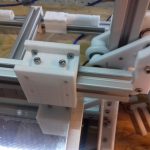

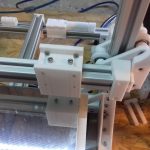

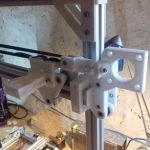

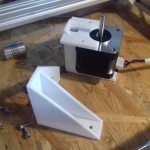

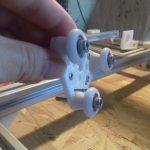

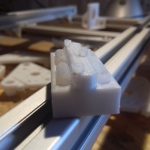

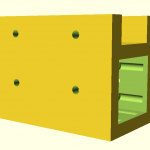

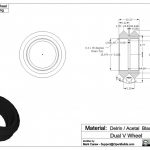

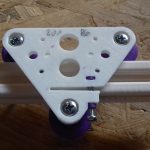

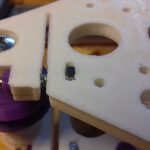

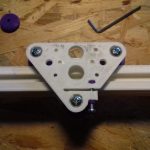

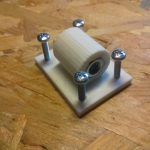

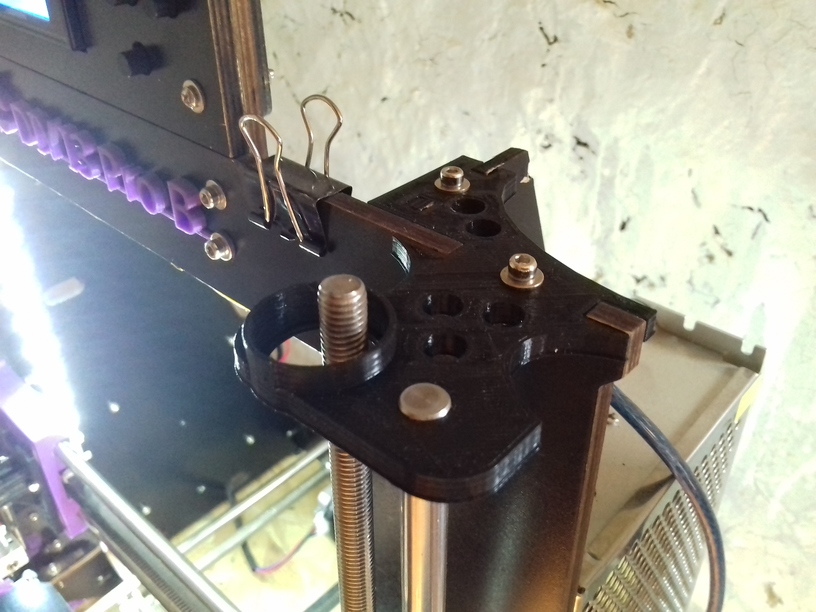

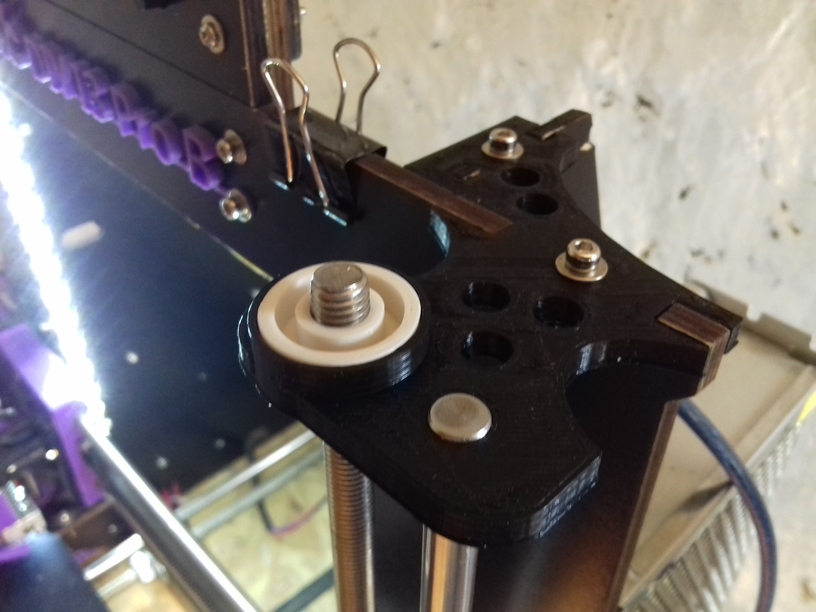

X carriage with white nylon wheels (23.mm OD / 7.3mm width)

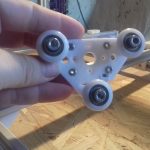

So, I changed back to wheel-based carriage, first again 23/7.3 white nylon wheels (right photo), but when I printed “L” shape with 200mm length in X and Y and 1mm height in Z, I noticed slight Z sinus form as I saw before – while it rolled nicely, there was a wobble . . . and so I printed a new carriage which holds the black OpenRail Double V (clone) 24.4mm OD / 11mm width, and put it on the X carriage:

