A small 3d printable Orange Pi Zero case with 3 cover variants:

- closed

- pins exposed

- grill

A small 3d printable Orange Pi Zero case with 3 cover variants:

LOLIN32 Lite (ESP32) with OLED 128×64 SSD1306 Combo (layered) case.

OLED SCK - ESP32 GPIO 4 / R10 (pin-to-pin) OLED SDA - ESP32 GPIO 0 / R11 (pin-to-pin) OLED GND - ESP32 GND (wire) OLED VDD - ESP32 3.3V (wire)

STL: https://www.thingiverse.com/thing:2853161

Simple case for TTGO T1 (ESP32), reset button built-in, and the 3 LED’s light are tunneled to the cover surface.

STL: https://www.thingiverse.com/thing:2853192

Three versions of Wemos D1 with 128×64 OLED:

OLED 128×64 with SSD1306 controller built on the same PCB with Wemos D1 Mini usually named “ESP12F OLED” at Aliexpress.

STL: https://www.thingiverse.com/thing:2853146

Using Wemos D1 Mini and put OLED 128×64 SSD1306 on-top/bottom of it, keeps it same width and height but a bit thicker.

OLED GND - Wemos D1 Mini GND (pin-to-pin) OLED VDD - Wemos D1 Mini D4 (pin-to-pin) OLED SCK - Wemos D1 Mini D3 (pin-to-pin) OLED SDA - Wemos D1 Mini D2 (pin-to-pin)

STL: https://www.thingiverse.com/thing:2853148

Using Wemos D1 Mini and put OLED 128×64 SSD1306 side-by-side (SBS) with hot glue, is a bit cheaper than the “same-PCB” version.

OLED GND - Wemos D1 Mini GND (wire) OLED VDD - Wemos D1 Mini 5V (wire) OLED SCK - Wemos D1 Mini D2 (wire) OLED SDA - Wemos D1 Mini D1 (wire)

STL: https://www.thingiverse.com/thing:2853149

I’ve got the 3D printer mainly as I wanted to design and print some cases for the small programmable devices based on ESP8266 and ESP32 I started to develop for:

STL: https://www.thingiverse.com/thing:2846772

See-through of the GPIO22 LED:

Also a small case for the Wemos D1 Mini to print yourself:

STL: https://www.thingiverse.com/thing:2847539

See-through LED blinking:

Updates

Updates2018/03/26: Initial post with description, assembling and first test print.

2018/03/27: Board identified as “Anet A1284-Base-Control Board V1.0”. More details on adding a printer to Cura and included brief video of the first print.

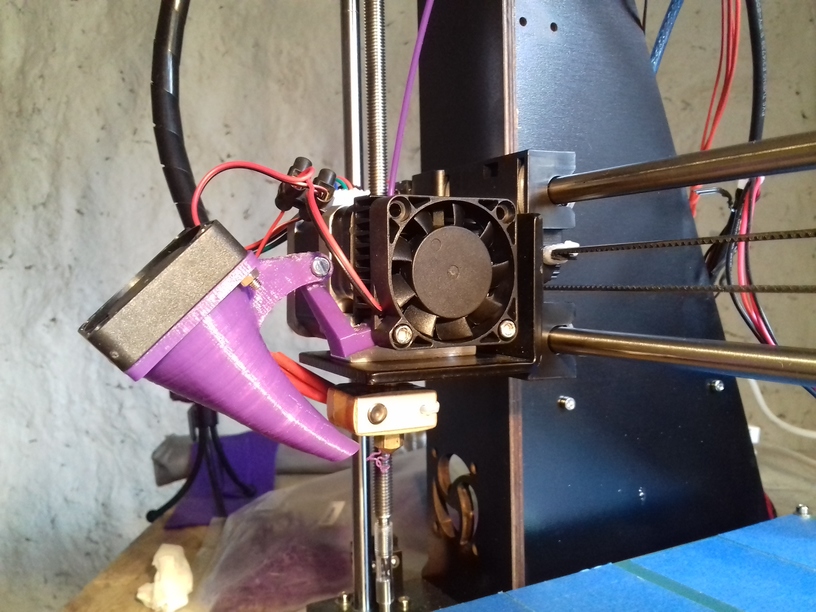

2018/03/28: fan duct added, replaced broken extruder fan (see section “Fixes & Upgrades”)