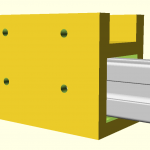

X carriage with double V black wheels 24.4mm OD / 11mm width

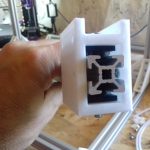

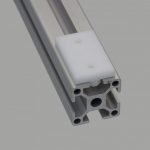

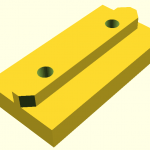

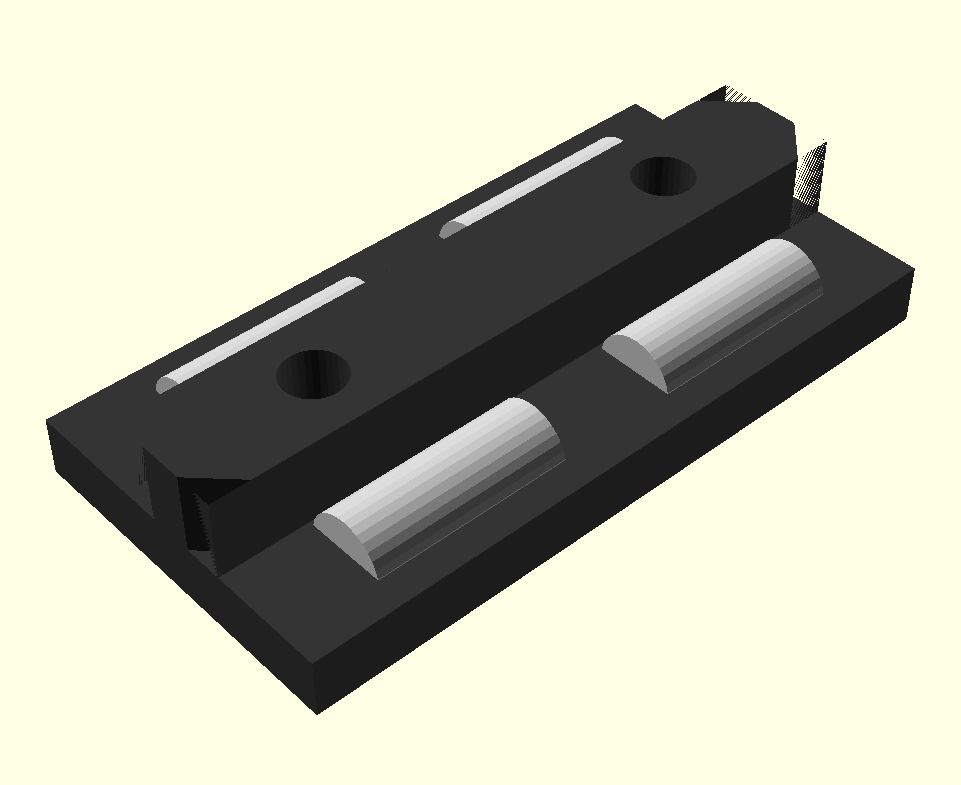

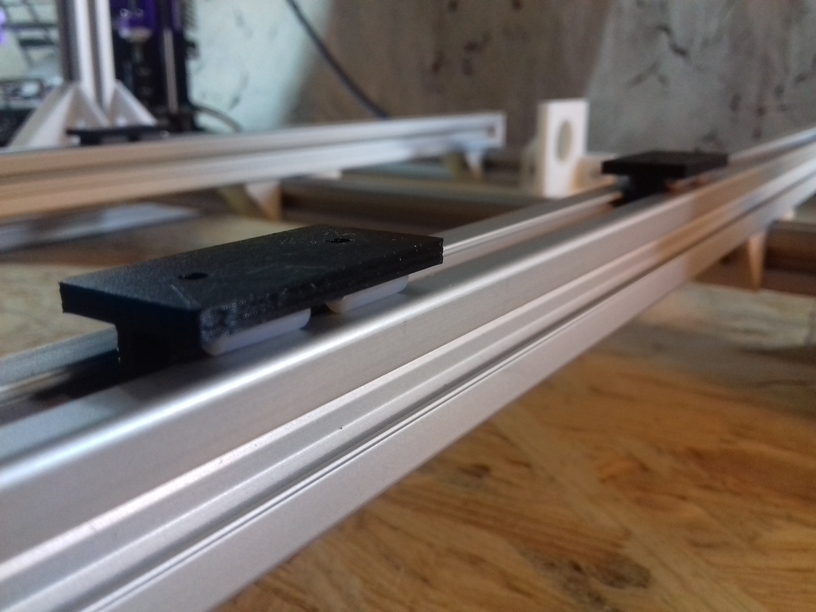

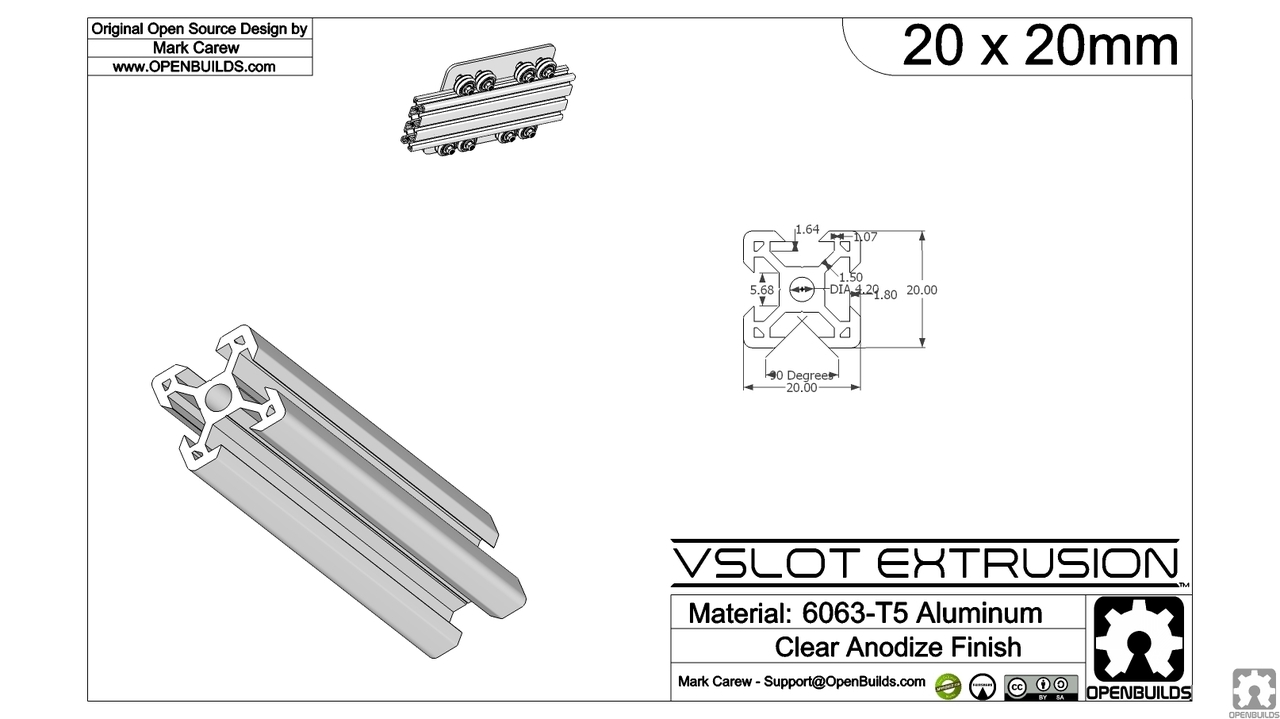

A brief overview of the carriages riding on 2020 T slot (B-Type) alu extrusion:

Sliders: on the X axis it did not last, the stuttering was not avoidable; the issue is that the X carriage is one of the hardest axis of the Prusa i3 style geometry to handle: it isn’t just X directional rail, but also pressure on the Z with the weight of the print head, and running over overextruded filament – and it’s hard to pull the X carriage perfectly without the carriage have some vertical tilt as well – anyway, I still use the slider option on the Y carriage – and works fine so far.

White nylon 23/7.3mm wheel: rolls nicely, but gives wobble to the Z height when used on X carriage, apprx. 1mm, also doesn’t stay vertical upright, but tilts a bit with pressure – when the print head moves over overextruded print it doesn’t level it, but jumps over it. I currently use white nylon wheels on the Z carriage successfully.

Black double V delrin 24.4/11mm wheel

- groove use: rolls very nicely, gives no wobble, and stays vertical. The next days and weeks will tell if the double V wheels do last on the T slot alu profiles – they are meant on proper V slot alu extrusions.

- diagonal/edge use: rolls very nicely too, but surprisingly gives less tilt rigidity than groove use – the T slot 6 (B-Type) gives less surface at supposed 90deg edge, but is rather 85deg

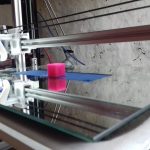

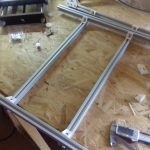

Z Axis Linearity