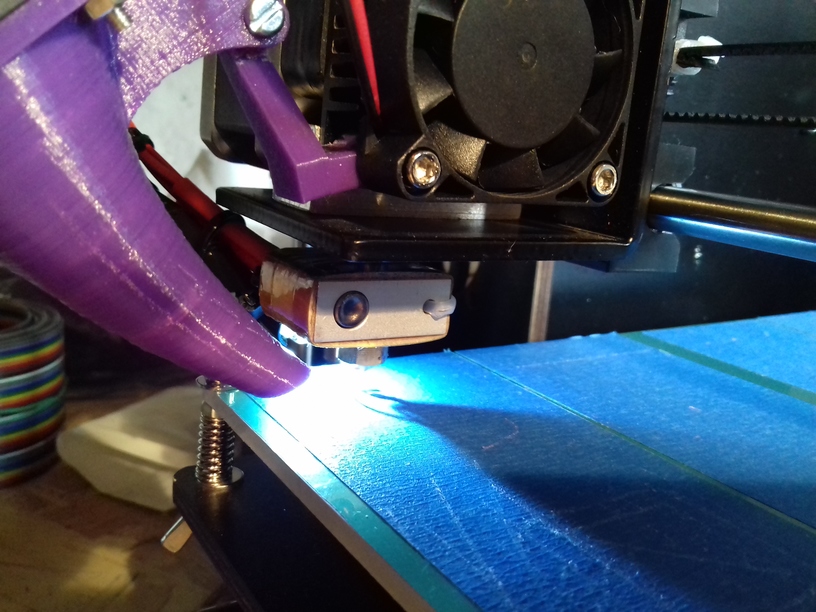

2018/03/29: added white LED near nozzle, XYZ calibration cube fan vs fanless printing.

2018/03/30: added serial plate and label plate, calibrating X and Y axis properly.

2018/04/19: cables sorting

2018/04/23: printed X gantry/axis parts and replaced them

2018/04/25: refasten screws & cable binders of Y carriage

Back in 2013 I’ve got pulled into 3D Printing and did some work on

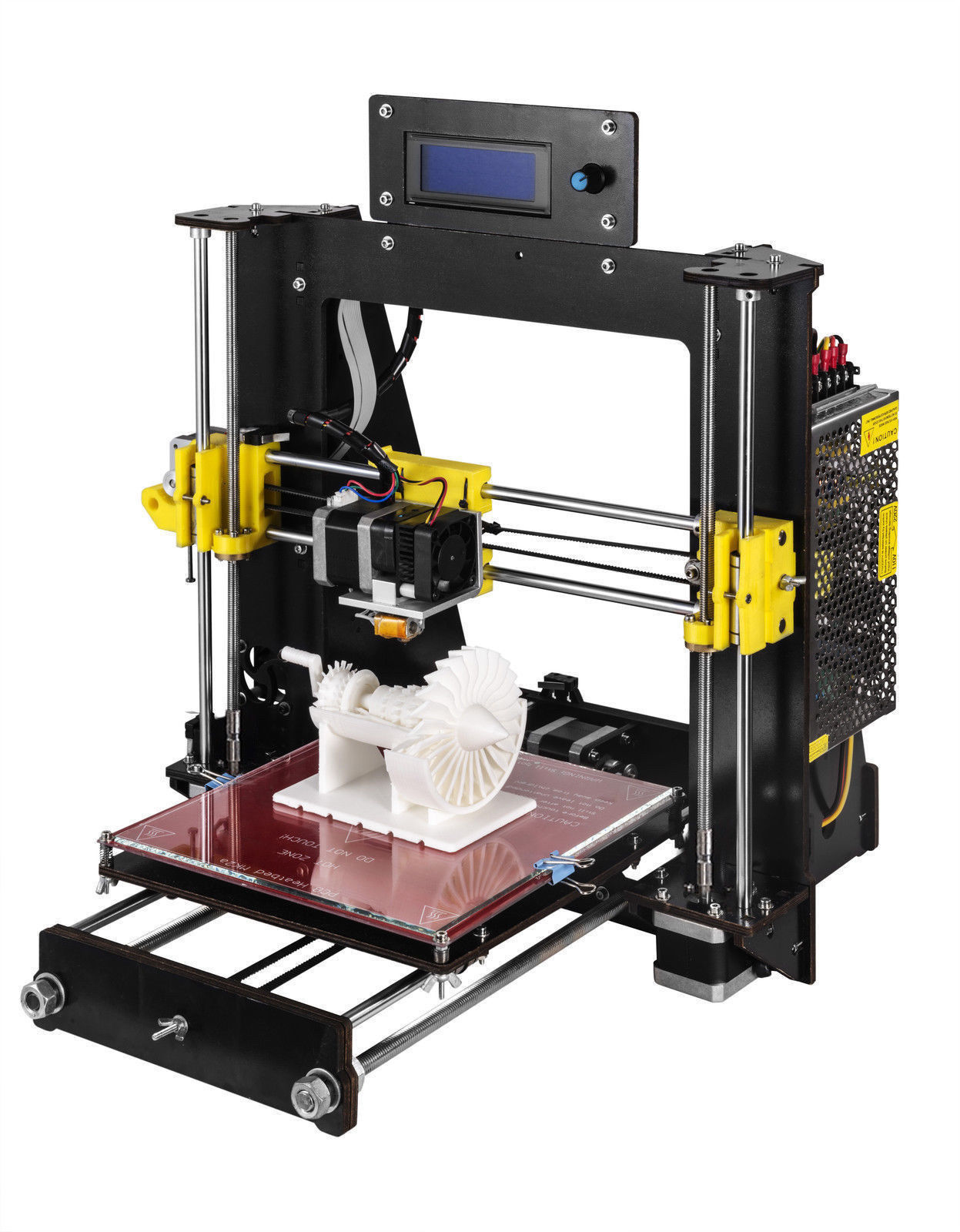

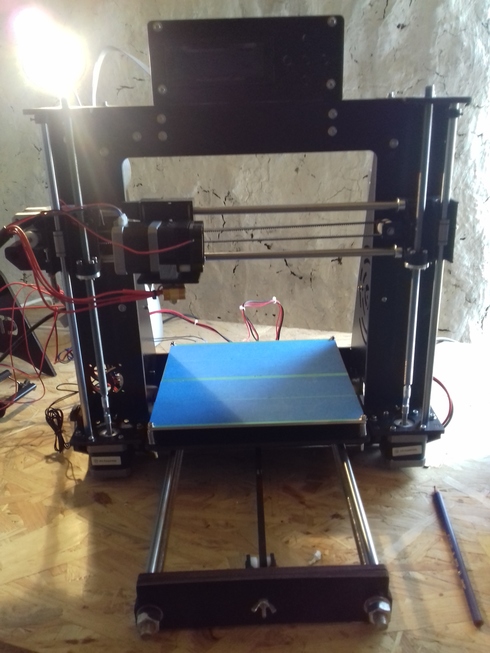

but I didn’t own a 3d printer myself until 2018/03/21 – roughly 5 years later – when I ordered an “DE A8 3D Printer DIY i3 Upgradest High Precision Reprap Prusa 3d Drucker” for EUR 99.00 (apprx. USD 120) shipment from and to Germany included – that is by far the most affordable 3d printer I ever saw (2018/03).

As the product image shows – it is hastly translated from english to german, and doesn’t make a very serious impression. After some research I realized it’s an CTC DIY Prusa i3 aka CTC DIY i3 Pro B (product link valid 2018/03/22) sold for USD 140, produced by Zhuhai CTC Electronic Ltd located at Zhuhai City, Guangdong, China – located at another peninsula west of Shenzen and Hong Kong. On further investigation I found out that the CTC DIY I3 Pro B is a clone of Geeetech DIY I3 Pro B, which is advertised as “Geeetech I3 pro is based on the Reprap open source project. Geeetech I3 is highly recommended for students and beginners who want to start journey in 3d printing technology.”