As you may have read in the other post(s), I use M6 threaded rods, it’s flexible and rather aligns with the Z axis itself, whereas M8 is stiffer and misalignment – which by the way doesn’t come from the rod itself, but the mounting with the couplers – won’t impose on the X carriage – this is my own view and it happens to come true again with Ashtar K, after I changed my cheap CTC DIY I3 also to M6.

Now, the 1m long M6 threaded rod, enough for two Z axis each 500mm long, did just cost EUR 0.70, made in China but purchased locally in Germany, and the nylon wheel-based Z carriage happen to work perfectly so far – I expected some slight sinus wobble imposed by the nylon wheels as I encountered on the X carriage, but it seems when there is little force applied on the wheel the carriage works good enough.

Printing 330mm high 10mm diameter cylinder (with slider-based X carriage):

There was some slight extrusion inconsistencies, this is likely due the material, an broken vacuum seal of a newly purchased glowing pink PLA roll, actually, after watching the 2nd print closely, either GCode errors or USB transmission errors, as some segments of the circle (layer of a cylinder) is repeated for some unknown reason and so overextrusion occurs there (needs proper investigation) – but the linearity is very good, and no Z wobble whatsoever.

Loopy Egg

60mm height “loopy egg”, printed with 0.5mm nozzle, 0.4mm layer height:

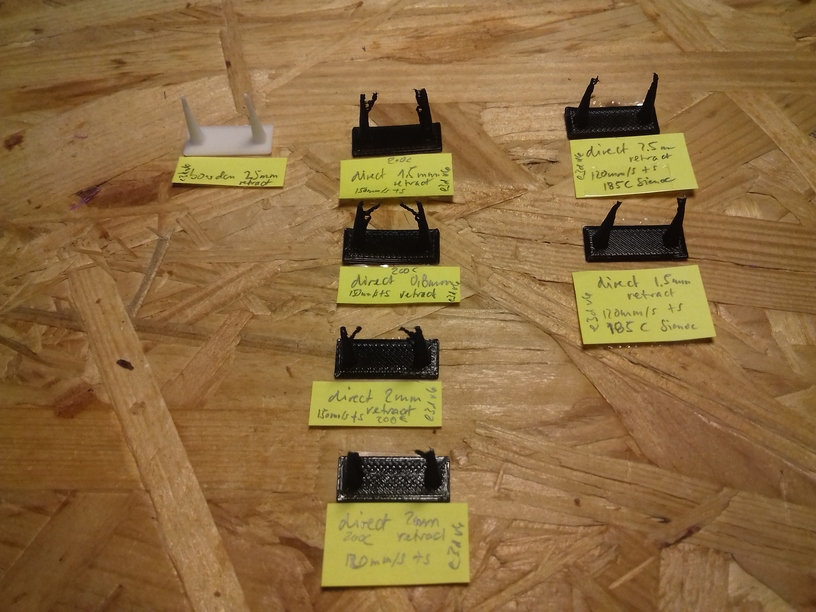

The “loopy egg” is a good benchmark for retraction settings, and stressing the extruder motor as the short segments making up the loops require a lot of push / pull on the filament. There was still some slight stringing, which I knew will happen, as the retraction is just set to 2mm at 35mm/s giving very good results. More prints will tell if I can stay with these retraction numbers.

Fighting Heat Creep

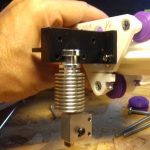

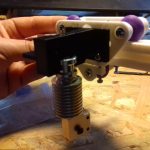

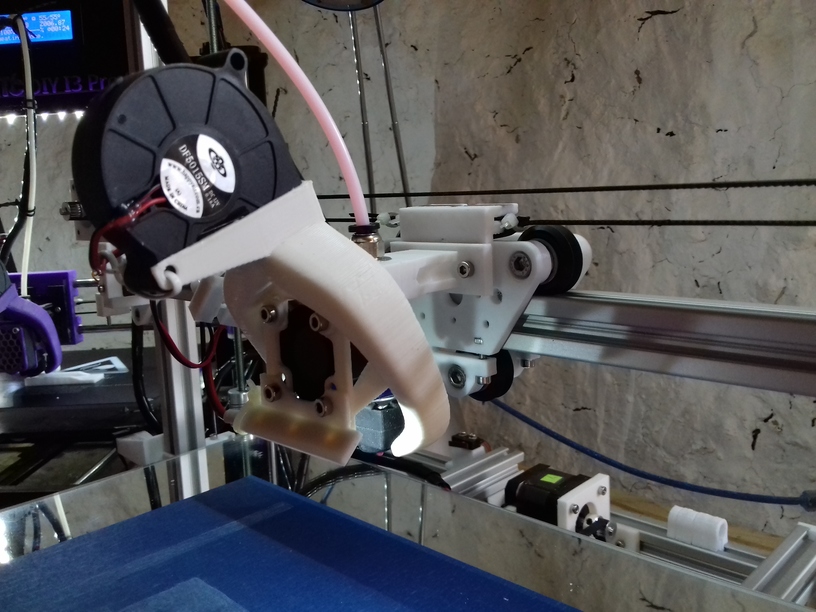

I currently use E3D V6 clones as hotends, one with 30mm “original” fan, and one with 40mm fan. And with the “original” smaller 30mm fan I experienced frequent clogging up within the hotend: some of the filament melted above the heat break and expanded and blocked any further extrusion – that happened now several times.

I tried to reduce the extrusion temperature but which caused decline of print quality. After trying to determine the root cause of the problem, I concluded that it was heat creep and insufficient cooling above the heat break, hence, the hotend fan, and I switched to 40mm fan – and the clogging disappeared, not quite yet . . . update follows.