As the product image shows – it is hastly translated from english to german, and doesn’t make a very serious impression. After some research I realized it’s an CTC DIY Prusa i3 aka CTC DIY i3 Pro B (product link valid 2018/03/22) sold for USD 140, produced by Zhuhai CTC Electronic Ltd located at Zhuhai City, Guangdong, China – located at another peninsula west of Shenzen and Hong Kong. On further investigation I found out that the CTC DIY I3 Pro B is a clone of Geeetech DIY I3 Pro B, which is advertised as “Geeetech I3 pro is based on the Reprap open source project. Geeetech I3 is highly recommended for students and beginners who want to start journey in 3d printing technology.”

(Numbers taken from the flyer 2018/03/24)

After 2 days, after ordering on Ebay.de, it arrived with DHL, a 9kg (20lbs) package.

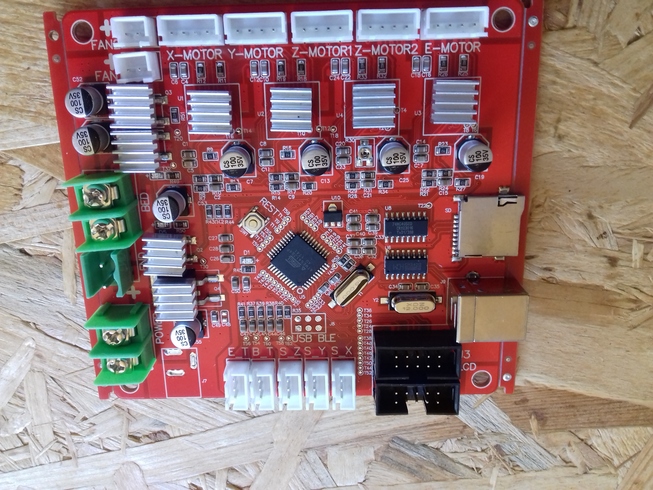

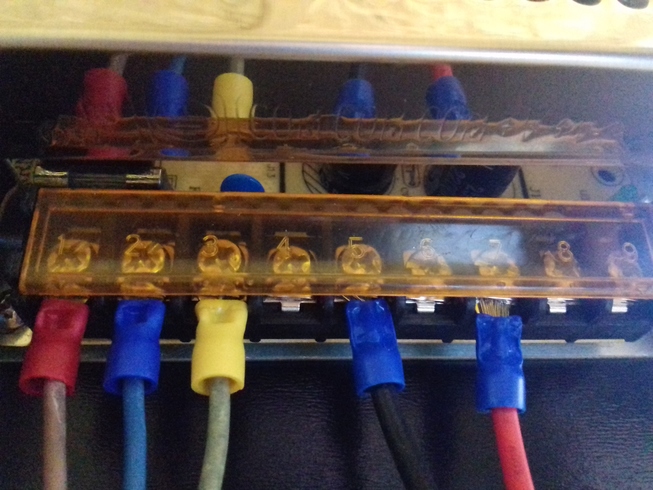

The package is well composed, most parts are marked, some of the labels didn’t stick to the parts though. The controller board is orange with an ATMEGA 1284P in the center, with all connectors well labeled – it seems it’s loosely identified as “Anet A1284-Base-Control Board V1.0”. Gcode M115, which identifies the firmware, responds as

Marlin V1; Sprinter/grbl mashup for gen6 FIRMWARE_URL:https://github.com/ErikZalm/Marlin/ PROTOCOL_VERSION:1.0 MACHINE_TYPE:I3 Pro B EXTRUDER_COUNT:1 UUID:00000000-0000-0000-0000-000000000000

The shipped 3d printer does not match the photos in the Ebay posting, therefore the product link to the CTC manufacturer is also not correct. It turns out it’s either another version of the “CTC DIY I3 Pro B” or a remix of another line, the included manual states it’s a “CTC DIY Printer” by “Zhuhai CTC Electronic Co., Ltd”.

Here the main differences:

The only things I thought was missing was

The XZ frame comes with a small plate “CTC Y 3228”, which likely is the serial number of this frame/printer.

The XZ frame comes with a small plate “CTC Y 3228”, which likely is the serial number of this frame/printer.

The included manual (diy-manual) on the CD is cumbersome to read – so here the assembling procedure which worked for me and for my own future reference:

I realized to first assemble mechanically and then electrical (wires) is the best procedure; also re-fasten all screws of the preassembled pieces to ensure the stability.

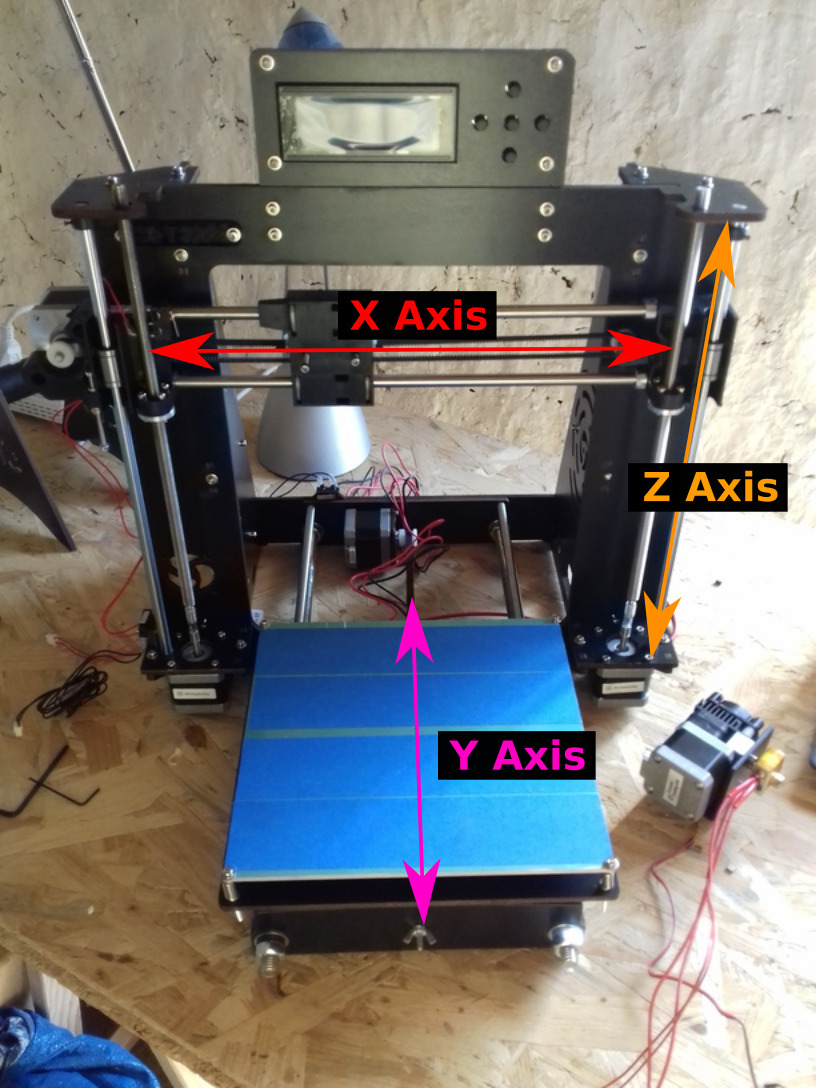

Here as reference the 3 axis as mentioned further below:

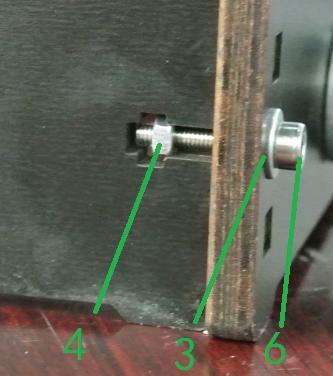

use the two sheets/feets so the XZ frame stands upward, the larger ventilation grill comes to the right-hand side when looking to the front; use M3 with washer on the front, and the nut within the sheets/feet; don’t tighten it too much otherwise you will crush the wood.

use the two sheets/feets so the XZ frame stands upward, the larger ventilation grill comes to the right-hand side when looking to the front; use M3 with washer on the front, and the nut within the sheets/feet; don’t tighten it too much otherwise you will crush the wood.

this finishes the mechanical assembling.

Attaching all the cables to the controller board is easy since all connectors are labeled:

before you bundle the cables, control all connections again – missing or mixing up just one connector can damage the 3d printer once powered on.