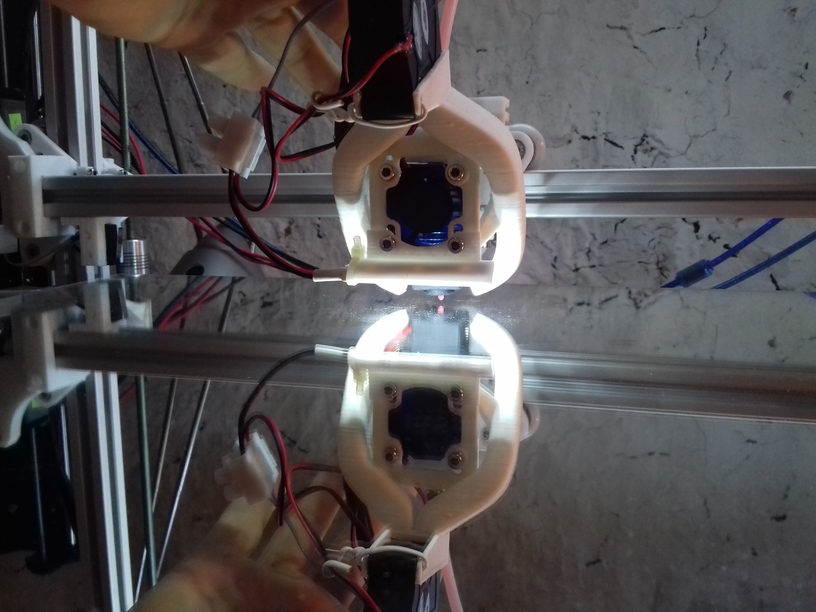

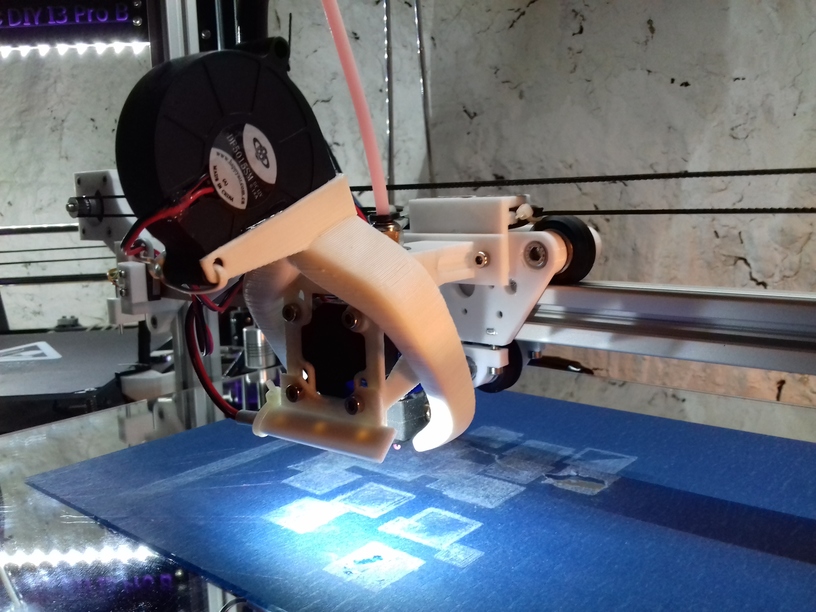

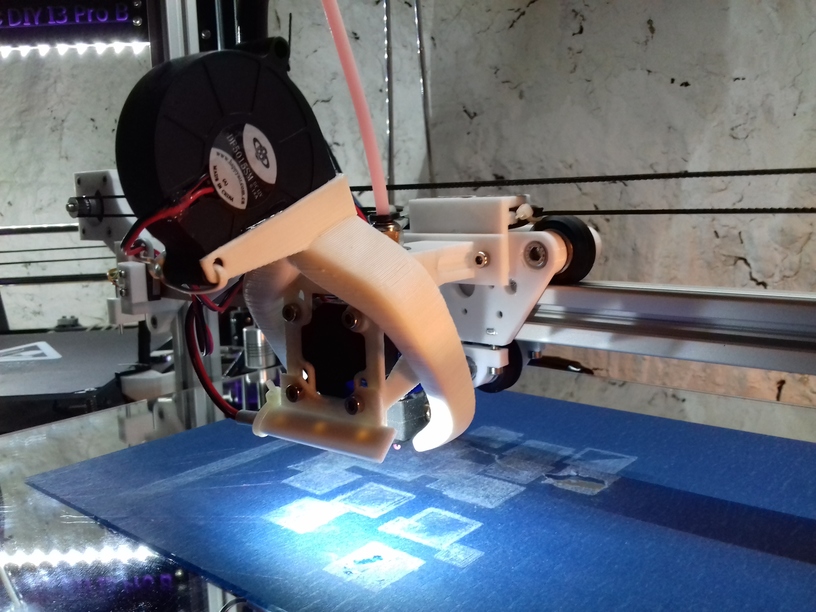

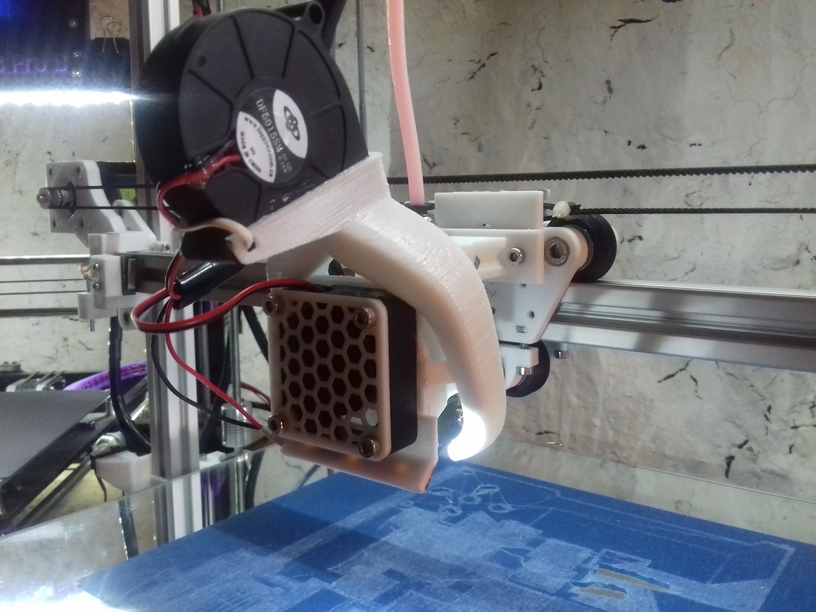

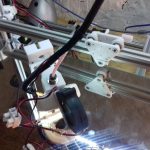

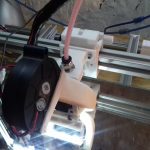

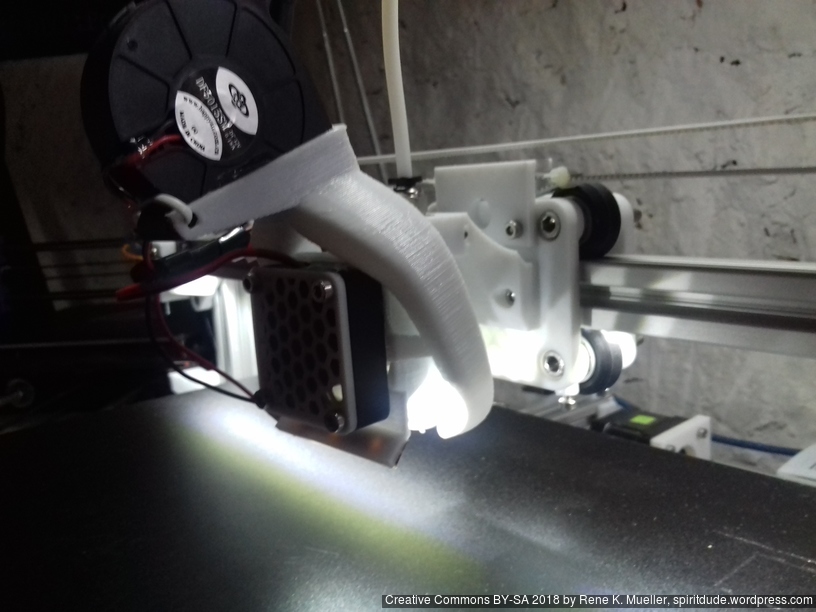

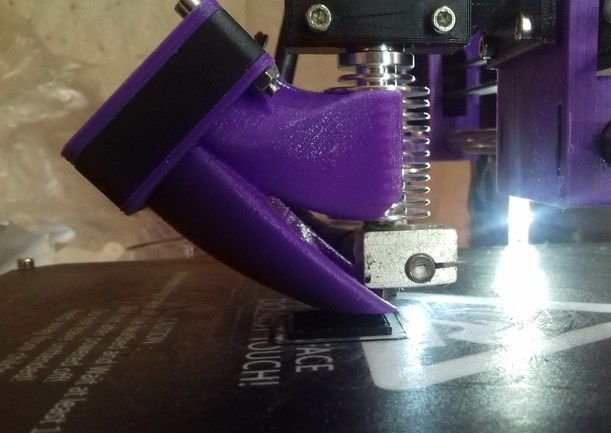

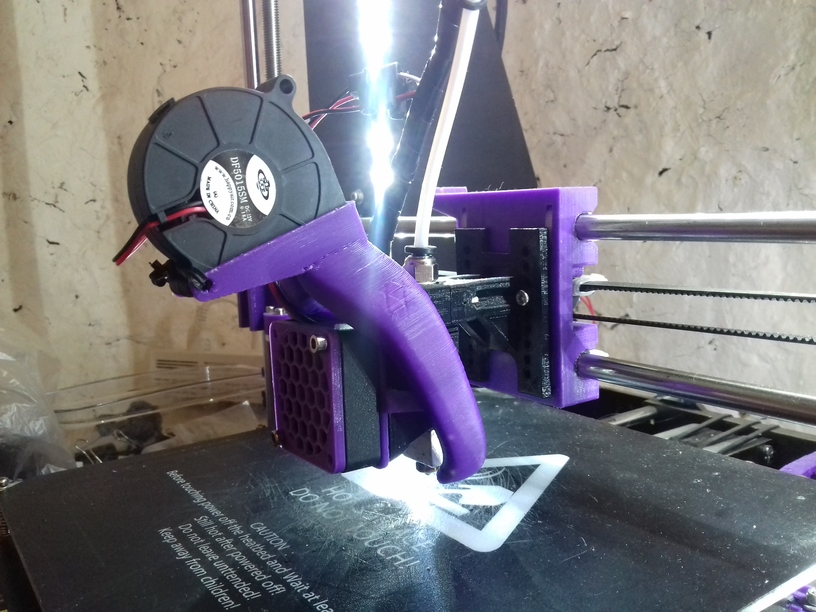

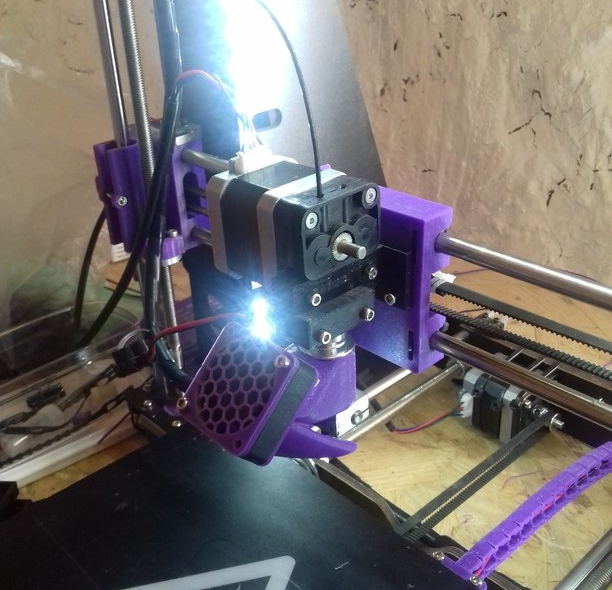

30mm Fan (front facing) with 5015 Fan Fang (top)

40mm Fan (front facing) with 5015 Fan Fang (top)

Although both setups look very alike, I had to print out another fan fang which can contain 40mm fan.

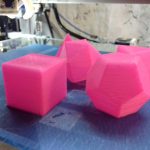

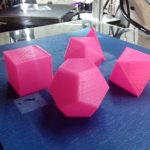

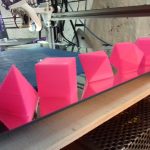

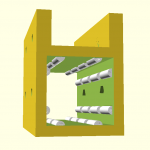

Five Platonics

My favorite geometrical forms – aside the sphere – the sacred set:

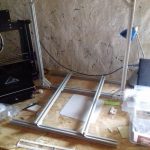

Mirror as Bed

I’ve got 40cm x 30cm mirror which became my bed base, underneath with some tight springs some 6mm multilayered plywood, which was warped 2-3mm on the edge – but it didn’t matter (much). The mirror was the reference, and the Y carriage had to hold the mirror. That turned out to work very well: the mirror is truly flat, I leveled the bed once for tilting, after a week, I only had to tweak the Z endstop screw slightly, but I didn’t touch the screws mounting the mirrors to re-level the bed anymore.