Make sure the correct voltage 110V or 220V is chosen at the power supply (default 220V).

As next bundle

This part is crucial for the geometric accuracy of all your prints:

As next make sure the Z axis stopper on the left-hand side near the bottom, that screw coming down on the X axis is fully extended: move the nuts up so the screws extends down and reaches the stopper early.

When all is assembled mechanically and electrically, you turn on the machine; the LCD display should light up in blue with white letters.

When all is assembled mechanically and electrically, you turn on the machine; the LCD display should light up in blue with white letters.

Note: when the printer is powered on, the stepper motors become active and hold their position, you can’t or shouldn’t move the X or Y axis manually anymore, unless you choose in the menu “Prepare -> Disable Stepper Motors”

You have now adjusted the printing bed, you are ready to print now.

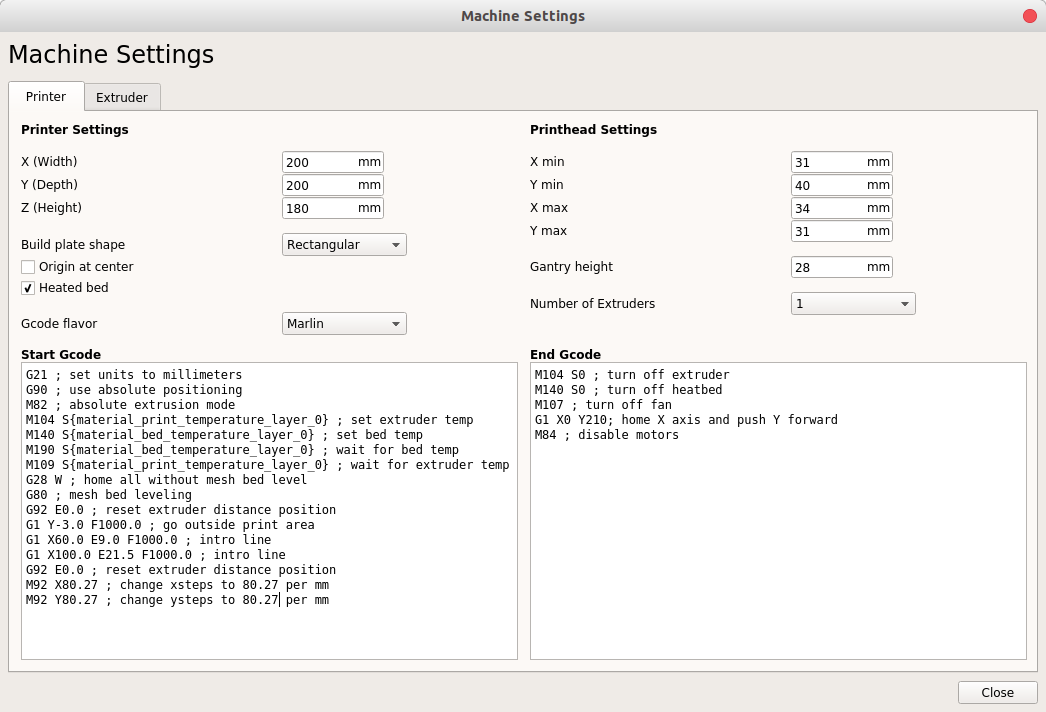

The included Cura slicer and front-end on the CD (as in my case) is of version 14.07 (roughly 5 years old) and has no Linux version, as of 2018 I can’t even find a binary anymore for Linux – so I installed the latest on my Linux laptop; you download Cura-3.2.1.AppImage or something newer, once downloaded you execute it direct (it does no install) with right mouse click and “Execute”; under Windows or Mac it may install differently.

Once Cura started up:

Best choose PLA in Cura as a first test print, it’s easier to print.

In my case the bed was too close to the bed, so the test cube was too firmly attached to the tape that I ripped the tape off the bed when removing the test cube.

The very first test print worked extremely well, beyond my expectations – no Z wobble at all, some stringing at “X” and “Y” though.