So, using the mirror as bed worked well so far due the flatness – but the glass didn’t turn out to print good on it, the printed parts often detached before finishing the print, and ruin the print – so I used blue tape sheet as temporary solution until the black sticker arrives which I already use on the other 3d printer.

Reflection

As I designed Ashtar K with larger build volume, I choose 0.5mm nozzle at least, and the max 0.4mm layer really pays off in regards of print speed, while still maintain some details – I’m quite pleased so far.

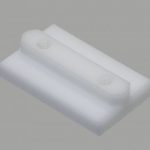

Commercially manufactured, apprx. cost EUR 2.50 per piece, sold in 10 pieces bag.

Commercially manufactured, apprx. cost EUR 2.50 per piece, sold in 10 pieces bag.

The CTC DIY I3 Pro B, a Geeetech I3 Pro clone, is the very low-end of 3d printers – quality and pricewise, and uses a direct drive to feed the filament aka “MK8 Extruder”. I ordered an E3D V6 clone with 0.2mm-0.4mm short nozzles with optional Volcano hotend for larger diameter nozzles (0.6mm – 1.0mm) from China, at EUR 9 price, as I wanted to

The CTC DIY I3 Pro B, a Geeetech I3 Pro clone, is the very low-end of 3d printers – quality and pricewise, and uses a direct drive to feed the filament aka “MK8 Extruder”. I ordered an E3D V6 clone with 0.2mm-0.4mm short nozzles with optional Volcano hotend for larger diameter nozzles (0.6mm – 1.0mm) from China, at EUR 9 price, as I wanted to