I had attached the extruder fan to “FAN2” which is an always on 12V source (surely can be turned off), the fan ran for few minutes and died; I replaced it and attached it to “FAN1” which turns on after 2nd layer of printing which is sufficient and kept it there, as I printed once a large piece which caused the extruder heat up so much that filament got stuck – so it’s remained on “FAN2” (always on).

Adding white LED near the nozzle for better viewing, attached to “FAN2” on the controller board (always on), 1K resistor in series with LED on 12V.

I thought the printer lacks proper labels, also one of the reasons it’s sold in so many variants and you don’t know what kind of “CTC DIY I3” you get.

When I printed the labels I realized my X and Y axis were off by 1.49% each, which made more than 2mm on 150mm distance (way too much); I printed out an “L shape” of 150mm length 10mm wide X and Y axis, and measured the length, apprx, 147.8mm. I went into the LCD menu “Control -> Motion -> XSteps/mm & YSteps/mm”:

Current settings:

and calculated 78.74 / 147.8 (measured) * 150 (should be) = 79.91

New settings:

I printed out the “L 150mm” again, and remeasured: 147.8mm – it made no difference, checking back the settings they were reset back to 78.74. So, I could edit it, but it had no effect whatsoever . . .

Using Repetier helped as I was able to manually send Gcode without actually printing anything and checking back with the LCD menu, and so reconfigured it to enter “M92 X79.91″ which was set as “XSteps/mm 79.9” when reading back in the LCD menu – when I printed with Repetier the L shape again I ended up with 149.5mm instead of 150mm, still a bit off.

I decided to stay for now with Cura – as I’m used to it right now – and after some additional test prints I ended up adding following “Start Code” in Cura at the bottom of the existing code:

M92 X80.27 ; change xsteps to 80.27 per mm M92 Y80.27 ; change ysteps to 80.27 per mm

That finally worked, the L shape of 150mm ended up with 150.0mm (+/- 0.2mm) as measured with a ruler.

Even though I printed out the 20mm calibration cube, the 1% or 0.2mm I could hardly see with the simple ruler (right, require analog or digital caliper) – the Z axis seems fine but needs verification as well.

Update 2018/04/25

After a lot of tuning, I ended up with this single line

M92 X80 Y80 E96

which sets X & Y Steps per second as well the extrusion flow (instead using 105 steps as the default and reduce by 95% you define E96 and stay with 100% extrusion flow).

I used some more cable spirals to sort the cables better and give them some kind of stiffness while still being flexible, e.g. the Y axis cable I lifted up so it stays flexible and won’t catch on anything while moving:

What’s left to do it is a cover over the controller board.

I finally dared to print the X gantry/axis parts as enclosed on the CD I received, and replaced the black parts:

I had to remove the XZ Frame flatter screw as it touched the X pulley on the right side slighly at the same Z height – and I didn’t want X position errors at that particular Z height. Also, the Z Stopper seemed now too far on the right, and the screw pushing on the stopper too far on the right, so I printed a 10mm wide 5mm height cylinder with 2.8mm hole inside, which I screwed on the bottom of the M3 Z Stopper screw which extends the area and now reliably pushes the X Stopper switch.

After roughly a month of usage, the printed started to make noises, more so the bed leveling was almost impossible to perform, after each print the level was misaligned and I wondered. Finally I removed the heatbed and retighten all screws and nuts and refastened the cable binders which held the linear bearings of the Y carriage.

That made a huge difference . . . I was finally to print again 60mm/s and most of the stringing went away due the higher speed; I even printed at 80mm/s at still acceptable quality. The entire printer sounded now differently, it mad an immense impact to retightend those screws, it did not just affect Y axis, but also the X axis – and the overall prints are cleaner, more precise and I’m able to print at higher speeds without loss but actual gain of printing quality.

This 3D Printer is the low cost hobbyist or entry-level “maker” approach to 3D printing – and even when you end up with a broken printer, the parts are worth it as you likely are unable to source the parts yourself for less than EUR 100 with shipment.

Expect to invest heavily in regards of time to educate yourself and fine-tune your printer and extend it so it becomes easy to use.

It is worth it – but what you order might not what you get . . .

Material

Note: I will update this post with new discoveries and experiences, and see also additional blog posts with CTC DIY i3 Pro B tag.