After some time I switched to

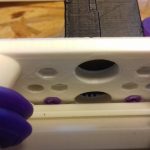

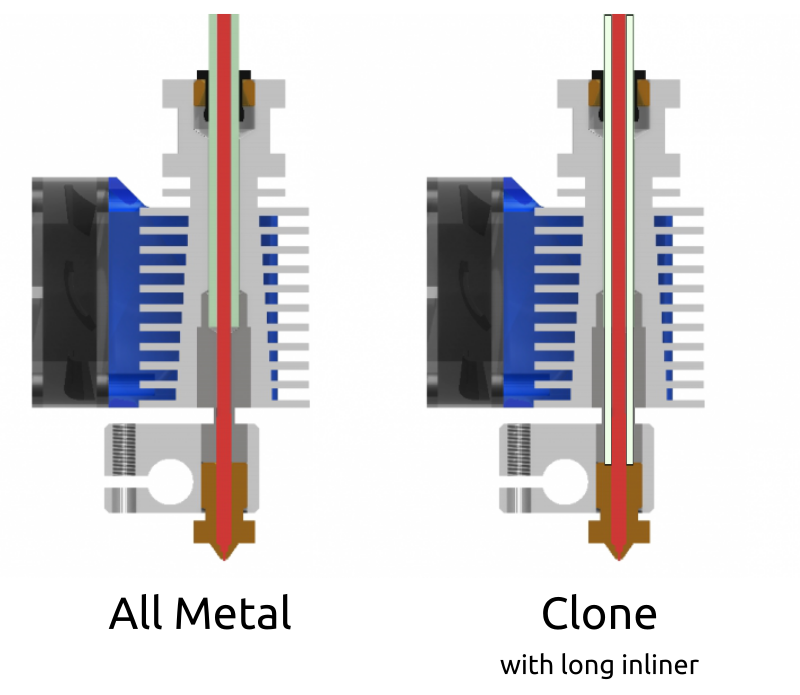

After some time I switched to  Before I go into the details, let me comment of the overall building quality of those E3D V6 clones: you get what you pay for, a compromise. My hotend leaked like crazy, at the junction of heatblock & nozzle, and heatblock & heatbreak – which is most annoying, and that did not happen with the original MK8 Extruder.

Before I go into the details, let me comment of the overall building quality of those E3D V6 clones: you get what you pay for, a compromise. My hotend leaked like crazy, at the junction of heatblock & nozzle, and heatblock & heatbreak – which is most annoying, and that did not happen with the original MK8 Extruder. Update 2: the real problem of leaking was the PTFE/teflon inliner, the end toward the nozzle wasn’t perpendicular sufficiently and likely a bit too short (by less than 1mm) and it was too narrow tube with 3mm OD instead of 4mm and be more tight – so the PLA leaked between the inliner and the threads of the heatbreak and nozzle – so the real remedy is to pay close attention of the length of the inliner (in case the E3D V6 clone comes without it as in my case), and give it 0.5mm to 1mm extend with a clean cut and preferably a conic end which presses then toward the nozzle.

Update 2: the real problem of leaking was the PTFE/teflon inliner, the end toward the nozzle wasn’t perpendicular sufficiently and likely a bit too short (by less than 1mm) and it was too narrow tube with 3mm OD instead of 4mm and be more tight – so the PLA leaked between the inliner and the threads of the heatbreak and nozzle – so the real remedy is to pay close attention of the length of the inliner (in case the E3D V6 clone comes without it as in my case), and give it 0.5mm to 1mm extend with a clean cut and preferably a conic end which presses then toward the nozzle.

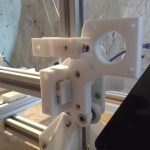

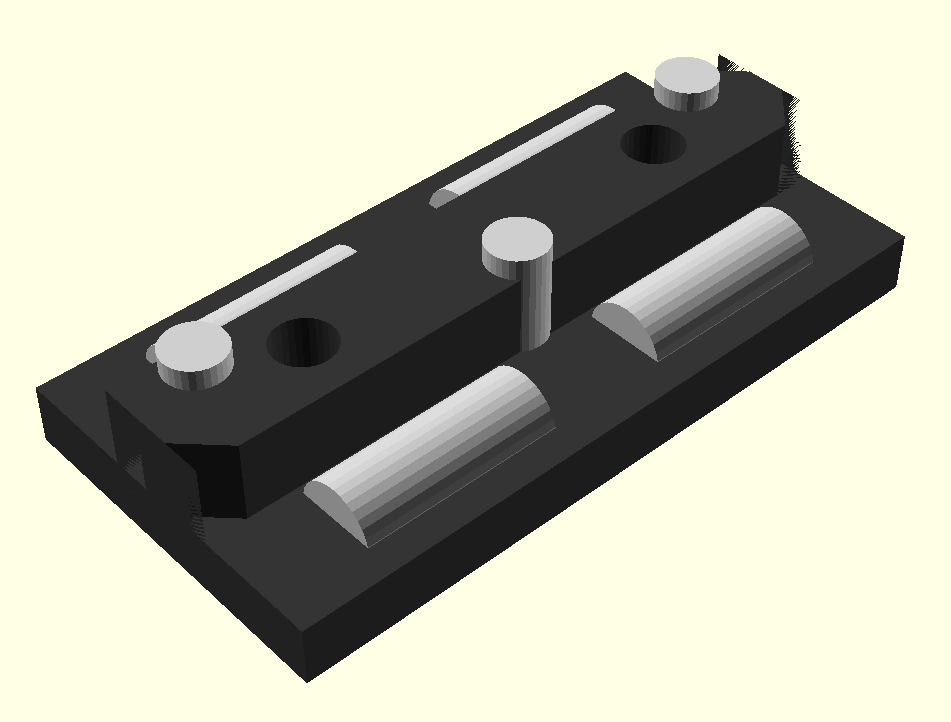

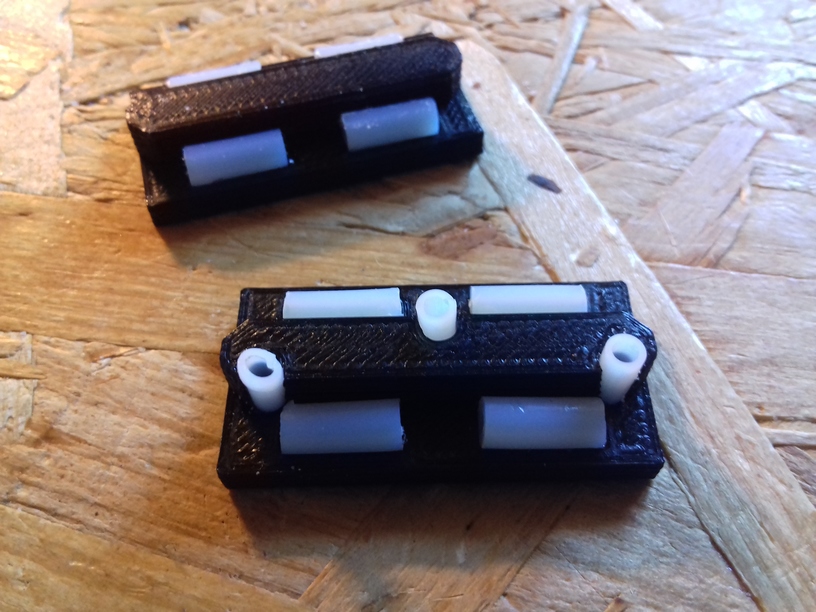

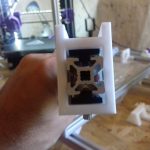

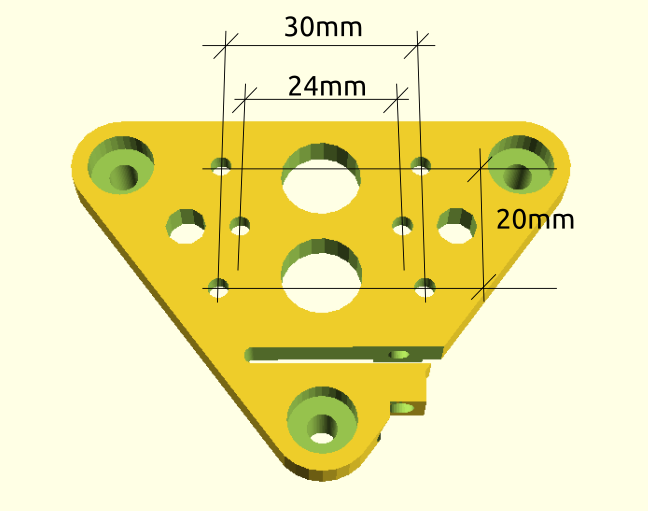

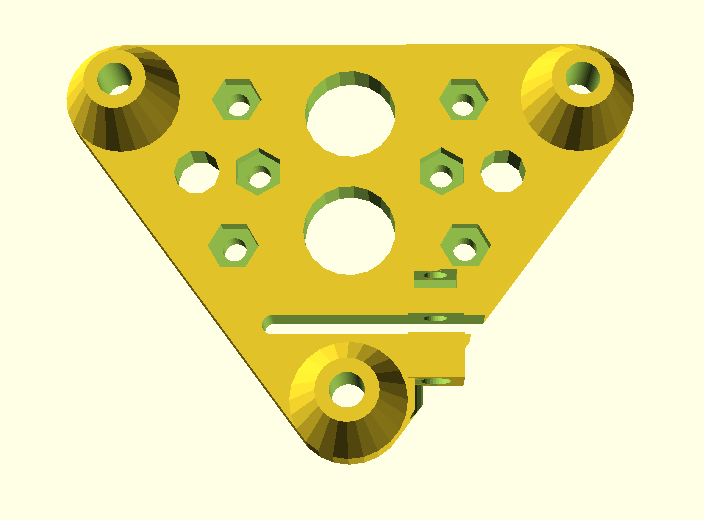

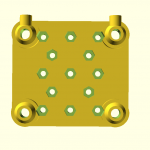

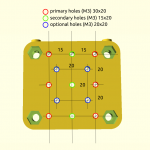

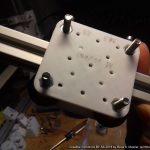

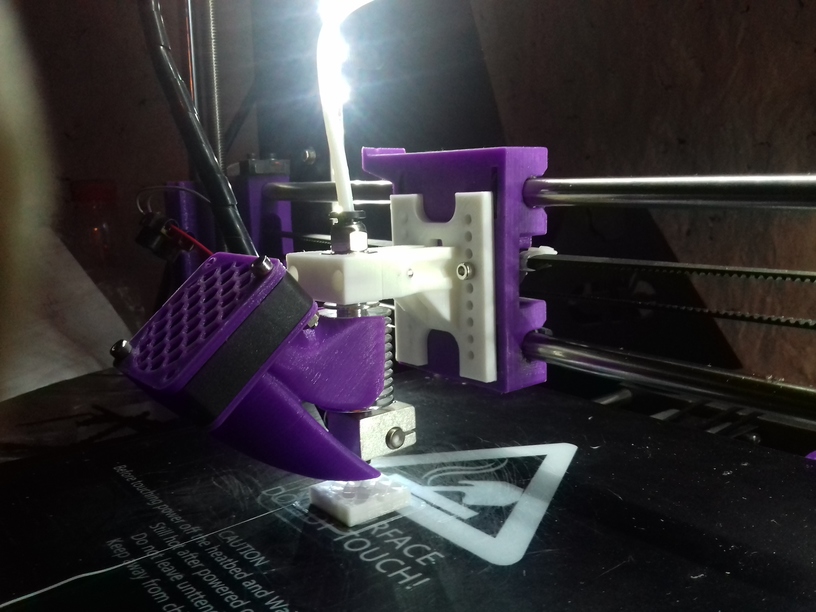

The two E3D V6 bowden adapters I first printed and used required quite some change in Z height, bringing my Z stopper screw to its limits and also were off in the Y axis – so I designed a more suitable adapter with multiple mounting holes:

The two E3D V6 bowden adapters I first printed and used required quite some change in Z height, bringing my Z stopper screw to its limits and also were off in the Y axis – so I designed a more suitable adapter with multiple mounting holes: